Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Extrusion Forming interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Extrusion Forming Interview

Q 1. Explain the difference between direct and indirect extrusion.

Direct and indirect extrusion are two fundamental methods in extrusion forming, differing primarily in how the material is forced through the die.

In direct extrusion, the ram pushes the material directly through the die. Think of it like squeezing toothpaste from a tube – the force is applied directly to the material being extruded. This method is simpler and less expensive for smaller scale operations. However, the die experiences significant friction, limiting the length of the extrudate and potentially causing defects.

Indirect extrusion uses a floating die that is driven by the ram. The material is pushed from the back of a container through a hole in the floating die, and the die itself moves over the material. Imagine pushing a plunger through a container of clay with a hollow die at the other end. This method reduces friction on the die significantly, allowing for longer extrudates and more complex shapes. The machinery, however, is more intricate and costly.

In essence, the choice depends on the desired product length, complexity, and budget constraints. For short, simple products, direct extrusion suffices. For longer, more intricate shapes where die wear is a major concern, indirect extrusion offers superior results.

Q 2. Describe the process of die design for extrusion.

Die design in extrusion is a critical step determining the final product quality and efficiency. It’s an iterative process involving several stages.

- Product Design: The first step involves clearly defining the desired dimensions, tolerances, and shape of the final product. This defines the overall die geometry.

- Material Selection: The die material must possess high hardness, wear resistance, and appropriate thermal properties to withstand the high pressures and temperatures. Common materials include tool steels and carbide alloys.

- Land Design: The die land, the region between the converging section and the orifice, is crucial. Its length influences the final product’s dimensions and surface finish. A longer land ensures better homogenization of the material and a smoother surface but may cause increased back pressure.

- Convergence Angle: The angle of the converging section dictates the material flow. A steeper angle promotes faster flow but can increase turbulence, leading to defects. A shallower angle reduces turbulence but increases pressure.

- Orifice Design: The shape and size of the die orifice precisely define the final product’s cross-section. Precise machining is vital to achieve the desired tolerances.

- Cooling Channels (often): For materials with high melting points, the incorporation of cooling channels in the die can help control temperature and prevent premature solidification within the die itself.

Designing an efficient die often involves simulations like Finite Element Analysis (FEA) to predict flow patterns, pressure drops, and stress distributions within the die, helping optimize the design for efficiency and quality. Iterative testing and adjustments are also frequently required to achieve the desired product specifications.

Q 3. What are the common defects found in extruded products and their causes?

Several defects can plague extruded products, significantly impacting their quality and usability. Understanding the causes is critical for prevention and process optimization.

- Surface Cracking: Often caused by rapid cooling, internal stresses, or insufficient lubrication.

- Internal Cracks and Voids: Result from trapped gas, insufficient material homogenization, or improper temperature control.

- Die Swell: An increase in the extrudate’s cross-sectional area compared to the die orifice. Caused by elastic recovery of the material after exiting the die. (This is discussed further in the next question)

- Dimension Inconsistency: Variations in the extrudate’s dimensions caused by inconsistent material feed rate, die wear, or temperature fluctuations.

- Wrinkling or Folding: Occur during the extrusion process due to improper die design, inadequate lubrication, or too high of a material viscosity.

- Surface Roughness: Caused by poor die surface finish, inadequate lubrication, or presence of contaminants in the material.

Careful attention to material properties, die design, process parameters (temperature, pressure, speed), and lubrication is essential to minimize these defects.

Q 4. How do you troubleshoot die swell in extrusion?

Die swell, or extrudate swell, is a phenomenon where the extrudate’s diameter increases after exiting the die. This increase is primarily due to the elastic recovery of the polymer after being under stress in the die. While a certain degree of swell is normal, excessive swell is undesirable because it can lead to dimensional inaccuracies and difficulties in further processing.

Troubleshooting die swell involves a multi-pronged approach:

- Die Design Optimization: A longer land length in the die can reduce die swell by allowing more time for stress relaxation. Modifying the die geometry, particularly the convergence angle, can also impact swell.

- Process Parameter Adjustment: Adjusting the extrusion speed, temperature, and pressure can influence the material’s viscosity and its response to stress, thus affecting die swell. Lower extrusion rates and/or higher temperatures can often reduce die swell.

- Material Modification: Using a different polymer grade with different rheological properties can reduce die swell. Additives can also be used to alter the material’s behavior.

- Lubrication: Proper lubrication can minimize friction and reduce die swell by making the flow more efficient.

Careful monitoring of the process and iterative adjustment of these parameters is key. Often, a combination of adjustments are necessary to achieve the desired results. Using computational fluid dynamics (CFD) simulations can significantly help in predicting and mitigating die swell prior to physical experimentation.

