Cracking a skill-specific interview, like one for Gas Well Construction and Installation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Gas Well Construction and Installation Interview

Q 1. Explain the different types of gas well drilling methods.

Gas well drilling methods are chosen based on factors like depth, geological formations, and environmental considerations. The two primary methods are:

- Rotary Drilling: This is the most common method. A rotating drill bit, attached to a drill string, grinds through the earth. Mud is continuously circulated to remove cuttings, cool the bit, and control well pressure. Think of it like using a giant, incredibly powerful drill to make a hole. Different bit types are used depending on the rock formation – diamond bits for harder rock, roller cone bits for softer rock.

- Directional Drilling: Used to reach targets that are not directly beneath the drilling rig, allowing access to multiple reservoirs from a single surface location or to navigate around obstacles. This involves using specialized tools to bend the drill string, creating a deviated wellbore. Think of it as steering the drill to reach a specific underground location.

Other specialized techniques, like underbalanced drilling (lowering pressure to reduce formation damage) or horizontal drilling (drilling parallel to the earth’s surface), are variations on these primary methods, often employed for specific geological conditions or enhanced recovery techniques.

Q 2. Describe the process of well completion.

Well completion is the process of preparing a well for production after drilling is finished. It’s like furnishing and equipping a newly built house to make it functional. This multifaceted process involves several key steps:

- Running Casing: Steel pipes (casing) are cemented into the wellbore to provide structural support, prevent collapses, isolate different formations, and prevent fluid migration.

- Cementing: Cement is pumped down the annulus (the space between the casing and the wellbore) to seal the casing and protect the environment. Proper cementing is crucial for well integrity.

- Perforating: Creating holes in the casing and cement to allow hydrocarbons to flow into the wellbore. This is done using shaped charges or other specialized tools.

- Installing Completion Equipment: This includes the wellhead (the topmost assembly controlling the well), subsurface safety valves (SSVs) for blowout prevention, and production tubing to carry the gas to the surface. Think of it as installing all the plumbing and safety features.

- Testing and Evaluation: Rigorous testing is done to ensure the well is structurally sound and ready for production.

The specific completion method used depends on the reservoir characteristics, production strategy, and environmental concerns.

Q 3. What are the key components of a gas wellhead?

The gas wellhead is the critical assembly at the surface controlling the well. It’s the topmost piece of equipment and plays a crucial safety role. Key components include:

- Casing Head: A flange that seals and supports the casing strings.

- Christmas Tree: A collection of valves, pressure gauges, and flow lines that regulate gas flow and allows for well control.

- Tubing Head: Similar to the casing head, but for the production tubing.

- Master Valve: A primary shut-off valve for emergency situations. Imagine this as the emergency stop button for the well.

- Pressure Gauges: Monitor well pressure to ensure safe operation.

All components are designed to withstand high pressures and temperatures and to ensure safe and efficient gas production.

Q 4. How do you prevent well blowouts?

Preventing well blowouts is paramount in gas well construction; a blowout can be catastrophic. Multiple layers of protection are implemented:

- Proper Drilling Mud: Mud weight is carefully controlled to maintain pressure balance and prevent formation fluids from surging up the wellbore. This is like using a weighted blanket to keep the underground pressure under control.

- Casing and Cementing: Strong casing and proper cementing isolate different formations, preventing fluid migration and providing structural support.

- Subsurface Safety Valves (SSVs): These valves, located downhole, automatically shut the well in case of a pressure surge or other anomalies. These are crucial safety features.

- Surface Blowout Preventers (BOPs): These are high-pressure valves situated on the wellhead that can quickly shut the well in case of a surface blowout.

- Well Monitoring Systems: Continuous monitoring of well pressure, flow rates, and other parameters allows for early detection of potential problems.

Regular inspections, adherence to safety protocols, and proper training of personnel are also vital in mitigating blowout risks.

Q 5. Explain the importance of casing design in gas well construction.

Casing design is crucial for well integrity and safety. It’s the backbone of the well, offering multiple vital functions.

- Structural Support: Casing prevents wellbore collapse, especially in unstable formations, acting as a skeleton for the well.

- Fluid Isolation: Different formations contain fluids of varying pressures and compositions. Casing, cemented in place, isolates these formations, preventing uncontrolled fluid movement and protecting the environment.

