Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Gang Mower Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Gang Mower Operation Interview

Q 1. Describe the different types of gang mowers and their applications.

Gang mowers come in various types, each suited for different applications. The most common distinction is between pull-type and self-propelled models. Pull-type gang mowers are towed behind a tractor and are ideal for large, open fields requiring high mowing capacity. Their multiple cutting units allow for wider swaths and increased efficiency. Self-propelled gang mowers offer greater maneuverability, especially in tighter spaces or around obstacles. They are commonly used in situations where a tractor might be cumbersome, such as maintaining sports fields or landscaping.

- Pull-Type: Best for large, flat areas; high mowing capacity; requires a tractor.

- Self-Propelled: Greater maneuverability; suitable for smaller areas and varied terrain; often used for landscaping or sports field maintenance.

- Rotary Gang Mowers: Utilize rotating blades for cutting. These are very common and widely adaptable.

- Flail Gang Mowers: Use flailing hammers instead of blades, offering advantages in dealing with rough terrain and dense vegetation, at the cost of a less clean cut.

The choice depends heavily on the terrain, the size of the area to be mowed, and the desired level of precision. For instance, a large golf course would benefit from a pull-type gang mower with many cutting units for high speed and wide coverage, while a park with intricate landscaping might require a more maneuverable self-propelled model.

Q 2. Explain the pre-operation checks you perform on a gang mower.

Pre-operation checks are critical for safe and efficient gang mower operation. Think of it as a pre-flight checklist for a plane – it ensures everything is in working order before you start. My routine includes:

- Visual Inspection: Checking for any loose bolts, damaged blades, or debris around the mower. I carefully examine the cutting units for any signs of wear or damage.

- Fluid Levels: Checking and topping off engine oil, hydraulic fluid (if applicable), and coolant levels. Low fluids can lead to overheating and breakdowns.

- Blade Sharpness: Dull blades lead to poor cuts and can damage the mower itself. I regularly check and sharpen or replace blades as needed. This is essential for a clean, even cut.

- Safety Mechanisms: Testing the PTO (Power Take-Off) engagement and disengagement, safety switches, and brakes to ensure they function correctly. This is a matter of safety for the operator and any bystanders.

- Tire Pressure: Ensuring proper tire inflation for optimal traction and performance. Underinflated tires can lead to poor handling and damage to the mower.

Failing to perform these checks can lead to accidents, inefficient mowing, and costly repairs. A few minutes spent on this preventative maintenance saves hours of headaches later.

Q 3. How do you adjust the cutting height on a gang mower?

Adjusting cutting height varies depending on the gang mower model, but generally involves adjusting the height of the cutting units. This is typically done using a series of levers, wheels, or a hydraulic system. Some mowers have individual adjustments for each cutting unit, allowing for precise control across the width of the cut.

- Lever Adjustments: Manually adjusting levers to raise or lower the cutting decks. This method is usually found in simpler models.

- Wheel Adjustments: Turning wheels or knobs to change the height. This mechanism provides a quick, precise way to alter the cutting height.

- Hydraulic Adjustments: Using a hydraulic system to adjust height. This is common in larger, more sophisticated models. It often offers finer and more automated control.

Before making any adjustments, it’s crucial to refer to the operator’s manual for specific instructions. Incorrect adjustments can lead to uneven cuts or damage to the mower.

For example, when mowing a steep hillside, one might adjust the cutting height on the uphill side slightly higher to prevent scalping.

Q 4. What are the safety procedures for operating a gang mower?

Safety is paramount when operating a gang mower. My safety procedures always include:

- Pre-Operation Checks (as previously described): Ensuring the mower is in good working condition is the first step.

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including hearing protection, safety glasses, sturdy work boots, and long pants to protect against flying debris and injuries.

- Area Assessment: Carefully inspecting the area to be mowed for any obstacles, such as rocks, holes, or debris that could damage the mower or cause an accident.

- Bystander Awareness: Keeping bystanders at a safe distance from the operating mower. This is crucial to prevent injuries.

- Safe Operating Speed: Maintaining a safe and controlled speed appropriate for the terrain. Avoid jerky movements.

- Proper Shut-Down Procedures: Following the correct shutdown procedure, ensuring the PTO is disengaged and the engine is completely shut off before exiting the machine or performing maintenance.

Ignoring these procedures can result in serious accidents. I always treat safety as the top priority.

