Preparation is the key to success in any interview. In this post, we’ll explore crucial Glass Fabricators interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Glass Fabricators Interview

Q 1. Explain the different types of glass used in fabrication.

Glass fabrication utilizes a variety of glass types, each with unique properties suited to different applications. The choice depends on factors like desired strength, transparency, thermal performance, and aesthetic appeal.

- Float Glass (Annealed Glass): This is the most common type, produced by floating molten glass on a bed of molten tin. It’s relatively inexpensive but brittle.

- Tempered Glass (Safety Glass): Heat-treated to increase strength and shatter resistance. When it breaks, it fragments into small, relatively harmless pieces, making it ideal for applications like automotive windows and shower doors.

- Laminated Glass: Two or more layers of glass bonded together with a layer of interlayer material, typically polyvinyl butyral (PVB). This provides increased strength, security, and sound insulation. It’s often used in automotive windshields and high-security applications.

- Insulating Glass Units (IGUs): Two or more panes of glass separated by a spacer filled with dehydrated air or inert gas (like argon or krypton). These significantly improve energy efficiency by reducing heat transfer.

- Colored Glass: Glass with added metal oxides or other substances to create a variety of colors and tints, allowing for creative design options.

- Patterned Glass: Glass with textured surfaces for decorative or privacy purposes. These designs are created during the manufacturing process.

For instance, a storefront might use laminated glass for security and tempered glass for impact resistance, while a residential window might utilize an IGU to improve energy efficiency.

Q 2. Describe the process of cutting glass to precise dimensions.

Precise glass cutting is crucial for accurate fabrication. Several methods achieve this, with the choice often depending on the glass type and desired dimensions.

- Manual Cutting: Using a glass cutter to score the glass, followed by applying controlled pressure to snap it along the score line. This method requires skill and precision, suitable for smaller projects.

- Automated Cutting (CNC Cutting): Computer-Numerically Controlled (CNC) machines use diamond wheels or lasers to cut glass with high accuracy and speed. This is ideal for high-volume production or complex shapes.

- Waterjet Cutting: A high-pressure stream of water, sometimes mixed with an abrasive, cuts glass with minimal heat and stress, making it useful for intricate designs or delicate materials.

Regardless of the method, a skilled fabricator will always double-check measurements before cutting to minimize waste and ensure accuracy. Imagine creating a custom shower enclosure – the slightest inaccuracy in cutting could lead to significant fitting problems. CNC machines offer significant advantages in such cases due to their superior accuracy and repeatability.

Q 3. How do you ensure the safety of yourself and others while working with glass?

Safety is paramount in glass fabrication. Several precautions are essential:

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and closed-toe shoes. For specific tasks, face shields and cut-resistant gloves might be necessary.

- Proper Handling Techniques: Use appropriate lifting techniques to avoid strain or injury. Never lift glass beyond your capacity. Use suction cups or other lifting aids for larger pieces.

- Clean and Organized Workspace: Maintain a clean workspace free of clutter to prevent accidents. Proper storage of glass sheets is crucial to avoid breakage.

- Machine Safety Procedures: Follow all manufacturer guidelines when operating machinery. Regular maintenance and safety checks are essential.

- Emergency Procedures: Familiarize yourself with emergency procedures, including how to handle glass cuts or other injuries. Have a first-aid kit readily available.

I once witnessed a colleague sustain a minor hand injury due to improper glove use. That incident served as a stark reminder of the importance of consistent adherence to safety protocols. It’s far better to be overly cautious than to suffer even minor injuries.

Q 4. What are the different methods for edging glass?

Edging glass improves aesthetics and safety by removing sharp edges and creating a finished look.

- Straight Edging: Creates a smooth, flat edge on the glass. This can be done manually or using automated machinery.

- Beveled Edging: Creates a sloped edge, adding a decorative touch.

- Pencil Edging: A rounded edge with a slightly curved profile.

- Ogee Edging: A more complex, decorative edge with a double curve.

The choice depends on the design and intended use. For example, a bevelled edge might be preferred for a mirror or a tabletop, adding a sophisticated aesthetic. Safety glass often requires a smooth, straight edge to prevent chipping or snagging.

Q 5. Explain the process of laminating glass.

Laminating glass involves bonding two or more sheets of glass together with a layer of interlayer material, usually PVB (polyvinyl butyral). This process enhances strength, safety, and sound insulation.

The process generally involves:

- Cleaning: The glass sheets are thoroughly cleaned to ensure proper adhesion.

- Layering: The interlayer is placed between the glass sheets.

- Autoclaving: The glass assembly is placed in an autoclave (a pressure vessel) where it’s heated and subjected to pressure. This process cures the interlayer, creating a strong, permanent bond.

The resulting laminated glass is significantly stronger than its individual components and offers exceptional safety. When broken, the fragments adhere to the interlayer, reducing the risk of injury. This is why laminated glass is used extensively in automotive windshields.

Q 6. Describe the process of creating an Insulating Glass Unit (IGU).

An Insulating Glass Unit (IGU), or double-pane (or triple-pane) window, consists of two or more sheets of glass separated by a spacer, creating an air or gas-filled cavity. This design significantly improves energy efficiency.

The manufacturing process typically involves:

- Spacer Preparation: The spacer, usually made of aluminum or other materials, is prepared and filled with desiccant (to absorb moisture) and sometimes inert gas (argon or krypton).

