The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Grading Planning and Execution interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Grading Planning and Execution Interview

Q 1. Describe your experience in developing grading plans from design documents.

Developing grading plans from design documents is a crucial step in any construction project. It involves translating the architect’s and engineer’s vision into a detailed, executable plan for moving earth. My process begins with a thorough review of the design documents, including site plans, topographic surveys, and construction specifications. I identify key elements like proposed grades, building footprints, utility locations, and drainage patterns. Then, I use this information to create a series of grading plans that show the precise amount of cut and fill needed to achieve the desired finished grade. This includes creating contour lines, calculating volumes, and designing appropriate drainage solutions. For example, on a recent residential development project, the initial design lacked sufficient detail on drainage around the foundation. My review uncovered this, and I incorporated swales and appropriate slopes into the grading plan to prevent water accumulation and foundation issues.

I also consider factors such as soil type, bearing capacity, and environmental regulations to ensure the plan is both feasible and environmentally sound. The final grading plan is a comprehensive document that guides the earthmoving process, showing the contractor precisely how to excavate and fill the site to meet the design specifications.

Q 2. Explain your process for calculating earthwork quantities.

Calculating earthwork quantities is essential for accurate cost estimation and efficient project execution. My process generally involves using a combination of digital terrain modeling (DTM) software and manual calculations to ensure accuracy. I begin by importing the survey data (often in the form of a point cloud or contour lines) into the software. The software then generates a DTM, a three-dimensional representation of the terrain. I then use the software’s tools to define the existing and proposed ground surfaces. The software automatically calculates the volumes of cut and fill between these two surfaces, providing a precise quantification of the earthmoving required.

For smaller projects or to verify software calculations, I may also employ manual methods like the average-end-area method or the prismoidal method. These methods involve calculating cross-sectional areas at regular intervals along the project length and using these areas to compute the total volume. It’s critical to use consistent units throughout the calculation process to prevent errors. For example, if I’m dealing with a large site, I might divide it into smaller sections for easier calculation and better accuracy. The results are then compiled and reviewed for consistency and reasonableness. Regular cross-checking and quality control measures prevent significant discrepancies in the final earthwork quantities.

Q 3. How do you ensure accurate grading plans align with site surveys and specifications?

Ensuring accurate grading plans that align with site surveys and specifications is paramount to the success of a project. My approach is multi-faceted and involves meticulous attention to detail at every stage. First, I conduct a thorough review of the site survey data. This includes checking for inconsistencies, errors, or missing information. I use this data to create a highly accurate digital terrain model (DTM) in the software I’m using. Then, I overlay the design specifications, including proposed grades, building footprints, and other key features, onto this DTM. Any discrepancies between the existing site conditions and the proposed design are highlighted and addressed.

This might involve revising the design, adjusting the proposed grades, or even requesting further site investigation. Throughout this process, I utilize a rigorous quality control system, including regular checks and cross-referencing between different data sources. This often includes conducting field verification checks to ensure that the digital model accurately reflects the on-site conditions. For instance, on a recent project, a discrepancy was identified between the survey data and the actual site conditions. This discrepancy was quickly resolved by conducting a further field survey, correcting the DTM, and ensuring the final grading plan accurately reflected the actual site. This proactive approach prevented potential issues during construction.

Q 4. What software and tools are you proficient in for grading planning and execution?

My proficiency in grading planning and execution relies heavily on a suite of software and tools. I’m highly experienced in using Civil 3D, AutoCAD, and ArcGIS. Civil 3D is my primary tool for creating and managing grading plans, performing earthwork calculations, and generating detailed construction drawings. AutoCAD is valuable for creating and editing 2D drawings and managing site plans. ArcGIS is useful for handling and analyzing large datasets and integrating geographic information.

In addition to software, I utilize various surveying instruments such as total stations and GPS equipment for accurate data acquisition. I also use construction-related software for project management and coordination, and other collaboration tools for seamless communication with engineers and contractors. My proficiency extends to utilizing various data formats including DXF, DWG, LandXML, and shapefiles, ensuring interoperability and seamless data transfer across different software and platforms.

Q 5. Describe your experience with managing cut and fill operations.

