Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important GPS Grading interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in GPS Grading Interview

Q 1. Explain the principles of GPS surveying in the context of grading.

GPS grading leverages satellite signals to determine the precise three-dimensional coordinates of points on the earth’s surface. This allows for highly accurate earthmoving and grading operations, ensuring surfaces are built to exact specifications. Think of it like a highly sophisticated level, but instead of relying on line of sight, it uses signals from space. The principles involve measuring the time it takes for signals to travel from the satellites to the receiver, which is then used to calculate the receiver’s position. These positional data are then used to guide machinery and ensure the grade meets design specifications.

In essence, the process involves:

- Satellite Signal Acquisition: The GPS receiver on the grader picks up signals from multiple satellites.

- Position Calculation: The receiver uses triangulation based on the known positions of the satellites to compute its location (latitude, longitude, and elevation).

- Grade Comparison: This calculated position is compared to a digital design model of the desired grade.

- Machine Guidance: The difference between the actual position and the design model is used to automatically adjust the machine’s blade or other grading equipment.

Q 2. Describe different GPS techniques used in grading (e.g., RTK, PPK).

Several GPS techniques are employed in grading, each offering different levels of accuracy and requiring varying infrastructure:

- Real-Time Kinematic (RTK): RTK is the gold standard for high-accuracy grading. It involves two GPS receivers: a base station at a known location and a rover station on the grading machine. The base station transmits corrections to the rover in real-time, eliminating many error sources and allowing centimeter-level accuracy. Think of it as continuously calibrating the rover’s position.

- Post-Processed Kinematic (PPK): PPK is a cost-effective alternative to RTK. Both the base and rover stations record data independently. This data is then processed later using specialized software and precise satellite ephemeris (data about the satellites’ positions) to achieve high accuracy. It’s like taking a detailed photo and then carefully analyzing it later to extract the most precise measurements. It offers accuracy comparable to RTK but doesn’t require real-time correction data transmission.

- Precise Point Positioning (PPP): PPP uses precise satellite orbit and clock information from global reference stations to determine position. It does not require a local base station but takes longer processing times. It’s suitable for situations where establishing a base station isn’t feasible. This is less common in real-time grading due to longer processing times.

Q 3. What are the sources of error in GPS grading, and how are they mitigated?

Several factors can introduce errors into GPS grading data:

- Atmospheric Effects: The ionosphere and troposphere can delay GPS signals, leading to positional errors. RTK and PPK techniques largely mitigate these through differential corrections.

- Multipath Errors: Signals bouncing off buildings or other surfaces before reaching the receiver can create false position readings. Careful receiver placement and antenna design help minimize this.

- Satellite Geometry (GDOP): The geometric arrangement of the satellites affects the accuracy of position calculations. Poor geometry (high GDOP) leads to greater uncertainty. This is largely unavoidable but can be monitored.

- Receiver Noise: Electronic noise in the receiver can introduce small errors. High-quality receivers are crucial.

- Antenna Phase Center Variations: The effective location of the antenna can vary slightly, depending on the signal’s frequency and other factors. This is usually accounted for during calibration.

Mitigation strategies include using RTK or PPK, proper antenna placement, employing high-quality receivers, and using post-processing techniques to filter out noise and systematic errors.

Q 4. How do you ensure the accuracy and precision of GPS data in grading projects?

Ensuring accuracy and precision involves a multi-faceted approach:

- Regular Calibration: The GPS equipment needs regular calibration to ensure its accuracy. This often involves comparison with known control points.

- Base Station Selection: For RTK, the base station location significantly impacts accuracy. A stable, unobstructed location is crucial.

- Data Post-Processing: PPK relies on sophisticated software for post-processing to remove errors. Selecting a robust software package is important.

- Quality Control Checks: Regular checks comparing GPS data with traditional surveying methods (e.g., total stations) are essential.

- Experienced Operators: Skilled operators who understand the limitations of GPS and know how to handle potential problems are key.

Regular maintenance and understanding the environmental conditions, such as atmospheric conditions and potential signal interference sources are also key aspects of data integrity.

Q 5. Explain the process of setting out control points for GPS grading.

Setting out control points is the foundation of any GPS grading project. These points provide reference points for the GPS system, enabling accurate positioning. The process involves:

- Design Review: Carefully review the design plans to identify key points where control points are needed.

