Unlock your full potential by mastering the most common Equipment Erection interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Equipment Erection Interview

Q 1. Describe your experience with different types of lifting equipment.

My experience with lifting equipment spans a wide range, encompassing various types crucial for efficient and safe erection. This includes:

- Tower Cranes: I’ve extensively used these for lifting heavy components, particularly in high-rise construction projects. Understanding their load charts, swing radii, and limitations is paramount for safe operation. For instance, on a recent project, we utilized a Liebherr tower crane to lift pre-fabricated sections of a steel structure, carefully planning the lifting sequence to avoid any collisions or overloading.

- Mobile Cranes: From smaller all-terrain cranes to larger rough-terrain and crawler cranes, I’m proficient in their operation, ensuring compliance with load capacities and safety protocols. Selecting the right crane for the job, based on lift capacity, reach, and site accessibility, is crucial. One example was utilizing a rough-terrain crane in a confined space with limited maneuverability.

- Forklifts and Telehandlers: These are essential for handling smaller components and materials. Safe operation necessitates understanding weight distribution, stability, and terrain conditions. I have extensive experience managing these machines, including pre-use inspections and operator training.

- Specialized Lifting Equipment: My experience extends to less common equipment like vacuum lifters for glass panels, and specific rigging gear like spreader beams and shackles, adapting to various project needs. The use of vacuum lifters significantly sped up the installation of large glass facades on a recent project.

Across all equipment types, rigorous adherence to manufacturer’s specifications, regular maintenance checks, and operator competency are non-negotiable.

Q 2. Explain the process of pre-erection planning and its importance.

Pre-erection planning is the cornerstone of a successful and safe project. It involves meticulously mapping out every stage of the erection process before a single bolt is turned. Think of it as creating a detailed blueprint for a complex construction puzzle.

- Site Survey and Assessment: This includes evaluating ground conditions, access routes, available utilities, and potential obstructions. A thorough survey prevents costly delays and safety hazards down the line. For example, identifying unstable ground early on allows us to plan for appropriate foundation solutions.

- Equipment Selection and Sequencing: Choosing the correct lifting equipment based on load capacities, reach, and site conditions is crucial. We carefully sequence the lifting operations to optimize efficiency and safety, minimizing the risk of collisions or equipment interference.

- Methodology and Lifting Plans: Detailed lifting plans are created, including lift diagrams, weight calculations, and rigging schemes. These plans account for all variables, like wind speed and direction, ensuring safe lifting procedures are followed.

- Risk Assessment and Mitigation: This critical step identifies potential hazards and develops strategies to mitigate them. It’s about proactively addressing potential problems, not reactively solving crises.

- Logistics and Resource Management: Effective planning ensures timely delivery of materials and equipment. We coordinate with other trades to prevent scheduling conflicts and delays.

The importance of thorough pre-erection planning cannot be overstated; it directly impacts project schedule, budget, and, most importantly, safety.

Q 3. How do you ensure the safety of personnel and equipment during erection?

Ensuring the safety of personnel and equipment is my top priority. This is achieved through a multi-layered approach:

- Strict Adherence to Safety Regulations: We comply with all relevant OSHA (or equivalent) regulations and industry best practices.

- Comprehensive Safety Training: All personnel involved in the erection process, including crane operators, riggers, and ground crew, undergo thorough safety training and certification.

- Pre-Lift Inspections: Rigorous checks of all lifting equipment, rigging gear, and the structural integrity of the components being lifted are conducted before every lift.

- Designated Safe Zones and Barriers: We establish designated safe zones around the lifting operations and erect barriers to prevent unauthorized personnel from entering the hazardous area.

- Use of Personal Protective Equipment (PPE): Appropriate PPE, including hard hats, safety glasses, and high-visibility clothing, is mandatory for all personnel on site.

- Emergency Response Plan: A detailed emergency response plan is in place, outlining procedures for handling accidents and emergencies.

- Regular Safety Meetings: We conduct regular safety meetings to address concerns, reinforce safe practices, and review incident reports.

Safety isn’t just a checklist; it’s a continuous process embedded in our project culture. A proactive approach, where safety is paramount, minimizes risks and creates a safer work environment for everyone.