- Assembly: The glass sheets and spacer are assembled, ensuring the air/gas seal is maintained.

- Sealing: The unit is sealed using a sealant, typically butyl sealant, to create an airtight and watertight assembly.

- Quality Control: The completed IGU is inspected to ensure the seal integrity and performance.

IGUs dramatically reduce heat transfer, making buildings more energy-efficient and lowering heating and cooling costs. They also contribute to sound insulation, improving comfort and reducing noise pollution.

Q 7. How do you handle and prevent glass breakage during fabrication?

Preventing glass breakage during fabrication is essential for safety and efficiency. This involves a combination of careful handling techniques and appropriate storage.

- Proper Lifting Techniques: Use suction cups, glass lifters, or other handling tools for larger or heavier sheets of glass. Avoid sharp impacts or excessive bending.

- Careful Transportation: Use appropriate transportation methods, minimizing vibrations and shocks during movement. Protect the edges of glass sheets with padding during transport.

- Suitable Storage: Store glass sheets vertically on edge, supported adequately to prevent warping or breakage. Keep the storage area clean and free of debris.

- Use of Protective Materials: Use protective materials like foam or felt padding to protect glass edges and surfaces during processing and storage.

- Regular Inspections: Regularly inspect glass sheets for any signs of damage and remove damaged sheets immediately.

One instance I recall involved a large sheet of glass cracking due to improper storage. The resulting downtime and waste highlighted the importance of meticulous attention to handling and storage protocols. It’s much more cost-effective to prevent breakage through careful practices than to deal with the resulting consequences.

Q 8. What are the common safety precautions when working with tempered glass?

Tempered glass, while incredibly strong, poses significant safety risks if mishandled. The most crucial precaution is always treating it as potentially hazardous. Even seemingly minor imperfections can lead to catastrophic failure.

- Protective Gear: Always wear safety glasses, gloves, and long sleeves. Tempered glass shards are incredibly sharp and can cause serious injuries.

- Handling with Care: Avoid sharp impacts or stress concentrations on the glass edges. Lifting tempered glass requires proper techniques to prevent breakage. Use suction cups or specialized lifters for large pieces.

- Proper Storage: Store tempered glass flat, away from sharp objects and potential impact sources. It should be carefully cushioned to minimize the risk of chipping or cracking during transport and storage.

- Edge Protection: Always handle tempered glass by its edges. Never apply force to the center, as this is a common point of failure.

- Processing Safety: The tempering process itself involves extreme heat and requires specialized equipment and expertise. Always follow manufacturer’s safety protocols for all machinery used.

- Disposal: Broken tempered glass requires special handling. Never place it in standard trash bins. Dispose of it according to local regulations, often requiring specialized containers or recycling facilities.

Imagine working with a glass sheet so strong it can withstand significant impacts. However, when broken, it shatters into countless tiny, razor-sharp pieces – this is the nature of tempered glass, hence the utmost care is needed.

Q 9. What tools and equipment are used in glass fabrication?

Glass fabrication requires a range of specialized tools and equipment, depending on the project’s complexity and desired finish. Here are some key examples:

- Glass Cutters: These are used for cutting glass sheets to precise dimensions, ranging from manual hand tools to automated CNC cutting systems.

- Grinders and Polishers: These are employed to smooth and refine the edges of cut glass, removing any sharpness and ensuring a safe, polished finish. This can range from simple hand-held grinders to sophisticated robotic polishing systems.

- Edging Machines: These machines create various edge profiles (e.g., bevelled, pencil polished, etc.) on the glass. They automate the process for faster and more precise results than manual grinding.

- Drilling Machines: Precisely drill holes in glass for mounting hardware or decorative purposes. Different drill bits are used depending on glass thickness and material.

- Tempering Furnaces: These high-temperature furnaces are used to heat and rapidly cool the glass, creating tempered glass, significantly increasing its strength and durability.

- Laminating Equipment: Used to bond multiple layers of glass with interlayers (e.g., PVB) to create laminated glass, enhancing safety and sound insulation.

- CNC Machines: Computer Numerical Control (CNC) machines provide automation for cutting, shaping, and drilling glass with high precision and repeatability. This is essential for large-scale production or intricate designs.

- Inspection Equipment: This includes equipment like microscopes, lasers, and other specialized tools to detect even microscopic flaws in glass.

For example, in a small workshop, a hand-held glass cutter and a grinder might suffice, while a large-scale glass production facility would rely on fully automated CNC machinery for efficient production.

Q 10. Explain the importance of quality control in glass fabrication.

Quality control is paramount in glass fabrication. It ensures the final product meets specified standards of safety, aesthetics, and performance, and is crucial for maintaining a positive reputation and avoiding costly recalls or liability issues.

- Raw Material Inspection: Incoming glass sheets are rigorously checked for imperfections, thickness variations, and other defects. This prevents flaws from propagating through the fabrication process.

- Process Monitoring: Throughout the fabrication process, regular checks are made to ensure parameters (temperature, pressure, etc.) are within acceptable limits, ensuring consistent quality. This can include data logging and statistical process control (SPC) techniques.

- Dimensional Accuracy: Regular measurements are performed to ensure the dimensions of the finished glass pieces meet the specifications, avoiding costly mistakes in installations. This involves using precise measuring equipment and quality control procedures.