Managing cut and fill operations requires a strategic approach that considers efficiency, cost, and safety. My experience involves meticulous planning and coordination. It starts with a thorough analysis of the grading plan, identifying areas of significant cut and fill. This allows me to optimize the earthmoving process by minimizing haul distances and maximizing the use of on-site materials. For example, I’d prioritize using material from cut areas to fill other areas, reducing the need to import or export large volumes of soil.

I work closely with contractors to develop a detailed earthmoving schedule that considers factors such as equipment availability, site access, and weather conditions. I regularly monitor the progress of the operations, ensuring adherence to the plan and addressing any potential issues promptly. Safety is paramount; I implement robust safety protocols and ensure that all personnel are properly trained and equipped. Regular inspections and safety meetings are integral to this process. Thorough documentation, including daily progress reports and as-built drawings, is maintained throughout the operation. This meticulous record-keeping allows for accurate tracking of materials and effective conflict resolution should any issues arise.

Q 6. How do you manage potential soil erosion and sedimentation during grading?

Soil erosion and sedimentation are significant environmental concerns during grading. My approach to managing these risks involves integrating erosion and sediment control measures (ESCM) into the grading plan from the outset. This includes implementing strategies like silt fences, sediment basins, and temporary vegetative cover. The selection of ESCM depends on factors like the site’s topography, soil type, and rainfall intensity. For instance, in areas with steep slopes, I might specify the use of geotextiles and erosion control blankets to prevent soil loss.

I also emphasize best management practices (BMPs), such as minimizing exposed soil surfaces, maintaining proper drainage, and stabilizing slopes as quickly as possible. This involves close coordination with contractors to ensure proper implementation of ESCM and BMPs. Regular inspections are conducted to monitor the effectiveness of these measures and address any issues promptly. Compliance with local, state, and federal regulations regarding erosion and sediment control is crucial, and I ensure all projects adhere to these standards.

Q 7. Explain your approach to quality control during grading and earthwork activities.

Quality control is an ongoing process throughout grading and earthwork activities. My approach emphasizes proactive measures and regular checks to ensure the final product meets the design specifications and quality standards. It starts with a detailed quality control plan developed early in the project, outlining specific checks and inspections at each phase. This includes verifying the accuracy of the site survey, monitoring earthwork quantities, and inspecting the construction of drainage features. I also implement regular inspections during the earthmoving process to ensure that the work is being performed according to the grading plan and to identify and rectify any deviations promptly.

Advanced surveying techniques are used to accurately track progress and ensure the finished grades conform to the design. Regular communication with contractors and other stakeholders is crucial for effective quality control. Any identified deficiencies are addressed immediately through corrective actions, documented, and reported. Final verification involves a detailed inspection of the completed work, verifying that the final grades meet the specified tolerances. This is typically followed by the preparation of as-built drawings that document the actual conditions post-construction.

Q 8. How do you handle unforeseen site conditions during grading?

Unforeseen site conditions during grading are a common challenge. My approach involves a proactive strategy focusing on thorough pre-construction investigation and a flexible, responsive plan during execution. Before starting, we conduct detailed site surveys, including geotechnical investigations to understand soil composition, potential subsurface obstacles (like rocks or buried utilities), and groundwater levels. This data informs the grading plan and allows for contingency planning.

If unexpected conditions arise—say, encountering unexpectedly hard rock where softer soil was anticipated—I immediately halt work and convene a meeting with the engineering team, the project manager, and the subcontractor. We assess the impact on the schedule and budget, revise the plan (potentially employing different excavation methods or equipment), and obtain necessary approvals. Documentation is crucial; we meticulously record all changes, including photos and detailed descriptions, to manage potential disputes and revisions to the contract. For example, on a recent project, we discovered a previously unmapped bedrock layer. Instead of simply blasting, which would be costly and potentially risky, we collaborated with the engineers to adapt the design, slightly modifying the building’s footprint to minimize excavation in the affected area. This saved both time and money compared to a brute-force approach.

Q 9. Describe your experience with managing subcontractors involved in grading.

Managing subcontractors in grading requires strong communication, clear expectations, and robust oversight. I begin by selecting reliable, experienced subcontractors with a proven track record of safety and quality. Before work starts, I hold pre-construction meetings to thoroughly review the plans, specifications, and safety protocols. We establish clear roles and responsibilities, including timelines and communication channels. Regular site visits are essential, where I monitor progress, ensure compliance with plans and safety regulations, and address any emerging issues promptly. I also maintain open communication through daily or weekly progress reports, ensuring transparency and resolving conflicts constructively. For example, on one project, a subcontractor experienced delays due to equipment malfunction. Through proactive communication, we were able to source a replacement quickly, minimizing downtime and preventing schedule impacts. Regular performance evaluations, incorporating aspects of safety, quality, and adherence to schedule, ensure that expectations are consistently met.

