Preparation is the key to success in any interview. In this post, we’ll explore crucial Elevator and Escalator Installation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Elevator and Escalator Installation Interview

Q 1. Describe your experience with different types of elevator systems (hydraulic, traction, etc.).

My experience encompasses a wide range of elevator systems, primarily hydraulic and traction elevators, with some exposure to machine-room-less (MRL) systems. Hydraulic elevators use a piston and fluid to lift the cab, best suited for low-rise buildings (typically up to six stories). I’ve worked on numerous projects involving various hydraulic system designs, including those with different types of pumps and control valves. Traction elevators, on the other hand, use counterweights and steel ropes wound around a motor-driven sheave, allowing for higher rise applications and faster speeds. My work with traction systems includes both geared and gearless machines, each presenting unique challenges and advantages in terms of efficiency, maintenance, and noise levels. I have also gained familiarity with MRL systems, which are increasingly popular due to their space-saving design and reduced operational costs. These systems offer a compelling alternative to traditional machine room elevator systems.

Q 2. Explain the process of installing an elevator from initial site survey to final inspection.

Elevator installation is a multi-stage process. It begins with a thorough site survey to assess building structure, weight capacity requirements, shaft dimensions, and electrical infrastructure. This survey informs the detailed design and engineering plans. Next comes the excavation and foundation work, followed by the shaft construction or modification. After this, the hoistway is prepared, including the installation of guide rails, doors, and safety mechanisms. The elevator cab and counterweight are then installed and precisely aligned. The control system is wired and rigorously tested, including all safety interlocks. Subsequently, the final inspection is conducted by independent authorities to ensure compliance with all safety standards and building codes before the elevator is released for operation. This process is meticulous and requires close collaboration with architects, engineers, and other tradespeople.

Q 3. What safety regulations and codes must be followed during elevator and escalator installation?

Safety is paramount. Elevator and escalator installations must strictly adhere to national and local building codes and safety regulations, such as those outlined by organizations like ASME (American Society of Mechanical Engineers) and local jurisdiction authorities. These regulations cover various aspects including:

- Shaft construction and integrity: Ensuring the shaft is structurally sound and free from obstructions.

- Electrical safety: Implementing proper grounding, bonding, and safety devices to prevent electrical hazards.

- Mechanical safety: Utilizing appropriate safety devices like limit switches, overspeed governors, and emergency brakes.

- Door and gate safety: Ensuring proper operation and safeguarding mechanisms to prevent entrapment.

- Emergency evacuation procedures: Incorporating emergency communication systems and escape mechanisms.

Q 4. How do you troubleshoot common elevator malfunctions?

Troubleshooting elevator malfunctions requires a systematic approach. I typically begin by gathering information, such as the type of malfunction, the elevator’s status indicators, and any error codes displayed on the control panel. A visual inspection of the equipment is then performed, checking for obvious problems like broken cables, damaged components, or loose connections. I use diagnostic tools to check the electrical system, hydraulic pressure (for hydraulic elevators), and the mechanical components. For example, a common issue is a stuck elevator. I would check the safety mechanisms first, then examine the control system for faults, and inspect the hoisting machinery for any mechanical problems. By using a methodical process of elimination and relying on my experience and knowledge of the system, I can usually pinpoint and fix the root cause of the malfunction efficiently and safely.

Q 5. Describe your experience with elevator control systems and their maintenance.

My experience with elevator control systems spans various types, from simpler relay-based systems to modern microprocessor-based controllers. I am familiar with programming and troubleshooting these systems, understanding their role in managing elevator operation, safety functions, and passenger comfort. Maintenance includes regular inspections of components, checking for wiring faults, software updates, and preventative measures. A crucial part of this involves monitoring the system’s performance through data logging and analysis to identify potential issues before they escalate into major breakdowns. For instance, monitoring the motor’s current draw can indicate early signs of wear and tear, allowing for proactive maintenance and preventing unexpected downtime. The control system’s reliability is critical for both passenger safety and the building’s operational efficiency.

Q 6. What are the key differences between hydraulic and traction elevators?