Q 5. How do you identify and address common gang mower malfunctions?

Identifying and addressing malfunctions requires a systematic approach. It starts with careful observation and listening.

- Uneven Cutting: This could indicate dull blades, improper cutting height adjustment, or problems with the gearbox.

- Mower Vibrating Excessively: Possible causes include loose belts, unbalanced blades, or worn bearings.

- Engine Problems: Difficulty starting, stalling, or unusual noises could point to fuel, ignition, or engine wear issues.

- Hydraulic Issues (if applicable): Leaks, slow response, or no response indicate problems with the hydraulic system itself.

My troubleshooting strategy involves:

- Identify the symptom: Precisely define the problem.

- Check the obvious: Inspect for loose parts, low fluids, or damaged components.

- Consult the manual: The operator’s manual provides troubleshooting guides and diagrams.

- Isolate the problem: Systematically check each potential cause to pinpoint the exact issue.

- Repair or replace: Fix the problem by repairing or replacing the faulty component.

If the problem persists, seeking professional help is always a good option.

Q 6. Describe your experience with gang mower maintenance and repair.

My experience with gang mower maintenance and repair spans several years. I’ve performed routine maintenance tasks such as oil changes, blade sharpening, belt replacement, and cleaning. I’m also proficient in diagnosing and repairing more complex problems, including hydraulic system leaks, gearbox issues, and engine repairs. I’ve learned the importance of preventative maintenance and have consistently found that proactive measures significantly reduce downtime and extend the life of the equipment. For example, regular blade sharpening not only improves cutting quality but also reduces stress on the entire mowing system.

I regularly consult service manuals and have access to parts suppliers and knowledgeable mechanics when facing more challenging repairs. Hands-on experience coupled with a methodical approach has been key to my success in maintaining and repairing gang mowers effectively and efficiently.

Q 7. How do you handle challenging terrain while operating a gang mower?

Challenging terrain demands careful and skilled operation. My approach involves:

- Slow and Steady Speed: Reducing speed significantly on inclines, uneven ground, and rough patches. This prevents the mower from tipping or getting stuck.

- Proper Weight Distribution: Ensuring the weight of the mower is evenly distributed to maintain stability. This is particularly crucial on slopes.

- Smooth Operation: Avoiding jerky movements or sudden changes in direction. Smooth, controlled actions help maintain balance and prevent accidents.

- Observation and Adjustment: Constantly observing the terrain and adjusting the mower’s position and speed as needed to navigate challenging conditions.

- Using the Right Equipment: Selecting the appropriate gang mower model for the terrain. Some terrains might require a different type of gang mower, such as a flail mower for rough conditions.

I’ve learned through experience that caution and precision are paramount when working in difficult conditions. Safety must never be compromised.

Q 8. What is your experience with different types of cutting blades?

Gang mowers utilize various cutting blade types, each with its strengths and weaknesses. My experience encompasses high-lift blades, low-lift blades, and mulching blades. High-lift blades excel at creating a clean cut, leaving behind a neatly trimmed surface, ideal for formal lawns or areas requiring a precise finish. Think of them as the ‘scalpel’ of the gang mower world. Low-lift blades, on the other hand, are better suited for rougher terrain or taller grasses, offering a more aggressive cutting action. They’re more like the ‘shears’ in our toolbox. Mulching blades, my personal favorite for many applications, finely chop the grass clippings, returning them to the lawn as natural fertilizer. This reduces the need for bagging and contributes to a healthier, greener lawn – the ‘blender’ option for efficient lawn care.

The choice of blade depends heavily on the grass type, the desired finish, and the overall condition of the mowing area. I’ve found that understanding the nuances of each blade type is crucial for achieving optimal performance and minimizing wear and tear on the equipment.

Q 9. How do you ensure the safety of others while operating a gang mower?

Safety is paramount in gang mower operation. Before starting any job, I conduct a thorough pre-operation inspection of the equipment, ensuring all guards are in place and functioning correctly. I also visually check the area for obstacles, such as rocks, debris, or hidden pipes, that could be thrown or damage the machine. Establishing a perimeter and clearly warning others of the operating area is critical. I use caution tape and signage as needed to keep bystanders at a safe distance. While operating, maintaining a slow and steady pace allows for better control and reaction time, reducing the risk of accidents. After completing the work, I thoroughly check the mower for any damage, secure it properly, and always ensure the engine is completely shut off before leaving the site.