- Environmental Protection: Casing and cement prevent the migration of fluids from one formation to another, protecting groundwater aquifers and surface environments.

- Containment: In case of a well failure, casing helps to contain the flow of fluids, minimizing environmental damage.

Casing design considers factors like well depth, pressure, temperature, and formation properties. Incorrect casing design can lead to wellbore instability, environmental contamination, and even blowouts.

Q 6. What are the different types of cement used in gas well construction?

Different cement types are selected based on the specific well conditions. Key properties to consider are compressive strength, setting time, and resistance to high temperatures and pressures.

- Portland Cement: The most common type, providing good strength and relatively fast setting times. Different classes are used to tailor properties for specific needs.

- High-Temperature Cement: Used in deep wells where high temperatures are encountered. These cements maintain their integrity even at extreme temperatures.

- Lightweight Cement: Used in situations where reduced weight is desired, such as in shallow wells or when minimizing pressure on formations is important.

- Specialty Cements: Additives can modify cement properties, such as accelerators to speed up setting, retarders to slow it down, or other additives for specific well conditions.

Proper cement slurry design and placement are critical to ensure a good cement job, preventing leaks and maintaining well integrity.

Q 7. Describe the process of perforating a gas well.

Perforating a gas well creates controlled openings in the casing and cement to allow hydrocarbons to flow into the wellbore. It’s like making controlled holes in a can to let its contents out.

The process involves using shaped charges or other perforating guns that are lowered into the wellbore. These tools create precise openings at predetermined depths. Different perforating techniques exist, including:

- Jet Perforating: A high-velocity jet of fluid creates the perforation.

- Shaped Charge Perforating: The most common method. Small explosive charges create precise holes.

Factors to consider include the number of perforations, their spacing, and the type of charge used, all tailored to the specific well and reservoir conditions. Accurate perforating is key to ensuring efficient hydrocarbon production.

Q 8. Explain the role of fracturing in gas well production.

Hydraulic fracturing, or “fracking,” plays a crucial role in boosting gas well production, particularly in unconventional reservoirs like shale gas formations. These formations contain gas trapped within tight rock matrices, making it difficult for the gas to flow naturally to the wellbore. Fracking creates pathways for the gas to escape.

The process involves injecting high-pressure fluid, typically water mixed with sand and chemicals, into the wellbore. This fluid creates fractures in the surrounding rock, and the sand acts as a proppant, keeping the fractures open even after the pressure is released. This significantly increases the surface area available for gas to flow into the wellbore, leading to a substantial increase in production.

Think of it like this: Imagine a sponge full of water (gas). You can squeeze out some water (gas) by just pressing on it, but you’ll get far more by creating many tiny cracks in the sponge to release the water more freely. Fracking does the same for the gas trapped in the rock formation.

Q 9. How do you monitor well pressure and production rates?

Monitoring well pressure and production rates is essential for optimizing well performance and ensuring safe operations. We use a variety of tools and techniques:

- Pressure Gauges and Transducers: These instruments, installed at various points in the wellhead and pipeline, provide real-time data on pressure changes within the wellbore and flowlines.

- Flow Meters: These devices accurately measure the volume of gas produced over time, helping us determine the production rate.

- SCADA (Supervisory Control and Data Acquisition) Systems: These automated systems collect and process data from various sensors and instruments throughout the wellsite, providing a centralized view of well performance and enabling remote monitoring.

- Downhole Gauges: For more detailed analysis, we occasionally use downhole gauges that are temporarily deployed to measure pressure and temperature at different depths within the wellbore. This helps us identify potential problems such as blockages or fluid accumulation.

This data is crucial for identifying any anomalies, such as a pressure drop indicating a potential issue or a decrease in production rate suggesting a need for intervention.

Q 10. What are the common safety procedures followed during gas well construction?

Safety is paramount in gas well construction. A comprehensive safety plan is developed and rigorously followed, including:

- Hazard Identification and Risk Assessment: A thorough assessment of all potential hazards is conducted before, during, and after construction.

- Permitting and Compliance: All work must adhere to relevant regulations and permits, ensuring compliance with local, state, and federal safety standards.

- Emergency Response Plan: A detailed plan is developed for handling emergencies, including fires, explosions, and well control issues.

