Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Grooving Machine Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Grooving Machine Operation Interview

Q 1. Explain the different types of grooving machines you are familiar with.

Grooving machines come in various types, each suited for different applications and workpiece materials. The primary distinction lies in their control systems and the method of groove creation.

- Manual Grooving Machines: These are simpler machines where the operator manually controls the depth and positioning of the groove. They are often used for smaller-scale operations or when high precision isn’t critical. Think of them as the ‘hand tools’ of the grooving world.

- Hydraulic Grooving Machines: These machines utilize hydraulic pressure to power the grooving process. They offer more power and precision than manual machines, allowing for deeper and wider grooves. Imagine these as the ‘power tools’ – more strength and control.

- CNC (Computer Numerical Control) Grooving Machines: These are the most advanced type, using computer programs to control the entire grooving process. This allows for high precision, repeatability, and complex groove geometries. They’re the ‘robots’ of the grooving world – highly efficient and precise.

- Specialized Grooving Machines: There are also specialized machines designed for specific applications, such as grooving pipes, creating tire treads, or working with unique materials like glass or ceramics. These are purpose-built for niche tasks.

The choice of machine depends heavily on factors such as production volume, required precision, material properties, and budget.

Q 2. Describe your experience with CNC grooving machines.

My experience with CNC grooving machines spans over ten years, encompassing programming, setup, operation, and maintenance. I’ve worked extensively with machines from various manufacturers, including [mention specific manufacturers if comfortable], mastering different control systems and programming languages like G-code. I’m proficient in setting up complex grooving operations involving multiple passes, variable depths, and intricate groove profiles. For example, I was once tasked with creating a series of precisely spaced, varying-depth grooves on a large batch of aluminum components. Using a Fanuc-controlled CNC grooving machine, I wrote a custom G-code program that accounted for tool wear and material variations, ensuring consistent results throughout the entire run. This involved careful consideration of feed rates, spindle speeds, and coolant application. The project was completed with high accuracy and efficiency, exceeding customer expectations.

Furthermore, I’m well-versed in troubleshooting CNC machine issues, ranging from software glitches to mechanical malfunctions. This includes diagnostics, repairs, and preventative maintenance practices.

Q 3. How do you set up a grooving machine for a specific job?

Setting up a grooving machine involves a systematic approach to ensure accuracy and safety. The specific steps vary based on the machine type and the job requirements, but the general process includes:

- Workpiece Securing: Securely clamping the workpiece in the machine’s vise or fixture to prevent movement during operation. The clamping must be firm yet gentle to avoid damaging the material.

- Tool Selection and Installation: Selecting the correct tooling (cutter, insert, etc.) based on the material, groove dimensions, and machine capabilities. Correctly installing the tooling, ensuring proper alignment and tightness.

- Machine Parameter Setting: Inputting the required parameters into the machine’s control system, including spindle speed, feed rate, depth of cut, and number of passes. These parameters are crucial for achieving the desired groove quality and preventing tool damage.

- Test Run and Adjustment: Performing a test run on a scrap piece of material to verify the settings and make any necessary adjustments before processing the actual workpiece. This step is vital for avoiding costly errors on finished parts.

- Tool Monitoring: Continuous observation of the tooling during operation for signs of wear or damage. Replacing worn tools promptly to maintain accuracy and consistency.

For example, when setting up a CNC machine, I would first import the CAD drawing of the part, then use CAM software to generate the G-code program which is then transferred to the machine’s controller. This allows for precise control over the entire process. Before running the program on the actual parts, a thorough simulation is done to verify the programming and ensure that the toolpaths are correct and safe. This step helps to prevent costly mistakes during production and increase the overall efficiency.

Q 4. What safety precautions do you take when operating a grooving machine?

Safety is paramount when operating any grooving machine. My safety practices include:

- Proper Personal Protective Equipment (PPE): Always wearing safety glasses, hearing protection, and appropriate clothing to protect against flying debris, noise, and potential hazards.

- Machine Inspection: Before each operation, I thoroughly inspect the machine for any damage, loose parts, or malfunctions. This ensures the machine is in safe operating condition.

- Lockout/Tagout Procedures: Following proper lockout/tagout procedures when performing maintenance or repairs to prevent accidental starts.

- Emergency Stop Awareness: Knowing the location and function of all emergency stop buttons and being ready to use them in case of emergencies.

- Proper Tool Handling: Handling tools carefully to prevent cuts, punctures, or other injuries. Using appropriate tool handling methods.

