Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Energy Efficiency and Conservation Measures interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Energy Efficiency and Conservation Measures Interview

Q 1. Explain the difference between energy efficiency and energy conservation.

While often used interchangeably, energy efficiency and energy conservation are distinct concepts. Energy efficiency focuses on reducing the amount of energy required to perform a task. Think of it as getting more out of less energy. For example, replacing an inefficient incandescent light bulb with an LED bulb is energy efficiency; you achieve the same amount of light (the task) with significantly less energy. Energy conservation, on the other hand, is about reducing overall energy consumption through behavioral changes and reducing energy use. Turning off lights when leaving a room is energy conservation. It directly reduces the amount of energy used, regardless of efficiency.

In short: efficiency is about doing things better with less energy, while conservation is about using less energy overall.

Q 2. Describe your experience with energy audits and reporting.

I have extensive experience conducting energy audits for a wide range of building types, from commercial offices to industrial facilities and residential complexes. My audits involve a thorough on-site assessment, including visual inspections, equipment performance testing (e.g., HVAC system efficiency testing), and data analysis of energy consumption patterns. I utilize various tools such as infrared cameras to identify thermal leaks and energy monitoring devices to track real-time energy usage. My reporting typically includes:

- A detailed summary of the building’s energy consumption profile.

- Identification of energy-wasting areas and equipment.

- Cost-benefit analyses of recommended energy efficiency improvements.

- Prioritized list of retrofit recommendations with detailed implementation strategies and timelines.

- Visual aids such as thermal images, charts, and graphs to clearly illustrate findings.

For example, I recently conducted an audit for a large office building where we discovered that outdated HVAC equipment was significantly impacting energy usage. Our report detailed the inefficiencies, proposed upgrades, and demonstrated a significant return on investment for implementing the recommended changes. The client successfully implemented these measures, leading to a 15% reduction in energy costs within the first year.

Q 3. What are the key performance indicators (KPIs) you use to measure energy efficiency improvements?

Key Performance Indicators (KPIs) are crucial for measuring the success of energy efficiency projects. Some of the most important KPIs I utilize include:

- Energy Use Intensity (EUI): Measures energy consumption per unit area (e.g., kWh/m²/year). A lower EUI indicates improved energy efficiency.

- Percentage Reduction in Energy Consumption: This directly shows the percentage decrease in energy use after implementing efficiency measures.

- Return on Investment (ROI): Calculates the financial return on energy efficiency investments, considering initial costs and long-term savings.

- Simple Payback Period: The time it takes for the cost savings to offset the initial investment.

- Greenhouse Gas (GHG) Emissions Reduction: Quantifies the reduction in carbon footprint resulting from efficiency improvements.

For instance, in a recent project, we aimed for a 20% reduction in EUI. By tracking the EUI before and after implementing energy efficiency upgrades, we were able to accurately assess the effectiveness of our strategies. We also calculated the ROI to demonstrate the financial benefits to the client.

Q 4. How do you identify and prioritize energy saving opportunities in a building?

Identifying and prioritizing energy-saving opportunities requires a systematic approach. I typically follow these steps:

- Data Collection and Analysis: Gather energy consumption data from utility bills, building management systems (BMS), and on-site measurements.

- Energy Audit: Conduct a thorough energy audit to pinpoint areas of energy waste, using tools like infrared cameras and blower door tests.

- Walkthrough and Visual Inspection: Identify potential issues through visual inspection of building envelope, lighting systems, and equipment.

- Prioritization: Prioritize opportunities based on factors like cost-effectiveness (ROI, payback period), potential energy savings, and ease of implementation. This often involves creating a matrix that weighs these factors.

- Cost-Benefit Analysis: Evaluate the costs and benefits of each potential measure to select the most impactful and financially viable options.

For example, in one project, the initial audit showed significant heat loss through poorly insulated walls and windows. We prioritized these improvements due to their high potential for savings and relatively straightforward implementation, before tackling more complex system upgrades.

Q 5. What are your experiences with different energy efficiency technologies (e.g., HVAC, lighting, insulation)?

I have extensive experience working with various energy efficiency technologies across different building systems:

- HVAC (Heating, Ventilation, and Air Conditioning): Experience with high-efficiency HVAC equipment (e.g., variable refrigerant flow (VRF) systems, heat pumps), building automation systems (BAS) for optimized control, and commissioning to ensure proper operation.

