Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Flocculant and Coagulant Optimization interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Flocculant and Coagulant Optimization Interview

Q 1. Explain the difference between flocculation and coagulation.

Coagulation and flocculation are both crucial steps in water treatment aimed at removing suspended solids, but they operate through different mechanisms. Think of it like this: coagulation is like gathering individual tiny grains of sand together, while flocculation is like clumping those small sand groups into larger, heavier masses.

Coagulation involves destabilizing the suspended particles in the water, causing them to collide and form small aggregates called microflocs. This destabilization is typically achieved by adding a coagulant, a chemical that neutralizes the surface charges of the particles, allowing them to overcome electrostatic repulsion and come together. Common coagulants include aluminum sulfate (alum) and ferric chloride.

Flocculation, on the other hand, is the process of gently mixing these microflocs to encourage them to grow into larger, heavier flocs. This process uses flocculants, which are long-chain polymers that act like bridges, connecting the microflocs together and forming larger, settleable particles. Polyacrylamide is a widely used flocculant.

In short: Coagulation brings particles close together; flocculation grows those particles into larger, settleable clumps.

Q 2. Describe the different types of flocculants and coagulants and their applications.

Coagulants and flocculants come in various types, each suited for specific applications. The choice depends heavily on the water quality, the desired outcome, and cost-effectiveness.

- Coagulants:

- Aluminum sulfate (alum): Widely used, relatively inexpensive, effective over a range of pH, but can produce sludge with high aluminum content.

- Ferric chloride: Effective at lower pH levels than alum, produces less sludge than alum but can be more corrosive.

- Ferric sulfate: Similar to ferric chloride but less corrosive.

- Polyaluminum chloride (PAC): Offers better performance at higher pH levels and produces less sludge than alum.

- Flocculants:

- Anionic polyacrylamides: Effective in removing negatively charged particles. Often used in wastewater treatment.

- Cationic polyacrylamides: Effective in removing positively charged particles and are sometimes used in combination with anionic polymers.

- Non-ionic polyacrylamides: Used for a wider range of applications, often where bridging is the primary mechanism.

- Natural polymers: Such as starches and clays, are sometimes used as more environmentally friendly alternatives.

Applications vary greatly. For example, alum is frequently used in municipal water treatment plants for primary clarification, while polymeric flocculants are often used in secondary clarification to improve sludge dewatering.

Q 3. How do you determine the optimal dosage of a flocculant or coagulant?

Determining the optimal dosage is crucial for effective and cost-efficient treatment. Too little coagulant/flocculant will result in poor removal efficiency, while too much can lead to excessive sludge production and increased costs. The optimal dosage is usually determined experimentally through methods like the jar test (discussed later).

A common approach involves conducting a series of jar tests with varying dosages of the chemical. The results are then analyzed to determine the dosage that yields the best floc formation, the fastest settling rate, and the clearest supernatant. This involves observing factors such as floc size, settling time, and supernatant clarity.

The optimum dosage isn’t a fixed value; it varies with water characteristics (turbidity, temperature, pH, etc.), the type of coagulant/flocculant used, and the treatment goals.

Q 4. What factors influence the effectiveness of flocculation and coagulation?

Many factors can significantly impact the success of coagulation and flocculation. These include:

- Water quality: Turbidity, temperature, pH, the presence of interfering substances (e.g., humic acids), and the type and concentration of suspended solids all play crucial roles.

- Coagulant/flocculant type and dosage: The selection of the right chemical and its optimal dosage are critical for effective treatment.

- Mixing intensity and time: Rapid mixing is needed for effective coagulation, followed by slow mixing for optimal floc growth during flocculation.

- Temperature: Temperature affects the kinetics of chemical reactions and the viscosity of the water.

- pH: Influences the charge of the particles and the effectiveness of the coagulant/flocculant.

- Presence of interfering substances: Certain substances can inhibit the coagulation/flocculation process.

Consider a scenario where high turbidity water is being treated. Higher dosages of coagulants might be necessary to overcome the higher concentration of suspended solids. Alternatively, a change in pH may be needed to optimize the performance of a chosen coagulant.

Q 5. Explain the jar test and its importance in water treatment.