Q 5. Explain the role of lubrication in extrusion.

Lubrication plays a vital role in extrusion, significantly impacting product quality, die life, and process efficiency.

Benefits of Lubrication:

- Reduced Friction: Lubricants minimize friction between the material and the die, reducing the required extrusion force and preventing die wear. This leads to longer die life and reduced energy consumption.

- Improved Surface Finish: Lubricants prevent sticking and improve the surface finish of the extruded product. Smoother flow leads to fewer defects like surface roughness and cracking.

- Enhanced Flow: Lubricants reduce the material’s viscosity and promote a smoother, more uniform flow through the die, leading to consistent product dimensions and fewer defects.

- Heat Transfer: Lubricants can assist in managing temperature gradients, reducing the risk of premature solidification within the die.

Types of Lubricants: Different lubricants are used for various materials and applications. These can range from simple oils and greases to more sophisticated polymer-based formulations.

Choosing the right lubricant is crucial. Incorrect lubrication can lead to poor surface finish, excessive die wear, and inconsistent product quality.

Q 6. What are the different types of extrusion dies and their applications?

Extrusion dies come in various configurations, each tailored to specific applications and product geometries.

- Simple Dies (Circular, Rectangular): These are used for producing simple shapes like rods, tubes, and flat sheets. They are generally the simplest and most economical type of die.

- Coextrusion Dies: Allow for the simultaneous extrusion of multiple materials to create layered structures with varying properties. This is extensively used in packaging films and other applications that require distinct layers.

- Multi-Manifold Dies: These have multiple inlets for material input, leading to more complex profiles or allowing different material inputs at different points in the extrusion process.

- Spider Dies: Used to produce wide, flat films or sheets. They feature a central spider-like structure that distributes the molten polymer evenly across the die opening.

- Crosshead Dies: Designed to produce tubular products or thick-walled sections. They feature an internal mandrel to shape the extruded material into a hollow profile.

The selection of a die type depends largely on the desired shape and complexity of the final product and factors such as material properties, desired production rate and cost considerations. Often custom dies are designed and fabricated for complex shapes.

Q 7. How do you control the temperature profile in an extrusion process?

Precise temperature control is paramount in extrusion, as it directly influences material viscosity, flow behavior, and final product quality. Effective temperature control ensures uniform heating and prevents defects.

Methods for Temperature Control:

- Preheating Zones: Material is preheated before entering the die to ensure consistent viscosity and flow. This involves precisely controlling the temperature of the heating elements in the barrel upstream of the die.

- Die Heating/Cooling: The die itself can be heated or cooled to fine-tune the material’s temperature as it passes through the die. This might involve circulating heated or cooled fluids through channels within the die.

- Barrel Heating: Heating elements along the barrel (extruder) carefully control temperature zones to ensure homogeneous material temperature.

- Temperature Sensors: Precise temperature monitoring is critical, often involving thermocouples strategically placed throughout the barrel and die to continuously monitor temperatures and ensure even heating.

- Feedback Control Systems: Modern extrusion processes typically use feedback control systems (PID controllers) to adjust the heating elements in response to temperature readings from the sensors, ensuring that the target temperature profiles are precisely maintained.

Precise temperature profiles are often critical in achieving desired product properties, especially for polymers that exhibit temperature-dependent behavior. An automated control system ensures consistency and reduces reliance on manual adjustments.

Q 8. Describe the different types of polymers used in extrusion and their properties.

Polymer selection is crucial in extrusion, as it dictates the final product’s properties. Different polymers exhibit unique behaviors under heat and pressure, influencing the process’s feasibility and the product’s characteristics. Here are some common polymers used in extrusion:

- Polyethylene (PE): A versatile thermoplastic known for its flexibility, toughness, and chemical resistance. Low-density polyethylene (LDPE) is used in films and bags, while high-density polyethylene (HDPE) is found in bottles and pipes. Its low melting point makes it relatively easy to extrude.

- Polypropylene (PP): Another popular thermoplastic, PP offers good strength, stiffness, and chemical resistance. It’s used in a wide variety of applications, from packaging to automotive parts. It’s slightly more difficult to extrude than PE due to its higher melting point.

- Polyvinyl Chloride (PVC): This versatile polymer is known for its durability and resistance to weathering. PVC is commonly used in pipes, window frames, and flooring. Extrusion of PVC often requires specialized equipment due to its higher melt viscosity.

- Polystyrene (PS): A rigid and relatively inexpensive thermoplastic used in food containers, insulation, and disposable tableware. It has a relatively low melt viscosity, making extrusion relatively straightforward.