- Lighting: Experienced with the design and implementation of energy-efficient lighting systems, including LED lighting retrofits, daylight harvesting, and occupancy sensors. I also understand lighting controls and their impact on energy savings.

- Insulation: Proficient in assessing insulation levels in building envelopes (walls, roofs, floors) and recommending improvements using various insulation materials (e.g., spray foam, fiberglass, cellulose). I’m familiar with air sealing techniques to reduce infiltration losses.

- Building Envelope Improvements: Experienced with assessing and improving the building envelope’s performance to minimize energy transfer through windows, doors, and walls.

For instance, in a recent project involving a school, we replaced outdated fluorescent lighting with high-efficiency LED fixtures and installed occupancy sensors, resulting in a 40% reduction in lighting energy consumption.

Q 6. Describe your experience with building energy modeling software.

I am proficient in using several building energy modeling (BEM) software packages, including EnergyPlus and TRNSYS. These tools allow me to simulate building energy performance under various conditions, enabling the assessment of energy efficiency measures before implementation. This predictive modeling helps to optimize design choices, accurately predict energy savings, and reduce uncertainty associated with retrofit projects.

For example, before recommending a significant HVAC upgrade in a large hospital, we used EnergyPlus to model the impact of different equipment options and control strategies. This allowed us to select the most effective and cost-efficient solution based on precise simulations rather than relying on estimations. This minimized risks and ensured the best outcome.

Q 7. How familiar are you with LEED certification and its energy efficiency requirements?

I am very familiar with LEED (Leadership in Energy and Environmental Design) certification and its energy efficiency requirements. I understand the various LEED rating systems (e.g., LEED for Building Design and Construction, LEED for Existing Buildings: Operations & Maintenance) and the specific credits related to energy performance. This includes the Energy and Atmosphere (EA) credit categories that address energy efficiency strategies, renewable energy sources, and overall energy performance.

My experience encompasses assisting clients in achieving LEED certification by implementing strategies that meet or exceed the required energy performance benchmarks. This includes developing energy models to demonstrate compliance with LEED requirements and preparing documentation for submission to the Green Building Certification Institute (GBCI).

Q 8. Explain the concept of life-cycle cost analysis in relation to energy efficiency projects.

Life-cycle cost analysis (LCCA) is a crucial tool for evaluating the long-term financial implications of energy efficiency projects. Unlike a simple upfront cost comparison, LCCA considers all costs associated with an asset or project over its entire lifespan, from initial investment to eventual disposal. This holistic approach allows for a more informed decision-making process, ensuring that the seemingly higher upfront cost of an energy-efficient option might actually yield significant long-term savings.

For example, imagine choosing between two heating systems: a cheaper, less efficient system versus a more expensive, highly efficient heat pump. While the initial cost of the heat pump is higher, LCCA would factor in lower energy bills over its lifetime, reduced maintenance costs, and potentially a higher resale value. By calculating the present value of all these costs and benefits, LCCA determines which option is truly more economical over its expected operational life.

In practice, LCCA involves estimating all relevant costs, such as initial investment, installation, operation, maintenance, repairs, and eventual replacement or disposal. These costs are then discounted to their present value using a chosen discount rate, reflecting the time value of money. The result is a comprehensive comparison of total lifecycle costs, enabling a more robust investment decision.

Q 9. How do you handle resistance to energy efficiency improvements from stakeholders?

Resistance to energy efficiency improvements often stems from misconceptions, financial concerns, or lack of awareness. My approach involves proactive communication and collaborative problem-solving. I begin by understanding the stakeholders’ concerns, addressing them directly with factual information and demonstrating the long-term benefits. This might involve presenting data on energy savings, reduced operational costs, and improved environmental performance. For example, if financial constraints are a concern, I would highlight potential incentives, rebates, or financing options available.

Furthermore, I find it helpful to involve stakeholders in the decision-making process. Engaging them in discussions about energy efficiency solutions fosters a sense of ownership and buy-in. This might include workshops, site visits, and interactive presentations showcasing successful case studies and demonstrating the feasibility and practicality of proposed solutions. Building trust and demonstrating expertise are key to overcoming resistance. Sometimes, addressing smaller, easier-to-implement improvements first can build momentum and demonstrate tangible results, encouraging further engagement.

