Are you ready to stand out in your next interview? Understanding and preparing for Floor Insulation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Floor Insulation Interview

Q 1. What are the different types of floor insulation materials?

Floor insulation materials vary greatly, each with its own strengths and weaknesses. The choice depends on factors like budget, climate, and the type of subfloor. Common options include:

- Rigid Foam Boards: Extruded polystyrene (XPS) and expanded polystyrene (EPS) are popular choices. They offer high R-values in a compact form, making them excellent for under-slab and above-joist installations. XPS is denser and more resistant to moisture, while EPS is less expensive but less durable.

- Batt Insulation: Fiberglass and mineral wool batts are readily available and easy to install between floor joists. Fiberglass is a cost-effective solution, while mineral wool provides better fire resistance and sound dampening.

- Loose-Fill Insulation: Materials like cellulose (recycled paper), fiberglass, and mineral wool can be blown into spaces between joists or poured into cavities. This is a good option for irregular spaces and hard-to-reach areas, providing excellent coverage.

- Spray Foam Insulation: Open-cell and closed-cell spray foam offer excellent air sealing and insulation properties. They can fill irregular cavities effectively and are suitable for both new construction and retrofit applications. However, they’re generally more expensive than other options.

- Reflective Insulation: This type, often made of foil-faced materials, reflects radiant heat. It’s not as effective as other options alone but can be used in conjunction with other materials to boost overall performance, especially in warmer climates.

Q 2. Explain the R-value and its importance in floor insulation.

The R-value represents a material’s resistance to heat flow. A higher R-value means better insulation. Think of it like this: a higher R-value is like a thicker, more robust winter coat – it keeps the heat in during winter and keeps the cool air in during summer. In floor insulation, a higher R-value translates to lower energy bills, increased comfort, and reduced risk of frost heave in colder climates. For example, an R-13 fiberglass batt will offer less insulation than an R-20 rigid foam board of the same area. Building codes often specify minimum R-values for floor insulation depending on the climate zone, so understanding and selecting the appropriate R-value is crucial for optimal performance and compliance.

Q 3. Describe the installation process for rigid foam board insulation.

Installing rigid foam board insulation is a relatively straightforward process, but attention to detail is crucial. Here’s a step-by-step guide:

- Prepare the Subfloor: Ensure the subfloor is clean, dry, and level. Any debris or unevenness will impact insulation performance.

- Measure and Cut: Accurately measure the areas to be insulated and cut the foam boards to size using a utility knife or specialized foam cutter. Ensure snug fit but avoid excessive compression.

- Install Vapor Barrier (if needed): If a vapor barrier is required, install it according to manufacturer instructions, usually before the insulation. Overlap seams and seal them with tape.

- Install Insulation Boards: Start installing the boards, ensuring tight fitting joints. Stagger seams to avoid creating continuous thermal bridges.

- Fasten Boards: Secure the boards with appropriate fasteners, such as adhesive or mechanical fasteners, following manufacturer recommendations. Over-fastening can damage the boards.

- Seal Joints and Gaps: Seal any gaps or joints between the boards using a compatible sealant to prevent air leakage. This is crucial for maximizing the R-value.

- Install Finishing Materials: Install any additional layers, such as a plywood subfloor or flooring material, over the insulation.

Remember to always wear appropriate personal protective equipment (PPE) when working with insulation materials.

Q 4. How do you address vapor barriers in floor insulation?

Vapor barriers are crucial in preventing moisture from entering the insulation and causing damage or mold growth. Their necessity depends greatly on climate and the location of the insulation (above or below grade). In colder climates, a vapor barrier is usually placed on the warm side of the insulation – typically the interior side in floor applications. This prevents warm, moist interior air from condensing within the insulation. In warmer climates, a vapor barrier might not be necessary, or it might be placed on the exterior side to manage outside moisture. Using the wrong type or location of vapor barrier could worsen issues, so it’s essential to consider your specific climate and building design. Always consult local building codes and manufacturer’s instructions.

For example, in a cold climate, a polyethylene sheet is often used as a vapor barrier installed beneath the subfloor, preventing moisture from entering the insulation below.

Q 5. What are the best practices for insulating concrete floors?