- Polycarbonate (PC): A high-performance thermoplastic known for its exceptional impact resistance, heat resistance, and optical clarity. Used in safety eyewear, automotive parts, and electronic components. Its high melting temperature and viscosity require high-performance extrusion equipment.

These are just a few examples; many other polymers, blends, and copolymers are used, each tailored to specific product requirements.

Q 9. Explain the importance of material selection in extrusion.

Material selection is paramount in extrusion because it directly impacts the final product’s quality, cost, and performance. The wrong polymer can lead to processing difficulties, inferior product properties, or even catastrophic equipment failure. Consider these factors:

- Melt flow index (MFI): This measures the polymer’s melt viscosity, influencing its processability. A high MFI indicates easier flow, while a low MFI requires higher processing temperatures and pressures.

- Thermal stability: Polymers degrade at high temperatures, so thermal stability is crucial. A thermally stable polymer will produce consistent quality with minimal degradation.

- Mechanical properties: The desired strength, stiffness, flexibility, and impact resistance of the final product dictate polymer choice.

- Cost: Polymers vary significantly in price, and this must be balanced against performance requirements.

- Environmental impact: Sustainability considerations increasingly influence polymer selection. Biodegradable and recyclable polymers are gaining popularity.

For example, choosing HDPE for a high-strength pipe application ensures durability and resistance to pressure, while LDPE is better suited for flexible films due to its lower strength and higher flexibility. Improper material selection might result in a pipe that bursts under pressure or a film that tears easily.

Q 10. What are the safety precautions associated with extrusion machinery?

Extrusion machinery involves high temperatures, pressures, and moving parts, demanding stringent safety precautions. These include:

- Lockout/Tagout procedures: Before any maintenance or repair, power to the equipment must be completely cut off and locked out to prevent accidental startup.

- Personal Protective Equipment (PPE): Workers should wear safety glasses, gloves, hearing protection, and heat-resistant clothing to protect against molten polymer, high temperatures, and noise.

- Emergency shutdown systems: Easily accessible emergency stop buttons should be strategically located throughout the extrusion line.

- Regular maintenance and inspections: Scheduled inspections and maintenance help prevent malfunctions and accidents. Dies, screws, and other components must be checked for wear and tear regularly.

- Proper ventilation: Adequate ventilation removes fumes and dust generated during the extrusion process, preventing respiratory problems.

- Training and awareness: Workers must receive thorough training on safe operating procedures and emergency response protocols.

Ignoring these precautions can lead to serious injuries such as burns, cuts, and hearing loss. Regular safety audits are essential to ensure compliance and prevent incidents.

Q 11. How do you calculate extrusion pressure?

Extrusion pressure calculation is complex and depends on many factors, but a simplified approach uses the following relationship:

Pressure (P) = K * (Q^n) * (L/D) * (η)

Where:

Pis the pressureKis a constant depending on the polymer and die geometryQis the volumetric flow ratenis a flow behavior index (typically between 0.5 and 1)L/Dis the die length-to-diameter ratioηis the apparent viscosity of the melt

This equation highlights that pressure increases with flow rate, die length, and melt viscosity. More accurate calculations involve sophisticated rheological models and computational fluid dynamics (CFD) simulations to account for non-Newtonian fluid behavior and complex die geometries. Experienced extrusion engineers use specialized software for these simulations.

Q 12. How do you measure and control the output rate in extrusion?

Output rate in extrusion is controlled primarily by adjusting the screw speed and the die geometry. Measurement involves techniques like:

- Weighing the extruded product over a set time interval: This provides a direct measure of the mass flow rate.

- Measuring the length of extruded product over a set time interval: This is useful for continuous profiles, like pipes.

- Using online sensors: Advanced extrusion lines employ sensors that measure parameters like melt pressure and temperature, which are correlated to output rate.

Controlling output rate involves careful manipulation of the screw speed. Increased speed generally increases output, but this must be carefully managed to avoid overheating the polymer or causing excessive pressure buildup. Die design also impacts output—larger die openings allow for higher flow rates. Feedback control systems, often based on PID controllers, are used to maintain a consistent output rate by automatically adjusting the screw speed in response to variations.

Q 13. Describe the process of calibrating an extrusion die.

Die calibration ensures the extruded product meets the desired dimensions and tolerances. This iterative process involves:

- Initial die machining: The die is manufactured to initial specifications, usually based on design calculations and simulations.

- Trial extrusion: A sample extrusion run is performed to assess the product’s dimensions.

- Measurement and analysis: Precise measurements of the extruded product are made using tools like calipers, micrometers, and optical profilometers. Deviations from target dimensions are carefully analyzed.