Q 10. What is your experience with energy management systems (EMS)?

I have extensive experience working with energy management systems (EMS), both in designing and implementing them. EMS are crucial for monitoring, controlling, and optimizing energy consumption in buildings and industrial facilities. My experience spans various types of EMS, from basic building automation systems to advanced systems incorporating machine learning for predictive energy management.

For instance, I’ve been involved in projects where we integrated EMS to control HVAC systems, lighting, and other energy-intensive equipment based on occupancy sensors and real-time energy usage data. This allows for optimized energy consumption by automatically adjusting operations based on actual demand rather than relying on fixed schedules. In another project, we used an EMS to identify and troubleshoot energy waste in a large industrial facility, resulting in significant reductions in electricity and natural gas consumption.

My understanding extends to data analysis and reporting capabilities offered by advanced EMS. This allows for the generation of detailed energy consumption reports, identifying areas for improvement and tracking the effectiveness of energy conservation measures. The ability to extract actionable insights from these reports is critical in maintaining and continuously improving energy efficiency.

Q 11. Describe your understanding of different energy codes and standards.

Energy codes and standards are crucial for setting minimum energy efficiency requirements for buildings and equipment. My understanding encompasses various national and international standards such as ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), IEC (International Electrotechnical Commission), and local building codes. These standards dictate factors like insulation requirements, window performance, lighting efficiency, and HVAC system design.

For example, ASHRAE Standard 90.1 provides a baseline for energy-efficient building design, specifying requirements for various building types and climates. Similarly, IEC standards address the energy efficiency of various equipment, such as motors, lighting fixtures, and power supplies. Local building codes often adopt and adapt these standards to suit the specific climatic conditions and regulatory framework of a given region. Keeping abreast of these evolving standards is vital for ensuring that energy efficiency projects comply with regulations and best practices.

My experience includes navigating the complexities of different codes and standards, ensuring that designs meet or exceed the required energy efficiency levels, while also optimizing for cost-effectiveness. This involves interpreting technical specifications, selecting appropriate materials and equipment, and coordinating with regulatory authorities to secure necessary approvals.

Q 12. How do you calculate simple payback period for an energy efficiency investment?

The simple payback period (SPP) is a crucial metric in evaluating energy efficiency investments. It indicates the time it takes for the cumulative energy cost savings to equal the initial investment cost. A shorter SPP signifies a quicker return on investment.

To calculate the SPP, we follow these steps:

- Determine the initial investment cost: This includes all costs associated with the project, such as equipment purchase, installation, and any professional fees.

- Estimate annual energy savings: This involves calculating the reduction in energy consumption resulting from the efficiency improvement and multiplying it by the cost of energy.

- Calculate the simple payback period: Divide the initial investment cost by the annual energy savings. The result is the number of years it will take to recoup the initial investment.

For example: If an energy-efficient lighting upgrade costs $10,000 and is expected to save $2,500 annually in electricity costs, the SPP is $10,000 / $2,500 = 4 years. This means the project will pay for itself in four years.

It’s crucial to remember that SPP is a simplified calculation, neglecting factors like inflation, the time value of money, and potential future maintenance costs. While it is a useful initial indicator, a more comprehensive LCCA is recommended for a more robust evaluation.

Q 13. What are some common barriers to implementing energy efficiency measures?

Several barriers hinder the widespread implementation of energy efficiency measures. These include:

- High upfront costs: Many energy efficiency improvements require significant initial investments, which can be a deterrent, especially for individuals or organizations with limited budgets.

- Lack of awareness and understanding: Many stakeholders are unaware of the available technologies or the long-term benefits of energy efficiency improvements.

- Uncertainty about return on investment: The long-term nature of energy savings can make it challenging to accurately predict and quantify the return on investment, leading to reluctance to make the initial investment.

- Lack of skilled labor: The successful implementation of some energy efficiency projects requires specialized knowledge and expertise, which can be limited in some areas.

- Regulatory hurdles: Navigating building codes, permitting processes, and other regulations can create obstacles and delays.