Q 10. How do you ensure the timely completion of grading projects within budget?

Ensuring timely and budget-conscious completion of grading projects requires a multi-pronged approach. It starts with detailed planning, including accurate quantity takeoffs and realistic scheduling. We employ project management software to track progress, manage resources, and identify potential delays proactively. Regular cost tracking and analysis are vital, ensuring any deviations are flagged and addressed immediately. This includes using value engineering techniques to optimize the design and construction methods without compromising quality or safety. For example, by strategically sequencing the excavation and fill operations, we can minimize the number of truck trips, reducing transportation costs and speeding up the process. Effective communication with the entire team, including subcontractors and suppliers, is paramount. Open and transparent communication helps us to identify and mitigate potential risks and delays early on. Contingency planning is crucial, incorporating buffer times to account for unexpected events like weather delays or equipment breakdowns. Regular project meetings, involving all stakeholders, allow for proactive problem-solving and course correction as needed.

Q 11. Explain your understanding of grading tolerances and their impact on construction.

Grading tolerances define the acceptable deviation from the designed grade. These tolerances are crucial because they directly impact the structural integrity, drainage, and overall functionality of the site. For example, exceeding the tolerance for slope inclination could result in instability, while incorrect elevations might compromise building foundations or drainage systems. Typically, tolerances are specified in inches or millimeters and vary depending on the specific application. Tight tolerances demand higher precision, often necessitating more refined grading techniques and potentially increased costs. Loose tolerances offer more flexibility but may compromise the overall accuracy and quality of the finished product. Understanding these tolerances is essential for both planning and execution. Before starting, I always clarify the required tolerances with the engineers and ensure that the chosen equipment and methods are capable of achieving them. Regular surveys and checks using precise instruments, such as laser levels and total stations, are necessary to ensure adherence to the specified tolerances throughout the process. Any significant deviations are addressed immediately through corrective actions.

Q 12. What safety measures do you implement during grading operations?

Safety is paramount during grading operations. My approach to safety involves a comprehensive program incorporating pre-work safety meetings, daily site inspections, and adherence to all relevant OSHA regulations. Before any work commences, we conduct thorough site assessments to identify and mitigate hazards such as unstable slopes, underground utilities, and traffic areas. We use proper safety equipment, including hard hats, safety glasses, high-visibility vests, and hearing protection. Regular training is provided to all personnel, emphasizing safe operating procedures for equipment like excavators and bulldozers. We establish clear signage and traffic control plans to ensure the safety of both workers and the public. Regular inspections ensure the proper maintenance and functionality of safety equipment. Emergency procedures and communication protocols are clearly defined and practiced, with readily available first-aid and emergency response systems in place. I maintain detailed records of all safety-related activities, including incident reports and training records, ensuring compliance and continuous improvement.

Q 13. How do you coordinate grading with other construction activities?

Coordinating grading with other construction activities is critical for efficient workflow and avoiding conflicts. This involves detailed scheduling and communication with other contractors. I typically create a coordinated schedule that shows the sequencing of grading and other activities, minimizing overlap and potential conflicts. For example, excavation should be completed before foundation work begins. Regular meetings with other contractors and project management ensure that everyone understands the timing and dependencies of different tasks. Grading needs to accommodate the placement of utilities, access roads, and other infrastructure. This necessitates close coordination with utility companies and other relevant stakeholders. Clear communication regarding access points, temporary storage areas, and material handling minimizes disruption and potential conflicts. Detailed staging plans, illustrating the sequence of grading activities and their impact on other works, are crucial. Finally, regular monitoring and adjustments to the schedule are necessary to address unexpected delays or changes to other parts of the project.

Q 14. Describe your experience with managing drainage and erosion control during grading.