- Traditional Survey: Establish the control points using traditional surveying techniques like total stations or other precise measurement methods. These points need to be accurately measured and documented with their coordinates.

- GPS Measurement: Measure the coordinates of the control points using the GPS equipment. This provides a link between the traditional survey data and the GPS coordinate system.

- Data Transformation: If necessary, transform the coordinate systems of the traditional survey data and the GPS data to ensure compatibility. This is vital to integrate design models with measured reality.

- Verification: Verify the accuracy of the established control points through various check measurements.

Properly established control points form the backbone of the entire grading process, ensuring that the final surface matches the design specifications.

Q 6. How do you handle signal obstructions or multipath errors during GPS grading?

Signal obstructions and multipath errors are common challenges in GPS grading. Strategies to handle these include:

- Careful Site Selection: Select base station and rover locations to minimize obstructions. This might involve clearing vegetation or temporarily relocating obstacles.

- Multiple Antenna Positions: Use multiple antenna positions and average the results to reduce the impact of multipath signals.

- Antenna Types: Use antennas specifically designed to reduce multipath effects.

- Software Filtering: Utilize post-processing software with algorithms that identify and filter out multipath and other errors.

- Redundancy: Collect data multiple times to check for consistency and identify potential errors.

Understanding the site’s characteristics and anticipating potential interference is crucial for successful GPS grading. Careful planning and data analysis are key to mitigating these challenges.

Q 7. What software and hardware are commonly used in GPS grading?

The hardware and software used in GPS grading are constantly evolving, but some commonly used elements include:

- Hardware:

- GPS Receivers: High-precision GNSS receivers (e.g., Trimble, Leica, Topcon) are essential for both base and rover stations.

- Antennas: Specialized antennas designed to minimize multipath errors and improve signal reception.

- Data loggers: To record raw GPS data.

- Grading Machines: Modern graders often incorporate integrated GPS systems for automatic guidance and control.

- Software:

- Data Acquisition Software: Software to collect and manage GPS data in the field.

- Post-Processing Software: Software to process PPK data and generate accurate coordinate information (e.g., Trimble Business Center, Leica GeoMos).

- CAD/Modeling Software: Software to create and manage digital design models of the desired grade (e.g., AutoCAD Civil 3D).

- Machine Control Software: Software to interface with the grader’s control system and provide real-time guidance.

Q 8. Describe your experience with different GPS receivers and their specifications.

My experience with GPS receivers spans various models and manufacturers, from basic single-frequency units to advanced multi-frequency, RTK (Real-Time Kinematic) capable receivers. I’ve worked extensively with Trimble, Leica, and Topcon brands, each offering unique features and specifications. For example, I’ve used Trimble R10 receivers for their robust performance in challenging environments, while Leica GS18 receivers provided excellent accuracy for precision grading projects. Specifications I regularly consider include:

- Frequency: Single-frequency receivers are cost-effective but susceptible to multipath errors. Multi-frequency receivers, however, mitigate these errors significantly improving accuracy.

- RTK Capability: Real-Time Kinematic technology is crucial for centimeter-level accuracy, essential for precise grading. I frequently use base station and rover configurations, or network RTK for even greater coverage.

- Antenna type: The choice of antenna is critical. Different antennas offer varying sensitivities to multipath and atmospheric interference. For example, choke ring antennas are very effective in mitigating multipath.

- Data logging capabilities: The capacity for internal data logging varies greatly and it’s critical to select a receiver with sufficient capacity for a given job. This includes the ability to log data at high rates for demanding applications.

Choosing the right receiver is all about understanding the project requirements. A large-scale earthmoving project will require a different receiver than a smaller, high-precision landscaping job.

Q 9. How do you interpret GPS data to ensure accurate grading?

Interpreting GPS data for accurate grading involves a multi-step process. It starts with understanding the coordinate system and datum used. Then, I carefully review the raw data for outliers or anomalies that may indicate signal interference or equipment malfunction. This often involves visual inspection of data plots alongside quality control checks within the post-processing software. Next, I apply appropriate corrections for atmospheric effects and antenna phase center offsets. Finally, the corrected data is used to generate a 3D model of the site which I compare to the design model to guide the grading process. Imagine it like comparing a real-world terrain map to a blueprint; the difference shows us what needs to be moved. We use this data to guide the machine operators to ensure accuracy within the design tolerances.