- Split incentives: In multi-tenant buildings or situations where energy costs are not directly borne by the decision-maker, incentives for implementing improvements are often low.

Addressing these barriers requires a multi-pronged approach involving financial incentives, educational programs, improved technical assistance, simplified regulatory frameworks, and strategies to align incentives for all stakeholders.

Q 14. How do you communicate complex technical information to non-technical audiences?

Communicating complex technical information to non-technical audiences requires clear, concise language and avoiding jargon. I utilize several strategies:

- Analogies and metaphors: I use relatable analogies to explain complex concepts. For instance, explaining energy efficiency using the analogy of a leaky bucket to illustrate energy loss.

- Visual aids: Charts, graphs, and diagrams effectively communicate data and trends, making complex information easier to grasp.

- Storytelling: Sharing real-world examples and case studies makes the information more engaging and memorable.

- Simplified language and definitions: Avoiding technical jargon and defining any necessary terms ensures clarity and comprehension.

- Interactive presentations: Engaging the audience through questions and discussions encourages participation and fosters understanding.

- Tailoring the message: Adapting the level of detail and complexity to the audience’s background and knowledge level ensures effective communication.

By employing these strategies, I ensure that non-technical audiences can understand and appreciate the importance of energy efficiency and the benefits of adopting appropriate measures.

Q 15. What are your strategies for monitoring and verifying energy savings after implementation?

Monitoring and verifying energy savings after implementing efficiency measures is crucial to ensure the project’s success. It’s not enough to simply install new equipment; we need data to prove the return on investment. My strategy involves a multi-faceted approach:

Baseline Data Collection: Before any changes, I meticulously collect baseline energy consumption data. This involves installing or utilizing existing smart meters to track energy use across different systems (lighting, HVAC, equipment) and analyze usage patterns. This baseline serves as the benchmark for comparison.

Post-Implementation Monitoring: After implementing the energy efficiency measures, I continue monitoring energy consumption using the same methods, ideally for at least a year to account for seasonal variations. This allows for a comprehensive comparison with the baseline data.

Data Analysis and Reporting: I use specialized software to analyze the collected data, identifying areas where energy savings are exceeding expectations or falling short. I then create detailed reports visualizing the energy savings, highlighting successes, and pinpointing areas needing further attention. These reports should clearly demonstrate the ROI of the implemented measures.

Regular Audits and Inspections: Regular site visits and system inspections ensure the continued effectiveness of the implemented measures. This helps identify any operational issues that may be impacting energy efficiency, allowing for timely corrective actions.

Key Performance Indicators (KPIs): I establish clear KPIs to measure the success of the energy efficiency project. These KPIs can include kilowatt-hour (kWh) savings, cost savings, reduction in carbon emissions, and improvement in energy efficiency ratios (EERs).

For example, in a recent project for a commercial building, we implemented LED lighting and optimized the HVAC system. By comparing pre- and post-implementation energy consumption data, we demonstrated a 25% reduction in overall energy usage, which translated to significant cost savings for the client.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What experience do you have with renewable energy technologies?

My experience with renewable energy technologies spans several areas. I’ve been involved in projects incorporating:

Photovoltaic (PV) Systems: I have experience in the design, installation, and commissioning of grid-tied and off-grid PV systems for various applications, including residential, commercial, and industrial buildings. This includes sizing arrays based on energy needs, selecting appropriate inverters, and ensuring compliance with safety regulations.

Wind Energy: I’ve worked on projects involving small-scale wind turbines, primarily in rural settings where grid connectivity is limited. My work here focuses on site assessment, turbine selection, and grid integration when applicable.

Geothermal Energy: I’m familiar with geothermal heat pumps for heating and cooling applications, understanding their energy efficiency advantages and the geological considerations for proper installation.

Energy Storage Systems: I’m knowledgeable about battery storage systems and their integration with renewable energy sources, recognizing their importance in stabilizing grid power and providing backup power during outages.

I understand the importance of integrating renewable energy sources effectively into existing infrastructure while also addressing the challenges associated with intermittency and storage. For example, in one project, we successfully integrated a solar PV system with a battery storage system into a remote community, providing them with reliable electricity while reducing their reliance on fossil fuels.

Q 17. How would you approach reducing energy consumption in a large industrial facility?