Insulating concrete floors presents unique challenges due to their mass and thermal conductivity. Best practices involve addressing both thermal and moisture control:

- Insulation Placement: For optimal results, consider installing insulation below the concrete slab (underslab insulation) during construction. This significantly reduces heat loss through the ground.

- Material Selection: High-R value rigid foam boards (like XPS) are excellent for underslab insulation due to their high compressive strength and resistance to moisture. A vapor retarder is often placed between the foam and the concrete.

- Moisture Management: A well-functioning drainage system and a vapor retarder or barrier are crucial to prevent moisture intrusion into the insulation. This often involves a layer of gravel below the insulation.

- Perimeter Insulation: Pay special attention to the perimeter of the slab, as this is a major area for heat loss. Extend the insulation around the edges of the slab to minimize thermal bridging.

- Above-Slab Insulation (Retrofit): If underslab insulation isn’t feasible, consider installing insulation above the slab (e.g., rigid foam boards followed by a floating floor). This is less effective than underslab insulation but can still offer significant improvement.

Q 6. How do you choose the appropriate insulation thickness for a given application?

Choosing the right insulation thickness depends on several factors including climate zone, desired R-value, budget, and available space. Building codes often specify minimum R-values for different climate zones. You can use online calculators or consult building codes to determine the R-value needed to meet energy efficiency standards for your region. Once the required R-value is known, you can select an insulation material with the appropriate thickness using the material’s R-value per inch. For example, if you need an R-20 floor insulation and a particular fiberglass batt provides an R-3 per inch, you’ll need approximately 6.7 inches of that material.

Often, there’s a balance between cost and performance. Using a higher R-value material means less thickness is needed, which can save space and sometimes money, depending on material costs. However, sometimes thicker lower-cost insulation becomes more economical.

Q 7. Explain the difference between batt insulation and loose-fill insulation for floors.

Batt and loose-fill insulations both aim to reduce heat transfer, but they differ significantly in their application and characteristics:

- Batt Insulation: Comes in pre-cut sections (batts or rolls) easily fitted between floor joists. It’s relatively easy to install but may leave gaps if not properly fitted. Fiberglass batts are a cost-effective option, while mineral wool offers better fire and sound resistance.

- Loose-Fill Insulation: Materials like cellulose, fiberglass, or mineral wool are blown or poured into spaces. This method is excellent for filling irregular spaces and hard-to-reach areas, achieving complete coverage. However, it requires specialized equipment for installation and may be slightly more expensive than batts.

The choice between the two often depends on the accessibility of the space to be insulated. If you have easily accessible, uniform spaces between floor joists, batts are likely a more convenient and cost-effective option. If you have irregular spaces or difficult-to-reach areas, loose-fill insulation is a better choice, despite the higher cost and specialized equipment requirements.

Q 8. Describe the challenges of insulating crawl spaces.

Insulating crawl spaces presents unique challenges due to their often-confined, damp, and poorly ventilated nature. Moisture is a significant concern, as it can lead to mold growth and reduce the effectiveness of insulation. Access can be difficult, requiring careful maneuvering of materials and potentially the use of specialized equipment. Additionally, uneven terrain and the presence of plumbing and wiring can complicate the installation process.

- Moisture Control: High humidity promotes mold, so proper vapor barriers and ventilation are critical. We often use dehumidifiers during and after installation to mitigate this.

- Pest Control: Crawl spaces can be havens for pests. Insulation needs to deter rodents and insects, often requiring pest-resistant materials or barriers.

- Uneven Ground: The uneven ground makes it difficult to create a uniform insulation layer. Solutions include using adjustable supports and filling gaps with appropriate materials.

- Limited Access: Working in a tight space is physically demanding and requires additional safety precautions.

Q 9. How do you deal with uneven subflooring during insulation installation?

Uneven subflooring is a common problem that can significantly impact the effectiveness of floor insulation. Ignoring it can lead to uneven heat distribution and potentially structural issues. We address this through several methods:

- Leveling the Subfloor: For minor unevenness, a self-leveling compound can create a smooth surface before insulation installation. This ensures consistent insulation depth.