An example: I once discovered a significant spike in elevation data due to a temporary obstruction near the base station, influencing a particular area of the site. By identifying and excluding this outlier, I prevented a significant error in the grading process. Consistent quality control is key.

Q 10. Explain the concept of coordinate transformations in GPS grading.

Coordinate transformations are fundamental in GPS grading, as GPS data is typically collected in a geographic coordinate system (e.g., WGS84), while design plans are often in a local, projected coordinate system (e.g., UTM or State Plane). This transformation is crucial for accurately overlaying GPS data onto the design. The process involves using transformation parameters (e.g., shift, scale, rotation) to mathematically convert coordinates from one system to the other.

Software packages typically handle these transformations automatically using methods like 7-parameter transformations or more sophisticated techniques considering ellipsoidal models and geoid undulations. This is essential for getting accurate results and aligning GPS data with other survey information. Incorrect transformations can lead to errors in cut and fill calculations and overall project inaccuracy. The process is similar to matching a puzzle; transforming coordinates aligns the puzzle pieces (GPS data and design) correctly.

Q 11. Describe your experience with GPS data post-processing.

GPS data post-processing is crucial for enhancing accuracy and correcting errors. I typically use software like Trimble Business Center or Leica Geo Office. This involves applying corrections from base station data (if using RTK), and accounting for atmospheric delays and satellite orbit errors. Post-processing allows for the refinement of positions, leading to improved accuracy. For instance, we can check for any data jumps or gaps in the dataset. After post-processing, the data is cleaner and more reliable for generating accurate surfaces and grading plans.

A practical example: I used post-processing to correct for multipath effects in a densely wooded area. The post-processed data revealed a more accurate surface model, improving the overall efficiency and cost-effectiveness of the grading operation by avoiding rework later.

Q 12. How do you integrate GPS data with other survey data (e.g., total station data)?

Integrating GPS data with other survey data, such as total station data, is common and enhances overall project accuracy and efficiency. We utilize software to combine different datasets. The total station provides highly accurate measurements of specific points, acting as control points for the GPS data. These control points are used to ensure the GPS data is correctly positioned and scaled. This integration increases the confidence and reduces uncertainties associated with relying solely on GPS data, especially in areas where GPS reception might be challenging.

For instance, total station data can be used to accurately define the locations of existing structures or utilities which are then incorporated into the GPS-based design to avoid damaging these elements during the grading process.

Q 13. What is your experience with different types of grading equipment (e.g., bulldozers, excavators)?

My experience encompasses various grading equipment, including bulldozers, excavators, and motor graders. I understand their capabilities and limitations concerning GPS integration. Different machines have different interface requirements. Some utilize onboard GPS systems, others rely on external systems. The focus is on the seamless integration of the GPS guidance system with the machine’s hydraulics or controls. Understanding these interfaces is key to effectively utilizing GPS for precise grading operations. I’m familiar with operating procedures for each type of machine when interfaced with GPS, which includes understanding the machine’s limitations and the correct use of the control system.

For example, I’ve used GPS-guided bulldozers for large-scale earthworks, ensuring accurate cut and fill operations, while using smaller excavators with GPS guidance systems for more intricate landscaping projects requiring fine adjustments.

Q 14. How do you ensure the safety of personnel during GPS grading operations?

Safety is paramount during GPS grading operations. We adhere to strict safety protocols, including site-specific safety plans. This involves clearly defined safety zones, regular equipment checks, and training for all personnel, including machine operators and surveyors. Communication is essential; clear communication channels and procedures must be established between operators and supervisors. Visibility is critical, we ensure clear sightlines, and implement warning systems as needed. We also frequently check the GPS system, making sure everything is working correctly and within the tolerance level for the task.

Examples include implementing traffic control measures when working near public areas and using safety harnesses and other personal protective equipment (PPE) for workers in high-risk environments. Proactive risk assessment and mitigation are crucial aspects of my approach to ensure everyone’s safety.

Q 15. How do you manage and organize large datasets of GPS data?