Reducing energy consumption in a large industrial facility requires a systematic approach that goes beyond simple replacements. It starts with a comprehensive energy audit.

Energy Audit: A thorough audit identifies energy-intensive processes and equipment. This audit will include detailed measurements of energy use, identifying energy waste points such as inefficient motors, compressed air leaks, or poor building insulation.

Process Optimization: Analyzing the manufacturing processes to identify areas for improvement. This could involve optimizing production schedules, streamlining workflows, or implementing lean manufacturing principles to reduce waste and energy consumption.

Equipment Upgrades: Replacing outdated or inefficient equipment with high-efficiency alternatives. This might involve upgrading motors, pumps, compressors, and HVAC systems with energy-efficient models. Variable frequency drives (VFDs) for motors can significantly reduce energy use.

Building Envelope Improvements: Improving the building’s insulation, sealing air leaks, and upgrading windows can significantly reduce heating and cooling loads.

Lighting Upgrades: Switching to high-efficiency lighting such as LED fixtures can drastically reduce energy use and maintenance costs.

Behavioral Changes: Implementing energy conservation practices among employees through training and awareness programs. This can include turning off equipment when not in use, properly maintaining equipment, and optimizing temperature settings.

Energy Management System (EMS): Installing an EMS to monitor and control energy usage in real-time. This allows for better energy management and facilitates proactive identification and resolution of energy waste.

For example, in a large manufacturing plant, we implemented a combination of these strategies resulting in a 30% reduction in energy usage, leading to substantial cost savings and a reduced environmental footprint.

Q 18. What are the key factors to consider when selecting energy efficiency upgrades?

Selecting energy efficiency upgrades requires careful consideration of several key factors:

Payback Period: The time it takes for the cost savings from the upgrade to recoup the initial investment. A shorter payback period is generally preferred.

Life-Cycle Cost: This considers the total cost of ownership over the asset’s lifetime, encompassing initial investment, maintenance, operation, and replacement costs. Selecting equipment with lower life-cycle costs is usually more cost-effective in the long run.

Energy Savings Potential: The estimated amount of energy that can be saved by the upgrade, often expressed in kWh or therms. Upgrades with higher energy savings potential are generally more attractive.

Reliability and Maintainability: Choosing reliable equipment that requires minimal maintenance minimizes downtime and operational costs.

Technology Maturity: Assessing the maturity and proven track record of the technology. It’s important to avoid unproven technologies that may not deliver on their promised performance.

Environmental Impact: Considering the environmental benefits, such as reduced greenhouse gas emissions, associated with the upgrade.

Incentives and Rebates: Investigating available government incentives, rebates, and tax credits that can reduce the initial investment costs.

A cost-benefit analysis is essential to compare different upgrade options and select the most economically and environmentally sound solution.

Q 19. Describe your familiarity with different types of lighting and their energy efficiency.

My familiarity with different lighting technologies and their energy efficiency is extensive. Here’s a breakdown:

Incandescent: These are the least energy-efficient, converting only a small percentage of electricity into light and emitting significant heat. They’re largely being phased out due to their inefficiency.

Fluorescent: These are more efficient than incandescent, but contain mercury and can be more expensive to dispose of. They also have a longer lifespan than incandescents.

High-Intensity Discharge (HID): HID lamps such as metal halide and high-pressure sodium lamps are more efficient than fluorescents, particularly in high-bay applications, but have longer startup times and are not as easily dimmed.

Light-Emitting Diode (LED): LEDs are currently the most energy-efficient lighting technology, offering long lifespans, low maintenance, and excellent color rendering. They’re also highly dimmable and come in various color temperatures.

The choice of lighting technology depends on the application and budget. For example, LED lighting is often the most cost-effective option in the long run, despite higher upfront costs, due to its long lifespan and low energy consumption. In situations where dimming is crucial, LED is the ideal choice. However, in specific industrial applications with high-bay needs, HID lights may remain cost-effective depending on operational hours.

Q 20. What is your experience with commissioning and retro-commissioning of building systems?

Commissioning (Cx) and retro-commissioning (RCx) are critical processes for ensuring building systems operate optimally and efficiently. I have extensive experience in both:

Commissioning: This involves verifying that new or renovated building systems are installed and performing according to the design specifications. This includes testing, adjusting, and balancing (TAB) HVAC systems, verifying the functionality of control systems, and documenting the performance of all systems. My approach involves creating a comprehensive commissioning plan, involving all stakeholders, and monitoring performance throughout the process.