- Adding a Furring Strip System: For more significant irregularities, a furring strip system — wooden or metal strips attached to the joists — raises the subfloor to a uniform level, creating an even space for insulation.

- Using Insulation That Adapts to Uneven Surfaces: Certain insulation types, like loose-fill cellulose or spray foam, can conform to irregular surfaces more effectively than rigid foam boards.

The choice of method depends on the severity of the unevenness, budget, and the type of insulation being used. A proper assessment of the subfloor is crucial before deciding on a solution.

Q 10. What safety precautions should be taken during floor insulation installation?

Safety is paramount during floor insulation installation. Crawl spaces are confined areas posing potential hazards. Here’s a comprehensive safety checklist:

- Proper Ventilation: Ensure adequate ventilation to prevent oxygen depletion and build-up of hazardous fumes from certain insulation materials.

- Respiratory Protection: Wear a respirator appropriate for the insulation material to avoid inhaling dust or fibers.

- Eye Protection: Safety glasses protect eyes from flying debris or irritants.

- Head Protection: A hard hat is essential to prevent head injuries, particularly in low-ceiling crawl spaces.

- Gloves: Wear appropriate gloves to protect hands from cuts, abrasions, or chemical reactions with insulation materials.

- Fall Protection: Use appropriate fall protection equipment if working at heights or on unstable surfaces.

- Fire Safety: Some insulation materials are flammable. Take precautions to avoid fire hazards, such as using appropriate tools and having a fire extinguisher readily available.

- Working in Pairs: Always work in pairs, especially in confined spaces, for added safety and assistance.

Q 11. How do you ensure proper air sealing around floor insulation?

Proper air sealing around floor insulation is crucial to maximizing its effectiveness. Air leaks defeat the purpose of insulation by allowing conditioned air to escape and outside air to infiltrate. We use a multi-pronged approach:

- Caulk and Sealant: Apply caulk or sealant to all gaps and cracks around pipes, wiring, and other penetrations through the floor.

- Weatherstripping: Use weatherstripping around access panels and other openings to seal any air gaps.

- Spray Foam: Spray foam insulation is excellent for sealing hard-to-reach areas and irregular gaps, providing a continuous air barrier.

- Vapor Barriers: Install a continuous vapor barrier over the insulation to prevent moisture migration into the insulation. This helps maintain its insulating properties and prevents mold growth.

- Inspection: After installation, a thorough inspection should be performed to identify and address any remaining air leaks. Thermal imaging cameras can be beneficial in identifying these leaks.

Air sealing is just as important, if not more so, than the insulation itself. A well-sealed space with even a modest amount of insulation is often far superior to a poorly sealed space with significantly more.

Q 12. Explain the impact of thermal bridging on floor insulation effectiveness.

Thermal bridging occurs when heat travels easily through a material that conducts heat more readily than the surrounding insulation. In floor insulation, this could be the joists, pipes, or wiring. This effectively creates a path for heat to flow directly through the insulation layer, reducing its overall effectiveness. Imagine a bridge over a river, the water (heat) easily flows through it rather than flowing around.

To mitigate thermal bridging:

- Insulate Joists: Insulate the joist edges and sides with rigid foam insulation, effectively creating a thermal break.

- Insulate Pipes and Wiring: Wrap pipes and wiring with insulation designed for those purposes.

- Choose High-R-Value Insulation: Although it won’t completely eliminate bridging, higher R-value insulation will lessen its impact because more resistance to heat flow is present.

Reducing thermal bridging can significantly improve the insulation’s R-value and the overall energy efficiency of the building.

Q 13. What are some common mistakes to avoid when installing floor insulation?

Avoiding common mistakes is key to successful floor insulation installation. Some frequent errors include:

- Insufficient Air Sealing: Failing to properly seal gaps and cracks significantly compromises the insulation’s effectiveness. Remember the analogy of a leaky bucket; no matter how much water you add, it will eventually all run out.

- Inadequate Vapor Barrier: An improperly installed or missing vapor barrier can lead to moisture accumulation in the insulation, causing mold growth and reduced insulation performance.

- Ignoring Thermal Bridging: Failing to address thermal bridging points can significantly reduce the overall R-value of the insulation.

