Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top familiarity with various process equipment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in familiarity with various process equipment Interview

Q 1. Describe your experience with different types of pumps (e.g., centrifugal, positive displacement).

My experience encompasses a wide range of pumps, primarily centrifugal and positive displacement types. Centrifugal pumps, which are the workhorses of many process industries, operate by converting rotational energy into fluid energy using a spinning impeller. They’re ideal for high-flow, low-pressure applications like moving large volumes of water or less viscous liquids. I’ve worked extensively with various designs, from single-stage to multi-stage, and understand the importance of selecting the correct impeller type (radial, axial, mixed-flow) based on the specific duty. For instance, I once helped optimize a centrifugal pump system in a refinery by changing the impeller design, resulting in a significant increase in efficiency and reduction in energy costs.

Positive displacement pumps, on the other hand, move fluids by trapping a fixed volume and then forcing it into the discharge line. These are suitable for high-pressure, low-flow applications, often handling viscous fluids, slurries, or abrasive materials. I’ve had experience with various types including piston, diaphragm, and gear pumps. In one project, we successfully replaced a failing piston pump in a chemical plant with a more robust diaphragm pump better suited to the corrosive nature of the process fluid, preventing further downtime and safety issues. The key to successful pump selection and operation is a deep understanding of the fluid properties and the required flow rate and pressure, taking into account factors like cavitation and NPSH (Net Positive Suction Head).

Q 2. Explain the principle of operation of a heat exchanger.

A heat exchanger’s primary function is to transfer heat between two or more fluids at different temperatures. This transfer can occur through conduction, convection, or radiation, but primarily relies on convection. The principle is based on the difference in temperature between the hot and cold fluids. The hot fluid loses heat, and the cold fluid gains heat, until thermal equilibrium—or a specified temperature difference—is reached. Imagine a simple scenario: you’re heating water in a pot on a stove. The pot itself acts as a heat exchanger, transferring heat from the burner (hot fluid) to the water (cold fluid). Heat exchangers come in various designs, including shell and tube, plate, and air-cooled types, each optimized for specific applications and fluid characteristics.

Q 3. What are the common causes of fouling in heat exchangers, and how can they be mitigated?

Fouling in heat exchangers is a major concern, reducing efficiency and potentially causing equipment failure. Common causes include:

- Scaling: Inorganic salts precipitate from solution onto heat transfer surfaces, forming a hard layer that reduces heat transfer. This is prevalent in water treatment and boiler systems.

- Fouling by particulate matter: Suspended solids in the fluid can accumulate, blocking flow passages and reducing heat transfer. This is common in oil refining and many chemical processes.

- Biological fouling: Microorganisms can grow and form biofilms on surfaces, again impeding heat transfer. This is a significant issue in wastewater treatment and food processing.

- Corrosion products: Corrosion of the heat exchanger surfaces can lead to the formation of deposits that reduce efficiency.

Mitigation strategies include:

- Proper fluid pretreatment: Filtering or treating the fluids before they enter the heat exchanger to remove suspended solids and control scaling.

- Chemical cleaning: Periodic cleaning with specialized chemicals to dissolve or remove accumulated fouling.

- Mechanical cleaning: Techniques such as brushing, scraping, or hydro-jetting to remove deposits.

- Optimized operating parameters: Maintaining appropriate temperatures and flow rates to minimize fouling.

- Material selection: Choosing corrosion-resistant materials to minimize corrosion product build-up.

Q 4. Describe different types of valves used in process industries and their applications.

The process industry employs a diverse range of valves, each designed for specific applications. Some common types include:

- Gate valves: These offer full or completely shut-off flow control, ideal for on/off service. They’re not suitable for throttling (regulating flow).

- Globe valves: Excellent for throttling, offering precise flow regulation, but they generate higher pressure drop than gate valves.

- Ball valves: Simple quarter-turn on/off operation, suitable for high-pressure applications. They are also used for isolation and shut-off.

- Butterfly valves: Compact and cost-effective for on/off service and throttling, but may experience greater wear during throttling.

- Check valves: Prevent backflow of fluids, acting as one-way valves.

- Control valves: Automatically regulate flow based on process signals, crucial for process control systems. These are usually pneumatic or electric actuators.

The selection of a valve depends on factors such as the fluid properties (viscosity, corrosiveness, temperature), pressure, flow rate, and required level of control.

Q 5. How do you troubleshoot a malfunctioning control valve?

Troubleshooting a malfunctioning control valve requires a systematic approach:

- Check for obvious issues: Inspect the valve for any physical damage, leaks, or obstructions.

- Verify air supply (for pneumatic valves): Ensure adequate air pressure and check for leaks in the pneumatic lines.

- Inspect the actuator: Check the actuator for proper operation and look for any binding or mechanical problems. For electric valves, check the power supply and wiring.

- Examine the valve positioner: If equipped, verify its proper calibration and function. A faulty positioner can lead to incorrect valve positioning.