Retro-commissioning: RCx focuses on optimizing the performance of existing building systems. This involves a detailed assessment of building systems, identifying operational problems, and implementing cost-effective solutions to improve efficiency. My RCx approach typically includes an initial building walk-through, data analysis, functional testing, and implementation of corrective actions.

For instance, during an RCx project in a large office building, we discovered several HVAC control issues that were causing inefficient operation. By identifying and resolving these issues, we achieved a 15% reduction in energy consumption for the HVAC system, demonstrating the significant impact of proper commissioning and retro-commissioning.

Q 21. How do you stay updated on the latest advancements in energy efficiency technologies?

Staying updated on the latest advancements in energy efficiency technologies is crucial in this rapidly evolving field. I employ several strategies:

Professional Organizations: I am an active member of professional organizations such as ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) and the Illuminating Engineering Society (IES), attending conferences, workshops, and webinars to learn about new technologies and best practices.

Industry Publications and Journals: I regularly read industry publications and journals such as Energy Efficiency and ASHRAE Journal, staying informed about research and development in the field.

Online Resources: I utilize online resources like the Department of Energy’s website and other reputable sources to access the latest energy efficiency data, reports, and research findings.

Networking: I maintain an active professional network, engaging with colleagues, attending industry events, and participating in online forums to share knowledge and learn from others’ experiences.

Continuing Education: I actively participate in continuing education programs to maintain my certifications and expand my knowledge in new and emerging energy-efficiency technologies.

This multi-faceted approach ensures that I remain at the forefront of the field, enabling me to provide the most effective and up-to-date energy efficiency solutions to my clients.

Q 22. Explain the concept of energy baseline and how it is established.

An energy baseline represents a building’s or system’s historical energy consumption, serving as a benchmark for measuring the effectiveness of energy efficiency improvements. Establishing a robust baseline requires a meticulous approach. It involves collecting energy consumption data over a representative period, typically 12 months, to account for seasonal variations. This data, often obtained from utility bills, smart meters, or building management systems (BMS), is then normalized to account for factors that might skew the results, such as changes in occupancy, weather conditions, or operational changes. For example, a significant increase in occupancy might inflate energy use, masking the impact of efficiency improvements. Normalization techniques involve statistical methods like regression analysis to isolate the impact of these external factors. Finally, data quality checks are crucial; inconsistencies or anomalies should be investigated and corrected. A reliable baseline provides a clear picture of pre-improvement energy performance, allowing for accurate measurement and verification (M&V) of energy savings after implementing efficiency measures.

Q 23. What is your experience working with energy data analysis and reporting tools?

My experience with energy data analysis and reporting tools is extensive. I’m proficient in using software such as EnergyPlus, eQUEST, and various building performance simulation tools to model energy consumption. I’m also experienced with data visualization tools like Tableau and Power BI to create insightful reports on energy performance, helping stakeholders easily understand complex data. I’ve worked extensively with building management systems (BMS) data, extracting and analyzing energy usage patterns. This involves understanding data structures, cleaning data, and employing various statistical techniques to identify trends, anomalies, and areas for potential energy savings. For instance, I once used BMS data to pinpoint a faulty HVAC system that was responsible for significant energy waste in a large office building. By creating visualizations of the data, I was able to clearly illustrate the problem to building management, leading to timely repairs and substantial cost savings.

Q 24. How do you ensure the accuracy and reliability of energy data collected for audits?

Ensuring the accuracy and reliability of energy data collected for audits is paramount. My approach involves a multi-pronged strategy. First, I rigorously verify the source and quality of the data. Utility bills must be carefully examined for accuracy, and meter readings must be double-checked. Second, I use data validation techniques, including identifying outliers and correcting for errors or anomalies. This might involve comparing energy consumption with historical data or adjusting for weather variations. Third, I implement a thorough quality control process, cross-referencing data from multiple sources to identify inconsistencies and verify their accuracy. For example, I might compare electricity consumption data with gas consumption data to determine if there are any discrepancies. Finally, I document all data sources, processing methods, and assumptions clearly and transparently. This level of scrutiny ensures the reliability and integrity of the data used for energy audits, preventing inaccurate conclusions and inefficient investments.