Q 10. Explain your understanding of proper fuel handling procedures for a gang mower.

Proper fuel handling is non-negotiable for safe and efficient gang mower operation. I always ensure the engine is completely cool before refueling. Spilled fuel is a serious fire hazard, so I meticulously clean up any spills immediately. I utilize the correct type and grade of fuel as specified in the operator’s manual; using the wrong fuel can damage the engine. Refueling should take place in a well-ventilated area, away from any ignition sources, to prevent the risk of fire or explosion. I also store fuel in approved containers, away from heat and direct sunlight. Finally, I never overfill the fuel tank, leaving room for fuel expansion to avoid spills.

Q 11. How do you maintain the proper cutting deck height for optimal performance?

Maintaining the proper cutting deck height is crucial for both the health of the lawn and the performance of the mower. A cutting height that’s too low can scalp the lawn, causing stress and damage to the grass. Conversely, a cutting height that’s too high can leave the lawn looking unkempt and uneven. I adjust the cutting deck height according to the type of grass, the time of year, and the desired lawn appearance. Most gang mowers have adjustable settings to control the height, usually via levers or a control panel. For instance, during hot summer months, I might slightly increase the height to minimize stress on the grass. I regularly check the cutting deck height to ensure consistent cutting across the entire width of the mower.

Q 12. What are the signs of a worn or damaged cutting blade?

Worn or damaged cutting blades significantly impact the quality of the cut and can pose safety risks. Signs of wear include nicks, chips, or cracks in the blade’s edge; these will produce a ragged, uneven cut. Excessive bending or warping of the blade is another clear sign of damage. A worn blade might also vibrate excessively during operation. This vibration not only affects the quality of cut but can also damage the mower itself. Regular inspection and timely replacement of worn blades are essential for optimal performance and safety. I often use a blade measuring gauge to precisely check the blade sharpness and balance for a professional finish and a safe operation.

Q 13. How do you troubleshoot issues with inconsistent cutting height?

Inconsistent cutting height is a common problem, often stemming from several factors. Firstly, I check the cutting deck for any obstructions like clumps of grass or debris. Next, I inspect the blades for wear and tear or damage, ensuring they are evenly sharpened and balanced. I then verify that all wheels are properly inflated and that the cutting deck is level. Uneven terrain can also contribute to inconsistent cutting height; in such cases, I adjust my speed and operating technique to minimize variations. Finally, I examine the gang mower’s linkages and hydraulics to rule out any mechanical issues. A systematic approach helps to isolate the root cause and ensure a consistent cut.

Q 14. Describe your experience with different gang mower brands and models.

My experience includes operating a range of gang mower brands and models, including Toro, John Deere, and Great Dane. Each brand offers unique features and performance characteristics. For example, Toro mowers are known for their reliability and ease of maintenance, while John Deere mowers often boast robust build quality and advanced features. I’ve worked with various models, from smaller, more maneuverable units ideal for tight spaces to larger, more powerful machines suited for expansive areas. My understanding extends beyond simply operating these machines; I am also familiar with their maintenance schedules, troubleshooting procedures, and specific safety protocols associated with each brand and model. This broad experience allows me to adapt effectively to different situations and optimize performance.

Q 15. How do you manage fuel consumption effectively while operating a gang mower?

Efficient fuel consumption in gang mower operation is crucial for both cost-effectiveness and environmental responsibility. It’s not just about how much fuel you use, but how effectively you use it.

- Regular Maintenance: A well-maintained engine burns fuel more efficiently. This includes regular oil changes, air filter cleaning, and spark plug checks. Think of it like a finely-tuned car – the better it’s maintained, the less fuel it consumes.

- Proper Operating Techniques: Avoid idling excessively. Let the mower’s momentum do the work whenever possible. Sudden acceleration and braking waste fuel. Imagine driving a car; smooth acceleration saves gas.

- Appropriate Engine Speed: Operate the mower at the recommended RPM for the specific cutting height and grass conditions. Over-revving wastes fuel and puts unnecessary strain on the engine. This is similar to selecting the right gear in a car based on the terrain.

- Terrain Awareness: Avoid mowing uphill whenever possible, as this requires more engine power and, therefore, more fuel. Choose the easiest route across the terrain if possible, just like choosing the most efficient driving route.