Q 4. What are your preferred methods for handling challenging site conditions during erection?

Challenging site conditions require creative solutions and adaptation. My approach focuses on:

- Detailed Site Analysis: Thorough analysis of the site conditions, including soil type, terrain, weather patterns, and accessibility limitations, informs our strategy.

- Specialized Equipment: We select equipment suited for the specific conditions; for example, using crawler cranes on soft ground or employing specialized rigging techniques for confined spaces.

- Temporary Works Design: This may involve designing and constructing temporary access roads, shoring systems, or other structures to overcome site limitations. One instance involved constructing a temporary elevated platform to reach a rooftop installation point.

- Method Statements and Risk Assessments: Specific method statements and risk assessments are developed for each task considering the unique site challenges. This minimizes risks and ensures safe execution of the work.

- Communication and Coordination: Effective communication with all stakeholders, including site management, subcontractors, and regulatory authorities, is crucial for navigating the complexities of a challenging site.

Flexibility and problem-solving skills are essential for successfully managing erection in demanding conditions. It’s about adapting the plan, not stubbornly sticking to it when faced with unforeseen circumstances.

Q 5. Describe your experience with different types of foundations and their suitability for specific equipment.

Experience with various foundation types is critical for ensuring the stability and longevity of erected equipment. The choice depends heavily on the equipment’s weight, vibration characteristics, and the soil conditions. I have worked with:

- Concrete Foundations: These are commonly used for heavy equipment and provide a stable base. The design considerations include depth, reinforcement, and load-bearing capacity. For example, we used a large reinforced concrete foundation for a massive industrial press.

- Steel Pile Foundations: These are suited for soft or unstable ground conditions. The design needs to account for the soil bearing capacity and potential settlement. We utilized steel piles for a large compressor in marshy terrain.

- Spread Footings: Suitable for lighter equipment, spread footings distribute the load over a wider area. Careful consideration of the soil bearing capacity is crucial. Many smaller pumps and auxiliary equipment utilized this foundation type.

- Grouting: Used to stabilize foundations and fill gaps, grouting ensures a firm and level base for the equipment. We employed grouting extensively in rocky terrain to level the foundation.

Selecting the right foundation type is a critical engineering decision influencing the equipment’s performance, stability, and safety.

Q 6. How do you manage equipment tolerances and alignment during erection?

Managing equipment tolerances and alignment is crucial for operational efficiency and longevity. My approach involves:

- Precise Measurement and Surveying: Accurate measurements and surveying techniques are used to establish precise baselines and reference points for equipment placement. Laser levels and total stations are frequently employed.

- Use of Alignment Tools: Various alignment tools, such as laser alignment systems, plumb bobs, and levels, are utilized to ensure accurate placement and alignment of equipment components.

- Shimming and Adjustment: Shims are used to adjust the equipment’s position to compensate for minor discrepancies in the foundation or surrounding structures.

- Regular Monitoring and Verification: Throughout the erection process, we regularly monitor and verify alignment using appropriate tools and techniques to ensure adherence to specified tolerances.

- Documentation: Detailed records of all measurements, adjustments, and alignment checks are maintained to provide a complete audit trail.

Precision is paramount; even minor misalignments can lead to vibration, stress, and premature equipment failure. The commitment to accuracy is a hallmark of our erection processes.

Q 7. Explain your experience with troubleshooting equipment erection problems.

Troubleshooting equipment erection problems requires a systematic approach. My experience involves:

- Careful Observation and Analysis: The initial step involves carefully observing the problem, gathering data, and analyzing the potential causes. This often involves reviewing the erection plans, checking site conditions, and assessing the equipment’s condition.

- Systematic Investigation: A methodical investigation is undertaken to pinpoint the root cause. This may involve consultations with engineers, equipment manufacturers, and other experts.

- Development of Corrective Actions: Once the root cause is identified, corrective actions are developed and implemented to resolve the issue. This could range from minor adjustments to more substantial modifications.

- Documentation and Reporting: All troubleshooting activities, findings, and corrective actions are thoroughly documented and reported to relevant stakeholders.