- Check the control signal: Use a multimeter or process instrumentation to measure the control signal sent to the valve. Compare this with the desired setpoint.

- Analyze the process: Consider whether process variables (pressure, temperature, flow) could be affecting the valve’s operation.

- Consult documentation: Review valve specifications, schematics, and maintenance records.

If the problem persists, it may require the assistance of a qualified technician or engineer for more in-depth diagnostics and repair.

Q 6. Explain the working principle of a distillation column.

A distillation column separates liquid mixtures into their individual components based on their boiling points. The process relies on the principle of vapor-liquid equilibrium. The mixture is heated, causing the more volatile components to vaporize. This vapor rises up the column, where it contacts a descending stream of liquid. A series of trays or packing materials inside the column provide a large surface area for efficient contact between the vapor and liquid phases. As the vapor rises, it cools and condenses, while the liquid falls, becoming richer in the less volatile components. The repeated vapor-liquid contact on multiple trays enhances the separation, ultimately producing relatively pure components at the top (distillate) and bottom (bottom product) of the column.

Think of it like separating different types of candies from a mix. The candies with lower melting points will evaporate first (boil), while the higher-melting ones remain behind. A distillation column efficiently repeats this separation process many times.

Q 7. What are the key parameters to monitor in a distillation process?

Several key parameters must be monitored in a distillation process to ensure efficient and safe operation. These include:

- Temperature: Temperatures at various points in the column, including the reboiler, condenser, and trays, are critical indicators of separation efficiency. Deviations from setpoints indicate potential problems.

- Pressure: Maintaining the correct pressure within the column is crucial for efficient operation. Pressure changes can affect the boiling points of the components.

- Flow rates: Monitoring the flow rates of feed, distillate, and bottom product ensures the column operates within its design limits.

- Reflux ratio: The ratio of liquid returned to the column to the liquid removed as distillate. This is a critical parameter affecting separation efficiency.

- Composition: Regular analysis of the distillate and bottom product composition is necessary to verify the purity of the separated components. This might involve online analyzers or periodic lab testing.

- Level: Maintaining the correct liquid level on trays and in the reboiler and condenser prevents flooding or dry-out, which could lead to poor performance or equipment damage.

Monitoring these parameters allows for early detection of problems and prevents costly downtime or product quality issues.

Q 8. Describe different types of reactors used in chemical processes.

Chemical reactors are the heart of many chemical processes, providing the environment for chemical reactions to occur. The choice of reactor depends heavily on the reaction kinetics, desired product quality, and scale of operation. Here are some common types:

- Batch Reactors: These are simple, versatile reactors where reactants are added at the beginning, the reaction proceeds, and the products are removed at the end. Think of a cooking pot – you add ingredients, cook, and then serve. Ideal for small-scale operations or reactions with complex kinetics requiring precise control.

- Continuous Stirred Tank Reactors (CSTRs): These reactors operate continuously, with reactants flowing in and products flowing out simultaneously. They’re well-mixed, resulting in a uniform temperature and concentration throughout. Imagine a constantly churning mixing tank in a factory – feedstock continuously enters, mixes, reacts, and the output is continuously removed. Excellent for large-scale operations and reactions with fast kinetics.

- Plug Flow Reactors (PFRs): In PFRs, reactants flow through a long tube or pipe, reacting as they move along. There’s minimal mixing, and the concentration and temperature vary along the length of the reactor. Think of a pipeline – reactants enter one end and gradually transform into products as they travel to the other end. Best for reactions where high conversion is needed and residence time is carefully controlled.

- Fluidized Bed Reactors: These reactors use a gas to suspend solid particles, creating a fluid-like mixture that enhances heat and mass transfer. This is ideal for gas-solid reactions, like many catalytic processes. Imagine a bed of sand being constantly agitated by an air stream – reactants flow through, and the suspended particles participate in the reaction.

Choosing the right reactor type involves carefully considering factors like reaction kinetics, heat transfer requirements, and desired product quality.

Q 9. How do you size a reactor for a specific chemical reaction?

Reactor sizing is a crucial step in process design, ensuring efficient operation and desired production rates. It typically involves these steps:

- Define Reaction Kinetics: Determine the reaction rate equation (e.g., using experimental data or literature values) which relates the reaction rate to concentrations and temperature. This is often represented as

-rA = k CAn, wherekis the rate constant,CAis the concentration of reactant A, andnis the reaction order. - Specify Design Parameters: Define desired conversion, production rate, temperature, pressure, and residence time. These specifications influence the reactor volume significantly.

- Perform Material and Energy Balances: Develop mass and energy balance equations for the reactor based on the chosen type. This involves calculating flow rates, reactant and product concentrations, heat generation or removal.

- Apply Design Equation: The design equation depends on the reactor type. For example, for a CSTR, the design equation is:

- where

Vis the reactor volume,FA0is the molar flow rate of reactant A at the inlet, andXis the conversion. - Perform Safety and Economic Evaluations: Consider safety aspects like pressure relief and runaway reactions. Evaluate the economic feasibility regarding capital costs and operating expenses to optimize the design.