- Sharp Blades: Dull blades require more engine power to cut the grass, leading to higher fuel consumption. Sharpen or replace blades regularly. Think of it as using a sharp knife versus a dull one—the sharp knife requires less effort.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your approach to cleaning and storing a gang mower after use?

Cleaning and storing a gang mower properly extends its lifespan and ensures its readiness for the next use. It’s a systematic process.

- Immediate Cleaning: As soon as you finish mowing, remove any accumulated grass clippings from the cutting deck, wheels, and chassis. A quick rinse with water prevents grass from drying and becoming difficult to remove. Think of it like cleaning your dishes immediately after a meal—it’s much easier.

- Thorough Inspection: Inspect the blades for damage, checking for bends, chips, or dullness. Check for any loose bolts, worn parts, or signs of damage. This regular inspection prevents bigger problems later.

- Lubrication: Lubricate all moving parts as recommended by the manufacturer’s manual. Proper lubrication minimizes wear and tear and ensures smooth operation.

- Storage Location: Store the gang mower in a dry, secure location, away from direct sunlight, moisture, and extreme temperatures. Covering it with a tarp helps protect it from the elements.

- Winterization (if applicable): If the mower won’t be used for an extended period, perform the necessary winterization steps, such as draining fuel and oil (following the manufacturer’s instructions). This will protect the equipment from the damaging effects of prolonged storage.

Q 17. What are the environmental considerations when operating a gang mower?

Environmental considerations are paramount in gang mower operation. Our actions directly impact the surrounding ecosystem.

- Fuel Efficiency: Reducing fuel consumption minimizes greenhouse gas emissions, contributing to cleaner air. This is crucial for reducing our carbon footprint.

- Noise Pollution: Gang mowers can be noisy. Mowing during permissible hours and using noise reduction techniques (where feasible) helps mitigate noise pollution. Being mindful of noise levels helps the environment and our neighbours.

- Soil Compaction: Overuse and improper mowing techniques can lead to soil compaction. Mowing at optimal heights and varying mowing patterns minimizes soil compaction and preserves its health. Think of it like walking in the same spot versus varying your path.

- Chemical Use: Avoid using harmful chemicals for weed control. Explore eco-friendly options whenever possible. This helps to maintain soil health and biodiversity.

- Recycling: Properly dispose of or recycle used oil and other waste materials following all relevant environmental regulations and safety protocols.

Q 18. How do you address issues with clogging or jamming of the cutting deck?

Clogging or jamming of the cutting deck is a common issue that can be addressed systematically.

- Shut Down the Engine: Safety first! Always shut off the engine and disconnect the spark plug before attempting any repairs or cleaning.

- Identify the Clog: Locate the source of the jam. It could be from thick grass, string, or other debris.

- Clear the Clog: Carefully remove the obstruction using appropriate tools. A stiff brush, broom, or even a piece of wood can be helpful. Avoid using your hands to prevent injury.

- Inspect the Blades: Check the blades for any damage or dullness that might be contributing to clogging. Sharpen or replace them if necessary.

- Check for Obstructions in the Discharge Chute: Ensure that the discharge chute is free of debris.

Q 19. What safety measures are needed when working around moving parts of a gang mower?

Safety around moving parts of a gang mower is non-negotiable. Following safety protocols is essential to prevent serious injuries.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, hearing protection, sturdy work boots, and gloves. This is the first line of defense.

- Clear the Area: Ensure that the area is clear of bystanders and obstructions before starting the mower.

- Start-up Procedure: Follow the manufacturer’s start-up procedure precisely and never engage the blades while someone is in the immediate vicinity.

- Never Reach into the Cutting Deck While the Engine is Running: This is crucial for avoiding severe injuries.

- Regular Inspections: Conduct regular inspections of the mower to check for any worn or damaged parts that could pose a safety risk.

Q 20. How do you handle emergencies or accidents while operating a gang mower?

Handling emergencies and accidents requires a calm and methodical approach. Preparation and quick thinking are essential.

- Immediate Action: Turn off the mower immediately and assess the situation.

- First Aid: Administer first aid if necessary. If the injury is serious, call for emergency medical assistance immediately.

- Secure the Area: Secure the area to prevent further accidents.

- Report the Incident: Report the incident to your supervisor or the appropriate authorities. Accurate documentation is vital.