- Preventive Measures: Following the resolution of a problem, preventive measures are put in place to avoid similar issues in the future.

Effective troubleshooting demands a combination of technical expertise, analytical skills, and practical problem-solving abilities. It’s about learning from mistakes and continuously improving our procedures.

Q 8. How do you ensure compliance with relevant safety regulations and standards during erection?

Ensuring safety compliance during equipment erection is paramount. It’s not just about ticking boxes; it’s about fostering a safety-first culture. We begin by thoroughly reviewing all relevant regulations and standards, which vary depending on location and the type of equipment. These include OSHA regulations (in the US), local building codes, and industry-specific standards like those from ASME or API.

Before any lifting commences, a comprehensive risk assessment is conducted, identifying potential hazards like unstable ground conditions, overhead obstructions, or weather risks. This assessment informs our safety plan, which details specific control measures like using appropriate Personal Protective Equipment (PPE), implementing traffic management plans, and establishing clear communication protocols. We conduct regular toolbox talks to reinforce safety procedures and address any concerns. Finally, we maintain meticulous records of all safety inspections and training, ensuring full traceability and accountability.

For example, during a recent turbine erection, we identified a risk of dropped objects from a significant height. Our solution involved implementing a designated exclusion zone, using safety nets below the working area, and providing all personnel with hard hats and high-visibility clothing. This proactive approach minimized risk and ensured a safe completion of the project.

Q 9. What are your experience with different types of rigging techniques and their applications?

My experience encompasses a wide range of rigging techniques, each tailored to the specific characteristics of the load and the environment. I’m proficient in various methods, including:

- Basic rigging: Using shackles, slings, and wire ropes for straightforward lifts.

- Complex rigging: Employing multiple slings and spreader beams for large or oddly shaped equipment, often requiring detailed calculations to distribute the load evenly.

- Critical lift rigging: For particularly sensitive or heavy components, this involves advanced planning, multiple redundancies, and specialized equipment like load cells and dynamometers for precise monitoring.

- Specialized rigging: This includes techniques for lifting equipment in confined spaces, over obstacles, or in challenging weather conditions. This often involves innovative solutions using specialized equipment like vacuum lifters or air-powered cranes.

For instance, during the erection of a large reactor vessel, we utilized a complex rigging system with multiple spreader beams and load cells to ensure the vessel’s weight was distributed evenly across the crane’s lifting points. The load cells provided real-time weight readings, ensuring the safety of the lift.

Q 10. How do you coordinate with other trades during the equipment erection process?

Coordination is crucial for a successful erection. It’s not simply about the erection crew; it involves seamless integration with other trades like civil, electrical, instrumentation, and piping. This is achieved through diligent planning and regular communication. We establish a clear project timeline with milestones for each trade, identifying potential dependencies and scheduling overlaps well in advance. This often involves using project management software to track progress and identify any potential conflicts.

Daily coordination meetings are held to discuss progress, address any unforeseen issues, and resolve conflicts. Regular site walkthroughs with representatives from each trade ensure everyone is aware of the ongoing work and any potential hazards. Open communication channels are essential – regular updates, progress reports and proactive problem-solving help to maintain a smooth workflow. For example, if the civil works are delayed, we adjust the erection schedule accordingly, communicating the changes to all affected parties. This proactive approach prevents delays and ensures the project remains on track.

Q 11. Describe your experience with the use of CAD drawings and erection plans.

I have extensive experience using CAD drawings and erection plans. These are essential for visualizing the project, understanding the sequence of operations, and identifying potential conflicts before they arise. I’m proficient in interpreting various CAD formats, including AutoCAD, Revit, and MicroStation. I use these plans to create detailed lifting plans, including load calculations, rigging diagrams, and crane charts. The plans also guide the sequencing of erection, helping to optimize the process and minimize downtime.

Furthermore, I use the CAD models to identify any potential clashes or interferences between different components of the equipment. This allows us to proactively address any design issues and make necessary adjustments before the erection process begins. This reduces rework and potential delays on-site. For instance, on a recent project, a review of the CAD models revealed a potential clash between a pipe rack and a newly erected vessel. By identifying and resolving this issue upfront, we prevented a costly delay and rework.