V = FA0 (X / (-rA))Iterative calculations and simulations often refine the design, achieving the best balance between performance and cost.

Q 10. Explain the concept of process safety and its importance.

Process safety focuses on preventing accidents and mitigating risks associated with chemical processes. It’s not just about following regulations; it’s a fundamental philosophy that emphasizes protecting people, the environment, and assets. A major incident can have devastating consequences, including fatalities, environmental damage, and significant financial losses. Therefore, process safety is paramount.

Key aspects include:

- Hazard Identification and Risk Assessment: Identifying potential hazards (e.g., flammable materials, toxic chemicals, high pressures) and assessing their risks (likelihood and severity of an accident).

- Engineering Controls: Implementing safety features like pressure relief valves, emergency shut-down systems, and fire suppression systems.

- Safe Operating Procedures: Developing and implementing detailed procedures for operating equipment safely, including lockout/tagout procedures for maintenance.

- Training and Competency: Ensuring operators and maintenance personnel are adequately trained and competent in safe operating practices.

- Emergency Response Planning: Developing and practicing emergency response plans to handle accidents effectively.

A strong process safety culture emphasizes continuous improvement and proactive risk management, integrating safety into every aspect of process design, operation, and maintenance.

Q 11. What are your experiences with Process Safety Management (PSM) systems?

I have extensive experience with Process Safety Management (PSM) systems, having worked on projects involving HAZOP (Hazard and Operability) studies, LOPA (Layer of Protection Analysis), and SIL (Safety Integrity Level) assessments. I’ve actively participated in developing and implementing safety procedures, reviewing Process Safety Information (PSI), and conducting safety audits. In one project involving the handling of highly reactive chemicals, I led a team in conducting a HAZOP study, identifying potential hazards and recommending safety improvements. This led to the implementation of enhanced alarm systems, improved emergency shutdown procedures, and additional safety interlocks, resulting in a significantly reduced risk profile.

My expertise also encompasses the use of various PSM software tools for risk assessment and management. I’m familiar with the regulatory framework surrounding PSM, including OSHA’s PSM standard in the US, and understand the importance of compliance and continuous improvement in maintaining a robust PSM system.

Q 12. Describe different types of industrial dryers and their applications.

Industrial dryers remove moisture or other solvents from materials, often a crucial step in many processes. Several types exist, each suited for specific applications:

- Rotary Dryers: These are large cylindrical drums that rotate, moving material through a hot gas stream. Suitable for large volumes of bulk materials, like ores or grains.

- Fluidized Bed Dryers: Use a gas stream to suspend solid particles, providing excellent heat transfer and uniform drying. Ideal for powders and granules.

- Spray Dryers: Atomize a liquid feed into a hot gas stream, rapidly drying the droplets into a powder. Widely used for food, pharmaceuticals, and chemicals.

- Conveyor Dryers: Materials move on a conveyor belt through a heated environment. Suitable for materials that can handle direct contact with heat sources.

- Vacuum Dryers: Dry materials under reduced pressure, reducing boiling point and preventing thermal degradation. Used for heat-sensitive materials.

- Freeze Dryers (Lyophilization): Freeze the material and then sublimate the ice under vacuum. Preserves the structure and quality of sensitive products like pharmaceuticals and food.

The selection of the dryer depends on factors such as the material’s properties (e.g., heat sensitivity, particle size, moisture content), desired drying rate, and production scale.

Q 13. How do you select an appropriate dryer for a specific material?

Selecting the right dryer involves careful consideration of the material’s properties and process requirements. Here’s a step-by-step approach:

- Material Characterization: Understand the material’s properties – moisture content, heat sensitivity, particle size, chemical composition, and abrasiveness.

- Drying Rate Requirements: Determine the required drying rate based on production capacity and the allowed residence time.

- Process Constraints: Consider factors like available space, energy costs, and environmental regulations.

- Dryer Type Selection: Based on the material and process constraints, select the most suitable dryer type (rotary, fluidized bed, spray, etc.).

- Pilot Testing: Conduct pilot-scale tests with the selected dryer type to optimize operating parameters and validate performance.

- Scale-up and Design: Once the pilot tests are successful, scale up the dryer to the desired production capacity.

For example, heat-sensitive materials might require vacuum or freeze drying, while large volumes of bulk solids might necessitate rotary or fluidized bed dryers. Always prioritize material compatibility and operational safety.

Q 14. Explain the concept of mass and energy balances in process systems.

Mass and energy balances are fundamental principles in process engineering, ensuring that matter and energy are conserved throughout a process. They are crucial for designing, operating, and optimizing chemical processes.

Mass Balance: This principle states that the mass entering a system must equal the mass leaving the system plus any accumulation within the system. This can be expressed mathematically as:

Mass In = Mass Out + Mass AccumulatedFor example, in a CSTR, the mass balance on a specific component would consider the inflow, outflow, reaction rate, and accumulation in the reactor.