- Die adjustment: Based on the analysis, the die’s internal dimensions are adjusted using techniques like laser machining or electro-discharge machining. Small adjustments are made to land dimensions to correct dimensional discrepancies.

- Iterative process: Steps 2-4 are repeated until the extruded product meets the required tolerances. This often involves several iterations of trial extrusions, measurements, and die adjustments.

Precise die calibration is critical for consistent product quality. Inconsistent dimensions can lead to functional problems in the final product (e.g., a pipe with irregular diameter might not fit correctly or withstand intended pressure) and cause rejection of the finished items.

Q 14. Explain the importance of quality control in extrusion.

Quality control in extrusion is essential to ensure consistent product quality, meeting customer specifications and avoiding costly waste. Key aspects include:

- Raw material inspection: Incoming polymers are tested to ensure they meet the required specifications (e.g., MFI, density, and additives).

- Process monitoring: Key parameters such as temperature, pressure, screw speed, and output rate are continuously monitored and recorded. Deviations from setpoints trigger alarms and corrective actions.

- Dimensional inspection: Regular measurements of the extruded product ensure that it conforms to specifications. Statistical Process Control (SPC) charts are used to track dimensional variations and identify potential issues.

- Mechanical testing: The final product is subjected to mechanical tests to verify its strength, stiffness, and other properties. This might include tensile testing, impact testing, or flexural testing.

- Visual inspection: Inspectors check for surface defects, such as scratches, discoloration, or inconsistencies.

Effective quality control minimizes defects, improves product consistency, and enhances customer satisfaction. It also helps identify and address potential process issues, preventing costly production downtime and material waste.

Q 15. What are the different types of extrusion equipment?

Extrusion equipment varies greatly depending on the material being processed and the desired final product. Generally, it involves a screw extruder, a die, and auxiliary equipment. Let’s break down the key components:

- Screw Extruders: These are the heart of the process, responsible for melting and pumping the material through the die. Single-screw extruders are common for simpler applications, while twin-screw extruders offer more precise control and are better for mixing sensitive materials. There are also counter-rotating and co-rotating twin-screw designs, each with unique mixing capabilities.

- Dies: The die shapes the molten material into its final form. Dies come in countless designs, from simple circular cross-sections for pipes to complex multi-hole dies for producing multiple profiles simultaneously. The design of the die is critical for product quality and consistency.

- Auxiliary Equipment: This includes material handling systems (feeding hoppers, conveying systems), temperature control units (heaters and coolers), vacuum systems (for degassing), and downstream equipment (pullers, cutters, calibrators, and winders). The specific auxiliary equipment needed will vary depending on the material and process.

For example, a food extruder might use a single-screw design with a relatively simple die, while a high-performance polymer extruder may utilize a sophisticated twin-screw extruder with complex temperature control and vacuum systems. The choice of equipment is a critical decision based on many factors including material properties, production rate, and product specifications.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting extrusion equipment malfunctions.

Troubleshooting extrusion equipment malfunctions requires a systematic approach. My experience has shown that focusing on the root cause rather than just addressing symptoms is crucial. I typically follow these steps:

- Identify the symptom: What exactly is going wrong? Is the output inconsistent, is there excessive die swell, are there material defects, or is the extruder producing an undesirable output?

- Gather data: Collect data points such as screw speed, temperature profiles (at various points along the barrel), pressure readings (at the die and along the barrel), and material flow rates. This data provides valuable clues.

- Analyze the data: Look for patterns or anomalies in the collected data. For instance, unusually high pressure drops could indicate a blockage or a problem with the screw. Inconsistent temperatures might point to a heating/cooling malfunction.

- Isolate the problem: Based on the data analysis, try to pinpoint the source of the issue. This may involve visual inspection of the equipment, testing individual components, or using more sophisticated diagnostic tools.

- Implement a solution: Once the problem is identified, implement the necessary corrective action. This may involve cleaning or replacing a component, adjusting machine settings, or even modifying the die.

- Monitor and adjust: After fixing the problem, monitor the process closely to make sure that the issue has been resolved and the extrusion is running smoothly.

For example, I once solved a problem of inconsistent extrudate thickness by carefully inspecting the die and discovering a small imperfection that was causing uneven flow. A simple polishing of the die resolved the issue. In another case, unusually high back pressure led to the discovery of a broken screw element.

Q 17. How do you optimize the extrusion process for maximum efficiency?

Optimizing the extrusion process for maximum efficiency involves a multi-faceted approach, focusing on material properties, machine settings, and process parameters. Key aspects include:

- Material selection and preparation: Using the correct grade of material and ensuring its proper drying (to avoid moisture-related problems) are vital steps.