- Surface Finish Inspection: The surface finish is examined for scratches, chips, and other imperfections that affect the product’s visual appeal and functionality. This can involve visual inspection, and potentially advanced optical techniques.

- Safety Testing: For safety-critical applications like automotive glass, rigorous testing is needed to verify that the glass meets required strength and impact resistance standards.

- Documentation: Detailed records are maintained for each step of the process, documenting the quality control measures taken, and allowing for traceability.

Consider the consequences of a poorly inspected piece of glass used in a skyscraper’s facade. The implications of structural failure could be catastrophic. Quality control prevents such disastrous outcomes.

Q 11. How do you measure and inspect glass for imperfections?

Measuring and inspecting glass for imperfections involves a combination of visual inspection and sophisticated techniques. The approach depends on the type of glass and the application.

- Visual Inspection: This is the most basic method, using good lighting to look for scratches, chips, cracks, bubbles, and other surface imperfections. Magnification tools can help detect smaller defects.

- Thickness Measurement: Precise thickness measurements are taken using specialized calipers or gauges to ensure consistency and meet specifications. This is especially crucial for applications where dimensional accuracy is paramount.

- Optical Inspection: This uses polarized light or specialized microscopes to detect internal flaws like stress points, bubbles, or inclusions that are not visible to the naked eye.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or thermal imaging can be used for more thorough internal inspection, to detect stress, and delaminations, especially in laminated glass.

For instance, a simple glass shelf might only require visual inspection, while safety glass for a vehicle would undergo much more rigorous testing, possibly involving NDT techniques.

Q 12. Describe your experience with different glass processing techniques.

My experience encompasses a broad range of glass processing techniques, from traditional methods to cutting-edge technologies.

- Cutting and Shaping: I’m proficient in using various glass cutters, from hand-held tools to CNC systems. This includes cutting straight lines, curves, and intricate shapes, depending on the design.

- Grinding and Polishing: I have extensive experience in grinding and polishing glass edges to create various profiles, from simple bevels to complex shapes, ensuring smooth, safe, and aesthetically pleasing finishes.

- Drilling and Shaping: I can accurately drill holes in glass of varying thickness, and use specialized tools to create shaped cutouts or holes.

- Tempering: I understand the process of heat treatment to create tempered glass, which significantly increases its strength and impact resistance. This includes operating and maintaining tempering furnaces.

- Laminating: I’m familiar with laminating techniques, combining layers of glass with interlayers to enhance safety, security, and acoustic performance.

- Heat-Strengthening: I understand the heat-strengthening process, an alternative to full tempering that increases the glass’s strength, but less than tempering.

- Surface Coating: I’m experienced in applying various coatings to glass to enhance properties like reflectivity, insulation, or self-cleaning capabilities.

For example, I’ve worked on projects ranging from simple window glass to complex architectural glass facades, requiring expertise across various techniques. This versatility is critical in this field.

Q 13. How do you troubleshoot common problems during glass fabrication?

Troubleshooting in glass fabrication requires a systematic approach. It’s crucial to carefully examine the problem and identify its root cause before attempting a solution.

- Chipping or Cracking: This can be due to improper handling, excessive force during processing, or flaws in the raw material. Check for stress points, impact damage, or insufficient support during processing.

- Surface Defects: Scratches, bubbles, or other surface imperfections often result from inadequate cleaning, improper cutting techniques, or contaminated tools. Review the process, clean the tools, and assess the quality of the raw materials.

- Dimensional Inaccuracies: Inaccurate cuts or shapes might be caused by faulty machine calibration or operator error. Recheck the machine settings and implement quality control measures to improve accuracy.

- Tempering Issues: Problems during tempering, such as uneven heating or cooling, can lead to stress fractures or breakage. Review the tempering furnace settings and monitor temperature control throughout the process.

- Laminating Defects: Air bubbles or delamination in laminated glass suggest issues with the lamination process or the quality of the interlayer material. Ensure proper pressure and temperature are maintained during the lamination process.

A methodical approach, including careful inspection and documentation, is essential. For example, if the problem is consistent, it’s more likely related to the machinery or process, but if it’s sporadic, operator error may be the culprit.

Q 14. What are the different types of glass coatings and their applications?

Glass coatings significantly enhance the properties of glass, extending its applications across various industries. Here are some common types:

- Low-E Coatings: These coatings reduce heat transfer through the glass, improving energy efficiency. They are widely used in windows to reduce energy consumption in buildings.

- Solar Control Coatings: These coatings reflect solar radiation, reducing heat gain inside buildings and improving comfort. They are frequently found in automotive and architectural glass.

- Anti-Reflective Coatings: Reduce glare and reflections, improving visibility and enhancing the clarity of optical instruments. These are used in displays and optical components.

- Self-Cleaning Coatings: These coatings utilize photocatalytic properties to break down dirt and grime, making the glass easier to clean. Popular in architectural applications, reducing the need for frequent cleaning.

- Decorative Coatings: Add color, patterns, or textures to glass, enhancing its aesthetic appeal. Widely used in interior and exterior applications.

- Scratch-Resistant Coatings: Improve the durability of glass and make it resistant to scratching. Commonly used in displays and other high-wear applications.

For example, a low-E coating on a window will significantly reduce energy loss during winter and heat gain during summer, showcasing the practical benefits of these specialized coatings.

Q 15. How do you determine the appropriate type of glass for a specific project?