- Incorrect Insulation Depth: Using inadequate insulation depth for the climate zone will not provide the intended level of energy efficiency.

- Compressing Insulation: Compressing insulation materials reduces their R-value, diminishing their effectiveness. This commonly happens with batt insulation when too tightly packed.

A thorough understanding of building codes, best practices, and the specific insulation materials chosen is crucial to avoiding these mistakes.

Q 14. How do you calculate the amount of insulation needed for a project?

Calculating the required amount of insulation involves determining the area to be insulated and the desired R-value. Here’s a step-by-step approach:

- Measure the area: Accurately measure the floor area that needs insulation. For crawl spaces, this includes the area between the joists.

- Determine the required R-value: Consult local building codes and climate zone guidelines to determine the minimum R-value recommended for your region. Higher R-values provide better insulation.

- Calculate the needed insulation thickness: Use the R-value and the type of insulation to determine the required thickness. This information is typically available from the manufacturer’s specifications.

- Calculate the volume or area: Depending on the type of insulation (e.g., batt, loose-fill), calculate the volume (for loose-fill) or the total surface area to cover (for batts).

- Account for waste: Add a percentage (usually 5-10%) to the calculated amount to account for cuts, waste, and fitting.

- Convert to purchase units: Insulation is sold in various units (e.g., square feet, cubic feet, per bag). Convert the calculated volume or area into the relevant units for purchasing.

For example: If you have a 100 sq ft floor area and require R-15 insulation with batts that provide R-15 per 6 inches, you would need enough batts to cover 100 sq ft, taking into account waste.

Q 15. Describe your experience with different insulation fastening methods.

Insulation fastening methods depend heavily on the type of insulation and the subfloor construction. My experience spans a wide range, from simple methods for batt insulation to more complex techniques for rigid foam boards.

- Batt Insulation: This commonly uses staples or adhesive for attachment to joists. Staples are quick but can damage the insulation if not applied carefully. Adhesives offer better hold but require careful application to avoid clumping and uneven distribution.

- Rigid Foam Boards: These often require mechanical fasteners like screws or nails for a secure fit, especially in high-traffic areas or where added strength is needed. The type and size of fastener depend on the foam’s thickness and density. Adhesives are sometimes used in conjunction with mechanical fasteners for superior bonding.

- Loose-Fill Insulation: This doesn’t require fastening in the traditional sense; it’s poured or blown into cavities. The key here is ensuring proper fill depth and avoiding settling, often achieved with appropriate barriers and careful installation techniques.

- Spray Foam Insulation: This adheres directly to the substrate, creating a seamless air seal. No additional fastening is required, but proper surface preparation is crucial for adhesion.

In every case, the best method depends on the specific project requirements, balancing speed, cost, and long-term performance. I always choose the method that provides the most secure and energy-efficient installation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental impacts of different floor insulation materials?

The environmental impact of floor insulation varies significantly depending on the material used. Some are more sustainable than others, considering their production, transportation, and end-of-life impacts.

- Fiberglass Batt Insulation: While relatively inexpensive and effective, fiberglass manufacturing uses energy and releases some airborne particles. Recycling options are limited.

- Mineral Wool Insulation: Often made from recycled materials, mineral wool boasts better environmental credentials than fiberglass due to its lower embodied carbon. It’s also non-combustible.

- Cellulose Insulation: Made from recycled paper, cellulose is a highly sustainable option with excellent insulation properties. Its production uses less energy compared to other materials.

- Rigid Foam Insulation (Polyurethane and Polyisocyanurate): These have high insulating values but can have a larger carbon footprint during production. Some manufacturers are focusing on using bio-based materials to lessen this impact.

- Sheep’s Wool Insulation: A completely renewable and biodegradable option, sheep’s wool provides excellent insulation and moisture regulation. However, its availability and cost might be higher.

A life-cycle assessment (LCA) is the best way to compare the environmental impact of different insulation materials holistically, considering every stage from production to disposal.

Q 17. How do you handle moisture issues during floor insulation installation?