Managing large GPS datasets requires a structured approach. Think of it like organizing a massive library – you wouldn’t just throw all the books in a pile! I typically use a combination of techniques. First, I employ a robust file naming convention, using a consistent format that includes project name, date, and data type (e.g., ProjectA_20241027_Raw.txt). This ensures easy identification and retrieval. Second, I leverage Geographic Information System (GIS) software like ArcGIS or QGIS to import and manage the data. These programs provide tools for spatial indexing, data filtering, and efficient storage. For truly massive datasets, cloud-based solutions like AWS S3 or Azure Blob Storage are beneficial for scalability and data backup. Finally, I regularly create backups of my data to prevent data loss. This multi-layered approach guarantees data integrity and efficient workflow.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with quality control procedures in GPS grading.

Quality control (QC) in GPS grading is paramount. Imagine building a house without checking the measurements – it wouldn’t stand! My QC process includes several steps. Firstly, I perform baseline checks on the equipment before each day’s work, verifying antenna phase center offsets and confirming signal reception. I then analyze the raw GPS data for any outliers or anomalies, looking for spikes or unusual patterns that might indicate errors. I use statistical methods to identify and filter out these noisy data points. Additionally, I always compare GPS measurements against design plans and independent checks, such as total stations, for confirmation. Finally, I meticulously document all QC procedures and findings, creating an audit trail for traceability.

Q 17. How do you troubleshoot GPS equipment malfunctions in the field?

Troubleshooting GPS equipment in the field requires a systematic approach. It’s like diagnosing a car problem – you need to find the root cause. I first check the obvious: batteries, antenna connections, and the receiver’s power. Then I verify satellite acquisition – a low satellite count can significantly impact accuracy. If the problem persists, I investigate possible interference sources, like nearby radio towers or other electronic devices. I also check the receiver’s settings, ensuring they are correctly configured for the project’s coordinate system and desired accuracy. If the issue remains unresolved, I’ll contact technical support for guidance or initiate a repair process. Detailed field notes are critical, noting the steps taken and any observations made for future reference.

Q 18. Explain your understanding of different coordinate systems (e.g., UTM, State Plane).

Understanding coordinate systems is fundamental. Think of it like addressing a letter – you need the correct address for it to reach its destination. UTM (Universal Transverse Mercator) is a global coordinate system that divides the Earth into 60 zones, each with its own projection. It’s commonly used for large-scale projects. State Plane Coordinate Systems are designed for individual states or regions and provide high accuracy within a smaller area. Each system has a specific datum (reference surface) associated with it, such as NAD83 or WGS84. I ensure that all GPS data is collected and processed using the appropriate coordinate system for the project, as errors can arise if inconsistent systems are used. The conversion between systems requires precise calculations which I perform using specialized software.

Q 19. How do you deal with discrepancies between design plans and GPS measurements?

Discrepancies between design plans and GPS measurements are common. It’s like finding a difference between the blueprint and the actual construction. My approach involves a thorough investigation. First, I verify the accuracy of both the design plans and the GPS data, checking for errors in either source. Then, I analyze the discrepancies spatially to identify patterns or localized issues. This might indicate problems with the design, the construction, or the GPS data itself. If the differences are minor and within the acceptable tolerance, they may be accommodated through adjustments on the ground. However, significant discrepancies often require a collaborative discussion with the engineers and contractors to identify and resolve the underlying cause.

Q 20. Describe your experience with using GPS technology for earthwork calculations.

GPS technology is essential for earthwork calculations. It’s like having a precise measuring tool for sculpting the land. I utilize GPS data to calculate volumes of cut and fill, optimizing earthmoving operations. Using software packages, I can generate digital terrain models (DTMs) from the GPS data, comparing them to the design surface to determine the exact volumes needed to achieve the final grade. This allows for efficient material management and cost estimations. Furthermore, GPS-guided machinery enables accurate and efficient execution of the earthmoving plan, minimizing waste and maximizing productivity. I’ve utilized this in several large-scale projects, resulting in significant cost savings and schedule improvements.

Q 21. How familiar are you with using CAD software for visualizing and analyzing GPS data?

CAD software is crucial for visualizing and analyzing GPS data. It’s like having a detailed drawing to understand a complex 3D model. I’m proficient in several CAD packages, such as AutoCAD Civil 3D and MicroStation. I use these programs to import and display GPS data, overlaying it with design plans for comparison and analysis. This allows for accurate identification of discrepancies and for creating detailed as-built drawings. I use CAD software to generate various visualizations, including contour maps, cross-sections, and 3D models, aiding in the comprehensive understanding and communication of project progress and outcomes. This also supports informed decision-making throughout the project lifecycle.