Choosing the right glass for a project involves considering several key factors. It’s like choosing the right ingredient for a recipe – the wrong one can ruin the whole dish! We start by understanding the project’s requirements: its intended use (e.g., storefront window, shower enclosure, tabletop), the aesthetic goals (e.g., transparency, color, texture), and environmental conditions (e.g., exposure to sunlight, temperature fluctuations).

- Intended Use: A high-traffic storefront needs impact-resistant glass like tempered or laminated glass. A shower enclosure requires water-resistant and easy-to-clean glass.

- Aesthetic Goals: Do we need a clear, transparent glass or a frosted, patterned one? Colored glass can add a touch of personality, while low-iron glass provides exceptional clarity.

- Environmental Conditions: Exposure to extreme temperatures might call for heat-strengthened glass. High-humidity environments might benefit from a specific coating to prevent condensation.

We then consult specifications and datasheets for different glass types (float glass, tempered glass, laminated glass, insulated glass units (IGUs), etc.) to find the best match. This ensures the final product is safe, durable, and meets the client’s expectations. For instance, a museum might require highly specialized low-iron glass for optimal artifact viewing, while a residential project might prioritize cost-effectiveness and standard annealed glass.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of polishing and beveling glass.

Polishing and beveling are essential finishing processes that enhance the appearance and functionality of glass. Think of it as adding the finishing touches to a piece of art. Polishing creates a smooth, flawless surface, while beveling adds a decorative edge.

Polishing involves using progressively finer abrasives to remove surface imperfections and achieve a high-gloss finish. This typically involves multiple stages, using different polishing compounds and tools, similar to how a jeweler polishes a gemstone. The process eliminates scratches, chips, and other surface flaws to provide a pristine surface. The end result is a brilliant, reflective surface.

Beveling involves precisely grinding and polishing the edges of the glass to create a sloped profile. This can range from a simple, subtle bevel to a more dramatic, complex design. Beveling not only adds a touch of elegance but also enhances safety by removing sharp edges. Different bevel profiles can be achieved depending on the project and desired aesthetic. The machine used for beveling can vary, from simple manual machines to advanced CNC machines.

Both polishing and beveling are often performed using automated machinery for increased efficiency and precision, although manual techniques might be used for particularly intricate or small-scale projects.

Q 17. How do you handle customer requests and specifications for custom glass projects?

Handling custom requests requires meticulous attention to detail and clear communication. We treat each project as a unique puzzle to solve. The process typically begins with a detailed consultation to gather all necessary information: the customer’s vision, dimensions, glass type preferences, design specifications (including drawings or sketches), and budget constraints.

- Detailed Design Review: We meticulously review the specifications, identifying potential challenges and suggesting optimal solutions. This could involve material selection adjustments or design modifications to ensure feasibility and safety.

- Prototyping (if necessary): For complex projects, we might create a prototype to refine the design and confirm the client’s satisfaction before proceeding with full-scale production.

- Open Communication: Throughout the project, we maintain constant communication with the customer, providing updates, addressing any concerns, and ensuring alignment with their vision. We regularly send updates and photographs of the process.

- Quality Assurance: Before delivery, we conduct rigorous quality checks to guarantee the final product meets or exceeds expectations.

Our goal is not just to fulfill the customer’s request but to exceed their expectations, transforming their ideas into reality. A successful project isn’t just about meeting the specifications; it’s about creating a truly personalized and satisfying experience.

Q 18. Describe your experience with CNC glass machining.

I have extensive experience with CNC (Computer Numerical Control) glass machining. CNC technology is the backbone of modern glass fabrication, allowing for unparalleled precision and automation. It’s like having a highly skilled, tireless artisan working 24/7, but with even greater precision.

My experience encompasses various CNC machining operations, including:

- Precise Cutting: CNC routers allow for intricate cuts and shapes, far beyond the capabilities of manual methods. We can create complex designs with sharp angles, curves, and intricate details.

- Drilling and Shaping: CNC machines can precisely drill holes of various sizes and shapes and also create intricate contours.

- Beveling and Edge Work: CNC machines can execute various beveling profiles with exceptional accuracy and consistency, enhancing both the aesthetics and the safety of the glass.

- Texturing and Engraving: CNC systems can create unique surface textures and engravings, adding artistic flair to glass pieces.

I am proficient in operating and programming CNC machines, understanding the importance of tool selection, feed rates, and other parameters to optimize the cutting process and avoid damage to the glass. We frequently use CAD software to design the patterns before feeding them into the CNC machine. This ensures that the outcome is exactly as desired.

Q 19. What is your experience with automated glass processing equipment?

My experience with automated glass processing equipment extends across a wide range of technologies, from automated cutting lines to advanced edge processing machines. Automation is crucial for maximizing efficiency and maintaining consistent quality in glass fabrication. It’s like having an assembly line for precision, ensuring each piece is crafted with the same high standards.

I’m familiar with the operation and maintenance of:

- Automated Glass Cutters: These machines significantly increase cutting speed and precision compared to manual methods. They are programmable and can handle large volumes of work.

- Edge Grinding and Polishing Machines: Automated edge processing machines streamline the finishing process, ensuring consistent edge quality across all pieces.

- Washers and Dryers: Automated cleaning systems are crucial for removing debris and ensuring a spotless final product.

- Laminating and Tempering Furnaces: These high-temperature processes require precise control and automation for consistent results.