Q 12. Explain your understanding of load calculations and load paths in equipment erection.

Understanding load calculations and load paths is fundamental to safe and efficient equipment erection. Load calculations determine the weight of the equipment, the forces acting on it during lifting, and the stresses on the supporting structures. This includes calculating the weight of the equipment itself, plus any additional loads such as rigging hardware, slings, and personnel. Load paths illustrate the transfer of weight from the equipment through the rigging and lifting devices to the supporting structure. Accurate load calculations ensure the chosen equipment (crane, slings, etc.) has sufficient capacity.

Failure to accurately determine load paths and calculations can result in equipment damage, structural failure, or even injury. We use specialized software and industry-accepted formulas to perform these calculations, considering factors like wind loads, dynamic forces during the lift, and the properties of the supporting structure. For example, during a heavy transformer lift, we used finite element analysis software to model the load path and confirm the structural integrity of the temporary supports. This rigorous approach ensured the safety and success of the lift.

Q 13. How do you maintain accurate records and documentation throughout the erection process?

Maintaining accurate records and documentation is crucial for accountability, safety, and future reference. We use a combination of electronic and hard-copy documentation. This includes detailed daily reports, photographs, videos, and inspection checklists. All critical information—lifting plans, risk assessments, and non-conformance reports—is stored digitally in a secure and easily accessible system.

Electronic records minimize the risk of losing information and simplify data analysis. A well-maintained database enables us to trace every step of the process. The records facilitate timely audits and help to continually improve our processes. For example, we document every inspection of the rigging equipment, including the date, inspector’s name, and any findings. This detailed documentation provides a robust audit trail and supports safety assurance.

Q 14. Describe your experience in managing equipment erection schedules and budgets.

Managing equipment erection schedules and budgets requires a meticulous approach. We start by developing a detailed project schedule, breaking down the work into manageable tasks with defined timelines and dependencies. We use project management software like Primavera P6 to create this schedule, enabling us to track progress, identify potential delays, and optimize resource allocation. This schedule is closely monitored throughout the project to ensure timely completion.

Budget management involves careful cost estimation, tracking actual expenditure, and identifying potential cost overruns. We develop a detailed budget at the outset, including material costs, labor costs, equipment rentals, and contingency funds. Regular cost reports are prepared, and variances are analyzed and addressed proactively. For instance, during a recent project, we encountered unexpected ground conditions. By carefully analyzing the impact on the schedule and budget, we developed contingency plans, communicated them to the client, and implemented cost-effective solutions to minimize project delays and cost overruns.

Q 15. What is your experience with different types of welding techniques used in equipment erection?

My experience encompasses a wide range of welding techniques crucial for equipment erection. I’m proficient in several, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW). The choice of technique depends heavily on the materials being joined and the required weld quality. For instance, SMAW, often called stick welding, is robust and portable, ideal for field work on thicker materials, while GTAW, or TIG welding, provides superior precision and is preferred for thin-walled stainless steel components, common in many process plants. GMAW, or MIG welding, offers a balance between speed and quality, making it suitable for many construction projects.

For example, during the erection of a large chemical reactor, I used GTAW to weld the thin stainless steel lining due to the need for a flawless, leak-proof joint. On the supporting steel structure, we used SMAW because of its practicality in the field and ability to handle the thicker steel. My expertise extends to understanding weld parameters, such as amperage, voltage, and travel speed, to ensure consistent weld quality and adherence to relevant codes and standards (like AWS D1.1).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage conflicts or disagreements between different teams during erection?

Conflict resolution is a crucial aspect of successful equipment erection projects. My approach centers around open communication and collaborative problem-solving. When disagreements arise between teams (say, between the riggers and the welders), I facilitate a meeting where each team explains their perspective and concerns. I actively listen, identify the root cause of the conflict, and guide them toward a mutually agreeable solution. This often involves prioritizing tasks based on project timelines, clarifying responsibilities, and ensuring all parties understand the overall objectives.