Q 22. Explain your understanding of the limitations of GPS technology in grading.

GPS grading, while highly accurate, isn’t without its limitations. One major constraint is the inherent inaccuracy of the GPS signal itself. While modern systems boast centimeter-level accuracy, factors like atmospheric interference (ionospheric and tropospheric delays), multipath signals (reflections from buildings or terrain), and satellite geometry can introduce errors. Think of it like trying to hit a golf ball – even the best golfer can’t always hit it perfectly straight, and the wind can affect the trajectory. These errors accumulate, impacting the overall precision of the grading process, especially over larger areas.

Another limitation stems from the need for clear visibility to sufficient satellites. In dense forests or heavily built-up areas, the signal can be blocked, leading to interruptions or inaccuracies. Finally, the accuracy of the base station’s position is crucial. An error in the base station’s coordinates will directly affect the accuracy of the entire project. Regular calibration and monitoring are essential to mitigate these limitations.

Q 23. How do you ensure compliance with relevant safety regulations during GPS grading?

Safety is paramount in GPS grading. My approach centers on rigorous adherence to OSHA (or equivalent local) regulations and best practices. This begins with thorough site surveys to identify potential hazards, like underground utilities, unstable slopes, and traffic patterns. We employ comprehensive safety briefings for all personnel involved, emphasizing the importance of personal protective equipment (PPE), such as hard hats, high-visibility clothing, and safety boots. Clear communication channels are established to ensure immediate reporting of any incidents or near misses. We also utilize job-site safety plans, incorporating specific risk assessments for the particular terrain and equipment used. Furthermore, GPS equipment itself needs regular inspection and calibration to prevent malfunction that could compromise safety.

Q 24. Describe your experience working with different types of terrain and soil conditions.

My experience encompasses a wide range of terrain and soil conditions, from the challenging slopes of mountainous regions to the flat, expansive plains. I’ve worked on projects involving rocky, clay-rich soils demanding precise control and others with loose, sandy soils that required careful consideration of compaction and erosion control. Working with varying soil conditions necessitates adjusting equipment settings, selecting appropriate cutting tools, and implementing different grading strategies. For instance, in rocky terrain, we might need to use specialized rippers or employ more cautious grading passes to avoid damaging equipment. In contrast, softer soils may require extra compaction measures to prevent settlement after grading.

Adaptability is key. I utilize various GPS-guided machinery and have experience with different types of earthmoving equipment, including bulldozers, excavators, and graders, adapting my techniques to the specific needs of each project and environment.

Q 25. How do you communicate technical information effectively to non-technical personnel?

Communicating technical details to non-technical personnel is crucial for successful project completion. My approach involves using clear, concise language, avoiding jargon whenever possible. I use visual aids such as diagrams, maps, and even simple 3D models to illustrate complex concepts. For example, instead of explaining coordinate systems, I might show a simplified map highlighting the project area and its intended elevations. I also break down complicated processes into simpler steps, using analogies and relatable examples. For instance, explaining the concept of ‘cut and fill’ can be easily understood by comparing it to leveling a garden. Regular progress reports, including visual updates of project milestones, keep stakeholders informed and engaged.

Q 26. Explain your experience with project management aspects of GPS grading projects.

My experience in project management for GPS grading projects is extensive. I’m proficient in all phases of a project, from initial planning and budgeting to execution and final handover. This includes developing detailed project schedules, managing resources effectively, and coordinating with multiple teams (surveying, engineering, and equipment operators). I leverage project management software to monitor progress, track costs, and identify potential delays or issues. Risk assessment and mitigation is a key part of my approach. I proactively identify potential problems and develop contingency plans. For example, if inclement weather is anticipated, we’ll adjust the schedule or make provisions for weather protection. Furthermore, I oversee the maintenance and calibration of equipment, ensuring optimal performance and preventing costly downtime.

Q 27. Describe a time you encountered a challenging GPS grading problem, and how you solved it.

On one project, we encountered significant challenges due to unexpected subsurface variations. The initial survey showed relatively uniform terrain, but during the grading process, we discovered significant pockets of dense rock far below the surface. This caused damage to the bulldozer’s blade and threatened to significantly delay the project. The solution involved a three-step process: First, we halted work to conduct a thorough subsurface investigation using ground penetrating radar (GPR) to accurately map the rock formations. Second, we revised the grading plan to accommodate the unexpected obstacles, incorporating alternative routing to avoid the most problematic areas. Finally, we used specialized rock-breaking equipment to remove or mitigate the obstacles in the remaining areas. Although the initial delay was frustrating, this systematic approach allowed us to complete the project within acceptable tolerances and still meet the deadline.