- Personal Protective Equipment (PPE): Appropriate PPE, such as hard hats, safety glasses, and specialized clothing, is required for all personnel on site.

- H2S Monitoring: Hydrogen sulfide (H2S) is a highly toxic gas often found in natural gas wells. Continuous monitoring and safety protocols are in place to mitigate the risk of exposure.

- Well Control Procedures: Strict well control procedures are followed throughout the drilling and completion phases to prevent uncontrolled gas flow or blowouts.

Regular safety training and drills are essential to ensure that everyone understands their roles and responsibilities in maintaining a safe work environment.

Q 11. Describe different types of gas well testing procedures.

Gas well testing procedures are vital for determining the reservoir’s productivity and overall well performance. Different types of testing are employed depending on the phase of the well’s life cycle:

- Initial Production Test (IPT): Conducted after well completion, this test evaluates the well’s initial gas flow rate and pressure behavior under controlled conditions.

- Well Test Interpretation: The data from IPT is analyzed to estimate reservoir properties, such as permeability and porosity. This analysis informs further development strategies.

- Production Logging Tools (PLT): These tools are deployed downhole to measure gas flow and pressure profiles along the wellbore, helping to pinpoint areas of restriction or potential damage.

- Multi-rate Testing: This test involves running the well at various flow rates to determine the relationship between pressure and flow rate, offering a more complete understanding of the reservoir’s behavior.

- Pressure Build-Up Tests: After a period of production, the well is shut in to allow the pressure to build up. Analyzing this pressure build-up provides additional insights into the reservoir’s characteristics.

The specific testing methods and procedures are carefully designed to address the unique challenges of each well and reservoir.

Q 12. How do you identify and mitigate risks associated with gas well construction?

Identifying and mitigating risks in gas well construction requires a proactive approach. We utilize several strategies:

- Geological and Geophysical Studies: Detailed subsurface studies help identify potential geological hazards, such as unstable formations or fault zones.

- Well Planning and Design: Careful well planning and design, considering the specific geological conditions and anticipated challenges, is crucial for minimizing risks.

- Risk Assessment and Management: A systematic risk assessment process helps identify, analyze, and prioritize potential hazards.

- Emergency Response Planning: Having a detailed emergency response plan in place is critical for handling unforeseen events.

- Regular Inspections and Maintenance: Routine inspections and maintenance of well equipment help prevent equipment failures and minimize operational risks.

- Data Analysis and Monitoring: Continuous monitoring of well performance and environmental conditions allows for early detection of potential problems and prompt mitigation.

For example, in areas prone to seismic activity, specialized well designs and construction methods may be required to mitigate the risk of well damage or collapse.

Q 13. Explain the concept of artificial lift in gas wells.

Artificial lift in gas wells is necessary when the natural pressure in the reservoir is insufficient to lift the gas to the surface at an economically viable rate. Several methods are used:

- Gas Lift: Injecting gas into the wellbore reduces the hydrostatic pressure, allowing gas to flow more easily to the surface.

- Electric Submersible Pumps (ESPs): These pumps, submerged in the wellbore, use electricity to lift the gas to the surface. This method is particularly effective in low-pressure gas wells.

- Compressor Stations: Boosting the pressure of the produced gas using compressors located at the wellhead or along the pipeline enhances the flow rate and efficiency of gas transportation.

The choice of artificial lift method depends on factors such as well depth, reservoir pressure, gas properties, and economic considerations. It’s a key element in maximizing gas recovery and profitability.

Q 14. What are the environmental regulations related to gas well construction?

Environmental regulations governing gas well construction are stringent and vary by location. Key regulations typically address:

- Air Emissions: Strict limits are imposed on the emission of greenhouse gases (GHGs) and other pollutants from well sites and processing facilities.

- Water Management: Regulations cover the responsible management of produced water and wastewater generated during drilling and production. This often includes requirements for treatment and disposal or reuse.

- Waste Management: Procedures for the safe handling and disposal of drilling waste and other materials are clearly defined.

- Land Reclamation: After well completion and decommissioning, regulations often mandate land restoration to its pre-construction condition.

- Seismic Monitoring: In some regions, regulations may require monitoring for induced seismicity, which is the potential for earthquakes related to fluid injection activities.