For instance, a conflict between the pipefitters and electricians over access to a particular area was resolved by creating a staggered schedule, allowing each team dedicated time slots to complete their work without interference. Documentation of agreements and decisions, coupled with clear communication to upper management, helps maintain transparency and avoids future misunderstandings.

Q 17. Describe your experience with the use of specialized tools and equipment for erection.

My experience with specialized tools and equipment is extensive. I’m familiar with and have operated various lifting equipment, including cranes (both tower and mobile), forklifts, and specialized rigging gear like shackles, slings, and load cells. I’m also proficient in using surveying equipment for precise alignment and leveling, which is crucial for the accurate positioning of equipment. Beyond lifting and positioning, my expertise extends to the use of specialized welding equipment, cutting tools (plasma cutters, oxy-fuel torches), and non-destructive testing (NDT) equipment, such as ultrasonic flaw detectors, ensuring the structural integrity of the erected equipment.

For example, during the erection of a large distillation column, we used a high-capacity crawler crane to carefully lift and position each section, and laser alignment tools to guarantee precise alignment.

Q 18. How do you handle unexpected delays or problems during equipment erection?

Handling unexpected delays or problems is a critical skill. My approach involves a structured process. First, I identify the problem and its impact on the project schedule and budget. Then, I assess the available resources and options, involving relevant personnel to brainstorm solutions. This might involve requesting additional resources, adjusting the work sequence, or implementing alternative methods. Throughout this process, transparent communication with stakeholders is key, ensuring everyone is aware of the situation and the planned mitigation strategy. Documentation of the issue, the solutions implemented, and lessons learned is critical for future project planning.

For example, a delay due to a supplier not delivering parts on time was addressed by prioritizing other tasks that didn’t rely on those parts while actively contacting the supplier and exploring alternatives, like sourcing parts from a different vendor, to ensure the project’s completion was not significantly impacted.

Q 19. Explain your process for inspecting erected equipment for quality and safety.

My inspection process is rigorous and follows a structured checklist tailored to the specific equipment being erected. It involves visual inspections for any damage, misalignment, or welding defects. I also employ NDT methods such as ultrasonic testing to verify the integrity of welds and critical components. Accurate documentation of the inspection findings, including photographs and detailed reports, is crucial. The inspection ensures the equipment meets the required specifications and safety standards, preventing potential hazards during operation.

This process is not merely a post-erection activity but is integrated throughout the erection phase. Regular inspections during the different stages of erection help identify and correct potential issues early on, preventing major problems later. All identified deficiencies are reported, documented, and addressed before proceeding with subsequent tasks.

Q 20. Describe your experience with different types of materials used in equipment erection.

Equipment erection involves a wide range of materials, and my experience spans various types including carbon steel, stainless steel, aluminum, and various specialty alloys. The selection of material depends on the application, the environmental conditions, and the required strength and corrosion resistance. Understanding the properties of each material is crucial, as different materials require different welding techniques and handling procedures. Carbon steel is commonly used for structural components, while stainless steel is often preferred for applications requiring corrosion resistance. Aluminum is used where lightweight construction is important.

For example, in a petrochemical plant, I’ve worked with various stainless steel grades to ensure corrosion resistance in harsh chemical environments. In other projects, I’ve utilized carbon steel for structural elements due to its strength and cost-effectiveness.

Q 21. How do you conduct a risk assessment for an equipment erection project?

Risk assessment is a fundamental part of project planning. I use a systematic approach that typically involves a Hazard and Operability study (HAZOP). This process involves a multidisciplinary team reviewing the erection process step-by-step, identifying potential hazards, analyzing their likelihood and severity, and developing appropriate mitigation strategies. This might include developing detailed safety procedures, providing adequate personal protective equipment (PPE), implementing engineering controls, and providing comprehensive training to the workforce.

For example, during the erection of a tall structure, a risk assessment highlighted the potential for falls from height. Mitigation strategies included the use of harnesses and fall arrest systems, appropriate scaffolding, and rigorous training on safe working at heights.

Q 22. How do you ensure the proper storage and handling of materials during erection?

Proper storage and handling of materials are paramount to a successful equipment erection project. Think of it like building a house – you wouldn’t start construction with scattered, damaged bricks, would you? We utilize a multi-pronged approach.