The jar test is a small-scale laboratory procedure that simulates the coagulation and flocculation process in a water treatment plant. It’s a crucial tool for optimizing coagulant/flocculant selection and dosage. Think of it as a miniature version of your full-scale treatment process.

The test involves using a series of jars containing the water sample. Different dosages of coagulant/flocculant are added to each jar, followed by rapid and then slow mixing. The jars are then allowed to settle, and the clarity of the supernatant (the clear liquid above the settled solids) is visually assessed after a certain settling time. The jar exhibiting the clearest supernatant with the best floc formation indicates the optimum dosage.

Its importance lies in its ability to quickly and cost-effectively evaluate various coagulant/flocculant combinations and dosages before implementing changes in a full-scale treatment plant. It minimizes the risk of operational problems and optimizes treatment efficiency.

Q 6. How do you troubleshoot poor flocculation or coagulation performance?

Troubleshooting poor flocculation/coagulation performance requires a systematic approach. Here’s a step-by-step guide:

- Review water quality data: Analyze parameters like turbidity, temperature, pH, and the presence of interfering substances. Changes in water quality can significantly impact performance.

- Check coagulant/flocculant dosage: Verify that the dosage is optimal using the jar test. A poorly calibrated system or aging chemicals can lead to problems.

- Inspect mixing conditions: Ensure proper rapid and slow mixing times and intensities. Issues such as malfunctioning mixers or incorrect mixing times need to be identified.

- Analyze floc characteristics: Observe floc size, strength, and settling rate. Small, weak flocs indicate problems with coagulation or flocculation. Poor floc characteristics can often point to improper chemical dosage or mixing conditions.

- Investigate equipment malfunction: Check for issues with pumps, mixers, and other equipment that could be affecting the treatment process.

- Consider alternative coagulants/flocculants: If problems persist, explore alternative chemicals that might be better suited for the specific water quality.

For example, if the flocs are too small and don’t settle properly, you might need to adjust the rapid mixing intensity, increase the coagulant dosage, or consider a different coagulant altogether.

Q 7. Describe the role of pH in flocculation and coagulation.

pH plays a critical role in coagulation and flocculation because it affects the surface charge of the particles and the charge of the coagulant/flocculant. Most suspended particles in water carry a negative charge. Coagulants like alum and ferric chloride work by neutralizing this negative charge, allowing the particles to come together.

The optimal pH range for coagulation varies depending on the coagulant used. Alum, for example, is most effective within a relatively narrow pH range (around 6-8). Outside this range, its effectiveness decreases significantly. Ferric chloride, on the other hand, is effective at a lower pH range. Flocculants, although less directly affected by pH compared to coagulants, are still influenced by it; the pH affects the polymer’s charge and its interaction with the flocs.

In practice, pH adjustment is often a necessary step in water treatment. This is achieved by adding acids (to lower pH) or bases (to raise pH). Careful pH control ensures the selected coagulant/flocculant works at its optimum efficiency. Without proper pH adjustment, you could experience poor floc formation and inefficient treatment.

Q 8. What are the common challenges in flocculant and coagulant optimization?

Optimizing flocculant and coagulant use presents several challenges. One major hurdle is the variability of water sources. The type and concentration of impurities (turbidity, color, organic matter) differ drastically between rivers, lakes, and industrial wastewater, requiring tailored treatment strategies. Another key challenge is finding the optimal dosage. Too little coagulant/flocculant leads to incomplete treatment, while too much increases sludge production and operational costs. Furthermore, achieving optimal performance often requires balancing multiple factors simultaneously – pH, temperature, mixing intensity, and residence time – all interacting in complex ways. Finally, the cost of chemicals themselves and the disposal of the resulting sludge can be significant. Imagine trying to bake a cake without knowing the exact recipe – you might get something edible, but perfecting it requires careful adjustment of all ingredients and baking parameters. Optimizing flocculation and coagulation is similar, requiring precise control and constant monitoring.

Q 9. Explain the concept of zeta potential and its relevance to coagulation.

Zeta potential is the measure of the electrical charge of particles in suspension. It’s essentially a measure of how much these particles repel each other. In coagulation, negatively charged particles (common in water) repel each other, preventing them from clumping together. Coagulants, typically positively charged chemicals like aluminum or iron salts, neutralize the negative charge on these particles, reducing the zeta potential. This allows the particles to overcome their repulsive forces and aggregate into larger flocs, which are easier to remove through sedimentation or filtration. Think of it like magnets – if two magnets have the same polarity (both positive or both negative), they repel. A coagulant acts like a magnet with the opposite polarity, neutralizing the charge and allowing the particles to attract and clump together.