Compliance with these regulations is mandatory and often involves submitting detailed environmental impact assessments, obtaining necessary permits, and adhering to strict operating procedures throughout the well’s lifecycle.

Q 15. Describe your experience with well control equipment.

My experience with well control equipment spans over 15 years, encompassing both onshore and offshore operations. I’m proficient in the operation and maintenance of a wide range of equipment, including but not limited to blowout preventers (BOPs), annular preventer (AP), choke manifolds, and kill lines. I understand the critical role these systems play in preventing uncontrolled well flow and have firsthand experience in their pre-job inspection, testing, and deployment. For instance, on one project in the Gulf of Mexico, I was responsible for overseeing the testing and certification of a new generation BOP stack before commencing drilling operations, ensuring that all safety protocols were rigorously adhered to. This involved detailed inspections, hydraulic testing, and functional checks to guarantee the equipment’s reliability and ability to withstand high pressures. I’m also familiar with various well control techniques, including using various types of mud weights and implementing the appropriate procedures in emergency situations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage well integrity issues?

Managing well integrity issues requires a proactive and multi-faceted approach. It begins with careful well design and planning, incorporating best practices to minimize risks from the outset. Throughout the well’s lifecycle, this includes regular monitoring of pressure, temperature, and flow rates. Any deviation from expected parameters warrants immediate investigation. We utilize advanced technologies like distributed acoustic sensing (DAS) and fiber optic monitoring to detect subtle changes indicative of potential issues. If problems are detected, a thorough investigation is conducted, which may include running specialized logging tools to assess the wellbore condition. The resolution strategy varies depending on the severity and type of issue. This could involve anything from minor remedial work such as cementing, to more complex interventions like milling or sidetracking. For example, I once encountered a situation where a casing leak was detected through pressure monitoring. We used a combination of logging tools to pinpoint the exact location and then employed a squeeze cementing operation to successfully seal the leak, preventing environmental damage and production loss. Documentation of all interventions and lessons learned are crucial for continuous improvement.

Q 17. Explain your experience with different types of drilling fluids.

My experience encompasses a broad spectrum of drilling fluids, tailored to various geological formations and well conditions. I’ve worked extensively with water-based muds (WBM), oil-based muds (OBM), and synthetic-based muds (SBM). The selection of drilling fluid is crucial, as it affects wellbore stability, hole cleaning, and formation damage. Water-based muds are cost-effective and environmentally friendly, but may not be suitable for all formations. Oil-based muds offer superior lubricity and shale stability, but raise environmental concerns. Synthetic-based muds provide a balance between performance and environmental impact. Choosing the right mud is a complex decision made after careful consideration of factors such as formation pressure, temperature, and the presence of reactive shales. For example, when drilling through a highly reactive shale formation, we opted for a specialized SBM that included specific additives to prevent swelling and maintain wellbore stability. This prevented potential wellbore collapses and ensured a safe and efficient drilling operation.

Q 18. How do you ensure the quality control during gas well construction?

Ensuring quality control during gas well construction is paramount. This starts with meticulous planning and design, including thorough geotechnical studies and risk assessments. Throughout the construction process, rigorous quality checks are performed at each stage. This includes regular inspections of materials, equipment, and procedures, along with detailed documentation of all activities. We use certified laboratories to test drilling fluids, cement slurries, and casing materials to ensure they meet required specifications. Non-destructive testing (NDT) techniques, such as ultrasonic testing and gamma ray logging, are employed to verify the integrity of casings and wellbore structures. Regular audits and safety meetings are conducted to ensure compliance with all relevant regulations and industry best practices. For example, we implemented a real-time monitoring system that provided continuous data on wellbore parameters during the cementing operation. This allowed for immediate detection and correction of any anomalies, ensuring the cement job was executed flawlessly. By meticulously maintaining quality control, we minimize risks, reduce operational costs, and ensure the long-term integrity and safety of the gas well.

Q 19. What are the different types of gas well logging tools?

Gas well logging tools are indispensable for evaluating reservoir properties and wellbore conditions. Several types are used, categorized by the information they provide:

- Resistivity logs: Measure the electrical resistance of formations, helping identify hydrocarbon-bearing zones.

- Porosity logs: Determine the pore space within rocks, indicative of potential reservoir capacity (e.g., neutron porosity, density porosity).