- Post-Incident Analysis: After the emergency, analyze the incident to identify contributing factors and implement preventative measures to avoid similar incidents in the future.

Q 21. Explain your understanding of the legal requirements for operating a gang mower.

Legal requirements for operating a gang mower vary by location, but some commonalities exist. Understanding these requirements is crucial for safe and legal operation.

- Licensing and Certification: In some jurisdictions, operators may need a specific license or certification to operate a gang mower. Check with local authorities for specific requirements.

- Safety Regulations: Adhere to all relevant safety regulations, including those related to PPE, operating procedures, and maintenance. These regulations are there for a reason—your safety.

- Environmental Regulations: Comply with all environmental regulations related to noise pollution, fuel emissions, and waste disposal. Respect for the environment is crucial.

- Insurance: Ensure that appropriate insurance coverage is in place to cover potential accidents or damages.

- Regular Inspections: Conduct regular inspections and maintain proper documentation. This will help to meet requirements for compliance.

Q 22. What is your experience with preventative maintenance schedules for gang mowers?

Preventative maintenance is crucial for maximizing the lifespan and efficiency of a gang mower. My approach involves a structured schedule encompassing daily, weekly, and monthly checks. Daily checks include inspecting cutting blades for sharpness and damage, checking fluid levels (hydraulic oil, engine oil), and ensuring all safety features are operational. Weekly maintenance includes lubricating moving parts and cleaning the mower deck thoroughly to remove grass buildup. Monthly maintenance includes more thorough inspections, checking for wear and tear on belts, pulleys, and bearings, and potentially changing fluids.

- Example: On a recent job, a daily blade inspection revealed a small crack in one blade. Replacing it prevented a more significant breakdown later, saving time and repair costs.

- Practical Application: This rigorous schedule helps to prevent costly repairs and downtime, ensuring consistent performance across large-scale mowing projects.

Q 23. How do you determine the appropriate mowing speed for varying conditions?

Mowing speed is dictated by several factors: terrain, grass type, and desired cut height. On even, relatively flat terrain with short, light grass, a higher speed is acceptable. However, uneven terrain, dense vegetation, or taller grass requires a significantly slower speed to ensure a clean cut and avoid scalping or clogging the mower deck.

- Example: When mowing a steep incline with thick, wet grass, I significantly reduce speed to prevent the mower from slipping or damaging the turf. I might even make multiple passes in different directions to achieve a uniform cut.

- Practical Application: Adapting speed based on the conditions prevents damage to the mower, ensures a quality cut, and enhances safety.

Q 24. How do you adjust the gang mower for different types of grass or vegetation?

Gang mowers can be adjusted to accommodate various grass types and vegetation. The key adjustments involve cutting height and the type of blade used. For instance, taller grasses require a higher cut height setting, and thicker grasses might necessitate using a heavier-duty blade designed for tougher vegetation. Some mowers also allow adjustments to the roller pressure, which can affect the quality of cut on different grass types.

- Example: When mowing a field with a mix of tall fescue and clover, I’d adjust the cutting height to a higher setting to avoid scalping the clover. I’d also make sure I’m using a blade sharp enough to cleanly cut through the tougher fescue stems.

- Practical Application: Adapting these settings optimizes the mowing performance and yields a uniform, healthy looking turf, even in mixed-vegetation areas.

Q 25. Explain your experience with hydraulic systems in gang mowers.

Hydraulic systems in gang mowers are vital for lifting, lowering, and adjusting the cutting decks. My experience includes troubleshooting hydraulic leaks, understanding pressure regulators, and performing routine fluid checks and replacements. Familiarity with hydraulic components such as pumps, valves, and cylinders is crucial for efficient maintenance and repair. I am proficient in diagnosing issues such as slow lift/lower times, noisy operation, and loss of lift capacity.

- Example: During one job, I identified a minor leak in a hydraulic hose by carefully inspecting the system after noticing a slow lift time. A timely replacement prevented a complete system failure.

- Practical Application: Effective hydraulic system management is crucial for operational efficiency and extends the lifespan of the mower.

Q 26. Describe your understanding of PTO (Power Take-Off) systems.

The Power Take-Off (PTO) system is what transfers power from the tractor’s engine to the gang mower. It’s crucial to understand its engagement and disengagement mechanisms to ensure safety and avoid damage to the equipment. Knowing how to check PTO shaft speed, lubrication, and overall condition is crucial for safe and efficient operation.