Q 28. How do you stay up-to-date with the latest advancements in GPS technology?

Staying current in GPS technology is essential. I regularly attend industry conferences and workshops, participate in continuing education programs, and actively engage with professional organizations like the American Society of Civil Engineers (ASCE) and relevant manufacturers’ training sessions. I also follow industry publications and journals, and subscribe to online resources that offer updates on technological advancements. Additionally, I continuously evaluate and test new software and hardware, ensuring that our team uses the latest and most efficient equipment and techniques to optimize efficiency and improve accuracy.

Key Topics to Learn for GPS Grading Interview

- GPS Data Acquisition: Understanding different GPS techniques (e.g., RTK, PPK), data collection strategies, and potential sources of error.

- Data Processing and Adjustment: Familiarize yourself with common software packages and their functionalities in processing raw GPS data, applying corrections, and achieving high accuracy.

- Coordinate Systems and Transformations: Mastering the conversion between different coordinate systems (e.g., UTM, Geographic) and understanding datum transformations.

- Error Analysis and Quality Control: Learn to identify and mitigate various error sources in GPS measurements, including atmospheric effects, multipath, and receiver noise. Understanding quality control procedures is vital.

- Applications of GPS Grading in Construction: Explore practical applications such as earthworks, road construction, and site leveling. Be prepared to discuss specific examples.

- Software Proficiency: Demonstrate familiarity with industry-standard software used for GPS data processing and grading design (mention specific software if applicable to your target roles).

- Understanding of Surveying Principles: A foundational understanding of surveying concepts, such as leveling, and their relationship to GPS grading will strengthen your application.

- Problem-Solving and Troubleshooting: Be ready to discuss how you would approach and resolve common challenges encountered during GPS grading projects.