Q 25. Explain your understanding of the different energy efficiency financing mechanisms.

Various financing mechanisms exist to support energy efficiency improvements. These include utility rebates and incentives, which offer financial rewards for installing energy-efficient equipment. Then there are low-interest loans and tax credits, reducing the upfront financial burden. Energy Performance Contracts (EPCs) are also significant; these involve third-party financing where energy savings pay for the improvements. For example, a company might agree to install new lighting in exchange for a share of the resulting energy savings. Finally, green bonds and private investment funds are increasingly providing capital for large-scale energy efficiency projects. The choice of financing mechanism depends on factors such as project size, budget, and risk tolerance. I’ve successfully leveraged several of these mechanisms in projects, optimizing the financial structure to ensure project feasibility and maximize cost-effectiveness.

Q 26. Describe your experience with the development and implementation of energy efficiency programs.

I have extensive experience in developing and implementing energy efficiency programs. This includes conducting energy audits, identifying cost-effective improvements, preparing detailed proposals, and managing the implementation of the selected measures. I have a strong track record of success in leading projects across diverse building types, including commercial offices, industrial facilities, and residential complexes. For example, in one project, I led the implementation of an energy efficiency program in a large hospital complex, resulting in a 15% reduction in energy consumption within a year. My role involved not only the technical aspects – including lighting upgrades, HVAC optimization, and building envelope improvements – but also stakeholder engagement, ensuring buy-in from building operators and staff to guarantee long-term success.

Q 27. What are the key considerations for designing an energy efficient building from the ground up?

Designing an energy-efficient building from the ground up necessitates a holistic approach considering several key aspects. First, site selection and orientation are crucial – maximizing solar gain in winter while minimizing it in summer. Second, the building envelope must be optimized for thermal performance, incorporating high-performance insulation, airtight construction, and high-efficiency windows. Third, the HVAC system should be carefully designed based on a load calculation, utilizing efficient equipment and controls. Fourth, incorporating renewable energy sources like solar photovoltaic (PV) panels or geothermal energy can drastically reduce reliance on fossil fuels. Fifth, efficient lighting systems, incorporating daylight harvesting and occupancy sensors, contribute significantly to energy savings. Finally, integrating smart building technologies enhances monitoring and control of energy consumption, facilitating real-time optimization. Thorough design, incorporating sustainable materials and construction techniques, is crucial for long-term energy efficiency.

Q 28. How do you ensure the long-term sustainability of energy efficiency improvements?

Ensuring the long-term sustainability of energy efficiency improvements requires a multi-faceted strategy. First, robust maintenance plans are critical – ensuring that equipment is regularly serviced and that any issues are addressed promptly. Second, comprehensive training programs for building operators are essential – enabling them to operate and maintain the improved systems effectively. Third, establishing a robust monitoring and verification (M&V) system is crucial – tracking energy consumption to identify any performance degradation and address any emerging issues. Fourth, incorporating flexible designs that can adapt to future needs minimizes the need for extensive retrofits. Fifth, promoting occupant engagement through awareness campaigns can foster responsible energy use, reducing energy consumption beyond what technological improvements can achieve alone. By focusing on these aspects, we can ensure that the energy savings realized from initial improvements persist for years to come.

Key Topics to Learn for Energy Efficiency and Conservation Measures Interview

- Building Envelope Optimization: Understanding insulation, air sealing, window performance, and their impact on energy consumption. Practical application: Analyzing building blueprints to identify areas for improvement in thermal performance.

- HVAC Systems and Efficiency: Knowledge of various HVAC technologies (e.g., heat pumps, geothermal systems), their efficiency ratings (SEER, EER), and maintenance best practices. Practical application: Evaluating the energy performance of existing HVAC systems and proposing upgrades.

- Renewable Energy Integration: Familiarity with solar PV, wind power, and other renewable energy sources, including their integration into building systems and grid management. Practical application: Designing a renewable energy system for a residential or commercial building.

- Lighting Efficiency: Understanding different lighting technologies (LED, CFL, etc.), their energy consumption, and the impact of lighting control systems. Practical application: Specifying energy-efficient lighting solutions for a retrofit project.