The key difference between hydraulic and traction elevators lies in their lifting mechanisms. Hydraulic elevators use a hydraulic ram to lift the car, while traction elevators use a counterweight system and steel ropes. This fundamental difference leads to significant variations in their suitability for various applications:

- Rise height: Hydraulic elevators are typically used for low-rise buildings (up to six stories), while traction elevators are better suited for high-rise applications.

- Speed: Traction elevators generally offer faster speeds than hydraulic elevators.

- Energy Efficiency: Traction elevators are generally more energy-efficient, especially in high-rise buildings. Hydraulic elevators consume significant energy during the lifting process, although newer systems are improving in this area.

- Maintenance: Hydraulic elevators require more extensive maintenance due to the hydraulic fluid and its associated components.

- Space requirements: Hydraulic elevators necessitate a machine room at the base, while traction elevators can use a smaller machine room or even a machine room-less design.

Q 7. How do you ensure the safety of workers during elevator and escalator installation?

Worker safety is my top priority. We strictly adhere to OSHA (Occupational Safety and Health Administration) regulations and implement comprehensive safety protocols throughout the installation process. This includes:

- Rigorous training: All personnel involved in the installation are extensively trained in safety procedures and the proper use of equipment.

- Personal Protective Equipment (PPE): The use of hard hats, safety harnesses, safety glasses, and other appropriate PPE is mandatory at all times.

- Fall protection: Safety harnesses and guardrails are used to prevent falls from heights.

- Lockout/Tagout procedures: Strict lockout/tagout procedures are followed to isolate power sources before any maintenance or repair work is performed.

- Regular safety meetings: Regular safety meetings are held to reinforce safety protocols and address any potential hazards.

- Scaffolding and access equipment: Properly constructed and inspected scaffolding and access equipment are used to ensure safe access to all work areas.

Q 8. Explain the process of leveling an elevator car.

Leveling an elevator car ensures it’s perfectly aligned with the landing floors, preventing jarring stops and ensuring passenger safety and comfort. This is achieved through a process involving precise adjustments to the elevator’s leveling system.

The process typically involves using the elevator’s control system to fine-tune the position of the car. This usually involves adjusting the leveling screws or hydraulic systems (depending on the type of elevator). Highly sensitive level sensors constantly monitor the car’s position. We use these readings in conjunction with adjustments to achieve a perfect level within a tolerance of just a few millimeters. Think of it like carefully adjusting a very precise scale – any slight imbalance affects the final result.

- Initial Inspection: We start by thoroughly checking the level sensors and confirming their accuracy.

- Adjustments: Using the control panel, we make incremental adjustments to the leveling screws or hydraulic system. Small changes are made and the car’s position is constantly monitored.

- Testing: Once adjustments are made, the elevator is cycled through several stops to verify proper leveling at each floor. This process might involve multiple iterations of adjustments and testing until perfection is achieved.

- Documentation: All adjustments and test results are meticulously documented for future reference and maintenance.

Failure to properly level an elevator can lead to passenger discomfort, damage to the equipment, and ultimately, safety hazards.

Q 9. Describe your experience with different types of escalator components (steps, handrails, etc.).

My experience encompasses a wide range of escalator components, from the intricate step mechanisms to the sophisticated handrail systems. I’ve worked with various types of steps, including those made of steel, wood, and composite materials, each with unique strengths and weaknesses. For example, steel steps are durable and long-lasting but can be heavier, whereas composite materials offer lighter weight but may require more frequent maintenance.

Handrail systems are another key area of my expertise. I’ve handled both comb-drive and belt-drive handrail systems, each presenting unique challenges in maintenance and repair. The comb drive system, with its individual handrail rollers, often requires more meticulous attention to individual roller alignment. Conversely, belt-drive systems can be more prone to belt slippage or wear and tear. Understanding the specifics of each system is crucial for effective maintenance.

Beyond steps and handrails, I’m also familiar with the various other components, including balustrades, trunnions, and the drive mechanisms themselves. The understanding of these intricate systems comes only from years of on-the-job experience and continued professional development.