Energy Balance: This principle states that the energy entering a system must equal the energy leaving the system plus any change in the system’s internal energy. This can be expressed as:

Energy In = Energy Out + Change in Internal EnergyEnergy can be transferred through heat, work, and the flow of materials. In a reactor, energy balances are important to determine the heating or cooling requirements to maintain the desired temperature.

Both mass and energy balances are used to calculate flow rates, concentrations, temperatures, and energy requirements for process design and optimization. They are essential for troubleshooting operational issues and improving process efficiency. Developing these balances often requires careful consideration of the specific process, including reaction stoichiometry and thermodynamic properties.

Q 15. How do you perform a material balance calculation for a process unit?

A material balance, also known as a mass balance, is a fundamental concept in chemical engineering. It’s based on the principle of conservation of mass: what goes into a process unit must either come out or accumulate within the unit. We perform these calculations to understand the flow rates and compositions of materials within a process. This helps in designing, optimizing, and troubleshooting processes.

Steps involved in performing a material balance:

- Define the system: Clearly identify the boundaries of your process unit. This could be a single reactor, a distillation column, or an entire plant section.

- Identify the inputs and outputs: List all the streams entering and leaving the system, specifying their flow rates and compositions (e.g., mass flow rate of reactants, molar fractions of components).

- Choose a basis: Select a convenient basis for your calculations. This might be a specific time period (e.g., one hour) or a specific mass flow rate of one stream.

- Write the mass balance equations: Apply the conservation of mass principle to each component in the system. For a steady-state process (where accumulation is zero), the equation is simple: Input = Output. For unsteady-state processes (where accumulation occurs), the equation becomes: Input – Output = Accumulation.

- Solve the equations: Use the known parameters and the mass balance equations to solve for the unknowns. This often involves solving a system of simultaneous equations. For example, if you know the input flow rate and composition and the output composition of one component, you can solve for the output flow rate of that component and subsequently, the flow rates of other components through their respective mass balances.

- Check your results: Verify your calculations by ensuring that the mass balance is consistent across all components. Any significant discrepancy requires a review of the assumptions and calculations.

Example: Consider a mixing tank where two streams of water are mixed. Stream 1 has a flow rate of 10 kg/hr and Stream 2 has a flow rate of 20 kg/hr. The output stream will have a flow rate of 30 kg/hr (10 + 20 = 30).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common safety hazards associated with process equipment?

Process equipment poses numerous safety hazards. These can be broadly classified into:

- Physical Hazards: These include moving parts (e.g., rotating shafts, gears, belts), high-pressure vessels that could rupture, and hot surfaces leading to burns. Confined space entry also presents significant physical hazards like oxygen deficiency, toxic gases, and engulfment.

- Chemical Hazards: Exposure to toxic or hazardous materials like solvents, acids, or reactive chemicals can cause acute or chronic health effects. These risks increase with spills, leaks, or inadequate ventilation.

- Fire and Explosion Hazards: Flammable or explosive materials are present in many process industries. Sparks, static electricity, or heat sources can ignite flammable vapors or dusts leading to fires or explosions. The potential severity increases with the presence of oxidizing agents.

- Electrical Hazards: Electrical shocks, arc flashes, and electrical fires are potential hazards associated with malfunctioning equipment or exposed wiring.

The severity of these hazards depends on the specific equipment and process. For example, a high-pressure reactor carries a much higher risk of a catastrophic failure than a low-pressure storage tank.

Q 17. How do you ensure the safe operation of process equipment?

Ensuring safe operation of process equipment requires a multi-layered approach focusing on prevention, detection, and mitigation:

- Engineering Controls: Implementing inherent safety features during design such as using intrinsically safe equipment, providing proper ventilation, installing pressure relief valves, and using interlocks to prevent unsafe operating conditions.

- Administrative Controls: Developing and implementing standard operating procedures (SOPs), conducting regular safety inspections, providing comprehensive training to operators, implementing lockout/tagout procedures for maintenance activities, and establishing clear emergency response plans.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE, such as safety glasses, gloves, respirators, and protective clothing, depending on the specific hazards.

- Regular Maintenance and Inspection: Regular maintenance and inspections are crucial to prevent equipment failures. This includes visual inspections, functional testing, and preventative maintenance according to a schedule.

- Process Safety Management (PSM): Implementing a comprehensive PSM program encompassing hazard identification, risk assessment, and mitigation strategies.

A strong safety culture within the organization is paramount. Everyone involved must understand and follow the safety procedures and take personal responsibility for safety.

Q 18. Describe your experience with process instrumentation and control systems.

I have extensive experience with various process instrumentation and control systems, from basic analog systems to advanced digital control systems using PLCs and distributed control systems (DCS). My experience includes selection, installation, calibration, and troubleshooting of different types of instruments.