- Energy Auditing and Modeling: Proficiency in conducting energy audits, using energy modeling software, and interpreting energy consumption data. Practical application: Identifying energy waste in a building and recommending cost-effective solutions.

- Energy Codes and Standards: Knowledge of relevant building codes and energy efficiency standards (e.g., ASHRAE, LEED). Practical application: Ensuring building designs comply with current regulations.

- Lifecycle Cost Analysis (LCCA): Ability to perform LCCA to compare the long-term cost-effectiveness of different energy efficiency measures. Practical application: Justifying investments in energy efficiency upgrades based on financial analysis.

- Demand-Side Management (DSM) Strategies: Understanding different DSM strategies to reduce peak demand and improve grid reliability. Practical application: Developing DSM programs for utility companies or large building owners.

Next Steps

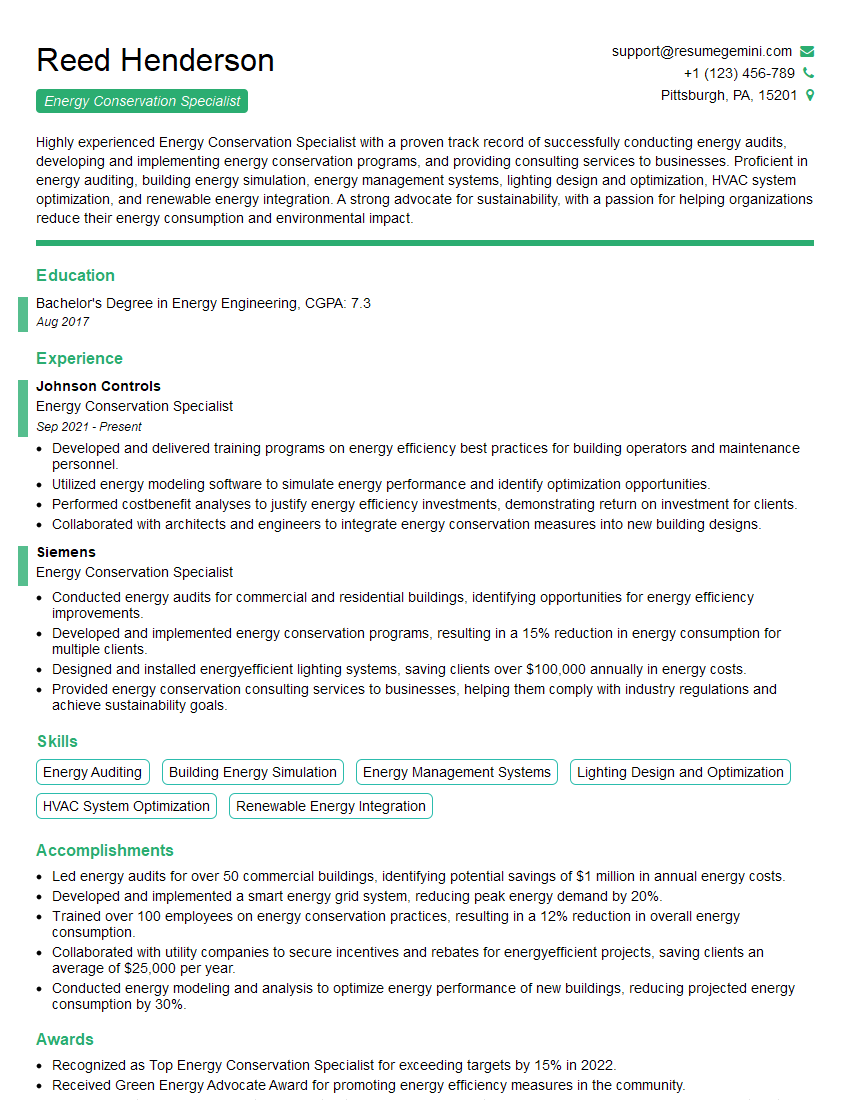

Mastering Energy Efficiency and Conservation Measures is crucial for career advancement in a rapidly growing green sector. Your expertise in sustainable building practices and energy optimization will be highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Energy Efficiency and Conservation Measures are available to help you craft the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.