Q 10. How do you inspect and maintain escalator handrails?

Inspecting and maintaining escalator handrails is crucial for safety and preventing accidents. A thorough inspection involves a visual check for wear and tear, proper tension, and alignment. We look for signs of fraying, damage, or slippage.

The process typically includes:

- Visual Inspection: We carefully examine the handrail for any signs of damage, such as cracks, tears, or loose sections. We pay close attention to the points where the handrail connects to the drive mechanism and the rollers.

- Tension Check: Using specialized tools, we measure the tension of the handrail to ensure it’s within the manufacturer’s specifications. Improper tension can lead to slippage or premature wear.

- Cleaning: We regularly clean the handrail to remove dirt, grime, and any potential contaminants that could affect its integrity or cause damage.

- Lubrication: Appropriate lubrication of the handrail system ensures smooth operation and reduces wear and tear. The type and frequency of lubrication depend on the system type and manufacturer’s recommendations.

- Roller Inspection: We inspect the rollers for wear, damage, or misalignment. Worn or damaged rollers can affect the handrail’s smooth operation and potentially cause it to come off track.

Regular and proactive maintenance of handrails is essential to prevent potential accidents and ensure the continued safe operation of the escalator.

Q 11. What are the common causes of escalator breakdowns?

Escalator breakdowns can stem from a variety of issues, often related to wear and tear, improper maintenance, or even misuse. Some of the most common causes include:

- Mechanical Issues: Wear and tear on steps, rollers, and the drive mechanism are frequent culprits. This often necessitates parts replacement or lubrication.

- Electrical Problems: Failures in the motor, control systems, or wiring can cause escalators to stop functioning. Regular electrical inspections and preventative maintenance are crucial to avoid such issues.

- Step and Handrail Problems: Issues with the step chain, handrail belt, or individual steps can disrupt operation, sometimes with safety implications.

- Lubrication Failure: Insufficient or improper lubrication causes excessive wear and can lead to component failure.

- Overloading: Exceeding the escalator’s weight capacity puts undue stress on the system, potentially leading to breakdowns.

- Foreign Objects: Debris such as coins, shoes, or other items can become lodged in the mechanism, causing malfunctions.

A proactive maintenance schedule, combined with regular inspections, significantly reduces the chances of these breakdowns.

Q 12. How do you troubleshoot escalator malfunctions related to the drive mechanism?

Troubleshooting escalator drive mechanism malfunctions requires systematic diagnosis. I start by visually inspecting the drive components, looking for obvious signs of damage or wear. Then, I’ll consult the manufacturer’s documentation and schematics to understand the specific workings of that escalator’s drive system.

The troubleshooting process typically follows these steps:

- Safety First: Isolate the escalator from the power supply to ensure safety before starting any troubleshooting.

- Visual Inspection: Check for any obvious signs of damage or wear and tear in the motor, gearbox, chains, sprockets, and other drive components.

- Check Power Supply: Verify that the correct voltage and current are reaching the motor and control circuitry. A multimeter is invaluable here.

- Check Motor and Gearbox: Listen for unusual noises such as grinding, whining, or excessive vibration. Check the motor’s temperature and ensure the gearbox oil level is correct. If there’s excessive heat or unusual sounds, motor failure or gearbox issues are likely.

- Examine the Control System: Check the control panel, relays, and sensors for any malfunctions. This often requires testing components using multimeters and understanding electrical diagrams.

- Test Components: Using diagnostic tools specific to the escalator’s model (if available), individual components can be tested to identify the faulty part.

Systematic troubleshooting, coupled with the knowledge of the specific manufacturer’s equipment, is paramount to efficiently resolving escalator drive mechanism issues.

Q 13. Describe your experience working with different elevator manufacturers’ equipment.

Throughout my career, I’ve had the opportunity to work with equipment from a variety of elevator manufacturers, including Otis, Schindler, ThyssenKrupp, and Kone. Each manufacturer has its unique design philosophies, control systems, and component specifications.