Moisture is the enemy of floor insulation. It can reduce its effectiveness, lead to mold growth, and damage the subfloor. My approach involves a multi-pronged strategy:

- Vapor Barriers: A properly installed vapor barrier is essential to prevent moisture migration from below. The location of the vapor barrier—above or below the insulation—depends on the climate and construction details. I carefully consider the dew point to determine the optimal placement.

- Ventilation: Adequate ventilation in the crawl space or under the floor is crucial to prevent moisture buildup. This often involves installing vents and ensuring proper air circulation.

- Moisture-Resistant Insulation: Choosing moisture-resistant insulation is vital. Some materials, such as closed-cell spray foam, are inherently resistant to moisture. Others might benefit from additional protection through a vapor barrier.

- Drainage: Proper grading and drainage around the building are essential to prevent water from accumulating near the foundation and entering the crawl space.

Before starting any floor insulation project, I thoroughly inspect the area for signs of moisture problems and address any issues before installing insulation. It is important to remember that prevention is always better than cure.

Q 18. What are the benefits of using reflective insulation in floors?

Reflective insulation, often made of foil-faced materials, works differently than traditional insulations. It doesn’t trap air; instead, it reflects radiant heat back to its source. In floors, this can be beneficial in several ways:

- Reduced Heat Transfer: Reflective insulation helps reduce heat transfer between the floor and the ground below, especially effective in warmer climates where radiant heat from the ground is significant.

- Improved Comfort: By reducing radiant heat transfer, reflective insulation can contribute to a more comfortable living space, especially during summer months.

- Ease of Installation: Reflective insulation is often easier and quicker to install compared to bulky batt or loose-fill insulations. This can lead to lower labor costs.

However, reflective insulation is not a complete solution on its own. It’s most effective when combined with other types of insulation, such as rigid foam, to create a multi-layered system for better thermal performance. It shines in reducing radiant heat, but traditional insulation handles conductive and convective heat transfer better.

Q 19. How do you address soundproofing concerns during floor insulation?

Addressing soundproofing during floor insulation requires selecting materials with good sound-dampening properties and employing proper installation techniques.

- Mass-Loaded Vinyl (MLV): This dense, flexible material is highly effective in reducing impact noise transmission through the floor. It’s often installed beneath the floor covering.

- Resilient Channels: These metal channels, installed between the joists, decouple the subfloor from the joists, reducing noise transmission. They work very well with drywall or other similar ceiling materials.

- Dense Insulation Materials: Materials like mineral wool and closed-cell spray foam offer superior sound insulation properties compared to less dense materials.

- Layered Approach: Combining multiple soundproofing strategies—MLV, resilient channels, and dense insulation—offers optimal performance. For example, using MLV under a floating floor and dense insulation in the joist bays creates a far better sound barrier.

I always consult with the client to understand their noise reduction goals and choose the most effective and practical approach within their budget. It’s crucial to remember that addressing soundproofing requires a holistic approach, considering not only the insulation but also the floor and ceiling constructions.

Q 20. Describe your experience with different types of adhesives used in insulation.

My experience includes working with a variety of adhesives designed for floor insulation applications. The selection depends on the type of insulation and substrate:

- Contact Adhesives: These are often used for installing rigid foam boards. They provide a strong bond but require precise application and careful alignment to avoid creating gaps.

- Spray Adhesives: These can be useful for smaller projects or for securing batt insulation in certain areas. Good ventilation is crucial during application to minimize fumes.

- Water-Based Adhesives: Some water-based adhesives offer good performance and are more environmentally friendly than solvent-based options. They’re generally used for lighter insulation materials.

I always follow the manufacturer’s recommendations when choosing and using adhesives, ensuring proper surface preparation and curing time for optimal results. Safety is paramount, and appropriate safety precautions are always taken when handling adhesives.

Q 21. What tools and equipment are essential for efficient floor insulation?

Efficient floor insulation requires a range of tools and equipment, depending on the project’s scope and insulation type:

- Measuring Tools: Tape measures, levels, and moisture meters are essential for accurate measurements and assessments.

- Cutting Tools: Utility knives, circular saws (for rigid foam), and tin snips (for reflective insulation) are commonly used.

- Fastening Tools: Staple guns, drills, and screw guns are needed for mechanical fasteners. Caulk guns are essential for sealing gaps.