Managing drainage and erosion control during grading is vital for environmental protection and preventing costly repairs. This starts with incorporating drainage and erosion control measures into the initial grading plan. This often involves designing swales, ditches, and other features to direct runoff away from sensitive areas. We use erosion control measures like silt fences, sediment basins, and temporary seeding to minimize soil erosion during and after grading. Regular inspections of these measures are critical to ensure their effectiveness, with repairs made promptly as needed. We meticulously manage the temporary storage and disposal of excavated soil to prevent erosion and sedimentation. Compliance with all applicable environmental regulations is paramount. Detailed plans, incorporating specifications for drainage features and erosion control measures, are reviewed and approved before the commencement of work. Post-grading inspections, incorporating checks on drainage effectiveness and erosion control, ensure that the site is stabilized and protects against potential environmental damage. For example, on a hillside project, we used a combination of terracing, silt fences, and hydroseeding to effectively control erosion and ensure the stability of the slopes.

Q 15. Explain your process for resolving conflicts between grading plans and site conditions.

Resolving conflicts between grading plans and site conditions requires a proactive and adaptable approach. It starts with thorough pre-construction site investigation, including geotechnical surveys and detailed as-built drawings. Discrepancies are inevitable; the key is early detection and effective mitigation.

My process involves:

- Identifying the Discrepancy: A careful comparison of the design plans against the actual site conditions, often using surveying equipment and photographic documentation. This might reveal unexpected rock formations, variations in soil type, or undocumented utilities.

- Assessing the Impact: Determining the severity of the discrepancy. A minor deviation might be easily addressed, while a significant one may require plan revisions.

- Developing Solutions: This stage often involves collaboration with the engineer and the client. Options might include minor adjustments to the grading plan, employing alternative construction techniques (e.g., using different earthmoving equipment or blasting techniques for rock), or negotiating a change order to accommodate unforeseen expenses.

- Documenting Changes: All changes to the original plan must be meticulously documented, including updated drawings, cost estimations, and approval signatures. This ensures transparency and avoids future disputes.

For example, on a recent project, we discovered a large, unexpected boulder during excavation. Instead of halting the project, we worked with the engineer to adjust the plan slightly, rerouting the drainage system to avoid the boulder and minimizing earthwork adjustments. This prevented costly delays and kept the project on schedule.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you monitor and control grading costs?

Monitoring and controlling grading costs requires a multi-pronged approach that starts well before the first shovel hits the ground. Accurate cost estimation, based on detailed quantity take-offs from the grading plan and realistic unit pricing, is crucial.

My strategies include:

- Detailed Quantity Take-Offs: Precise calculations of earthwork volumes are vital. We use both manual methods and sophisticated software (like AutoCAD Civil 3D) to ensure accuracy.

- Realistic Unit Pricing: Pricing must account for factors like soil conditions, haul distances, equipment efficiency, and potential unforeseen challenges. Historical data from similar projects is invaluable.

- Regular Progress Tracking: Close monitoring of actual quantities of earth moved against planned quantities, coupled with regular cost reporting, allows for early detection of potential cost overruns. We use project management software to track progress and flag potential issues.

- Value Engineering: Continuously evaluating potential cost-saving measures without compromising quality. This might involve optimizing haul routes, selecting more efficient equipment, or adjusting the grading plan to reduce earthwork volumes.

- Contingency Planning: Allocating a portion of the budget to address unforeseen circumstances like unexpected soil conditions or equipment breakdowns. This helps mitigate risk and prevents cost overruns from derailing the project.

Imagine a project where the initial cost estimate was off by 15%. By employing meticulous tracking and value engineering, we were able to bring the final cost back within 5% of the revised budget, minimizing financial impact on the client.

Q 17. How do you use technology to improve grading efficiency?

Technology plays a transformative role in enhancing grading efficiency and accuracy. From planning to execution, leveraging the right tools makes all the difference.

My experience includes using:

- 3D Modeling Software: Programs like AutoCAD Civil 3D allow for accurate earthwork calculations, visualization of the final grade, and identification of potential conflicts before construction begins. This reduces rework and saves time and money.

- GPS-Guided Equipment: Using GPS-guided bulldozers, excavators, and graders allows for precise grading operations. This eliminates reliance on manual grade checking and significantly improves accuracy, minimizing over-excavation or under-excavation.

- Machine Control Systems: These systems integrate seamlessly with GPS and provide real-time feedback to operators, enabling them to maintain the correct grade with minimal effort. This enhances productivity and reduces the need for surveying crews.