This experience has given me a broad understanding of various technologies and approaches to elevator design and construction. For example, Otis’s Gen2 system has unique features that require specific knowledge in maintenance and troubleshooting, while Schindler’s PORT technology presents its own set of challenges and opportunities. I’ve learned to adapt my skills to each manufacturer’s specific requirements and documentation, ensuring safe and efficient operation of the equipment.

Working with multiple manufacturers has broadened my perspective and enhanced my problem-solving abilities. It’s not just about knowing how to fix a particular component; it’s about understanding the underlying principles and being able to adapt my knowledge to different systems.

Q 14. Explain the process of replacing elevator cables.

Replacing elevator cables is a complex and critical procedure requiring specialized tools, equipment, and expertise, impacting safety and building functionality. The process is inherently dangerous due to the weight and tension involved.

Here’s a step-by-step breakdown:

- Safety First: The elevator must be completely de-energized and secured. Appropriate safety measures, including lockout/tagout procedures, are paramount. This ensures no accidental energizing during the process.

- Disassembly: The old cables need to be carefully disconnected from the elevator car and the counterweights. This may involve removing sheaves and other components.

- Cable Removal: The old cables are systematically and carefully removed, often requiring specialized equipment to manage the weight and tension. This process is slow and meticulous to avoid damaging the elevator shaft or surrounding structure.

- Shaft Preparation: The elevator shaft needs to be thoroughly inspected to ensure there’s no damage that might interfere with the new cables. Any obstructions need to be removed.

- New Cable Installation: The new cables are carefully fed through the shaft and connected to the car and counterweights. This process is typically done using specialized equipment to ensure proper tension and alignment.

- Tensioning: The new cables must be carefully tensioned according to the manufacturer’s specifications using appropriate equipment. Incorrect tension can lead to serious malfunctions or safety issues.

- Testing and Inspection: After installation, a thorough test is conducted to ensure proper operation. This may involve several test runs to verify correct weight distribution and smooth operation.

Replacing elevator cables is not a task for the inexperienced. Improper installation can have devastating consequences.

Q 15. How do you perform a safety inspection on an elevator or escalator?

A safety inspection of an elevator or escalator is a systematic process aimed at identifying potential hazards and ensuring compliance with safety regulations. It’s like a thorough health check-up for these vital transportation systems. We use checklists specific to the equipment type and manufacturer, covering various aspects.

- Mechanical Components: We inspect cables, sheaves, governors, brakes, and safety mechanisms for wear, tear, and proper function. For example, we’d meticulously check the elevator’s braking system, ensuring its ability to stop the car safely in an emergency.

- Electrical Systems: We test the power supply, control circuits, emergency lighting, and safety interlocks to make sure they’re functioning correctly and reliably. A faulty electrical connection could lead to a power failure, so this is crucial.

- Doors and Gates: We check for proper operation, ensuring smooth and safe closing and opening mechanisms and verifying that safety features like light curtains or pressure plates are working as designed. Imagine a child’s hand getting caught – these features prevent accidents.

- Emergency Systems: This is critical. We test emergency phones, alarms, and lighting to ensure they’re readily accessible and functioning. Imagine a power outage – these systems become lifelines.

- Documentation Review: Finally, we review maintenance logs and records to identify any patterns or issues that may need attention. Regular records give us valuable insight into the equipment’s history and health.

The inspection concludes with a detailed report outlining any necessary repairs or maintenance, prioritizing safety concerns.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of elevator door malfunctions?

Elevator door malfunctions can stem from several sources, often linked to wear and tear, mechanical issues, or electrical problems. Think of it like a car door – multiple things can go wrong.

- Worn-out components: Guides, rollers, and cables can wear down over time, leading to misalignment and jamming. Imagine a car door hinge rusting and sticking – it’s a similar principle.

- Sensor failures: Sensors that detect obstructions or signal door closure can malfunction, resulting in erratic door behavior. This could be a faulty signal similar to a car’s malfunctioning parking sensor.