- Protective Gear: Safety glasses, gloves, and respirators are essential when working with insulation and adhesives.

- Specialized Equipment: For loose-fill insulation, a blower machine is required. For spray foam, a specialized spray foam rig is essential.

Properly maintaining and using this equipment is paramount for efficiency, safety, and achieving a high-quality insulation installation. Regular inspection and calibration of tools ensure accurate measurements and trouble-free operation. A clean and organized workspace improves efficiency and reduces the risk of errors.

Q 22. Explain the importance of proper ventilation in floor insulation systems.

Proper ventilation in floor insulation systems is crucial for preventing moisture buildup, which can lead to mold growth, structural damage, and reduced insulation effectiveness. Think of it like this: your floor insulation is a blanket keeping heat in, but if you don’t allow moisture to escape, it gets trapped, just like sweat under a poorly ventilated blanket.

Adequate ventilation is achieved through several methods, including:

- Vapor barriers: These strategically placed membranes prevent moisture from migrating into the insulation from the warmer side (typically the living space). They need to be installed correctly to be effective, as any tears or gaps will negate their benefit.

- Air gaps: Leaving a small air gap between the insulation and the subfloor allows air circulation to help reduce moisture. This is particularly important in crawl spaces.

- Vents: Properly sized and located vents in crawl spaces and basements are essential for air exchange, allowing moist air to escape and drier air to enter.

Ignoring ventilation can lead to significantly higher energy bills, health problems due to mold, and costly repairs. A well-ventilated system ensures the longevity and effectiveness of your floor insulation.

Q 23. How do you determine the appropriate insulation for different climate zones?

Determining the appropriate insulation for different climate zones requires considering several factors, most importantly the climate’s heating and cooling degree days (HDD and CDD). HDDs represent the number of days a year that heating is needed, while CDDs represent cooling needs. The higher the HDD, the more insulation is needed to retain heat. Conversely, higher CDDs might indicate a need for insulation to minimize heat gain.

We also consider other elements such as:

- Local building codes: Many areas have specific insulation requirements based on their climate zone.

- Building type: A well-insulated new build may require less insulation than retrofitting an older structure with poor thermal performance.

- Budget considerations: Different insulation materials vary in price and performance. A cost-benefit analysis helps to find the most effective solution given the budget.

- Insulation R-value: This value indicates the thermal resistance of the insulation. Higher R-values mean better insulation properties. The required R-value will increase with colder climates.

For instance, a home in northern Canada will require a significantly higher R-value (e.g., R-30 or higher) for floor insulation compared to a home in southern California (which might only need R-13 or R-19). I always consult local building codes and utilize energy modeling software to determine optimal insulation for each specific project.

Q 24. What are the common building codes and regulations related to floor insulation?

Building codes and regulations regarding floor insulation vary significantly depending on location (national, state, or local level), but common themes include:

- Minimum R-values: Codes often specify minimum R-values required for floor insulation in different climate zones.

- Moisture control: Regulations often address the use of vapor barriers and ventilation to prevent moisture problems.

- Fire safety: Insulation materials must meet fire safety standards, typically specified in codes.

- Installation methods: Codes sometimes detail acceptable installation techniques to ensure proper performance and avoid safety hazards.

- Accessibility requirements: Codes address accessibility to crawlspaces and other areas where insulation is installed, particularly for maintenance and inspection.

Staying current with relevant codes is critical. I regularly consult the International Energy Conservation Code (IECC) and local jurisdiction-specific building codes to ensure compliance. Non-compliance can result in project delays, fines, and even safety risks.

Q 25. Describe your experience with troubleshooting insulation installation problems.

Troubleshooting insulation installation problems is a regular part of my work. A common issue is uneven insulation leading to cold spots. This is often due to improper installation, gaps in the insulation, or insufficient material. My approach involves a systematic process:

- Visual Inspection: Carefully examine the installed insulation for gaps, settling, or areas where the material is compressed. I use thermal imaging cameras in many cases to detect these problems quickly and efficiently.

- Moisture Check: Assess the moisture content of the insulation and surrounding materials. Excess moisture points to potential ventilation issues.