Specific examples of my experience include:

- Temperature measurement and control: Utilizing thermocouples, RTDs, and temperature transmitters to measure and control temperature in reactors and distillation columns. I’ve worked with PID controllers to maintain setpoint temperatures accurately.

- Level measurement and control: Experience with various level sensors, such as DP cells, ultrasonic level sensors, and radar level sensors. I’ve designed control loops to maintain optimal liquid levels in storage tanks and reactors.

- Flow measurement and control: Working with various flow meters, including orifice plates, rotameters, and magnetic flow meters. I’ve implemented control systems to regulate flow rates in pipelines and process streams.

- Pressure measurement and control: Using pressure transmitters and regulators to monitor and control pressure in various process units. This includes experience with safety relief valves and pressure control systems.

I am proficient in using various control system software packages to configure, monitor, and optimize process control loops. This includes familiarity with various communication protocols (e.g., Modbus, Profibus, Ethernet/IP).

Q 19. How do you troubleshoot problems in process control systems?

Troubleshooting process control system problems requires a systematic approach:

- Gather Information: Begin by gathering all available information related to the problem. This includes error messages, process data logs, operator observations, and any recent changes made to the system. Start by reviewing historical trends to identify patterns.

- Identify the Problem: Analyze the gathered information to identify the root cause of the problem. Is it a sensor malfunction, a faulty valve, a problem with the control algorithm, or something else?

- Verify the Problem: Once a potential cause is identified, verify it through testing and observation. Isolate the problem area to minimize disruption to the rest of the process.

- Implement a Solution: Develop and implement a solution to correct the problem. This could involve repairing or replacing faulty equipment, modifying the control algorithm, or adjusting setpoints.

- Verify the Solution: Once the solution is implemented, verify that the problem is resolved and the system is operating normally. Monitor the system closely for any recurring issues.

- Document the Process: Keep a clear record of the problem, the troubleshooting steps taken, and the solution implemented. This will be helpful in preventing similar issues in the future.

Example: If a reactor temperature is consistently higher than the setpoint despite adjustments to the controller, you would first check the temperature sensor for calibration issues or potential failure. Then, you would inspect the heating system, checking for blockages or malfunctioning components before considering any problems within the control algorithm itself.

Q 20. What are the different types of sensors used in process industries?

The process industries utilize a wide array of sensors, each designed for specific measurements. Here are some common types:

- Temperature Sensors: Thermocouples (for wide temperature ranges), Resistance Temperature Detectors (RTDs) (for high accuracy), and Thermistors (for precise measurements in limited ranges).

- Pressure Sensors: Bourdon tubes, diaphragm seals, piezoelectric sensors, and capacitive pressure sensors.

- Level Sensors: Float switches, ultrasonic sensors, radar level sensors, differential pressure (DP) cells.

- Flow Sensors: Orifice plates, rotameters, magnetic flow meters, ultrasonic flow meters, turbine flow meters.

- pH Sensors: Electrochemical sensors used to measure the acidity or alkalinity of liquids.

- Conductivity Sensors: Measure the ability of a solution to conduct electricity, often used for monitoring water purity.

- Gas Sensors: Detect the presence and concentration of specific gases, such as oxygen, carbon monoxide, or methane.

- Analytical Sensors: These include more sophisticated instruments for measuring specific components within a process stream, such as gas chromatographs (GC) or mass spectrometers.

The choice of sensor depends on factors such as accuracy requirements, temperature and pressure ranges, material compatibility, and cost.

Q 21. Explain your experience with Programmable Logic Controllers (PLCs).

I possess substantial experience working with Programmable Logic Controllers (PLCs) in various process control applications. My experience includes programming, troubleshooting, and maintaining PLCs for a range of industrial processes.

Specific areas of my PLC experience include:

- Programming: I’m proficient in ladder logic programming (the most common PLC programming language) and other programming languages including function block diagrams and structured text. I’ve written programs to control complex sequences of operations, handle various inputs and outputs, and implement safety interlocks.

- Troubleshooting: I’ve successfully diagnosed and resolved a wide variety of PLC-related problems, including hardware malfunctions, software errors, and communication issues. My troubleshooting skills involve using diagnostic tools to identify the root causes of problems and implement effective solutions.

- Networking: I’m familiar with various PLC communication protocols, including Ethernet/IP, Modbus TCP, and Profibus, and have experience configuring PLCs to communicate with other devices such as HMIs, SCADA systems, and other PLCs.

- HMI Integration: I’ve integrated PLCs with Human Machine Interfaces (HMIs) to create user-friendly interfaces for operators to monitor and control processes. This includes designing custom screens, creating alarms and reports, and implementing various visualization techniques.

I have worked with various PLC brands and models and have a solid understanding of PLC architecture, including input/output modules, CPU, and communication interfaces.

Q 22. Describe your experience with Supervisory Control and Data Acquisition (SCADA) systems.