- Electrical issues: Short circuits, loose wiring, or problems with the motor control system can also cause malfunctions. This is comparable to faulty wiring in a car’s electrical system affecting window operation.

- Improper adjustment: Improper adjustment of door mechanisms can also lead to problems. Think of it like a car door not closing properly because of a misaligned strike plate.

- Foreign object interference: Obstacles in the door track, such as debris or damage to the surrounding walls, can prevent proper operation. Similar to something jammed in your car door track.

Troubleshooting involves systematic checks, starting from simple visual inspections to testing electrical components and then investigating mechanical parts. We often use specialized diagnostic tools to pinpoint the exact problem.

Q 17. Describe your experience with elevator modernization projects.

I have extensive experience in elevator modernization projects, which involve upgrading existing equipment to enhance safety, efficiency, and aesthetics. It’s like giving an old building a facelift with increased functionality.

In one particular project, we modernized a 1970s-era elevator system in a high-rise building. This entailed replacing the aging hydraulic system with a more energy-efficient traction system, upgrading the control system with a state-of-the-art computerized system, improving the car’s interior design, and installing new safety features, including a sophisticated fire service.

The process involved careful planning, meticulous execution, and close coordination with building management and occupants to minimize disruptions. We used advanced 3D modeling to ensure a seamless integration of new equipment with the existing infrastructure and also incorporated modern energy-saving technologies, resulting in significant cost savings for the building owners.

These projects challenge us to balance preserving historic elements with integrating cutting-edge technology, enhancing both safety and user experience.

Q 18. How do you handle emergency situations involving elevators or escalators?

Handling emergency situations with elevators and escalators requires immediate action and a calm, methodical approach. It’s like being a first responder but in a vertical setting.

- Assess the situation: The first step is determining the nature of the emergency, such as a person trapped in an elevator, a power failure, or a mechanical malfunction.

- Activate emergency procedures: This involves contacting emergency services and following established protocols for the specific situation. We utilize established communication channels immediately.

- Secure the scene: If necessary, we secure the area to prevent further incidents and keep bystanders safe.

- Rescue and evacuation: This may involve rescuing people trapped in an elevator using specialized equipment or assisting in the safe evacuation of passengers from an escalator experiencing a malfunction.

- Post-incident analysis: Finally, we conduct a thorough analysis of the incident to identify contributing factors and implement preventative measures to prevent similar incidents in the future. This helps create a safer environment.

Training plays a huge role. My team and I undergo rigorous training on emergency response procedures, including first aid, CPR, and the use of specialized rescue equipment.

Q 19. Explain the process of balancing an elevator car.

Balancing an elevator car is crucial for smooth operation and minimizing wear and tear on the system. It’s like balancing a seesaw – equal weight on both sides is needed.

The process involves adjusting the weight distribution of the elevator car and counterweights to achieve equilibrium. This is done to ensure the elevator moves smoothly and efficiently and that the motor isn’t overworked. We carefully add or remove weights from the counterweight system to achieve the perfect balance point.

The procedure requires precision and involves using specialized tools to measure the weight of the car and counterweights. We might need to utilize precise scales and other testing equipment to reach optimal balance and might work closely with the manufacturers’ specifications.

An unbalanced elevator car can lead to increased wear and tear on the hoisting machinery and ultimately equipment failure. Proper balancing ensures a longer lifespan and smoother operation.

Q 20. What are your skills in using specialized tools and equipment for elevator and escalator work?

My skills with specialized tools and equipment are extensive and essential to the job. We’re talking more than just a screwdriver here.

- Hydraulic and traction elevator tools: I’m proficient in using specialized tools for maintaining and repairing both hydraulic and traction elevator systems, including cable testing equipment, tensioning devices, and hydraulic pumps.

- Electrical testing equipment: I am adept at using multimeters, meggers, and other electrical testing instruments to troubleshoot electrical systems.

- Diagnostic software: I can use diagnostic software to diagnose problems with elevator control systems and identify potential issues proactively. It’s similar to using a car’s onboard diagnostics.

- Safety equipment: I’m well-versed in using all necessary safety equipment, including harnesses, fall protection gear, and lockout/tagout devices to ensure a safe working environment.