- Acoustic logs: Measure the speed of sound waves in the formation, providing information on porosity and lithology.

- Gamma ray logs: Measure natural radioactivity in the formation, helping to distinguish between different rock types.

- Nuclear magnetic resonance (NMR) logs: Provide detailed information on pore size distribution and fluid properties.

- Formation pressure testing tools: Directly measure the formation pressure to assess the reservoir’s energy state.

Q 20. How do you interpret well logs to determine reservoir properties?

Interpreting well logs to determine reservoir properties is a complex process that requires expertise and experience. It involves integrating data from multiple logs and using established petrophysical models. For example, porosity can be calculated from density and neutron logs, while water saturation can be estimated using resistivity logs. Permeability, a key indicator of reservoir productivity, is often indirectly derived from correlations with porosity and other log responses. Advanced techniques, such as those involving petrophysical modeling software, are often employed to generate more accurate estimations. The interpretation process begins with a detailed review of the individual log curves. Then, we look at cross-plots of different log parameters to identify key relationships and patterns. Finally, we develop a geological model of the reservoir, which considers not just the log data, but also geological information from other sources such as cores and seismic surveys. It’s important to note that the interpretation is never perfect and always involves a level of uncertainty; a good interpretation minimizes this uncertainty.

Q 21. What is your experience with horizontal drilling?

I have significant experience in horizontal drilling, having participated in numerous projects involving the design, planning, and execution of horizontal wells. Horizontal drilling is a technique that involves drilling a wellbore that deviates from vertical to reach a reservoir laterally, enabling increased contact with the producing formation and significantly enhancing hydrocarbon recovery. My involvement has included well planning and trajectory design, utilizing specialized software to optimize the wellbore path to maximize reservoir exposure. Furthermore, my experience includes managing the drilling operations, working closely with the drilling crew to ensure directional control and maintaining wellbore stability. The use of measurement-while-drilling (MWD) tools and logging-while-drilling (LWD) tools is vital in real-time monitoring and control during horizontal drilling. On one particularly challenging project, we utilized advanced steerable motor technology to navigate a complex fault zone, which was crucial to reach our target reservoir and avoid compromising well integrity. The successful completion of this project showcased the importance of precise planning, technology, and the expertise of the drilling team involved.

Q 22. Describe your experience with multilateral wells.

Multilateral wells are highly productive wells with multiple branches extending from a single wellbore. Think of it like a tree with a main trunk and several large branches reaching out to tap different parts of a reservoir. This allows for increased contact with the gas-bearing formation, resulting in higher production rates compared to conventional single-borehole wells. My experience encompasses the entire lifecycle of multilateral wells, from initial well planning and design, incorporating reservoir simulation data to optimize branch placement, to the execution of complex drilling operations using advanced steerable drilling systems. I’ve been involved in projects requiring the use of various completion techniques, including openhole completions, cemented liners, and gravel packs, to ensure efficient production from each lateral branch. Post-completion, my expertise includes well testing, production optimization, and ongoing surveillance using advanced monitoring technologies. For instance, on one project, by strategically positioning lateral branches in a fractured reservoir, we achieved a 30% increase in gas production compared to the projected yield of a conventional well.

Q 23. Explain the process of decommissioning a gas well.

Decommissioning a gas well is a critical process that involves permanently shutting down the well and restoring the site to a safe and environmentally sound condition. It’s a multi-stage process starting with well isolation. This typically involves cementing off the production tubing and potentially the casing to prevent future gas migration. Then, the wellhead and surface equipment are removed. Next comes site restoration, which involves removing any infrastructure such as pipelines and platforms, and reclaiming the land to its pre-drilling state. This may include soil remediation and vegetation planting. Throughout the process, strict regulatory compliance is paramount, requiring meticulous documentation and environmental monitoring. For example, in one project, we implemented a specialized cementing procedure to ensure a strong and durable seal, preventing potential future leaks. Furthermore, we utilized innovative methods for site remediation, which significantly reduced the environmental impact and achieved faster land reclamation.

Q 24. What are the challenges associated with unconventional gas well development?