- Air Leakage Test: Use blower-door testing to identify air leaks in the floor assembly, which can compromise insulation effectiveness.

- Material Analysis: Verify that the installed insulation material meets the specified R-value and that the installation aligns with the manufacturer’s specifications.

For example, in one project, we found that cold spots were due to settling of the loose-fill insulation over time. We addressed the issue by compacting the existing insulation and adding more material to restore the desired R-value. Addressing these issues promptly can prevent costly future repairs and energy losses.

Q 26. Explain the different methods for assessing the effectiveness of floor insulation.

Several methods assess the effectiveness of floor insulation:

- Thermal Imaging: A thermal camera identifies temperature differences across the floor surface, pinpointing areas with inadequate insulation.

- Blower Door Testing: This method measures air leakage, which directly impacts insulation performance. High air leakage leads to heat loss even with adequate insulation.

- Energy Audits: Comprehensive energy audits analyze the overall energy performance of the building, including the effectiveness of floor insulation. They often involve analyzing energy bills and performing in-situ measurements.

- In-situ Measurements: Using probes to measure the temperature gradient across the insulation to calculate the actual R-value. This directly determines the insulation’s effectiveness.

In a recent project, thermal imaging revealed areas with lower temperatures despite seemingly properly installed insulation. Further investigation revealed small gaps around pipes that were allowing air infiltration and heat loss. Once sealed, the thermal imaging showed a significant improvement.

Q 27. How do you manage a team during a floor insulation project?

Managing a team during a floor insulation project requires clear communication, organization, and a focus on safety. I employ a collaborative approach, involving team members in planning and problem-solving:

- Pre-Project Briefing: I provide clear instructions, highlighting safety procedures and installation techniques specific to the project.

- Regular Check-ins: I maintain open communication, ensuring that everyone understands their roles and responsibilities. Addressing any questions or concerns promptly prevents misunderstandings and delays.

- Quality Control: I conduct regular quality checks throughout the process, ensuring that work meets standards and codes.

- Safety Emphasis: Maintaining a safe working environment is paramount. I use safety talks, provide proper PPE, and enforce safety regulations diligently.

A positive team dynamic leads to better efficiency and fewer errors. I foster a collaborative spirit where everyone feels empowered to contribute and share ideas. For example, in a recent project, a team member suggested a more efficient insulation installation technique that significantly reduced installation time without compromising quality.

Q 28. Describe your experience with working in confined spaces during insulation installation.

Working in confined spaces, such as crawl spaces, requires meticulous safety precautions. My experience includes:

- Confined Space Entry Procedures: I strictly adhere to confined space entry procedures, including atmospheric testing for oxygen levels, flammable gases, and other hazards.

- Proper Ventilation: Ensuring adequate ventilation is crucial to prevent oxygen depletion and the accumulation of harmful gases.

- Personal Protective Equipment (PPE): Team members use appropriate PPE, including respirators, safety harnesses, and head protection.

- Emergency Procedures: Clear emergency procedures are in place, including communication protocols and rescue plans.

- Regular Breaks and Monitoring: Frequent breaks are scheduled to prevent heat stress and fatigue. Team members monitor each other for any signs of distress.

In one instance, we discovered a potential carbon monoxide leak in a crawl space. Our established safety procedures allowed us to immediately stop work, ventilate the area, and investigate the source of the leak before resuming work. Our proactive safety measures prevent accidents and ensure the well-being of my team.

Key Topics to Learn for Floor Insulation Interview

- Types of Floor Insulation: Understanding the properties and applications of various insulation materials (e.g., fiberglass, foam boards, cellulose, radiant barriers). Consider their R-values and thermal performance in different climates.

- Installation Methods: Familiarize yourself with different installation techniques for various insulation types, including considerations for existing flooring, subflooring conditions, and moisture barriers. Think about best practices for achieving optimal performance and minimizing air gaps.

- Building Codes and Regulations: Know the relevant building codes and regulations pertaining to floor insulation in your area. Understanding energy efficiency standards and compliance is crucial.

- Moisture Management: Master the principles of moisture control in floor assemblies. Learn how to prevent condensation, water damage, and the growth of mold and mildew within the insulated space.