- Escalator maintenance tools: I also have expertise with escalator-specific tools, including handrails, step rollers, and comb plates. It’s a different skillset that requires equal levels of precision.

Safety is paramount when working with these tools. Proper training and adherence to safety protocols are crucial in preventing accidents.

Q 21. Describe your experience with preventative maintenance of elevators and escalators.

Preventative maintenance is critical for ensuring the safe and reliable operation of elevators and escalators. It’s like getting your car regularly serviced – it prevents major issues down the line.

Our preventative maintenance program involves a regularly scheduled inspection and lubrication of all critical components, including the hoisting machinery, door mechanisms, safety devices, and electrical systems. We also conduct thorough inspections of the escalator steps, handrails, and treads. Think of it as a comprehensive health check-up.

We follow manufacturer recommendations and utilize a computerized maintenance management system (CMMS) to track maintenance activities, manage parts inventory, and schedule future maintenance tasks. Our goal is to prevent failures before they occur, thereby minimizing downtime and preventing potentially dangerous situations.

A well-maintained system will not only operate smoothly and efficiently, but it will also have a longer lifespan, resulting in cost savings in the long run. This type of proactive approach is essential for any building owner concerned about both safety and finances.

Q 22. What is your understanding of the National Elevator Industry Code (NEIC)?

The National Elevator Industry Code (NEIC) is a comprehensive set of safety standards and regulations for the design, installation, inspection, testing, maintenance, and repair of elevators and escalators. It’s crucial for ensuring public safety and preventing accidents. Think of it as the ‘bible’ for our industry, providing a uniform set of rules across different jurisdictions. The NEIC aligns with, and often exceeds, many local building codes, providing a high standard of safety. It covers everything from the mechanical components, like the hoisting mechanism and safety devices, to the electrical systems and emergency controls. Compliance is essential for legal operation and minimizing liability. Understanding the NEIC is fundamental to my work, allowing me to design, install and maintain systems that meet and exceed the highest safety requirements.

Q 23. Explain the process of commissioning a new elevator or escalator installation.

Commissioning a new elevator or escalator installation is a multi-stage process that verifies the system operates as intended and meets all design specifications and safety standards. It involves meticulous testing and documentation at every step.

- Pre-Commissioning: This involves thorough inspections of all components before operation, verifying proper installation according to the NEIC and building codes. We ensure all safety devices are installed correctly and functioning.

- Testing: Rigorous testing is performed, including load testing to verify weight capacity, testing of safety devices (e.g., limit switches, overspeed governors), and comprehensive inspection of electrical and mechanical systems. This might involve simulating various scenarios such as power failures.

- Documentation: Detailed records of all tests, inspections, and any corrective actions taken are meticulously maintained. This forms a critical part of the system’s operational history.

- Final Inspection and Sign-off: Once all tests are passed and documentation is complete, a final inspection is conducted usually by a qualified third-party inspector to verify compliance. Upon approval, the system is officially commissioned and ready for operation.

Imagine commissioning a new car – you wouldn’t just drive it off the lot; you’d want to ensure all the features work as intended, and it’s safe to drive. Commissioning an elevator or escalator is analogous; we’re guaranteeing safe and reliable operation.

Q 24. How do you ensure compliance with local building codes during installation?

Ensuring compliance with local building codes during installation requires a thorough understanding of the specific requirements of the jurisdiction where the project is located. This often involves reviewing the codes before the installation even begins. We then work closely with building inspectors throughout the process, providing documentation and undergoing inspections at key stages. This might include submitting detailed plans, obtaining necessary permits and undergoing rigorous inspections before, during, and after the installation. It’s a collaborative effort to ensure the installation meets all local, regional and national regulations; it’s often a process of working with multiple sets of codes to satisfy them all.

For example, in one project, we needed to adapt the elevator design to accommodate stricter seismic requirements than those in the NEIC, reflecting the area’s susceptibility to earthquakes. This involved reinforcing certain structural elements and incorporating specialized dampeners.