Q 10. How do you select the appropriate flocculant or coagulant for a specific water source?

Selecting the right coagulant or flocculant involves a systematic approach. First, a thorough water quality analysis is essential, determining parameters like turbidity, pH, alkalinity, and the nature of suspended solids (organic or inorganic). Then, jar tests are performed. These involve adding various dosages of different coagulants/flocculants to small water samples under controlled conditions (pH adjustment, mixing speed, etc.). The resulting floc size, settling characteristics, and final turbidity are observed to determine the most effective treatment. For example, if a water source has high organic content, a polymeric flocculant might be preferable over an inorganic coagulant like alum. If the pH is already high, a coagulant that works effectively at higher pH ranges would be chosen. This selection process is iterative; the goal is to find the chemical(s) and dosages that deliver optimal water quality at the lowest cost while minimizing sludge production.

Q 11. Describe different methods for measuring turbidity and their importance.

Turbidity, a measure of water clarity, is crucial in evaluating the effectiveness of coagulation and flocculation. Several methods exist to measure it. Nephelometry is the most common, measuring the light scattered by particles in the water. Higher turbidity indicates more scattering, hence more suspended solids. Another method is the visual comparison using a turbidity tube, providing a simple yet less precise measurement. For higher accuracy and automation, instruments using infrared light scattering are employed. The importance of measuring turbidity lies in its direct relation to treatment performance. The reduction in turbidity following coagulation/flocculation directly reflects the efficiency of the process. Consistent turbidity monitoring allows for real-time process control and optimization – ensuring consistently clean water and preventing potential treatment failures.

Q 12. What are the safety precautions associated with handling flocculants and coagulants?

Handling flocculants and coagulants requires strict adherence to safety protocols. Many are corrosive or irritating to skin and eyes. Personal protective equipment (PPE) is essential, including gloves, safety glasses, and lab coats. Proper ventilation is crucial to prevent inhalation of dust or fumes. In the case of spills, appropriate spill kits must be readily available and staff trained in their proper use. Chemical storage should follow guidelines to prevent cross-contamination and accidental exposure. Detailed safety data sheets (SDS) for each chemical are to be reviewed, understood, and readily accessible. Regular training on safe handling procedures, emergency response protocols, and waste disposal methods is vital to minimize risks associated with these chemicals.

Q 13. Explain the impact of temperature on flocculation and coagulation.

Temperature significantly impacts flocculation and coagulation. Generally, higher temperatures promote faster reactions, leading to quicker floc formation. However, excessively high temperatures can sometimes lead to smaller, weaker flocs that are less easily removed. Lower temperatures can slow down the entire process, requiring longer retention times or higher dosages of chemicals. The optimal temperature range varies depending on the specific coagulant/flocculant and water characteristics. This variability highlights the importance of performing jar tests at the expected water temperature range and using this knowledge to adapt the process during seasonal temperature fluctuations. Imagine making jello – if the temperature is too low, the jello will take longer to set; too high and it might not set properly at all. Similarly, temperature plays a significant role in the effectiveness of flocculation and coagulation.

Q 14. How do you manage sludge generated during flocculation and coagulation?

Sludge management is a crucial aspect of flocculation and coagulation processes. The generated sludge contains residual coagulants, flocculants, and removed impurities. Improper management can lead to environmental pollution. Common methods include thickening (concentrating the sludge to reduce volume), dewatering (removing water to further reduce volume and facilitate transport), and disposal. Disposal options include land application (for specific sludge types and following regulations), landfilling, or incineration. In many cases, advanced treatment methods are implemented before disposal to reduce environmental impact. The sludge characteristics dictate the appropriate management strategy. For example, sludge with high organic content might be suitable for anaerobic digestion, producing biogas while reducing volume. Effective sludge management is not only environmentally responsible but also economically significant, reducing disposal costs while minimizing potential risks to human health and the environment.

Q 15. What are the environmental considerations related to flocculant and coagulant use?