Unconventional gas well development, targeting resources like shale gas and tight gas, presents unique challenges. The low permeability of these formations requires extensive stimulation treatments, such as hydraulic fracturing, to create pathways for gas flow. This process itself is complex, costly, and can pose environmental concerns. Furthermore, the unpredictable nature of fracture networks makes production forecasting difficult. Other challenges include managing high-pressure formations, dealing with the potential for formation damage during drilling and completion, and optimizing production from complex reservoir geometries. For example, optimizing fracturing fluid design to minimize formation damage and maximize fracture conductivity is crucial, and accurately predicting the extent and connectivity of fractures is a key component of reservoir modeling and well placement optimization. The sheer volume of data generated during unconventional well development necessitates advanced data analytics and interpretation techniques to improve production efficiency.

Q 25. How do you handle unexpected situations during well construction?

Unexpected situations during well construction are common. My approach is rooted in proactive risk assessment and mitigation. We develop comprehensive contingency plans that address potential issues like stuck pipe, wellbore instability, or equipment failures. These plans include detailed procedures, specialized equipment, and readily available expertise. Effective communication and a strong team are vital. When a problem occurs, my focus is on rapid and accurate diagnosis, followed by implementing the most appropriate solution while ensuring safety is the top priority. For instance, during one operation, we encountered an unexpected influx of high-pressure water. By quickly implementing our pre-planned emergency response procedures, we were able to safely control the situation and prevent a potential well control incident without any damage to the equipment or personnel.

Q 26. What is your experience with different types of gas measurement equipment?

My experience encompasses a wide range of gas measurement equipment, including orifice meters, turbine meters, ultrasonic meters, and more recently, smart meters with advanced data analytics capabilities. I am familiar with their principles of operation, calibration procedures, and limitations. I understand the importance of selecting the appropriate meter for a given application, considering factors such as flow rate, pressure, gas composition, and accuracy requirements. For example, I’ve worked on projects where ultrasonic meters were chosen for their ability to measure gas flow accurately across a wide range of flow rates, while in other situations, orifice meters were more cost-effective for specific applications. Regular maintenance and calibration of this equipment is crucial to ensure reliable and accurate data acquisition, a fact I emphasize in all projects.

Q 27. Describe your experience with data acquisition and interpretation in gas well operations.

Data acquisition and interpretation is central to optimizing gas well operations. My experience involves collecting data from various sources, including surface measurement equipment, downhole sensors, and reservoir simulation models. I utilize specialized software to process, analyze, and interpret this data to understand well performance, reservoir behavior, and identify areas for improvement. This includes analyzing pressure, temperature, flow rate, and gas composition data to identify potential issues, such as water or sand production, changes in reservoir pressure, or formation damage. Advanced techniques like machine learning and artificial intelligence are increasingly being incorporated to facilitate the analysis of massive datasets and predict future performance. For instance, on a recent project, the analysis of downhole pressure data revealed a near-wellbore restriction, which was addressed by optimizing the completion technique. This resulted in a significant increase in production.

Q 28. How do you optimize gas well production?

Optimizing gas well production is a continuous process that involves several key strategies. Firstly, maintaining optimal wellbore pressure and flow rates is crucial, which often involves adjusting choke settings to balance production with reservoir pressure depletion. Secondly, regular well testing and analysis are vital for detecting and addressing any production problems early. Thirdly, improving the efficiency of stimulation treatments like hydraulic fracturing by adapting techniques to reservoir characteristics can significantly improve production. Finally, water management and handling of produced fluids efficiently is important. The implementation of artificial lift methods, like gas lift or electric submersible pumps, can improve production from low-pressure wells. For example, in one project, we optimized the choke management strategy based on real-time data analysis, resulting in a 15% increase in gas production without compromising well integrity.

Key Topics to Learn for Gas Well Construction and Installation Interview

- Well Planning & Design: Understanding reservoir characteristics, well trajectory design, and completion strategies. Practical application: Analyzing geological data to optimize well placement and production.

- Drilling Operations: Knowledge of drilling techniques (rotary, directional), mud systems, well control procedures, and safety protocols. Practical application: Troubleshooting drilling problems and ensuring operational efficiency.

- Completion & Stimulation: Understanding various completion methods (perforating, fracturing), stimulation techniques (hydraulic fracturing, acidizing), and production logging. Practical application: Selecting appropriate completion and stimulation techniques based on reservoir characteristics.