Next Steps

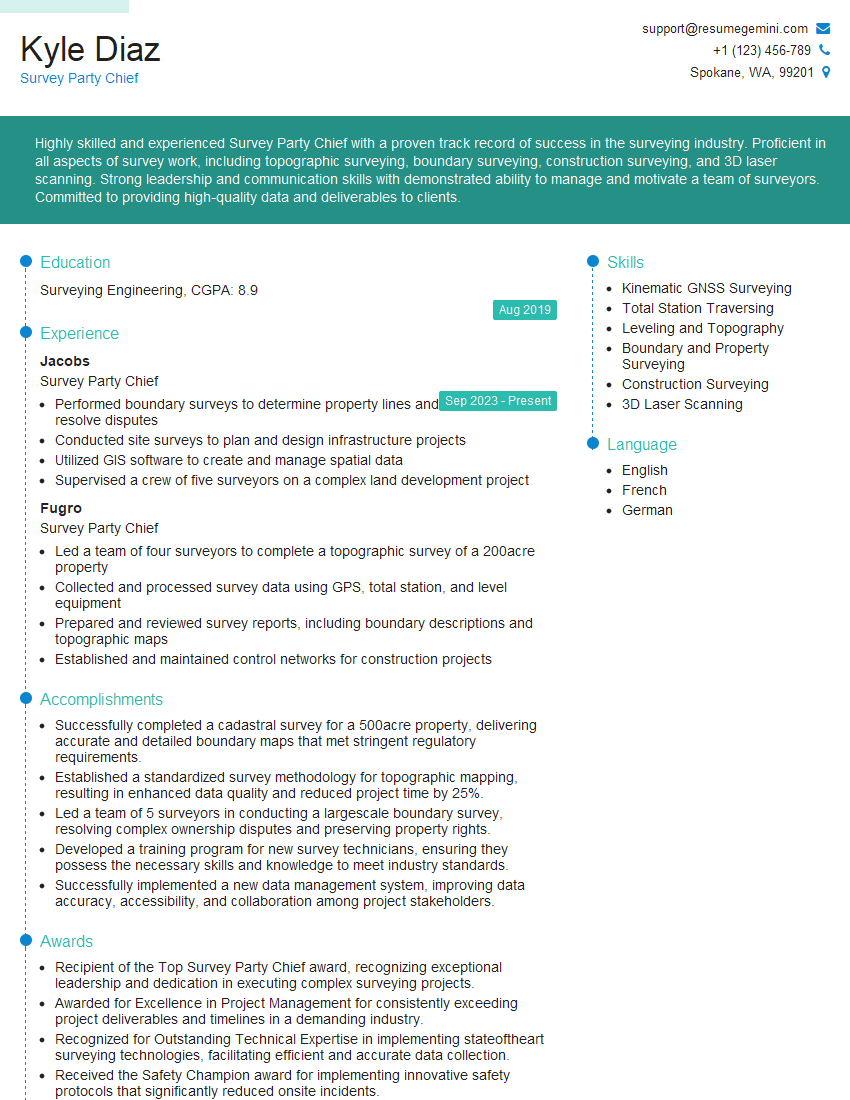

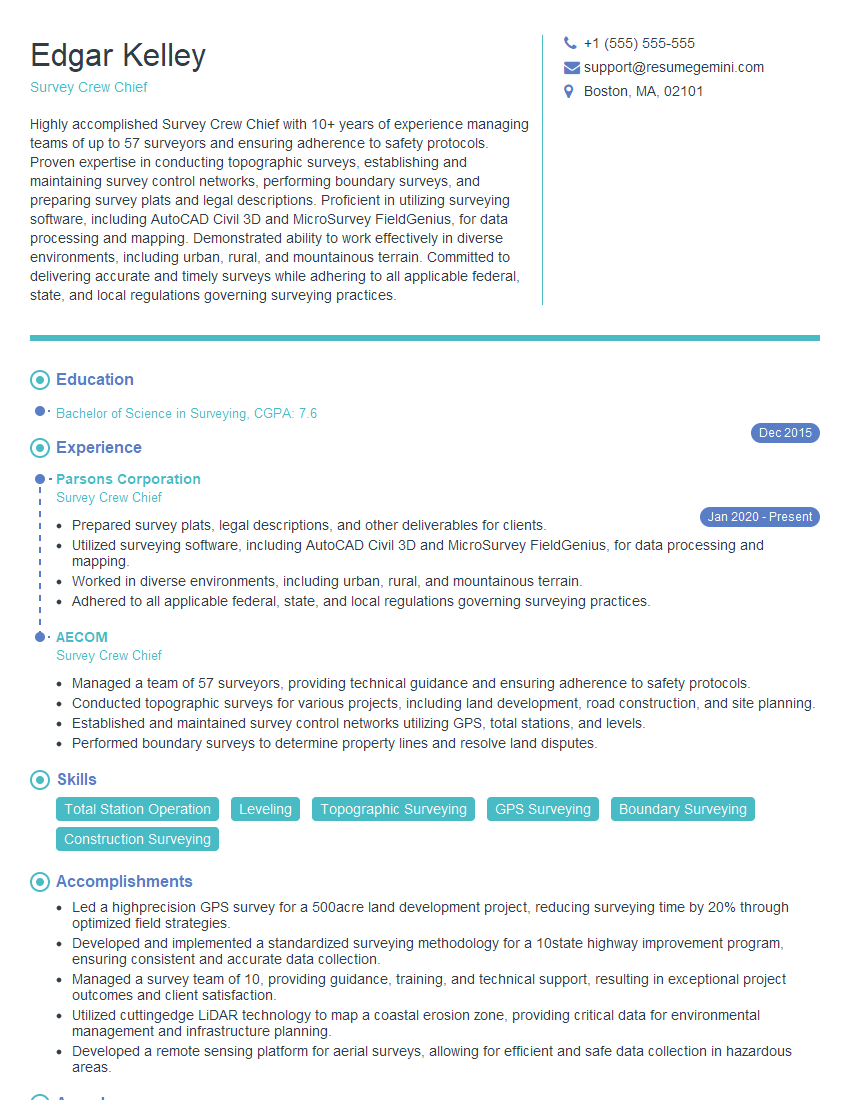

Mastering GPS Grading opens doors to exciting career opportunities in the construction and surveying industries, offering high earning potential and a chance to work on cutting-edge projects. To maximize your job prospects, it’s crucial to present your skills effectively. Create an ATS-friendly resume that highlights your expertise in GPS Grading and related technologies. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to GPS Grading are available to guide you, showcasing how to effectively present your qualifications to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.