Environmental considerations in flocculant and coagulant use are crucial. Improper use can lead to several issues. Firstly, residual chemicals can impact aquatic life. Some coagulants, like aluminum and iron salts, can be toxic at certain concentrations. Flocculants, while generally less toxic, can still contribute to increased sludge volume, which requires careful disposal. This sludge itself may contain adsorbed pollutants, adding another layer of complexity. Secondly, sludge management poses challenges. The volume of sludge generated during water treatment is significant, and its disposal often requires energy-intensive processes. Improper disposal can lead to soil and water contamination. Thirdly, the manufacturing and transportation of these chemicals has an environmental footprint. The energy consumption during production and the emissions from transporting large quantities of chemicals should be considered. Sustainable sourcing and greener alternatives are therefore crucial in minimizing the overall environmental impact. For instance, using naturally derived flocculants, optimizing dosage to minimize sludge, and employing advanced sludge treatment methods can significantly reduce these environmental concerns.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different types of mixing equipment used in flocculation.

Mixing is critical in flocculation, and several equipment types are used depending on the scale and application. Rapid mix utilizes high-shear mixers to quickly disperse coagulants, creating optimal conditions for destabilization of colloidal particles. These often involve turbines or propeller mixers. Following rapid mix, slow mix uses gentle agitation to promote particle aggregation and flocculation. This can be achieved with paddle mixers, or more sophisticated systems like hydraulic flocculators. In large-scale water treatment plants, mechanical flocculators are common. They use rotating paddles to create slow, controlled mixing, ensuring optimal floc formation. For smaller applications, static mixers might be sufficient. These mixers use a series of internal elements to create turbulence and promote mixing without moving parts. Finally, air mixing can be employed, typically in aeration tanks where dissolved air flotation is used for subsequent solid-liquid separation. The selection of the appropriate equipment depends on factors like the volume of water being treated, the properties of the water, and the type of coagulant/flocculant used.

Q 17. How do you monitor and control the flocculation and coagulation process?

Monitoring and controlling the flocculation and coagulation process is essential for efficient and effective water treatment. This involves continuous monitoring of several key parameters. Turbidity measurements provide a direct indication of the effectiveness of the treatment. Lower turbidity after flocculation suggests better particle removal. pH is another critical parameter as it significantly affects coagulant performance. Regular pH adjustments are often needed to maintain optimal coagulation conditions. Zeta potential measurements can be used to determine the surface charge of the particles, indicating the effectiveness of charge neutralization. Finally, residual coagulant levels are monitored to ensure that the treatment does not introduce excessive amounts of chemicals into the treated water. Control strategies involve adjusting the dosage of coagulants and flocculants based on the real-time data from monitoring. This can be automated using process control systems with feedback loops. Regular jar testing, described in a later question, also aids in optimizing the process.

Q 18. What are the advantages and disadvantages of using different types of flocculants?

Different flocculants offer distinct advantages and disadvantages. Inorganic flocculants, such as alum (aluminum sulfate) and ferric chloride, are cost-effective but can leave residual metals in the treated water. They are also less effective at low temperatures. Organic polymers, on the other hand, are more effective at lower temperatures and dosages, requiring less sludge production, and often produce higher quality flocs. However, they can be more expensive. Within organic polymers, different types exist: cationic polymers are effective for negatively charged particles; anionic polymers work best with positively charged ones; and non-ionic polymers are often used as bridging agents. The choice depends on water characteristics (such as turbidity, pH, and the nature of the suspended solids) and cost considerations. For example, in treating water with high turbidity and a complex mixture of suspended solids, an organic polymer might be preferred despite its higher cost due to its better performance, resulting in less sludge and lower residual chemicals. In simpler applications with less stringent water quality standards, a less expensive inorganic flocculant may be suitable.

Q 19. Explain the concept of rapid mix and its importance in coagulation.

Rapid mix is a crucial initial step in coagulation. It involves rapidly dispersing the coagulant throughout the water to ensure uniform contact with suspended particles. Think of it like mixing paint—if you don’t mix it thoroughly, you’ll end up with streaks of color. Similarly, if you don’t rapidly mix the coagulant, you’ll have uneven distribution and ineffective coagulation. The goal is to achieve a rapid and homogeneous distribution of the coagulant within the water, facilitating the destabilization of colloidal particles. The intensity and duration of rapid mixing are critical parameters, influenced by factors such as water temperature and the type of coagulant used. Insufficient rapid mixing leads to uneven coagulation, resulting in poor floc formation and inefficient particle removal. Conversely, excessive rapid mixing can shear flocs, hindering sedimentation. Optimization of rapid mix parameters, therefore, is crucial for achieving optimal coagulation performance.