My expertise also includes troubleshooting and optimizing these systems, identifying and resolving potential issues to minimize downtime and maintain peak productivity. Experience with these automated systems allows me to reduce operational costs and increase production volumes significantly.

Q 20. How do you maintain and troubleshoot glass fabrication equipment?

Maintaining and troubleshooting glass fabrication equipment is crucial for ensuring safe and efficient operations. Regular maintenance is like providing routine check-ups for a car – it prevents major problems down the line. Our maintenance program involves a combination of preventive maintenance and reactive troubleshooting.

Preventive Maintenance: This includes regular inspections, lubrication, and cleaning of all equipment components. We adhere to manufacturers’ recommended maintenance schedules and document all procedures meticulously.

Reactive Troubleshooting: When equipment malfunctions, we systematically diagnose the problem, identifying the root cause before implementing a solution. Our troubleshooting process often involves:

- Visual Inspection: Checking for obvious signs of damage or wear.

- Testing: Using diagnostic tools to identify electrical, mechanical, or software issues.

- Component Replacement: Replacing faulty parts promptly with genuine OEM components.

We maintain detailed maintenance logs, tracking repairs, replacements, and preventive measures to ensure the equipment operates at peak performance and safety standards are upheld. This systematic approach ensures minimal downtime and maximizes the lifespan of our equipment.

Q 21. Explain the importance of following safety regulations and procedures.

Safety regulations and procedures are paramount in glass fabrication. Working with glass involves sharp edges, heavy machinery, and high temperatures – neglecting safety can have severe consequences. It’s not just about compliance; it’s about protecting our team and delivering quality work.

Our safety protocols cover all aspects of the fabrication process:

- Personal Protective Equipment (PPE): All employees are required to wear appropriate PPE, including safety glasses, gloves, and protective clothing.

- Machine Guarding: All machinery is equipped with appropriate safety guards to prevent accidental contact.

- Safe Handling Procedures: Strict procedures are followed for lifting, transporting, and handling glass sheets to prevent breakage and injury.

- Emergency Procedures: Emergency response plans are in place to deal with accidents and injuries promptly and effectively.

- Regular Training: Employees receive regular safety training to ensure they are aware of all risks and procedures.

We also maintain a clean and organized work environment to minimize the risk of accidents. Regular safety audits and inspections ensure compliance with all relevant regulations and continual improvement of our safety practices. This commitment to safety is not just a policy; it’s a fundamental value deeply ingrained in our company culture.

Q 22. How do you manage your time effectively in a fast-paced production environment?

In a fast-paced glass fabrication environment, effective time management is crucial. I approach it strategically, using a combination of techniques. Firstly, I prioritize tasks based on urgency and importance, often employing a Kanban-style system to visualize workflow. This allows me to quickly identify bottlenecks and re-allocate resources as needed. Secondly, I break down large projects into smaller, manageable tasks, setting realistic deadlines for each. This prevents feeling overwhelmed and allows for consistent progress monitoring. Thirdly, I utilize time-blocking techniques, scheduling specific blocks of time for particular activities, minimizing distractions during those periods. For example, I might dedicate two hours in the morning to precision cutting and then switch to assembly in the afternoon. Finally, regular communication with my team is essential; we discuss progress, challenges, and potential delays proactively, allowing for swift adjustments to the schedule.

Think of it like a conductor leading an orchestra – each musician (team member) has their part, and I ensure everyone is on the same page, playing in harmony to meet the overall deadline. This proactive approach minimizes delays and ensures smooth, efficient production.

Q 23. Describe your experience with different types of glass sealants and adhesives.

My experience encompasses a wide range of glass sealants and adhesives, each suited for specific applications. For instance, I’m proficient with silicone sealants, known for their flexibility and weather resistance – ideal for exterior applications like curtain walls or storefronts. I also have extensive experience with polyurethane sealants, offering superior adhesion and strength, particularly beneficial in structural glazing systems. Furthermore, I’m skilled in using epoxy adhesives, which provide excellent bonding strength and are commonly employed in laminated glass production or when precise bonding is crucial. Selecting the appropriate sealant or adhesive is critical; it’s not a one-size-fits-all situation. The choice depends on factors such as the type of glass, the application’s environment (indoors vs. outdoors, exposure to UV radiation), the required structural integrity, and aesthetic considerations. In my experience, understanding the properties of each material – its cure time, elasticity, and resistance to various environmental factors – is vital for successful glass fabrication.

Q 24. How do you ensure the structural integrity of glass installations?

Ensuring structural integrity in glass installations is paramount. My approach involves meticulous attention to detail at every stage, beginning with careful design and engineering considerations. This includes performing accurate calculations to determine the appropriate glass thickness and support systems based on the load requirements and environmental factors. During the fabrication process, I strictly adhere to quality control measures, ensuring precise cuts and proper handling to avoid damage. Installation is equally critical. I utilize appropriate fastening systems, such as structural silicone, specialized clamps, or anchors, depending on the design and glass type. Furthermore, I always double-check the alignment and secureness of each component to prevent stress concentrations that could lead to failure. Finally, regular inspections throughout the process and post-installation are crucial to identify and address any potential issues promptly. For example, I might conduct a thorough visual inspection for cracks, and in larger projects, leverage tools like strain gauges to measure stress levels within the glass.

Q 25. What are your experiences with different types of glass installation techniques?