- Sound Insulation: Explore the role of floor insulation in reducing noise transmission. Understand the concepts of sound absorption and transmission loss.

- Sustainability and Environmental Impact: Discuss the environmental considerations related to different insulation materials and their lifecycle assessment. Highlight sustainable and eco-friendly options.

- Cost-Effectiveness and ROI: Analyze the cost-benefit analysis of different insulation solutions. Be able to explain the return on investment (ROI) for homeowners and contractors.

- Troubleshooting and Problem Solving: Practice identifying and solving common problems encountered during floor insulation installation, such as uneven surfaces, air leaks, and moisture issues.

Next Steps

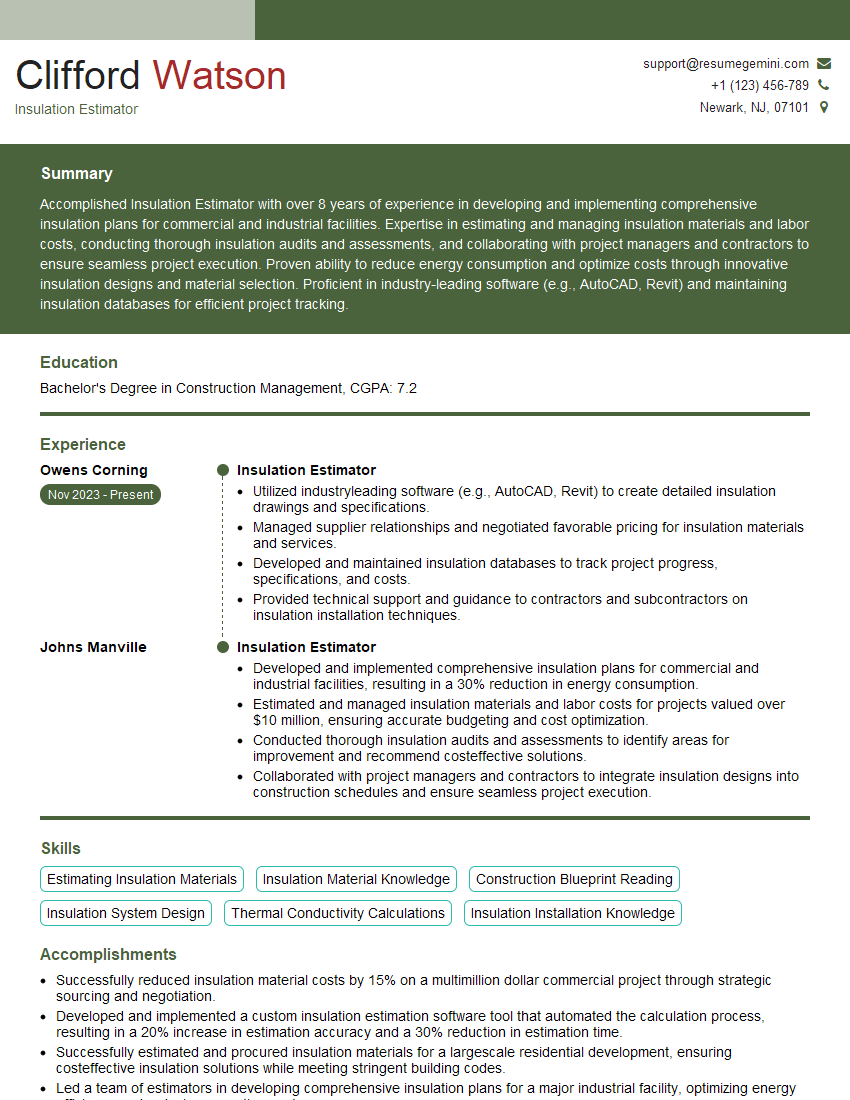

Mastering floor insulation techniques opens doors to rewarding career opportunities in construction, energy efficiency, and home improvement. A strong understanding of these concepts significantly enhances your value to potential employers. To maximize your job prospects, it’s essential to create a compelling and ATS-friendly resume that highlights your skills and experience. Use ResumeGemini to build a professional resume that showcases your expertise in Floor Insulation. ResumeGemini provides examples of resumes tailored to this specific field to help you create a standout application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.