Q 20. How do you interpret the results of a jar test?

The jar test is a simple yet powerful tool for optimizing coagulant and flocculant dosage. In this test, several jars are filled with a representative sample of water, and varying doses of coagulants and flocculants are added to each jar. The jars are subjected to rapid and slow mixing, mimicking the conditions in a water treatment plant. After settling for a specific time, the clarity and the size of the formed flocs are visually assessed. The jar with the clearest supernatant (the water above the settled solids) and the largest, well-formed flocs indicates the optimal dosage. Observations are recorded, often noting the time taken for floc formation, the size and structure of the flocs, and the clarity of the settled water. These observations help in determining the optimal chemical dosages for effective coagulation and flocculation in full-scale water treatment. For example, if the jar with the lowest dosage shows good clarity, this is cost-effective, while the jar with the largest flocs might indicate the best solids removal. The jar test’s results are directly translated into operational settings, influencing the selection and dosage of chemicals used in a water treatment plant.

Q 21. Describe different sedimentation techniques used after flocculation.

Following flocculation, sedimentation techniques are employed to separate the formed flocs from the treated water. Several methods exist: Gravity sedimentation is the simplest method, utilizing settling basins or clarifiers where flocs settle under gravity. This is the most common method and is cost-effective. Dissolved air flotation (DAF) introduces tiny air bubbles into the water, which attach to the flocs, making them buoyant and rise to the surface for easy removal. DAF is suitable for removing lighter flocs or when high efficiency is required. Lamellar sedimentation uses inclined plates to enhance settling efficiency by providing larger surface areas for floc attachment and increasing the overall flow path. Lamellar clarifiers are space-efficient and require less floor area than traditional settling basins. The choice of sedimentation technique depends on several factors, including the size and nature of flocs, the available space, and the desired treatment efficiency. For instance, DAF might be preferred for treating wastewater with low concentrations of suspended solids, while gravity sedimentation remains widely used in large-scale potable water treatment plants due to its simplicity and cost-effectiveness.

Q 22. How does the presence of suspended solids impact flocculation and coagulation?

Suspended solids, essentially tiny particles in water, significantly affect both flocculation and coagulation. These processes aim to remove these solids, so their presence is a key factor. In coagulation, suspended solids provide surfaces for coagulant chemicals to attach to, initiating the destabilization of these particles. The more solids present, the more coagulant may be needed. Flocculation, which follows coagulation, relies on the gently aggregating these destabilized particles into larger, easier-to-remove flocs. The concentration and size distribution of suspended solids directly influence the effectiveness of this aggregation process. High concentrations of very fine particles can lead to smaller, less settleable flocs, requiring more effective flocculant and potentially longer retention times. Think of it like trying to glue together tiny grains of sand versus larger pebbles – the smaller grains are harder to stick together efficiently.

For example, in a wastewater treatment plant, high levels of suspended solids from industrial discharge might necessitate a higher coagulant dose and optimized flocculation conditions to achieve satisfactory effluent quality.

Q 23. Explain the role of polymers in enhanced flocculation.

Polymers play a crucial role in enhanced flocculation by acting as bridging agents between destabilized particles. These long-chain molecules have numerous active sites that can adsorb onto the surfaces of multiple particles simultaneously, effectively linking them together to form larger flocs. This bridging action is particularly important for smaller particles that may not readily aggregate on their own. Different polymer types, such as cationic, anionic, and non-ionic, exhibit different charge characteristics, making them suitable for various types of suspended solids. Cationic polymers, for instance, are commonly used to flocculate negatively charged particles found in many wastewater streams.

The molecular weight of the polymer also influences its effectiveness. Higher molecular weight polymers typically result in larger and more robust flocs, leading to better settling and improved solid-liquid separation. Imagine it like using long strands of yarn to bind together a collection of small buttons – the longer the yarn, the more buttons you can link effectively.