- Screw design and optimization: The screw design significantly impacts mixing, melting, and conveying efficiency. Simulation software can be used to optimize screw parameters.

- Temperature control: Precise temperature control throughout the barrel is essential to achieve consistent melt flow and product quality. Temperature profiles need to be optimized based on the material and product requirements.

- Pressure optimization: Monitoring and controlling melt pressure at the die is crucial. Excessive pressure can lead to equipment damage, while insufficient pressure may cause inconsistent output.

- Die design and optimization: The die design must be optimized for the desired shape and dimensions of the final product. Finite element analysis (FEA) can help predict die performance and identify potential problems.

- Process monitoring and control: Implementing automated process control systems allows for real-time monitoring and adjustment of key parameters, ensuring consistent output and minimal waste.

By carefully controlling these factors, we can minimize energy consumption, reduce material waste, and improve product quality, ultimately maximizing efficiency.

Q 18. What are the environmental considerations in extrusion?

Environmental considerations in extrusion are becoming increasingly important. Key aspects include:

- Energy consumption: Extrusion is an energy-intensive process. Optimizing the process to reduce energy consumption is a key sustainability goal. This can be achieved through efficient equipment design, process optimization, and the use of renewable energy sources.

- Waste reduction: Minimizing material waste is crucial. Proper process control, material handling, and the use of efficient dies helps reduce scrap and off-spec products.

- Emissions: Extrusion processes can generate emissions, such as volatile organic compounds (VOCs) or particulate matter. Implementing effective emission control systems and utilizing environmentally friendly materials are important steps.

- Material selection: Choosing recyclable and sustainable materials reduces the environmental impact of the product throughout its lifecycle.

- Wastewater treatment: Proper management of wastewater is important if cleaning agents or other materials are used during the process.

Companies are increasingly adopting green manufacturing practices, including implementing closed-loop systems for recycling materials and reducing energy use, to address these environmental concerns.

Q 19. Explain the concept of back pressure in extrusion.

Back pressure in extrusion refers to the pressure generated by the resistance to the flow of molten material as it is pushed through the die. It’s a crucial parameter influencing the quality and consistency of the extrudate.

Imagine trying to squeeze toothpaste out of a tube. The harder you squeeze (higher throughput), the higher the pressure inside the tube (back pressure). This pressure is essential for several reasons:

- Melt homogenization: Higher back pressure improves the mixing and homogenization of the melt, ensuring consistent product quality.

- Melt density: Increased back pressure enhances the density and compactness of the extrudate, reducing porosity and improving mechanical properties.

- Die swell control: Back pressure helps manage the expansion of the extrudate (die swell) as it exits the die, resulting in more precise dimensions.

- Pumping action: Back pressure assists the screw in pumping the melt through the die, ensuring a consistent flow rate.

However, excessively high back pressure can lead to equipment damage, uneven flow, and higher energy consumption. Therefore, maintaining the optimal back pressure is crucial for efficient and high-quality extrusion.

Q 20. How do you handle variations in raw material properties during extrusion?

Variations in raw material properties can significantly affect the extrusion process. To handle these variations effectively, a combination of strategies is employed:

- Strict quality control: Implementing rigorous quality control measures on incoming raw materials is crucial. This involves regular testing of key properties such as melt flow index (MFI), moisture content, and particle size distribution. Materials that don’t meet specifications are rejected.

- Process adjustments: Based on the variations in raw material properties, adjustments to process parameters, such as screw speed, temperature profiles, and back pressure, are made to maintain consistent output. This often requires real-time monitoring and feedback control.

- Recipe adjustments: For some materials, minor adjustments to the extrusion recipe, such as adding lubricants or other additives, can compensate for variations in raw material properties.

- Material blending: Blending different batches of raw material can sometimes help to even out variations in properties, particularly in terms of MFI.

- Process modeling and simulation: Advanced techniques like process modeling and simulation can help predict the impact of raw material variations on the extrusion process and enable proactive adjustments.

For example, if the MFI of a polymer is higher than expected, the screw speed may be reduced to compensate and prevent excessive output. Conversely, lower MFI may require a higher temperature to maintain the required flow rate.

Q 21. Describe your experience with different extrusion processes (e.g., hot, cold, hydrostatic).

My experience encompasses various extrusion processes, each with its own advantages and applications:

- Hot Extrusion: This is the most common type, involving the extrusion of a heated, softened material. It’s widely used for thermoplastics and some metals. I have extensive experience with this method, particularly in polymer processing, where precise control of temperature and pressure is paramount to achieving desired properties.