Q 25. Describe your experience with troubleshooting electrical issues in elevators and escalators.

Troubleshooting electrical issues in elevators and escalators requires a methodical approach combining theoretical knowledge and practical experience. I start by identifying the symptoms, such as a malfunctioning indicator light, irregular operation, or a complete shutdown. Then, I use diagnostic tools like multimeters and circuit testers to pinpoint the problem. This could involve tracing wiring, checking for short circuits, testing motor controllers, or inspecting the power supply. I’m proficient in interpreting electrical schematics to understand the system’s wiring and identify potential points of failure.

For example, I once diagnosed a malfunction in a high-rise building’s elevator where the lights in the car would flicker intermittently. After thorough testing, I found a loose connection in the main power supply leading to fluctuating voltage. Fixing that connection resolved the problem.

Q 26. What is your experience with hydraulic systems in elevators?

I have extensive experience with hydraulic systems in elevators, particularly in older installations. These systems use hydraulic fluid under pressure to move the elevator car. My experience encompasses everything from routine maintenance like fluid level checks and leak detection to more complex repairs involving hydraulic pumps, valves, and cylinders. I am also well-versed in troubleshooting common problems such as fluid leaks, pump malfunctions and the associated safety concerns these may pose. We use specialized equipment and techniques to test and maintain these systems safely and efficiently, while always prioritizing safety, including pressure testing and leak detection methods.

Hydraulic systems, while effective, require careful management due to environmental concerns relating to fluid leaks and the requirement for a dedicated hydraulic pit underneath the building. Modern systems often favor traction elevators for space and environmental considerations.

Q 27. How do you diagnose and repair problems related to elevator safety devices (e.g., limit switches, safety gears)?

Diagnosing and repairing problems with elevator safety devices requires a deep understanding of their function and the potential consequences of failure. This typically begins with a visual inspection to look for any obvious damage or wear. Then, testing is carried out to verify their functionality, often involving the use of specialized tools, such as ohmmeters, to check for continuity and signal integrity. Safety devices like limit switches, which prevent over-travel, and safety gears, which engage in case of cable breakage, require rigorous testing to ensure reliable operation.

For instance, if a limit switch fails, it could lead to the car overshooting its designated floor, potentially causing serious injury or damage. My approach involves meticulously inspecting and testing these critical components to prevent such scenarios.

Q 28. Describe your experience with working at heights and using appropriate safety equipment during installations.

Working at heights is an inherent part of elevator and escalator installations. Safety is paramount and I adhere strictly to all safety regulations and best practices. This includes using appropriate fall protection equipment, such as harnesses and lifelines, and employing safe work practices, such as using scaffolding and properly secured platforms. I ensure that all team members receive adequate training on working at heights and on the use of all safety equipment, before commencing any work at heights. Regular safety briefings and toolbox talks reinforce safety protocols. We also conduct risk assessments prior to every task to identify and mitigate potential hazards. My experience involves working on various projects with diverse height requirements, and safety is always the top priority.

One project involved working on the top floor of a high-rise building, necessitating the use of specialized harnesses and secure anchor points. We meticulously planned the work to ensure the safety of everyone involved.

Key Topics to Learn for Elevator and Escalator Installation Interview

- Safety Regulations and Procedures: Understanding and adhering to all relevant safety standards, including OSHA regulations, is paramount. This includes proper use of PPE and emergency procedures.

- Blueprint Reading and Interpretation: Ability to accurately read and interpret architectural and engineering drawings to understand installation requirements and specifications.

- Mechanical and Electrical Systems: Comprehensive knowledge of the mechanical and electrical components within elevators and escalators, including motors, controls, and safety mechanisms. This includes troubleshooting basic malfunctions.

- Installation Processes: Familiarity with the step-by-step procedures involved in installing elevators and escalators, from foundation preparation to final testing and commissioning.

- Hydraulic and Traction Systems: Understanding the differences and applications of hydraulic and traction elevator systems, including their maintenance and repair.