Q 24. What are the economic considerations related to flocculant and coagulant selection?

Economic considerations are paramount in flocculant and coagulant selection. The cost of the chemicals themselves is a major factor, but it’s not the sole determinant. The optimal choice balances chemical cost with operational costs such as: the required dosage, the impact on sludge volume (larger flocs may mean less sludge), and energy consumption (related to pumping and dewatering). For example, a more expensive, but highly efficient coagulant could lead to a lower overall cost due to decreased sludge handling, reduced energy consumption, and less frequent chemical addition.

Furthermore, the availability and transport costs of the chemicals should also be considered, especially for remote or geographically challenging locations. Life cycle analysis, considering the environmental impact of production, transportation, and disposal of chemicals, also plays an increasingly significant role in decision-making.

Q 25. How do you ensure compliance with regulatory standards related to water treatment?

Ensuring compliance with regulatory standards is critical in water treatment. This involves adhering to limits on residual chemicals, turbidity, and other water quality parameters set by relevant agencies (e.g., EPA in the US). A robust quality control program is necessary, involving regular monitoring of influent and effluent water quality, as well as the performance of the treatment process. This includes keeping meticulous records of chemical dosages, process parameters (pH, temperature), and test results.

Proper calibration and maintenance of analytical equipment are essential. We must also stay updated on evolving regulations and industry best practices. Regular internal audits and external inspections are vital to demonstrate compliance and identify areas for improvement. Non-compliance can lead to significant penalties, operational disruptions, and reputational damage.

Q 26. Describe your experience with troubleshooting flocculation and coagulation issues.

I’ve encountered numerous flocculation and coagulation challenges during my career. One instance involved a municipal wastewater treatment plant experiencing poor settling and high effluent turbidity. After a thorough investigation, we identified the cause to be fluctuating influent characteristics – sudden changes in pH and organic load. We addressed this by implementing a real-time monitoring system for influent parameters and a supervisory control and data acquisition (SCADA) system. This allowed for automated adjustments of coagulant and flocculant dosages based on the measured influent conditions, ensuring consistent treatment performance despite variability. The result was a significant improvement in effluent quality, reducing turbidity levels by over 50% and improving overall plant efficiency.

Q 27. What software or tools are you familiar with for data analysis in water treatment?

I’m proficient in using several software and tools for data analysis in water treatment. This includes statistical software packages like R and SPSS for analyzing experimental data, trend analysis, and process optimization. I also have experience with SCADA systems for real-time monitoring and control of water treatment processes, as well as dedicated water quality modeling software. Spreadsheet software, like Excel, is crucial for routine data management and analysis. Finally, familiarity with database management systems for storing and retrieving large datasets is essential for effective data analysis and reporting.

Q 28. Describe a time you optimized a water treatment process. What were the results?

In a previous role, I optimized the flocculation process at an industrial water treatment facility facing high operating costs. By carefully analyzing historical data, including chemical dosages, effluent quality, and operational parameters, I identified that the existing flocculation strategy was inefficient. Through systematic experimentation, we determined the optimal polymer type and dosage for different influent conditions. We also optimized the mixing intensity and flocculation time in the clarifier. The result was a 20% reduction in chemical costs, a 15% decrease in sludge volume, and a consistent improvement in effluent quality. This optimization resulted in significant cost savings and improved environmental performance.

Key Topics to Learn for Flocculant and Coagulant Optimization Interview

- Fundamentals of Coagulation and Flocculation: Understanding the underlying chemical and physical processes involved in destabilizing and aggregating colloidal particles.

- Types of Coagulants and Flocculants: Familiarize yourself with various chemical agents, their properties, and suitability for different applications (e.g., alum, ferric chloride, polyDADMAC).

- Jar Testing and its Applications: Master the principles and techniques of jar testing for determining optimal coagulant and flocculant dosages and identifying ideal mixing conditions.

- Influencing Factors on Coagulation and Flocculation: Understand how factors like pH, temperature, turbidity, and the characteristics of the treated water affect the efficiency of these processes.

- Process Optimization Techniques: Explore methods for optimizing the coagulation and flocculation process, including the use of advanced analytical techniques and data analysis.

- Practical Applications in Wastewater Treatment: Understand the role of coagulation and flocculation in various wastewater treatment processes, such as primary clarification, sludge thickening, and dewatering.