My experience with Supervisory Control and Data Acquisition (SCADA) systems spans over ten years, encompassing design, implementation, and troubleshooting across various industrial processes. SCADA systems are essentially the nervous system of large-scale industrial operations, allowing centralized monitoring and control of diverse equipment. I’ve worked extensively with systems from major vendors like Siemens and Rockwell Automation, utilizing their HMI (Human Machine Interface) software for real-time process visualization and control. For example, in a previous role at a petrochemical plant, I was responsible for configuring and maintaining a SCADA system that monitored and controlled over 500 process variables, including temperature, pressure, flow rates, and level sensors. This involved scripting, alarm management, historical data analysis, and troubleshooting network connectivity issues. I am proficient in both hardware and software aspects, including network protocols like Modbus and Profibus.

I’m also familiar with implementing cybersecurity measures within SCADA environments, recognizing the critical need to protect industrial control systems from cyber threats. This includes implementing network segmentation, access control lists, and intrusion detection systems.

Q 23. Explain the concept of process optimization and how it’s achieved.

Process optimization aims to enhance efficiency and reduce costs by identifying and eliminating bottlenecks or inefficiencies in a production process. It’s like fine-tuning a well-oiled machine to make it even better. This is achieved through a multi-faceted approach that may involve improving equipment performance, streamlining workflows, and optimizing control strategies. For example, in a chemical reactor, process optimization might involve adjusting temperature and pressure to maximize yield while minimizing energy consumption. Think of it like baking a cake – you want the perfect rise and texture, achieving that requires adjusting oven temperature and baking time precisely.

Methods for achieving process optimization include:

- Data Analysis: Analyzing historical process data to identify trends and areas for improvement.

- Statistical Process Control (SPC): Using statistical methods to monitor process variations and identify sources of variability.

- Advanced Process Control (APC): Implementing sophisticated control algorithms to maintain optimal operating conditions automatically.

- Simulation and Modeling: Using computer models to simulate different process scenarios and optimize parameters before implementation.

Successful optimization relies on a strong understanding of the process, data-driven decision-making, and effective collaboration between engineers, operators, and management.

Q 24. How do you use data analytics to improve process efficiency?

Data analytics plays a pivotal role in enhancing process efficiency. I leverage various techniques to extract actionable insights from process data, leading to tangible improvements. This process typically involves several steps:

- Data Collection: Gathering data from various sources, including SCADA systems, sensors, and production logs.

- Data Cleaning and Preprocessing: Removing errors, outliers, and inconsistencies in the collected data.

- Exploratory Data Analysis (EDA): Performing statistical analysis to identify patterns, trends, and relationships within the data. This might involve creating histograms, scatter plots, and other visualizations.

- Predictive Modeling: Building statistical models to predict future process behavior and identify potential issues before they occur. This could include using techniques like regression analysis or machine learning algorithms.

- Prescriptive Analytics: Using advanced algorithms to recommend optimal process parameters or control strategies based on the data.

For instance, in a previous project involving a food processing plant, I used data analytics to identify a correlation between ambient temperature fluctuations and product quality. By implementing a temperature control system based on predictive modeling, we reduced product defects by 15% and saved the company significant costs.

Q 25. Describe your experience with different types of filtration equipment.

My experience with filtration equipment is extensive, encompassing various types used across different industries. I’m familiar with:

- Gravity Filters: Simple and cost-effective for removing larger particles. I’ve used these in water treatment applications.

- Pressure Filters: Utilizing pressure to force the fluid through a filter medium. I’ve worked with various types, including cartridge filters, plate and frame filters, and leaf filters in chemical processing.

- Vacuum Filters: Employing vacuum to draw the fluid through the filter medium. I have experience with rotary vacuum filters and drum filters, commonly used in mineral processing and wastewater treatment.

- Membrane Filters: Utilizing semi-permeable membranes to separate components based on size or charge. My experience includes microfiltration, ultrafiltration, nanofiltration, and reverse osmosis, often applied in pharmaceutical and biotech applications.

I understand the strengths and limitations of each type and can select the appropriate filter based on the specific application requirements.

Q 26. How do you select the appropriate filtration method for a specific application?

Selecting the right filtration method is crucial for process efficiency and product quality. The process involves a systematic evaluation of several factors:

- Fluid properties: Viscosity, temperature, solids content, and chemical composition.

- Particle size and type: Determining the size and nature of particles to be removed.

- Filtration rate and capacity: Matching the flow rate and volume of the fluid to the filter’s capacity.

- Filtrate quality requirements: Specifying the required level of clarity and purity.

- Cost and maintenance: Considering capital and operational costs, as well as maintenance requirements.

For example, if you need to remove very fine particles from a high-viscosity fluid, you might choose a membrane filtration system like ultrafiltration. If you are dealing with large volumes of slurry with coarse particles, a pressure filter like a plate and frame filter might be more suitable. The selection process often involves performing pilot tests to optimize filter selection and operation.

Q 27. What are your experiences with predictive maintenance techniques for process equipment?