- Troubleshooting and Diagnostics: Ability to identify and resolve common issues during installation and maintenance, employing systematic diagnostic techniques.

- Quality Control and Inspection: Knowledge of quality control measures and inspection procedures to ensure compliance with safety standards and project specifications.

- Teamwork and Communication: Effective communication and collaboration skills are crucial for coordinating with other tradespeople and adhering to project timelines.

- Material Handling and Logistics: Safe and efficient handling of heavy equipment and materials during the installation process.

- Modernization and Upgrades: Familiarity with the process of upgrading and modernizing existing elevator and escalator systems.

Next Steps

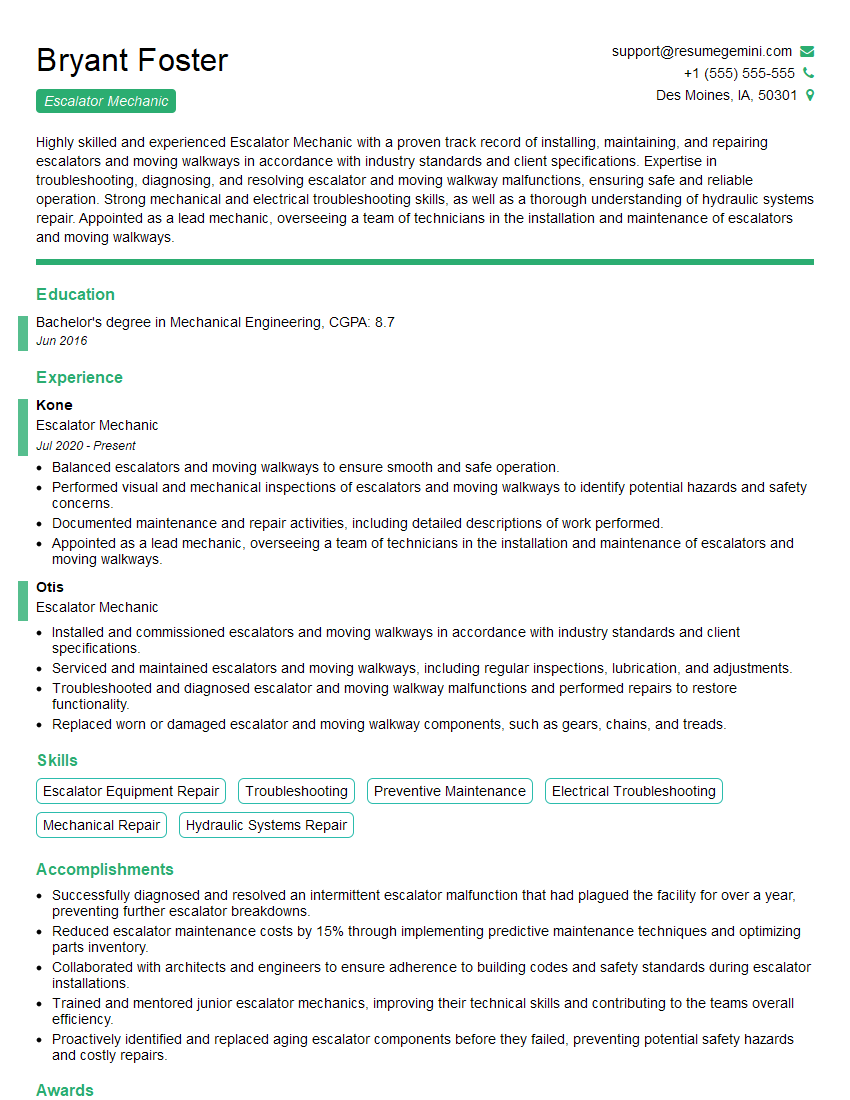

Mastering Elevator and Escalator Installation opens doors to a rewarding career with excellent growth potential. Specializing in this field positions you for high-demand roles within construction, maintenance, and modernization teams. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume tailored to the specific requirements of Elevator and Escalator Installation roles. Examples of resumes tailored to this industry are available within ResumeGemini to help you get started. Invest in your future – build a winning resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.