I’m experienced in various glass installation techniques, including but not limited to: Frameless glass systems, where precision and accurate measurements are paramount; Curtain wall installations, demanding careful coordination and expertise in handling large glass panels; Structural glazing techniques, requiring specialized sealants and expertise in ensuring structural integrity; and Point-fixed glass systems, where the precise placement of fittings is crucial. The choice of technique hinges on the project’s architectural design, the glass type, the environmental conditions, and the budget. Each technique requires a distinct set of tools, materials, and safety precautions. For instance, working with large curtain wall panels necessitates the use of specialized lifting equipment and safety harnesses, emphasizing safe working practices. My experience allows me to adapt to different installation challenges and select the most efficient and secure method for each specific job.

Q 26. How do you work effectively as part of a team in a glass fabrication shop?

Effective teamwork is essential in a glass fabrication shop. I believe in clear communication, active listening, and mutual respect. I contribute by actively participating in team discussions, sharing my expertise, and offering support to colleagues. I readily assist others when needed, fostering a collaborative environment where everyone feels valued. Furthermore, I’m always receptive to feedback and willing to learn from others’ experience. I contribute to maintaining a safe and organized workspace, adhering to safety protocols, and keeping our tools and equipment well-maintained. Think of it like a well-oiled machine – each part contributes to the overall efficiency and success of the operation. This collaborative spirit enhances productivity and ensures high-quality results.

Q 27. Describe a time you had to problem-solve a difficult situation during a glass fabrication project.

During a recent project involving a large, custom-designed glass atrium, we encountered a significant challenge. A crucial support beam arrived damaged, jeopardizing the project timeline and structural integrity. Instead of panicking, I immediately gathered the team to assess the situation. We explored several solutions: waiting for a replacement beam (causing significant delays), modifying the design to eliminate the beam (potentially compromising aesthetics), or attempting a repair. We opted for the repair, employing high-strength epoxy and carbon fiber reinforcement. The repair required meticulous precision and careful planning. We used 3D modeling software to design a reinforcement system, ensuring the repair would be structurally sound and aesthetically pleasing. This collaborative problem-solving approach allowed us to complete the project successfully, albeit with a slight adjustment to the timeline, and ultimately satisfied the client.

Key Topics to Learn for Glass Fabricators Interview

- Glass Types & Properties: Understanding the characteristics of various glass types (e.g., annealed, tempered, laminated) and their suitability for different applications. This includes knowledge of strength, thermal properties, and optical clarity.

- Fabrication Processes: Familiarity with cutting, grinding, polishing, edging, drilling, and other processes used in shaping and finishing glass. Be prepared to discuss the tools and equipment involved.

- Safety Procedures & Regulations: Demonstrate understanding of safety protocols related to handling glass, operating machinery, and adhering to industry safety standards. This is crucial for any fabrication role.

- Design & Engineering Principles: Knowledge of basic engineering concepts relevant to glass fabrication, including stress analysis, structural integrity, and design considerations for different glass applications (e.g., windows, facades, shower enclosures).

- Quality Control & Inspection: Understanding quality control measures, inspection techniques, and the importance of meeting industry standards for precision and defect-free products.

- Troubleshooting & Problem-Solving: Be ready to discuss your approach to identifying and resolving common issues encountered during the glass fabrication process, such as cracks, imperfections, or measurement inaccuracies.

- Project Management (if applicable): Depending on the role, understanding project timelines, resource allocation, and client communication might be essential.