- Cold Extrusion: This process involves extruding a material at room temperature, often using a high-strength metal as the material. It’s used to create complex shapes with close tolerances but is typically limited to ductile materials. I have worked on projects involving cold extrusion of metals, where the focus was on die design and optimizing the extrusion force to avoid material fracturing.

- Hydrostatic Extrusion: This involves extruding a material under high hydrostatic pressure, which helps to improve the material’s ductility and reduce friction. I’ve used this technique for producing high-quality components from materials that are difficult to extrude using conventional methods. It is excellent for materials that are difficult to work with, reducing defects and enhancing product quality.

Each process requires specific expertise in equipment operation, material selection, and process control. Understanding the nuances of each method is essential for successful extrusion and manufacturing.

Q 22. Explain the role of automation in modern extrusion processes.

Automation plays a crucial role in modern extrusion processes, significantly improving efficiency, consistency, and overall product quality. Think of it like this: a highly skilled artisan can produce excellent results, but a machine can replicate that excellence thousands of times over without fatigue or variation.

Specifically, automation impacts various stages: material handling (automatic feeding and weighing of raw materials), process control (precise regulation of temperature, pressure, and screw speed via programmable logic controllers (PLCs)), die control (adjustments for consistent profile and dimensions), and product handling (automated cutting, stacking, and inspection). This level of precision reduces waste, minimizes human error, and enables consistent production runs even for complex profiles.

- Example: In a PVC pipe extrusion line, automated systems control the melt temperature to ensure consistent viscosity, leading to uniform wall thickness and preventing defects.

- Example: Automated vision systems can detect surface imperfections in real-time, enabling immediate adjustments to the process or rejection of defective products, ensuring high quality control.

Q 23. Describe your experience with statistical process control (SPC) in extrusion.

Statistical Process Control (SPC) is fundamental to maintaining consistent quality in extrusion. It’s like having a constant ‘check engine’ light for your extrusion process. By continuously monitoring key parameters – like melt temperature, pressure, and output – we can identify trends and deviations from the ideal process before they lead to significant defects.

My experience involves implementing and managing SPC charts (e.g., X-bar and R charts, control charts for individual values) to track critical process parameters. We use these charts to establish control limits and identify assignable causes (like a worn die or change in raw material) that lead to process variations. We then use these insights to implement corrective actions, whether it’s minor adjustments to the extruder settings or more extensive maintenance.

For instance, if we notice an upward trend in the melt temperature control chart, we investigate potential causes such as heater malfunction or insufficient cooling. This proactive approach helps prevent large batches of defective products, saving both time and materials.

Q 24. How do you maintain and improve the quality of extruded products?

Maintaining and improving extruded product quality requires a multifaceted approach, starting with raw material selection and ending with rigorous quality checks.

- Raw Material Control: Careful selection of resins, ensuring consistent quality from suppliers. Regular testing of raw materials for properties like melt flow index and additives.

- Process Optimization: Careful monitoring and adjustment of process parameters, such as screw speed, temperature profiles, and die pressure. Regular preventative maintenance of the extruder and associated equipment.

- Quality Control: Regular sampling and testing of extruded products to ensure conformance to specifications. Using tools like dimensional measurement, tensile testing, and visual inspection to identify and address defects. Implementation of process capability studies (Cp and Cpk) to assess the ability of the process to meet the specifications consistently.

- Continuous Improvement: Employing lean manufacturing principles and six sigma methodologies to identify and eliminate sources of variation and waste. Regularly reviewing process data and making adjustments based on the results. Implementing root cause analysis of recurring defects.

Consider a scenario where we observe excessive surface defects. We’d use a combination of process adjustments (like optimizing die temperature) and material analysis to identify the root cause, which might be related to poor resin quality or contamination. Then, we can take corrective action – either switching suppliers or implementing better cleaning procedures.

Q 25. What are the common challenges faced in extrusion and how you have overcome them?

Extrusion presents several challenges, but experience has taught me effective strategies for overcoming them.

- Die Swelling: This is when the extrudate expands in diameter after leaving the die. Addressing this involves adjusting the die design, melt temperature, and screw speed. A well-designed die with appropriate land length and a controlled melt temperature is crucial.

- Melt Fracture: This occurs when the surface of the extrudate becomes unstable, leading to a rough or irregular finish. The solution usually involves optimizing melt temperature and pressure to minimize shear stress. Correcting screw design to reduce shear rates also helps.

- Gel Formation: High temperatures or moisture in the resin can lead to gel formation, causing defects and poor product quality. Solutions include careful moisture control during resin handling and optimization of processing temperatures to prevent degradation.