- Practical Applications in Water Treatment: Understand the role of coagulation and flocculation in various water treatment processes, such as removal of suspended solids and color.

- Troubleshooting and Problem-Solving: Develop your ability to diagnose and resolve common problems encountered during coagulation and flocculation processes. This includes understanding the impact of poor floc formation and inadequate settling.

- Regulatory Compliance and Standards: Be aware of relevant environmental regulations and industry standards pertaining to water and wastewater treatment.

- Advanced Techniques: Explore advanced concepts such as electrocoagulation, membrane filtration, and the use of polymers in enhanced coagulation and flocculation.

Next Steps

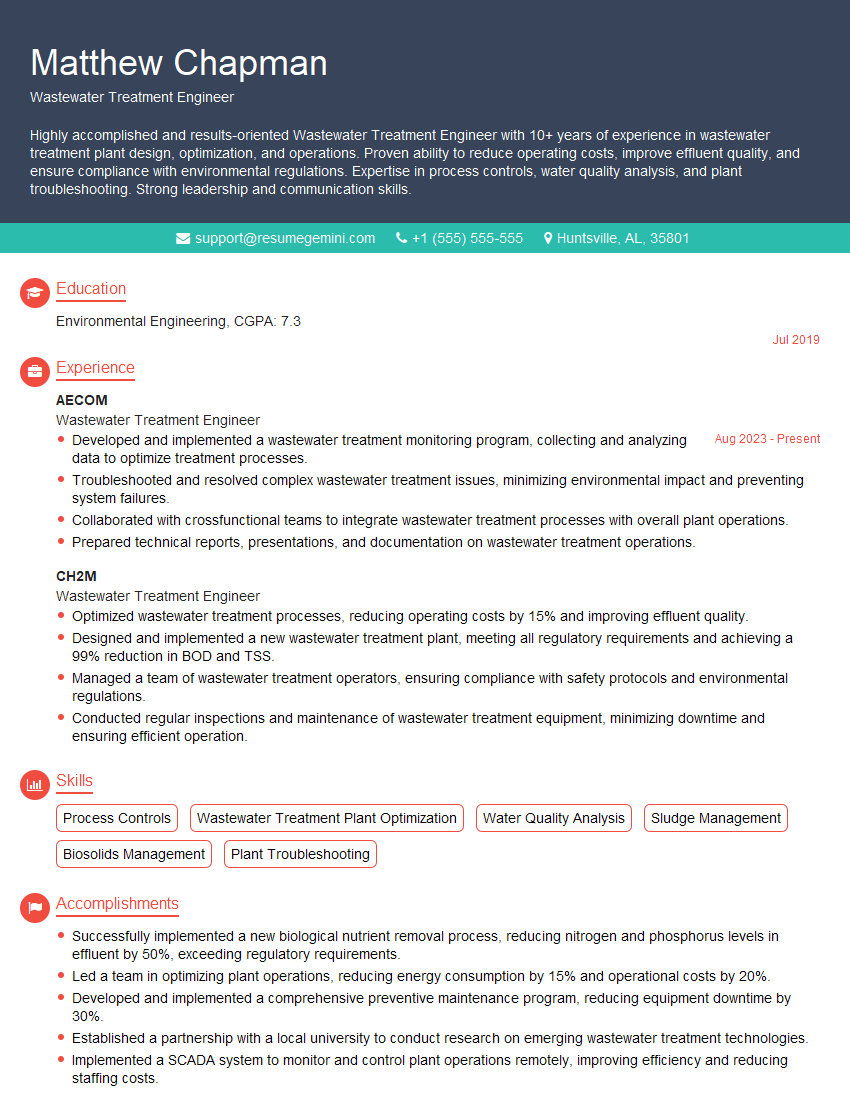

Mastering Flocculant and Coagulant Optimization is crucial for career advancement in water and wastewater treatment, environmental engineering, and related fields. It demonstrates a strong understanding of core principles and practical skills highly sought after by employers. To significantly boost your job prospects, creating an ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you craft a professional and effective resume tailored to the specific requirements of your target roles. Examples of resumes tailored to Flocculant and Coagulant Optimization are available to guide you, ensuring your qualifications shine through.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.