Next Steps

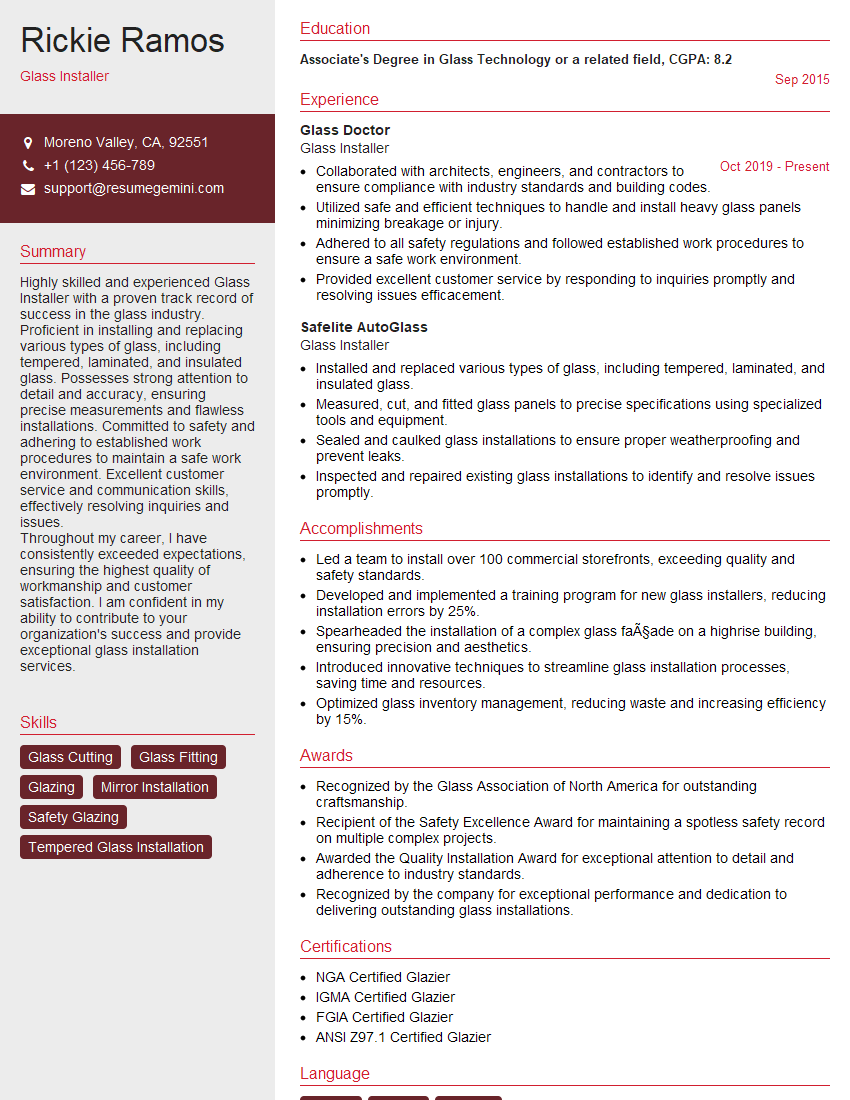

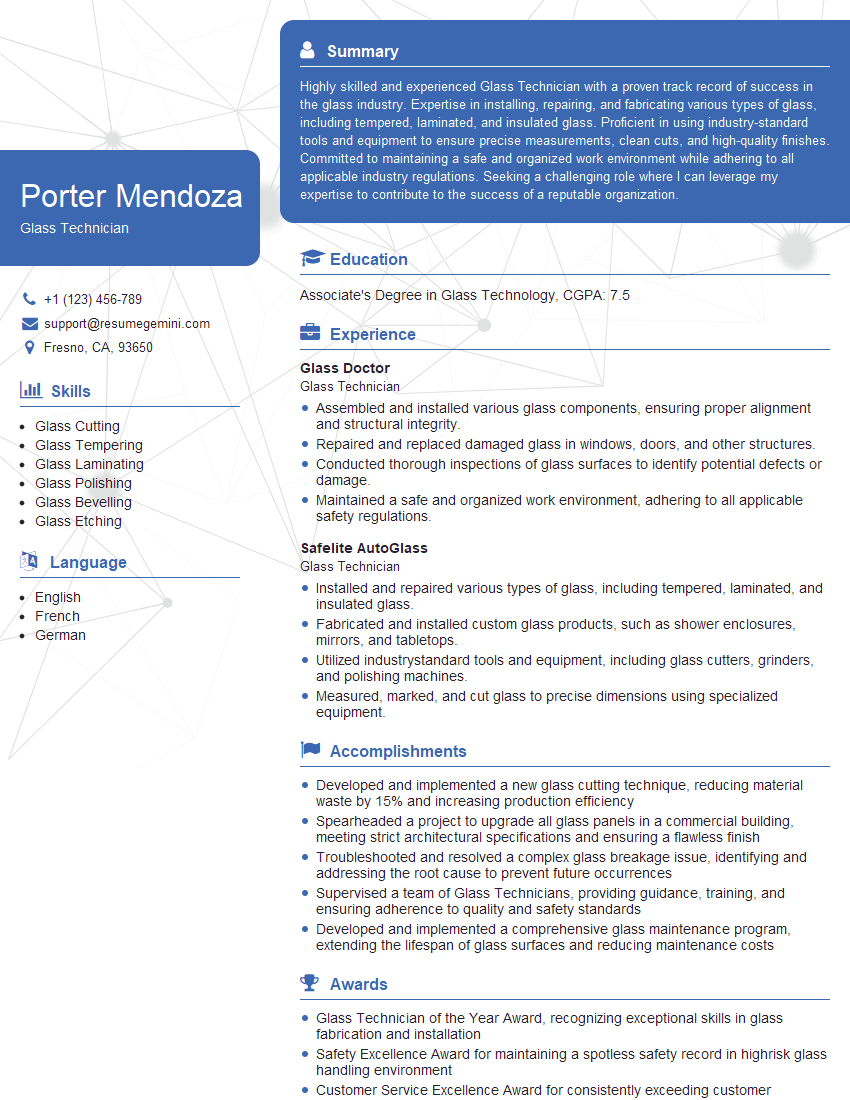

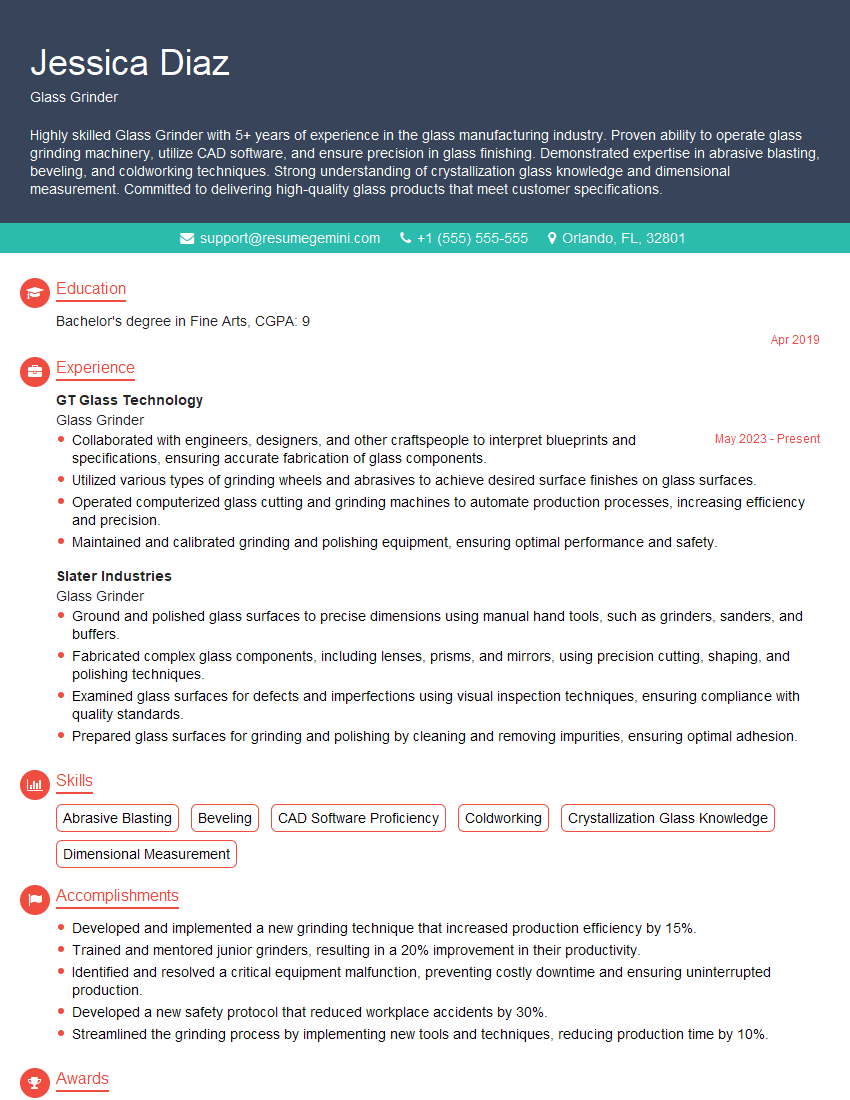

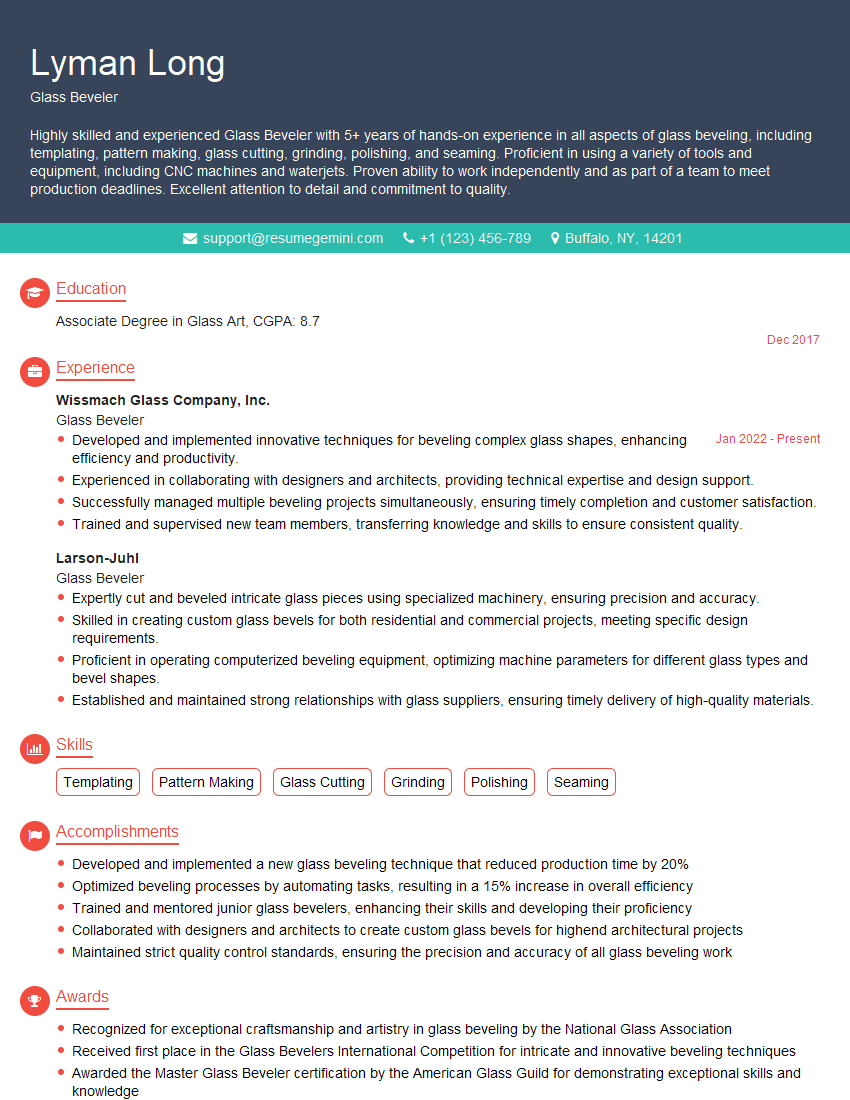

Mastering the intricacies of glass fabrication opens doors to exciting career opportunities in a growing industry. A strong understanding of the technical aspects, combined with effective communication skills, will significantly enhance your job prospects. To maximize your chances of landing your dream role, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to the Glass Fabricators industry are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.