Predictive maintenance, unlike reactive maintenance (fixing things only after they break), anticipates equipment failures by using data analytics and sensor technologies to predict when maintenance is needed. This reduces downtime, extends equipment lifespan, and optimizes maintenance costs. I have extensive experience implementing and managing predictive maintenance programs. This typically involves:

- Sensor data acquisition: Installing sensors on critical equipment to monitor key parameters like vibration, temperature, and pressure.

- Data analysis and modeling: Using machine learning and statistical techniques to analyze sensor data and predict potential failures.

- Alerting systems: Setting up systems to automatically alert maintenance personnel when a potential failure is detected.

- Maintenance scheduling: Optimizing maintenance schedules based on predicted failure probabilities.

For instance, in a power generation plant, we used vibration sensors to monitor the condition of turbines. By analyzing vibration data, we were able to predict potential bearing failures weeks in advance, allowing for timely repairs and preventing costly unplanned outages.

Q 28. Describe your experience with root cause analysis techniques for process equipment failures.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of equipment failures, going beyond simply fixing the immediate symptom. My experience involves using various RCA techniques, including:

- 5 Whys: Repeatedly asking “why” to drill down to the root cause of a problem.

- Fishbone diagrams (Ishikawa diagrams): Identifying potential causes grouped by categories like people, materials, methods, and environment.

- Fault tree analysis (FTA): Creating a tree-like diagram to illustrate the sequence of events leading to a failure.

- Failure Mode and Effects Analysis (FMEA): Proactively identifying potential failure modes and their consequences.

For example, a pump failure might initially be attributed to a worn-out bearing. However, using RCA techniques, we might discover the root cause was due to inadequate lubrication, which was itself caused by a faulty lubrication system. By addressing the root cause, we prevent similar failures in the future.

Key Topics to Learn for Process Equipment Familiarity Interviews

- Process Unit Operations: Understand the fundamental principles behind common unit operations like mixing, separation (filtration, distillation, centrifugation), heat transfer (evaporation, condensation), and mass transfer (absorption, extraction). Consider theoretical models and their limitations.

- Equipment Types and Applications: Develop a strong understanding of various equipment used in these operations. This includes reactors (batch, continuous, CSTR), pumps (centrifugal, positive displacement), heat exchangers (shell and tube, plate), and separation devices (distillation columns, filters, centrifuges). Be ready to discuss their specific applications and limitations based on process parameters.

- Material Selection and Corrosion: Discuss the importance of selecting appropriate materials for process equipment based on factors like temperature, pressure, and chemical compatibility. Understand common corrosion mechanisms and mitigation strategies.

- Instrumentation and Control: Familiarize yourself with common process instrumentation (pressure, temperature, flow, level sensors) and control systems (PID controllers, PLC). Be able to explain how these systems maintain process parameters within desired ranges.

- Troubleshooting and Problem Solving: Practice diagnosing common process equipment malfunctions. Develop a systematic approach to troubleshooting, involving identifying the problem, analyzing root causes, and proposing solutions.

- Safety and Regulations: Understand relevant safety procedures and regulations related to operating and maintaining process equipment. This includes lockout/tagout procedures and hazard analysis techniques.

- Process Diagrams and P&IDs: Learn to interpret process flow diagrams (PFDs) and piping and instrumentation diagrams (P&IDs). Be prepared to discuss the information they convey about process equipment and their interconnections.