- Casing & Tubing: Knowledge of different casing and tubing materials, design considerations, and installation procedures. Practical application: Calculating casing and tubing requirements based on wellbore conditions.

- Production Equipment & Systems: Familiarity with surface equipment (Christmas trees, separators, flow lines), instrumentation, and control systems. Practical application: Diagnosing and resolving production equipment issues.

- Health, Safety, and Environmental (HSE) Regulations: Deep understanding of relevant HSE regulations and best practices within the oil and gas industry. Practical application: Implementing safety procedures and minimizing environmental impact.

- Problem-Solving & Troubleshooting: Demonstrating the ability to analyze complex situations, identify root causes, and develop effective solutions. Practical application: Responding effectively to unexpected events during well construction or operation.

- Well Testing & Analysis: Understanding well testing methodologies and interpreting test data to assess well performance. Practical application: Optimizing production based on well test results.

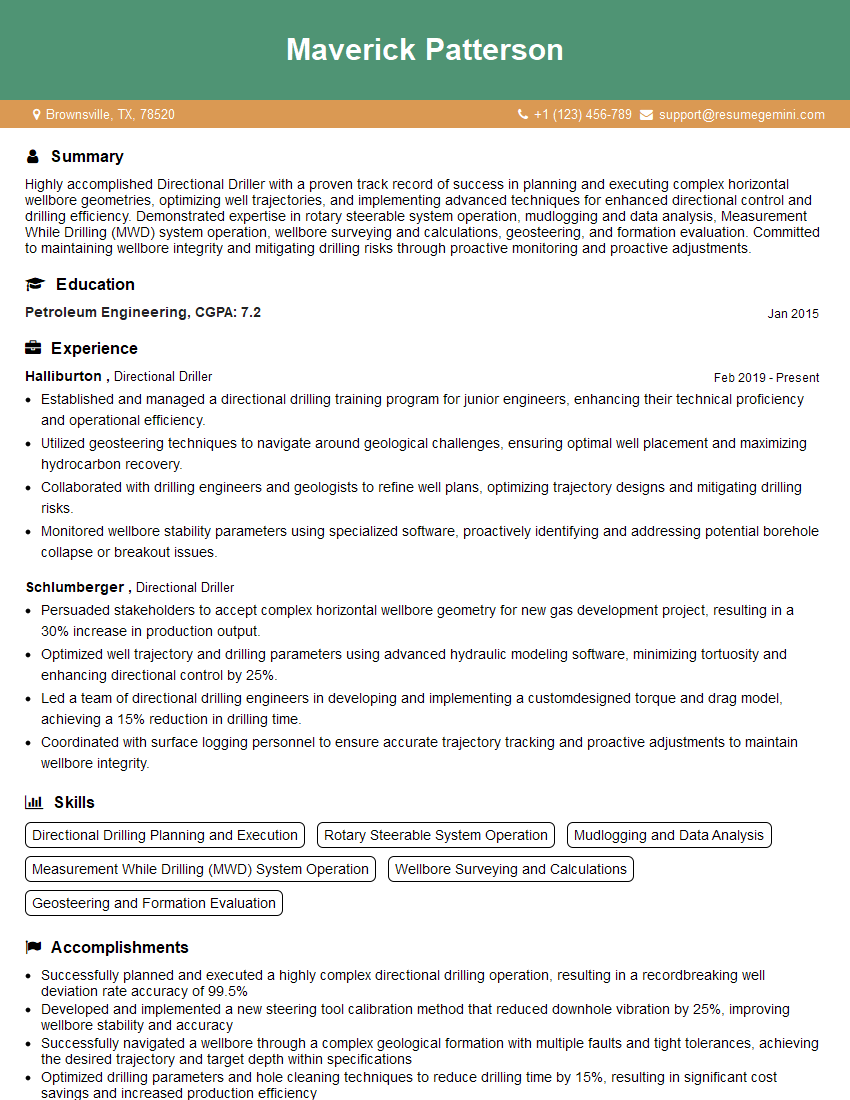

Next Steps

Mastering Gas Well Construction and Installation opens doors to a rewarding career with significant growth potential within the energy sector. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your skills and experience in this competitive field. Examples of resumes tailored to Gas Well Construction and Installation are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.