Designated Storage Areas: We establish clearly marked and organized storage areas, categorized by material type and project phase. This prevents mix-ups and damage from improper stacking.

Material Protection: Materials are protected from the elements using tarps, covers, and appropriate weatherproofing techniques. For instance, sensitive electronics are stored in climate-controlled containers.

Inventory Management: We implement rigorous inventory tracking systems, often using barcodes or RFID tags, to ensure materials are accounted for and readily available when needed. This prevents delays caused by missing parts.

Safe Handling Procedures: All personnel are trained on safe material handling practices, including proper lifting techniques, the use of personal protective equipment (PPE), and the operation of forklifts and cranes. We regularly conduct safety briefings to reinforce these procedures.

Regular Inspections: We conduct routine inspections of stored materials to identify any damage or deterioration. This proactive approach allows for timely repairs or replacements, preventing problems during the erection process.

For example, on a recent petrochemical plant project, we implemented a color-coded system for piping materials, which significantly reduced errors and improved efficiency.

Q 23. Describe your experience with commissioning and start-up of erected equipment.

Commissioning and start-up are critical phases, ensuring the erected equipment functions as designed. It’s like performing a final health check on a newly built car before taking it for a test drive. My experience encompasses various aspects:

Pre-Commissioning Checks: This involves verifying the installation’s compliance with specifications, including dimensional accuracy, alignment, and proper connections. We utilize laser alignment tools for precise measurements.

System Testing: We conduct thorough testing of individual components and the integrated system to identify and resolve any malfunctions. This often includes pressure testing, leak checks, and functional tests.

Instrumentation and Control: We verify the accuracy and functionality of all instrumentation and control systems, ensuring proper readings and control over the equipment’s operation.

Performance Testing: Once the system is operational, we conduct performance testing to validate its efficiency and output against design specifications. We collect and analyze data to identify areas for optimization.

Handover to Client: We provide comprehensive documentation, including as-built drawings, test reports, and operating manuals, to ensure a smooth handover to the client.

In one project involving a large industrial boiler, we identified a minor misalignment during pre-commissioning, preventing potential damage and downtime after start-up. This highlights the importance of meticulous checks.

Q 24. Explain your understanding of different types of lifting and rigging gear.

Understanding lifting and rigging gear is fundamental to safe and efficient equipment erection. It’s like knowing the tools of your trade as a surgeon – precision and safety are paramount. I’m familiar with a wide range of equipment:

Lifting Gear: This includes overhead cranes, mobile cranes, forklifts, and hoists. Each has its own capacity, operational limitations, and safety protocols.

Rigging Hardware: This encompasses slings (chain, wire rope, synthetic), shackles, hooks, and other components used to attach the load to the lifting gear. Selecting the appropriate hardware based on load weight and geometry is crucial.

Load-bearing Structures: Understanding the load-bearing capacity of various structures, including beams, columns, and foundations, is essential for ensuring the structural integrity of the erection process.

Safety Devices: Safety devices like load cells, shackles with safety pins, and load limiters are used to monitor and control loads, preventing overload incidents.

For instance, choosing a wire rope sling for a heavy, sharp-edged load would be inappropriate, as the sharp edges could easily damage the sling. We always select the right equipment for the job and conduct thorough inspections before use.

Q 25. How do you ensure the proper communication and coordination between the erection team and client representatives?

Effective communication and coordination are the cornerstones of successful project execution. It’s like a well-orchestrated symphony – each section needs to play in harmony. We employ several strategies:

Regular Meetings: We hold regular meetings with client representatives to discuss progress, address concerns, and plan upcoming activities. This maintains transparency and allows for proactive issue resolution.

Progress Reporting: We provide regular written and visual progress reports, often incorporating photographs and videos, to keep the client informed. This includes highlighting any challenges and proposed solutions.

Dedicated Point of Contact: We assign a dedicated point of contact for seamless communication and efficient problem-solving. This ensures a single point of accountability.

Collaboration Tools: We leverage collaboration tools like project management software and email to streamline information sharing and ensure everyone is on the same page.