- Remote Monitoring and Data Analysis: Software and hardware systems allow for remote monitoring of equipment performance, fuel consumption, and productivity. This data provides insights for optimizing operations and reducing costs.

- Drone Technology: Drones equipped with high-resolution cameras are used for site surveys, progress monitoring, and volumetric calculations, providing up-to-date information and improving decision-making.

For example, on a recent large-scale highway project, using GPS-guided equipment reduced the grading time by 20% and material waste by 10%, resulting in substantial cost savings.

Q 18. What are your methods for optimizing earthwork movement?

Optimizing earthwork movement is crucial for minimizing costs and environmental impact. It goes beyond simply moving dirt; it’s about strategic planning and efficient execution.

My methods include:

- Cut-and-Fill Balancing: Analyzing the grading plan to minimize the need for importing or exporting soil. This involves strategically placing cuts and fills to balance earthwork volumes, reducing transportation costs and environmental impact.

- Optimizing Haul Routes: Planning efficient haul routes to minimize distances traveled by trucks and other equipment. This reduces fuel consumption, wear and tear on equipment, and project time.

- Material Management: Properly handling and managing excavated materials. This involves separating different soil types for proper disposal or reuse, and minimizing waste through recycling or repurposing.

- Phasing of Work: Sequencing earthwork operations to maximize efficiency. This might involve starting with bulk excavation and moving to finer grading in stages.

- Employing Appropriate Equipment: Selecting equipment based on the volume and type of soil being moved. For example, using larger equipment for bulk excavation and smaller equipment for fine grading.

In one project, by carefully balancing cuts and fills and optimizing haul routes, we reduced the total haul distance by 15%, resulting in significant fuel savings and reduced project time. We also implemented a soil recycling plan, repurposing excavated topsoil for landscaping, saving the client further expense and promoting sustainability.

Q 19. Describe your experience with various types of compaction equipment.

My experience encompasses a broad range of compaction equipment, including static and vibratory rollers, plate compactors, and sheep’s foot rollers. The selection of the appropriate equipment depends on the soil type, the required compaction level, and the project scale.

Specific examples of my experience include:

- Vibratory Rollers: Effective for compacting granular soils like sand and gravel. These are widely used in road construction and base preparation.

- Static Rollers: Used for compacting cohesive soils like clay. These rollers apply pressure to consolidate the soil, improving its strength and stability.

- Plate Compactors: Ideal for confined spaces or areas requiring detailed compaction. These are frequently used in trench backfilling and utility work.

- Sheep’s Foot Rollers: Best for cohesive soils where high compaction is needed. Their unique design penetrates the soil deeply, offering high compaction efficiency.

I also have experience monitoring compaction using various methods such as nuclear density gauges and plate load testing to ensure compliance with project specifications and regulations.

Understanding the capabilities and limitations of each type of equipment is vital for achieving optimal compaction, ensuring the long-term stability of the graded area. The wrong equipment choice can lead to poor compaction, settlement problems, and costly rework later on.

Q 20. How do you communicate effectively with engineers, contractors, and clients regarding grading?

Effective communication is the cornerstone of successful grading projects. I approach communication with engineers, contractors, and clients proactively and transparently, ensuring everyone is informed and aligned.

My communication strategies include:

- Regular Meetings: Holding regular meetings with all stakeholders to discuss progress, address challenges, and make decisions collaboratively.

- Clear and Concise Documentation: Maintaining meticulous records, including daily reports, meeting minutes, and updated drawings. This keeps everyone informed and reduces misunderstandings.

- Using Visual Aids: Employing drawings, 3D models, and photos to enhance understanding and facilitate communication. This is especially effective for explaining complex concepts or showcasing progress.

- Active Listening: Paying close attention to the concerns and suggestions of all stakeholders. This demonstrates respect and fosters a collaborative environment.

- Proactive Problem-Solving: Addressing issues promptly and developing solutions in collaboration with the team.

For example, on one project, early identification and clear communication of a potential delay due to unforeseen weather conditions allowed us to make informed decisions to mitigate the impact, keeping the client informed and minimizing disruption.

Q 21. What is your experience with permitting and regulatory compliance for grading projects?

Permitting and regulatory compliance are paramount in grading projects. My experience includes navigating the complexities of local, state, and federal regulations, ensuring projects adhere to all relevant codes and standards.