- Material Degradation: Overheating of the polymer can lead to changes in its molecular structure and resulting in reduced strength and other undesirable properties. Careful temperature control throughout the process is vital, as well as using additives that enhance thermal stability.

For example, when facing melt fracture in a polyethylene film extrusion line, we systematically adjusted the die gap, melt temperature, and screw speed. Through a series of controlled experiments, we determined the optimal parameters that eliminated the defect, significantly improving product quality. This required careful documentation, analysis, and a structured approach to problem-solving.

Q 26. What are your experience with different types of extrusion resins?

My experience encompasses a broad range of extrusion resins, including thermoplastics like polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and engineering thermoplastics such as polycarbonate (PC), polyetheretherketone (PEEK), and various blends. Each resin has unique processing characteristics, requiring specific adjustments to the extrusion parameters to achieve optimal results.

- Polyethylene (PE): Widely used for films, pipes, and packaging, it exhibits good melt strength but can be sensitive to shear degradation at high temperatures.

- Polypropylene (PP): Used for fibers, films, and containers, it has good stiffness and chemical resistance but requires careful control of melt temperature to avoid degradation.

- Polyvinyl Chloride (PVC): Common in pipes, profiles, and window frames, it needs precise temperature control to avoid thermal degradation and ensure proper plasticizer distribution.

- Engineering Thermoplastics: These materials are employed in high-performance applications demanding high strength, temperature resistance, and chemical inertness. Processing these materials often requires specialized equipment and processing expertise.

Understanding the rheological properties (flow behavior) of each resin type is crucial for optimizing the extrusion process. For instance, the melt flow index (MFI), a measure of a material’s fluidity, dictates the optimal screw design and processing parameters. A higher MFI implies easier flow, while a lower MFI requires higher melt temperatures and screw speeds.

Q 27. Explain your understanding of the different types of extrusion screws and their applications.

Extrusion screws are the heart of the extrusion process, responsible for melting and conveying the polymer. Different screw designs are optimized for specific applications and materials.

- Single-screw extruders: These are the most common type, featuring a single rotating screw within a barrel. They are versatile but may not be ideal for highly viscous materials.

- Barrier screws: These incorporate a barrier section to improve mixing and promote uniform melt temperature. They are particularly useful for processing materials that are prone to degradation or require high levels of homogeneity.

- Mixing screws: These have special features that enhance mixing, preventing segregation and promoting homogenous blends. This is especially relevant when processing materials with different densities or additives.

- Twin-screw extruders: These have two screws that rotate in a co-rotating (same direction) or counter-rotating (opposite direction) configuration. They offer superior mixing, high output, and the ability to handle materials with a wide range of viscosities.

The choice of screw depends on factors like the material being processed, desired output, and required melt homogeneity. For instance, a barrier screw is ideal for PVC to prevent degradation. For highly filled materials, a mixing screw may be preferred to ensure good dispersion of fillers throughout the melt.

Q 28. How do you ensure consistent product quality throughout the extrusion process?

Ensuring consistent product quality throughout the extrusion process involves a combination of proactive measures and continuous monitoring.

- Process parameter control: Precise control of temperature, pressure, and screw speed, using automated systems and feedback loops to maintain stable operating conditions. Deviation alarms ensure prompt response to any drift.

- Regular maintenance: Preventative maintenance schedules, including die cleaning, screw inspection, and heater checks, are essential for preventing disruptions and maintaining consistent performance. A well-maintained machine is a reliable machine.

- Raw material consistency: Working with reliable suppliers who provide consistent raw material quality. Incoming inspection of materials is essential to prevent variations introduced at the source.

- Real-time monitoring and control: Employing process analytical technologies (PAT) such as in-line rheometers, spectroscopic sensors, and automated vision systems for real-time monitoring and adjustments. Early detection of anomalies minimizes defects.

- Statistical Process Control (SPC): Continuously monitoring key process parameters using control charts to identify and address potential sources of variation before they lead to quality problems. This ensures consistent conformance to specification over time.

For instance, in a film extrusion line, we might use an in-line gauge to measure film thickness continuously. Any deviation from the setpoint would trigger an automatic adjustment of the die gap, maintaining consistency in film thickness.

Key Topics to Learn for Your Extrusion Forming Interview

Ace your next Extrusion Forming interview by mastering these key areas. We’ve broken down the essentials to help you confidently showcase your expertise.

- Extrusion Processes: Understand the different types of extrusion (direct, indirect, hydrostatic), their applications, and the advantages and disadvantages of each. Be prepared to discuss specific machinery and their operational parameters.