Open Communication Channels: We encourage open and honest communication, providing opportunities for client feedback and actively responding to concerns.

In one instance, we used a dedicated online platform to share real-time progress updates, including photos and videos, enabling the client to remotely monitor the project and immediately address any issues.

Q 26. What software or tools do you use to plan and manage equipment erection projects?

Planning and managing equipment erection projects requires efficient tools and software. Think of it as using a GPS for navigation rather than relying on a paper map. We utilize several tools:

Project Management Software: We use software like Primavera P6 or Microsoft Project to create schedules, track progress, allocate resources, and manage costs.

3D Modeling Software: Software like AutoCAD or Revit allows for detailed 3D modeling of the equipment and its surroundings, helping to identify potential interference and optimize the erection sequence.

Simulation Software: Simulation software can be used to model the erection process, optimizing lifting plans and minimizing risks.

Document Management Systems: We use document management systems to store and share project documents, ensuring easy access for all stakeholders.

For example, using 3D modeling software allowed us to identify a potential clash between a large pipe and a structural column during a refinery project, preventing costly rework during erection.

Q 27. Describe your experience with site safety inspections and accident prevention measures.

Site safety is our utmost priority – it’s not just a procedure; it’s a culture. We believe that all accidents are preventable. Our approach includes:

Pre-Erection Site Inspections: Before commencing erection, we conduct thorough site inspections to identify and mitigate potential hazards, such as uneven ground, overhead obstructions, and the presence of underground utilities.

Job Safety Analysis (JSA): We conduct JSAs for every critical task to identify potential hazards and develop control measures, ensuring that the risks are minimized before work commences.

Toolbox Talks: We conduct regular toolbox talks to reinforce safety procedures, address specific hazards, and share lessons learned from near misses or incidents.

Permit-to-Work Systems: We utilize permit-to-work systems for high-risk activities, ensuring that all necessary precautions are in place before work is allowed to commence.

Emergency Response Plan: We develop and regularly practice emergency response plans to ensure that personnel know how to respond effectively in the event of an accident or emergency.

Regular Safety Audits: We conduct regular safety audits to monitor compliance with safety regulations and identify areas for improvement.

For example, during a wind turbine erection, we discovered a weakness in the ground near the base. By immediately addressing this, we prevented a potential catastrophic collapse.

Q 28. What is your approach to continuous improvement in equipment erection procedures and safety?

Continuous improvement is essential in any field, especially in equipment erection where safety and efficiency are paramount. It’s an ongoing journey, not a destination. We employ several methods:

Post-Project Reviews: After each project, we conduct thorough post-project reviews to identify areas where we exceeded expectations and areas where improvements are needed. This includes analyzing near misses and incidents.

Lessons Learned Database: We maintain a database of lessons learned, sharing best practices and insights across projects and teams. This allows us to leverage past experience to improve future projects.

Training and Development: We invest heavily in training and development, ensuring our personnel are equipped with the latest techniques, technologies, and safety procedures.

Technology Adoption: We continuously explore and adopt new technologies, such as advanced lifting equipment, digital tools, and simulation software, to improve efficiency and safety.

Industry Best Practices: We actively monitor industry best practices and standards, adapting our procedures to ensure we are consistently at the forefront of safety and efficiency.

For example, after a project where we experienced a minor delay due to a logistical issue, we implemented a new process for material handling, resulting in improved efficiency on subsequent projects.

Key Topics to Learn for Equipment Erection Interview

- Planning & Logistics: Understanding project timelines, resource allocation, and safety protocols crucial for successful erection.

- Site Safety & Risk Management: Detailed knowledge of OSHA regulations, hazard identification, and risk mitigation strategies in the field.

- Lifting & Rigging Techniques: Mastering safe lifting procedures, proper rigging techniques, and load calculations to prevent accidents.

- Equipment Assembly & Disassembly: Practical experience with the assembly and disassembly of various equipment types, including troubleshooting common issues.

- Blueprint Reading & Interpretation: Ability to accurately interpret engineering drawings, specifications, and schematics to ensure correct erection procedures.