My approach involves:

- Early Engagement with Regulatory Agencies: Initiating contact with relevant agencies early in the project planning phase to clarify permitting requirements and address potential concerns.

- Thorough Permit Applications: Preparing comprehensive and accurate permit applications, including detailed plans, specifications, and supporting documentation.

- Environmental Impact Assessments: Conducting environmental assessments where necessary, identifying potential impacts and developing mitigation strategies to minimize disruption.

- Compliance Monitoring: Implementing and monitoring a robust compliance program throughout the project lifecycle. This ensures adherence to all environmental regulations and permits.

- Maintaining Detailed Records: Maintaining detailed records of all permits, inspections, and compliance activities. This serves as proof of adherence to regulations.

I have successfully navigated the permitting process for numerous projects, including projects involving sensitive environmental areas. My experience ensures projects are completed in compliance with all legal requirements, minimizing the risk of delays, fines, or legal challenges.

Q 22. Explain your understanding of different soil types and their impact on grading.

Understanding soil types is fundamental to successful grading. Different soils possess varying properties impacting compaction, drainage, and stability, directly influencing the grading process and the longevity of the finished project.

- Clay soils: These soils are fine-grained and exhibit high plasticity, meaning they can be easily molded. However, they are prone to shrinking and swelling with changes in moisture content, which can lead to cracking and instability in graded surfaces. Proper compaction is crucial to mitigate this.

- Sandy soils: These are coarse-grained and well-drained. They are generally easier to grade but can be less stable than clay soils, especially on slopes. They may require additional stabilization measures.

- Silty soils: These soils are intermediate in grain size between sand and clay. Their behavior is often unpredictable and can exhibit characteristics of both sandy and clayey soils, necessitating careful assessment before grading commences.

- Organic soils: These soils contain significant amounts of decomposed organic matter. They are highly compressible and weak, requiring extensive preparation or potentially even removal before grading can begin. They are also prone to settling.

For instance, a project involving a steep slope with clay soil requires careful consideration of drainage to prevent erosion and slope instability. Conversely, a project on sandy soil might need compaction techniques to ensure the final grade remains stable and supports the intended structures.

Q 23. Describe your problem-solving approach when faced with complex grading challenges.

My approach to complex grading challenges follows a structured problem-solving methodology:

- Problem Definition: I start by clearly defining the challenge, gathering all relevant data including site surveys, soil reports, and project specifications. This often includes discussions with engineers, contractors and clients to ensure a shared understanding.

- Data Analysis: I analyze the collected data to identify the root causes of the challenges and assess potential risks. This might involve using specialized software to model ground conditions and predict potential issues.

- Solution Generation: I brainstorm multiple solutions, weighing their feasibility, cost-effectiveness, and environmental impact. This stage often involves exploring alternative grading techniques and materials.

- Solution Evaluation: Each potential solution is critically evaluated based on factors such as time constraints, budget, and potential risks. A cost-benefit analysis is often conducted.

- Implementation and Monitoring: The chosen solution is implemented, and regular monitoring and adjustments are made throughout the process to ensure it’s progressing as planned. Any unforeseen issues are addressed promptly.

For example, if a project encountered unexpected bedrock during excavation, I would re-evaluate the grading plan, possibly incorporating blasting techniques or adjusting the design to avoid the problematic area. This requires quick adaptation and open communication amongst the team.

Q 24. How do you ensure accurate and timely completion of grading documentation?

Accurate and timely completion of grading documentation is paramount. My approach involves a combination of meticulous on-site recording and efficient data management.

- Real-time Documentation: I utilize digital surveying equipment and software to record all grading activities in real-time, minimizing transcription errors. This includes daily progress reports, as-built drawings, and GPS data logs.

- Quality Control Checks: Regular quality control checks are performed on all documentation, ensuring accuracy and consistency with project specifications. This often involves cross-checking data from multiple sources.

- Data Backup and Security: All data is backed up regularly and stored securely to prevent data loss. Cloud-based solutions and version control systems are utilized to ensure accessibility and collaboration.

- Clear Communication: Regular communication with the project team ensures everyone has access to the latest documentation and any revisions are communicated promptly.

Employing this approach ensures all stakeholders have access to the accurate information they need, minimizing delays and disputes.

Q 25. What is your experience with using GPS and surveying equipment in grading projects?