- Example: Before engaging the PTO, I always confirm that the mower is correctly aligned and that the PTO shaft is properly lubricated. I also ensure all safety features, such as the safety shield, are correctly positioned.

- Practical Application: Properly operating and maintaining the PTO prevents accidents and prolongs the life of the mower and tractor.

Q 27. How do you calculate fuel costs and usage based on job size?

Calculating fuel costs is straightforward. I start by recording the initial fuel level before the job. After completion, I measure the remaining fuel to determine fuel consumption. Then, I multiply the amount of fuel used (in gallons or liters) by the current price per unit of fuel to arrive at the total fuel cost. I typically also maintain records of fuel efficiency (gallons per acre) for each mower and job to monitor performance and optimize fuel use.

- Example: If I use 10 gallons of fuel at $4 per gallon, the fuel cost for that job is $40. By tracking fuel efficiency, I can identify areas for improvement, such as optimizing mowing speed or adjusting mower settings.

- Practical Application: Accurate fuel cost tracking is essential for bidding on jobs, monitoring expenses and profitability, and making informed decisions on future projects.

Q 28. Describe your experience with GPS-guided gang mower operation.

My experience with GPS-guided gang mowers involves using systems that allow for precise, overlapping mowing patterns, minimizing missed areas and maximizing efficiency. I’m familiar with the setup and calibration of GPS guidance systems, including the proper connection to the mower’s control system and the creation of accurate field boundaries. This technology allows for consistent swath widths and accurate area coverage.

- Example: Recently, I used a GPS-guided system on a large, irregular-shaped field. The system guided the mower with precision, resulting in a perfectly uniform cut with minimal overlap, saving both time and fuel.

- Practical Application: GPS-guided mowing enhances accuracy, reduces fuel consumption and labor costs, and allows for efficient operation even in challenging terrain and large fields.

Key Topics to Learn for Gang Mower Operation Interview

- Mower Mechanics: Understanding the internal workings of gang mowers, including engine systems, cutting mechanisms, and hydraulics. This includes preventative maintenance procedures and troubleshooting common mechanical issues.

- Safe Operation Procedures: Mastering safe operating practices, including pre-operation checks, proper maneuvering techniques, and emergency shutdown procedures. This also encompasses understanding and adhering to all relevant safety regulations and personal protective equipment (PPE) requirements.

- Terrain Assessment and Adjustment: Learning to assess different terrain types and adjust mower settings accordingly to optimize cutting efficiency and prevent damage to the equipment or the landscape. This includes understanding the impact of slope, soil conditions, and vegetation density.

- Maintenance and Repair: Developing practical skills in performing routine maintenance tasks, such as blade sharpening, lubrication, and cleaning. This also involves recognizing the signs of potential malfunctions and performing minor repairs or knowing when to call for professional assistance.

- Calibration and Adjustment: Understanding how to calibrate the mower’s cutting height, overlap, and other settings to achieve a consistent and high-quality cut. This includes troubleshooting issues related to uneven cutting or other performance problems.

- Environmental Awareness: Understanding the environmental impact of gang mower operation and implementing practices to minimize its effect. This includes fuel efficiency, responsible disposal of waste materials and adherence to environmental regulations.