- Troubleshooting & Problem-Solving: Demonstrated ability to identify and resolve issues on-site, adapting to unexpected challenges and maintaining project timelines.

- Communication & Teamwork: Effective communication with supervisors, colleagues, and clients, fostering collaboration and positive team dynamics.

- Heavy Equipment Operation (if applicable): Safe and proficient operation of relevant heavy machinery used in the erection process.

- Maintenance & Inspection: Knowledge of preventative maintenance procedures and regular equipment inspections to ensure optimal performance and safety.

- Environmental Considerations: Awareness of environmental regulations and best practices to minimize the environmental impact of equipment erection projects.

Next Steps

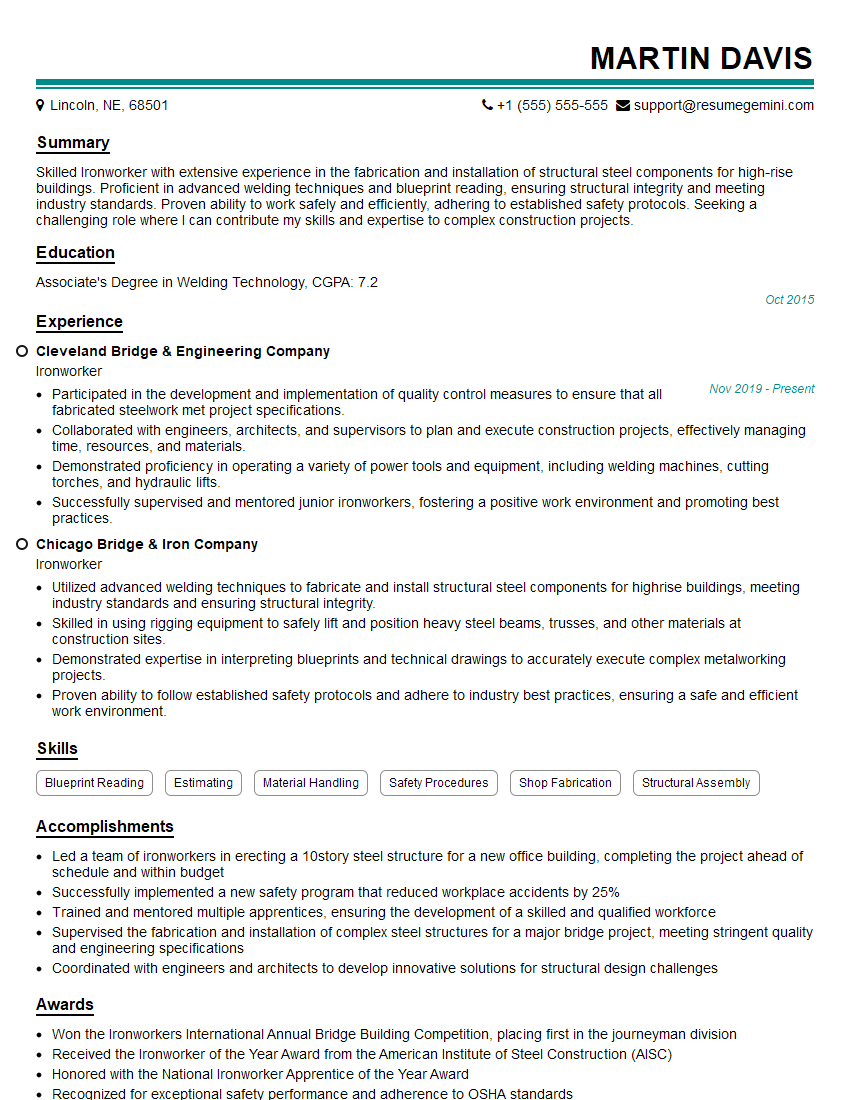

Mastering Equipment Erection opens doors to exciting career advancements, offering opportunities for specialization, increased responsibility, and higher earning potential. To maximize your job prospects, creating an ATS-friendly resume is essential. This ensures your qualifications are effectively highlighted to potential employers. ResumeGemini can help you build a professional and impactful resume that showcases your skills and experience effectively. We provide examples of resumes tailored to Equipment Erection to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.