I have extensive experience using GPS (Global Positioning System) and surveying equipment in grading projects. This includes:

- Total Stations: Precisely measuring distances, angles, and elevations for accurate topographic surveys and setting out grades.

- GPS Receivers: Utilizing RTK (Real-Time Kinematic) GPS for high-accuracy positioning during earthworks, ensuring the grade conforms to the design specifications. This provides real-time positioning data, crucial for efficient work.

- Data Collectors: Recording and managing the collected data using specialized software, allowing efficient data processing and analysis. This also aids in preparing as-built drawings.

- Leveling Instruments: Using auto levels and traditional levels for accurate leveling and grading, crucial for achieving precise elevations.

For example, on a large-scale highway project, we employed RTK GPS to ensure the accuracy of the longitudinal and cross-sectional grades, preventing costly rework and delays.

Q 26. Describe your experience with managing the environmental impact of grading projects.

Managing the environmental impact of grading projects is crucial. My approach incorporates several key strategies:

- Erosion and Sediment Control: Implementing measures such as silt fences, sediment basins, and straw bales to prevent soil erosion and runoff contamination. This is particularly important for protecting waterways.

- Waste Management: Developing a plan for managing excavated soil and other waste materials, aiming to minimize landfill disposal and promote reuse or recycling wherever possible. This minimizes the project’s carbon footprint.

- Habitat Protection: Taking steps to protect existing vegetation and wildlife habitats during the grading process. This might involve relocating sensitive species or using selective clearing techniques.

- Water Management: Implementing strategies for managing stormwater runoff, preventing flooding and erosion. This includes proper drainage design and the construction of retention ponds.

- Compliance with Regulations: Ensuring strict adherence to all relevant environmental regulations and obtaining necessary permits.

For example, on a residential development project, we implemented a rainwater harvesting system to reduce stormwater runoff and minimize the impact on the local watershed.

Q 27. How do you incorporate sustainable practices into grading projects?

Incorporating sustainable practices into grading projects is essential for long-term environmental responsibility and cost savings. My strategies include:

- Minimizing earthworks: Optimizing the grading design to minimize the amount of earth moved, reducing fuel consumption and greenhouse gas emissions.

- Soil conservation: Reusing topsoil and other excavated materials whenever possible, reducing the need for imported materials and minimizing waste. This is especially beneficial in minimizing land disturbance.

- Water conservation: Employing techniques to minimize water usage during compaction and other processes. This can include using recycled water.

- Renewable energy: Exploring the use of renewable energy sources, such as solar power, to power grading equipment where feasible.

- Biodiversity enhancement: Incorporating features that enhance biodiversity, such as creating habitats for pollinators or planting native vegetation.

For instance, on a recent project, we utilized GPS-guided machinery to optimize earthmoving, minimizing fuel consumption and reducing the project’s carbon footprint.

Q 28. Explain your understanding of the importance of precise leveling and grading.

Precise leveling and grading are critical for several reasons. Inaccurate grading can lead to significant problems down the line, impacting both functionality and aesthetics:

- Structural Integrity: Improper grading can compromise the structural integrity of buildings and other structures built on the site, potentially leading to settling or damage.

- Drainage: Inaccurate grading can cause poor drainage, leading to water accumulation, erosion, and potential damage to infrastructure. Proper grading ensures efficient water runoff.

- Functionality: For areas like roadways, parking lots, and sports fields, proper grading is essential for functionality and safety. Uneven surfaces can be hazardous.

- Aesthetics: Accurate grading contributes to a more aesthetically pleasing landscape. Smooth, even surfaces are more visually appealing.

- Cost-effectiveness: Precise grading from the start minimizes the need for costly rework later in the project, saving time and resources.

Think of it like building a house: a strong foundation requires a level base. Similarly, precise leveling and grading provide the necessary foundation for any construction project.

Key Topics to Learn for Grading Planning and Execution Interview

- Project Scope & Definition: Understanding project goals, deliverables, and constraints related to grading. This includes defining clear success metrics.

- Resource Allocation & Management: Efficiently planning and allocating resources (personnel, equipment, materials) for optimal grading execution. Consider scenarios involving resource limitations.

- Methodology & Techniques: Familiarity with various grading methodologies (e.g., different grading scales, rubrics, assessment strategies) and their appropriate application. Be prepared to discuss the pros and cons of each.