Next Steps

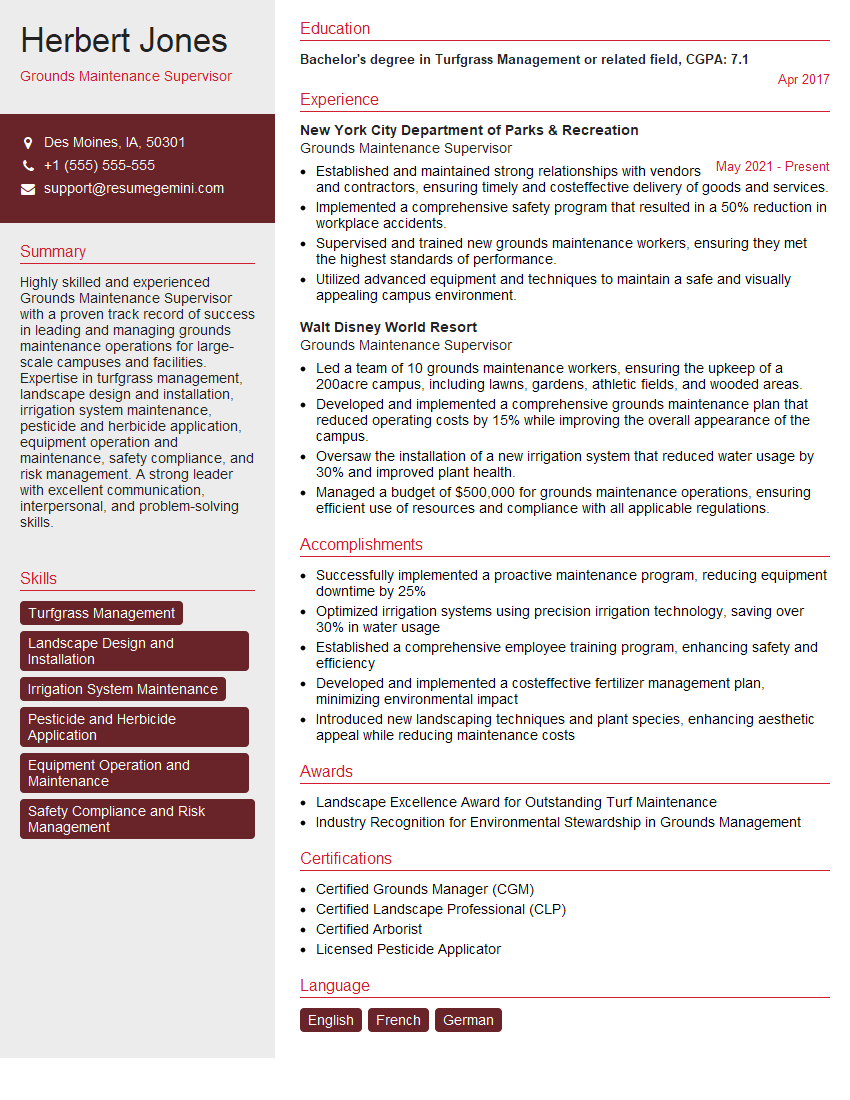

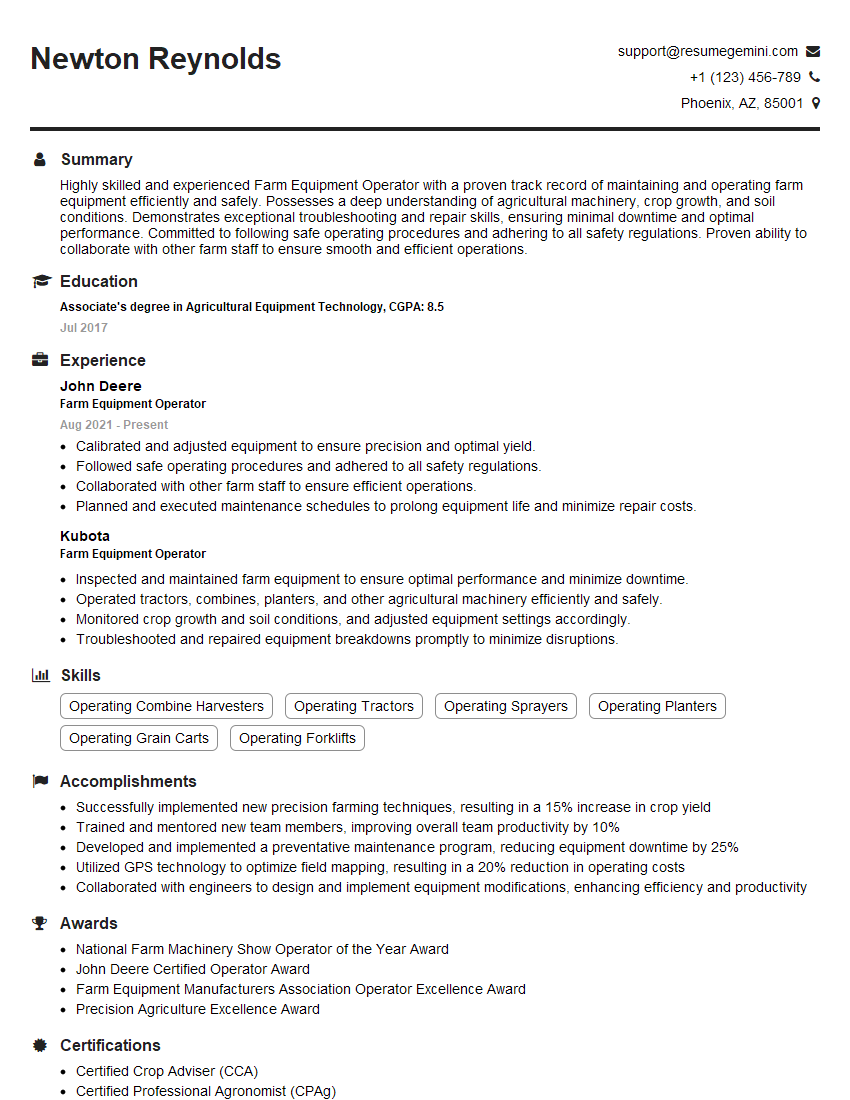

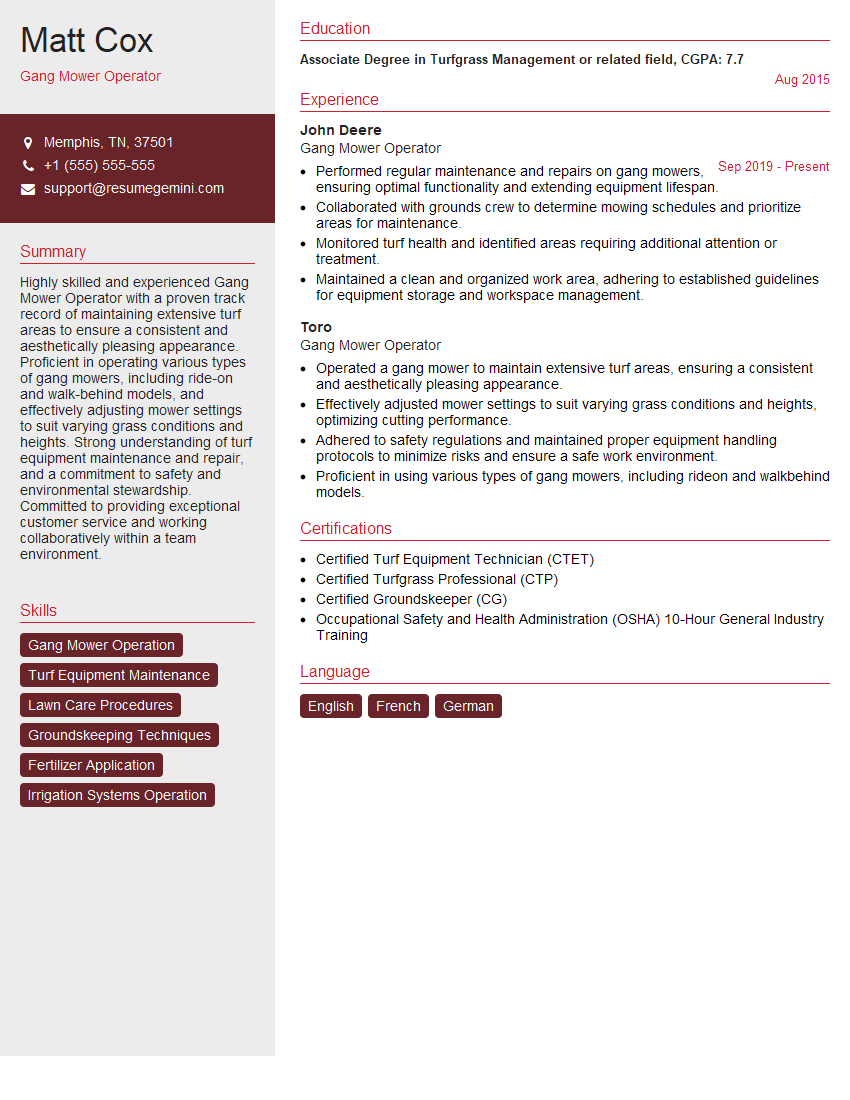

Mastering gang mower operation opens doors to rewarding careers in landscaping, agriculture, and grounds maintenance, offering opportunities for advancement and specialization. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by potential employers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, designed to highlight your skills and experience in gang mower operation. Examples of resumes tailored to this specific field are available within ResumeGemini to guide your creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.