- Material Selection and Properties: Discuss the impact of material properties (viscosity, yield strength, thermal conductivity) on the extrusion process. Know how to select appropriate materials for different applications and understand the implications of material defects.

- Die Design and Optimization: Explain the principles of die design, including land length, die angles, and the influence on product geometry and quality. Be ready to discuss troubleshooting common die-related issues.

- Process Parameters and Control: Discuss the key process parameters (temperature, pressure, ram speed) and their impact on the final product. Explain how to monitor and control these parameters for optimal results. Consider the role of automation and process control systems.

- Quality Control and Troubleshooting: Understand common defects in extruded products (surface imperfections, dimensional inaccuracies, internal defects) and the methods used to identify and rectify them. Discuss quality control procedures and statistical process control (SPC) techniques.

- Safety and Regulations: Demonstrate awareness of safety protocols and regulations specific to extrusion forming, including machine guarding, personal protective equipment (PPE), and waste management.

- Advanced Extrusion Techniques: Explore specialized extrusion techniques such as co-extrusion, hydrodynamic lubrication, and reactive extrusion, depending on your experience and the job description.

Next Steps: Elevate Your Career with a Strong Resume

Mastering Extrusion Forming opens doors to exciting career opportunities. To maximize your chances of landing your dream job, a well-crafted resume is crucial. An ATS-friendly resume ensures your qualifications are effectively communicated to potential employers.

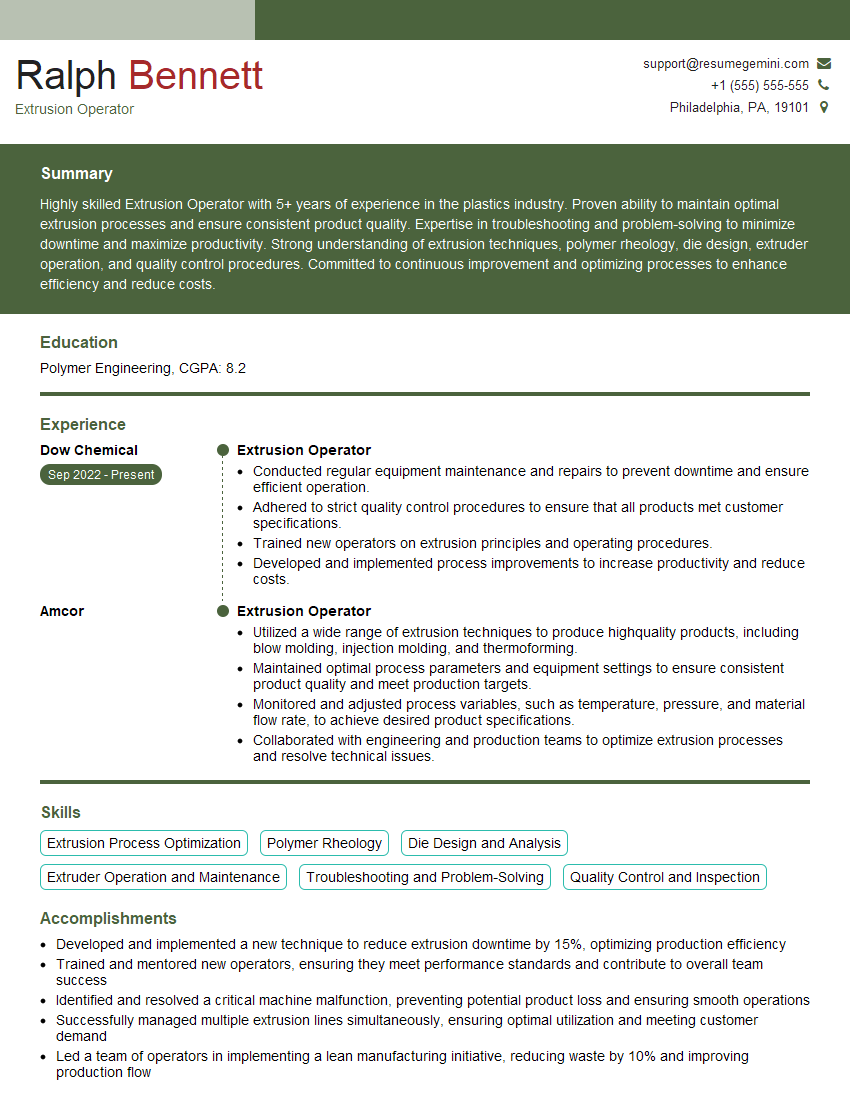

We recommend using ResumeGemini to build a professional and effective resume. ResumeGemini provides tools and resources to help you create a compelling document that highlights your skills and experience in Extrusion Forming. Examples of resumes tailored to this field are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.