- Quality Control & Assurance: Implementing processes to ensure accuracy, consistency, and fairness throughout the grading process. This includes developing methods for identifying and addressing errors.

- Timeline & Scheduling: Creating realistic and achievable timelines for all phases of the grading process, including contingency planning for unexpected delays.

- Data Analysis & Reporting: Understanding how to effectively collect, analyze, and present grading data to stakeholders. Consider different methods of visualizing and interpreting results.

- Technological Proficiency: Demonstrating familiarity with relevant software and technology used in grading processes (e.g., grading platforms, data analysis tools). Be prepared to discuss your experience with specific systems.

- Problem-Solving & Decision-Making: Preparing for scenarios requiring quick and effective problem-solving, particularly related to unforeseen challenges during grading execution.

- Communication & Collaboration: Highlighting your ability to effectively communicate with stakeholders, team members, and other involved parties throughout the grading process.

Next Steps

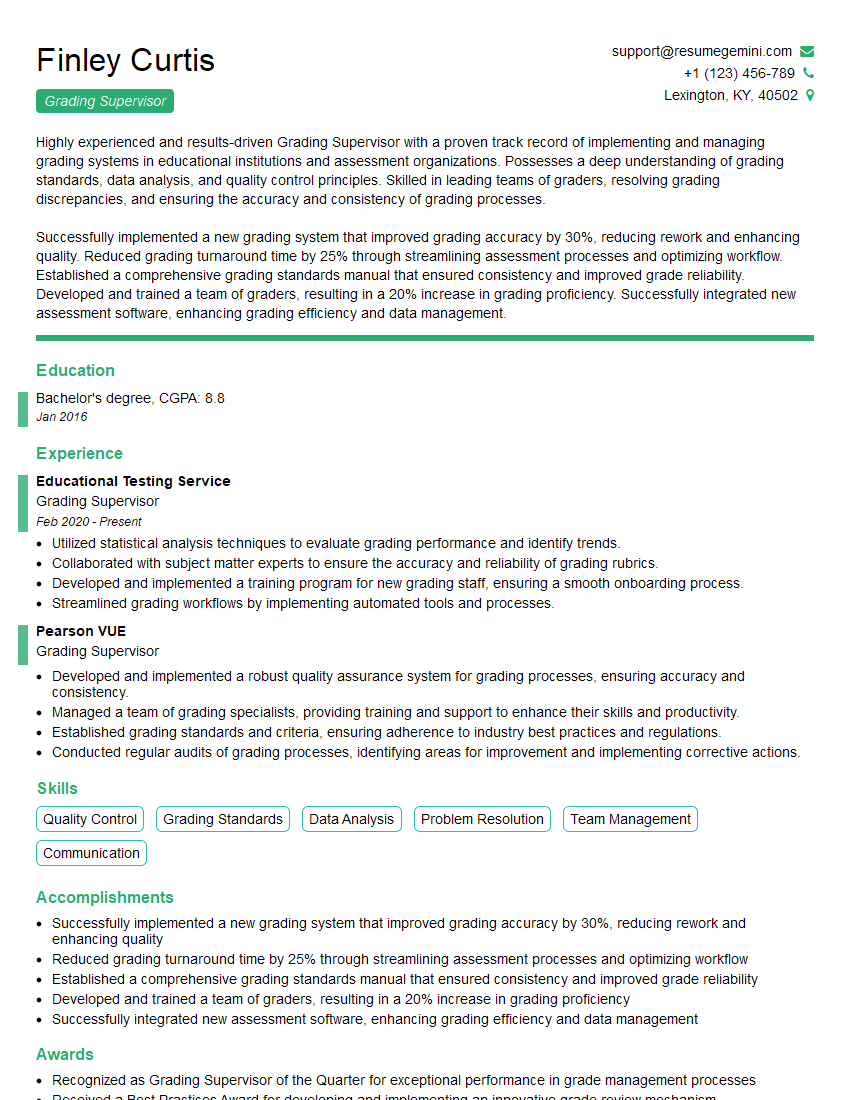

Mastering Grading Planning and Execution is crucial for career advancement in many fields, demonstrating your organizational skills, attention to detail, and ability to manage complex projects. To maximize your job prospects, a well-crafted, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to Grading Planning and Execution are available, allowing you to see how to present your qualifications in the most compelling way.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.