Next Steps

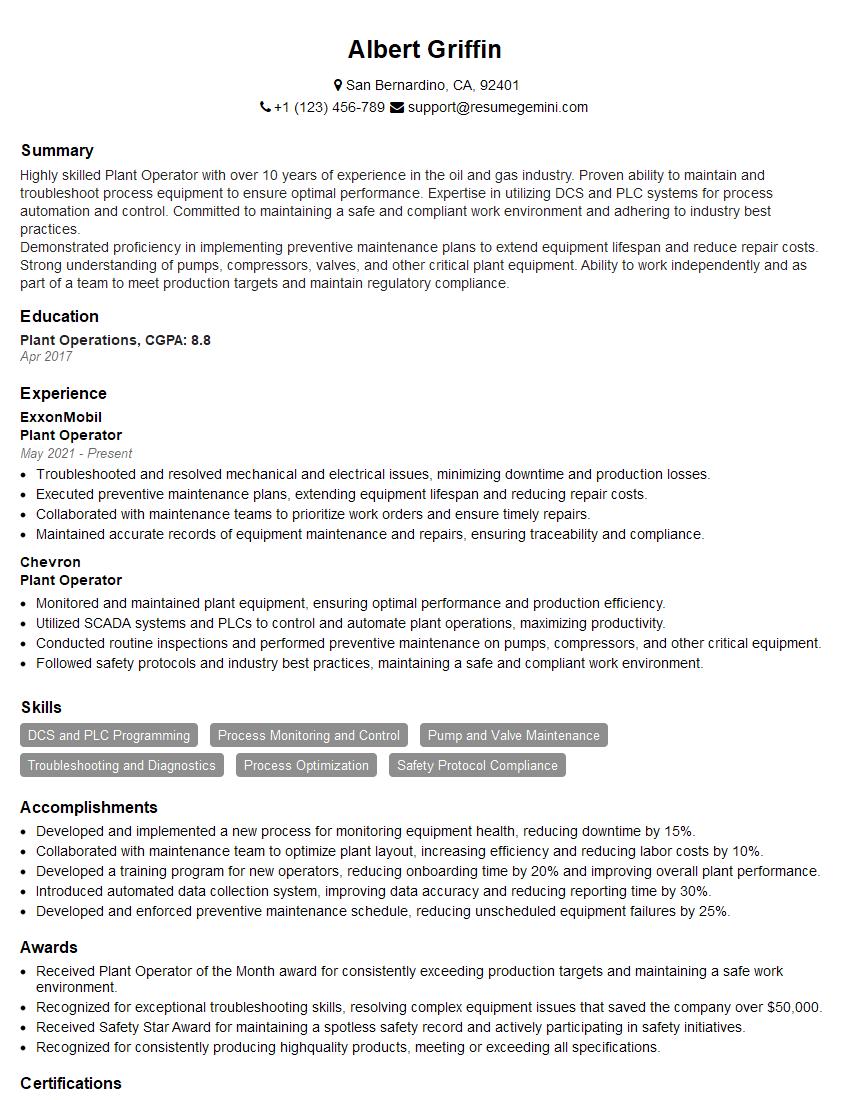

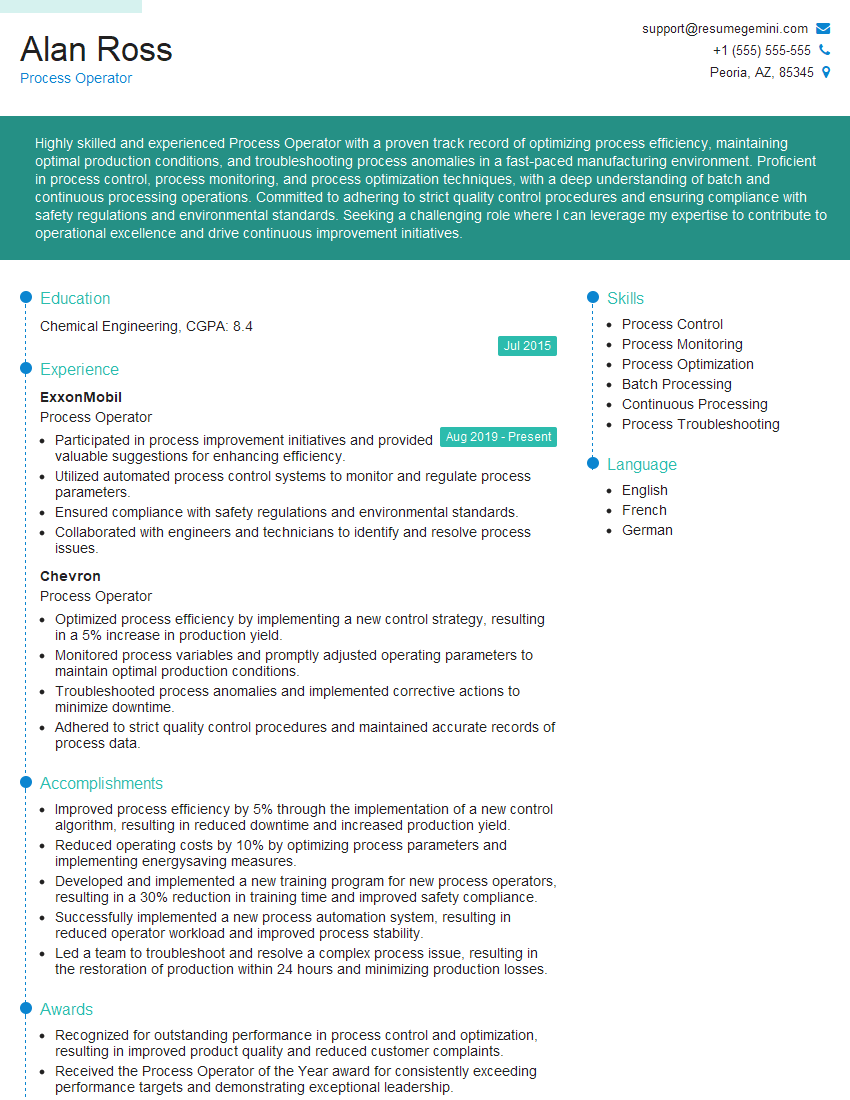

Mastering familiarity with various process equipment is crucial for career advancement in engineering and related fields. A deep understanding of these topics demonstrates practical skills and problem-solving abilities highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to showcasing expertise in process equipment, allowing you to craft a document that truly represents your capabilities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.