- Workplace Organization: Maintaining a clean and organized workspace to minimize trip hazards and ensure efficient operation.

These precautions are essential for preventing accidents and maintaining a safe working environment. Safety is not just a set of rules, but a state of mind – a constant vigilance that is part of every operation.

Q 5. How do you troubleshoot common problems with grooving machines?

Troubleshooting grooving machine problems requires a systematic approach. I typically start with visual inspection, followed by more in-depth diagnostics. Common problems include:

- Tool Wear/Damage: This leads to inaccurate grooves or machine damage. Solution: Inspect and replace worn tools.

- Incorrect Machine Settings: Incorrect feed rate, spindle speed, or depth of cut can cause poor groove quality or machine malfunction. Solution: Review and adjust settings based on the material and desired groove characteristics.

- Workpiece Misalignment: Improper workpiece clamping can lead to uneven grooves. Solution: Recheck workpiece alignment and secure properly.

- Mechanical Malfunctions: Issues with hydraulic systems, motors, or other components can stop production. Solution: Consult maintenance manuals and repair documentation or contact service technicians.

- Software Glitches (for CNC machines): Errors in the CNC program can lead to inaccurate grooves or machine errors. Solution: Review and debug the CNC program.

For instance, if the grooves are inconsistent in depth, I might first check the tooling for wear. If the tool is fine, I’d then examine the machine settings and ensure they’re correct for the material being used. If the problem persists, more thorough investigation into the machine’s mechanical components or the CNC program may be necessary.

Q 6. What are the different types of tooling used in grooving operations?

Grooving operations utilize a variety of tooling depending on the material, groove geometry, and machine type. Common types include:

- Single-Point Cutting Tools: These are typically used in lathe-style grooving operations and allow for fine control over groove shape.

- Groove Inserts: These are small, replaceable cutting inserts that are used in various grooving tools and are particularly useful for high-volume production due to their ease of replacement.

- Form Tools: These create grooves with a specific shape in a single pass.

- Fly Cutters: These are used for creating wider, shallower grooves.

- Abrasive Wheels: Used for grooving harder materials such as hardened steel or ceramics.

The selection of tooling often involves trade-offs between cost, productivity, and surface finish quality. For example, carbide inserts are more expensive than high-speed steel but offer greater wear resistance, increasing tool life and thus productivity.

Q 7. How do you select the appropriate tooling for a specific grooving application?

Selecting the right tooling for a specific grooving application requires considering several factors:

- Material Properties: The hardness, toughness, and machinability of the material dictate the required tool material (e.g., carbide for harder materials, high-speed steel for softer materials).

- Groove Geometry: The dimensions (width, depth, radius) and profile of the groove determine the tool type and size.

- Machine Capabilities: The machine’s power, spindle speed range, and tooling capacity constrain the tool choices.

- Production Volume: For high-volume production, tooling with high wear resistance and easy replacement (like insert tooling) is preferred. For small batches, a more versatile but potentially less durable tool might suffice.

- Surface Finish Requirements: The desired surface finish determines the tool’s geometry and cutting edge sharpness.

For instance, creating a narrow, deep groove in hardened steel would necessitate a carbide insert designed for that application with a sharp cutting edge. Meanwhile, a wider, shallower groove in aluminum might be effectively created using a high-speed steel fly cutter. The decision hinges on achieving the optimum balance of cost-effectiveness, precision, and production efficiency.

Q 8. How do you ensure the accuracy and precision of grooving operations?

Ensuring accuracy and precision in grooving operations hinges on meticulous attention to detail throughout the entire process. It starts with proper machine setup and calibration. We verify the accuracy of the tooling – the grooving insert or wheel – using precision measuring instruments like micrometers and calipers. The workpiece needs to be securely clamped and precisely positioned, minimizing any vibrations or movement during the operation. Furthermore, consistent feed rates and cutting speeds are crucial; these are determined by the material being grooved and the desired groove profile. Finally, regular monitoring of the grooving machine’s performance using built-in feedback mechanisms, like spindle speed indicators and depth gauges, helps maintain consistency. Think of it like baking a cake: precise measurements and consistent oven temperature are vital for a perfect outcome. Inconsistent speeds or improper clamping, for instance, can result in uneven grooves or damage to the workpiece.

For example, if I’m grooving a hardened steel shaft, I would use a very rigid setup with high clamping pressure to prevent workpiece deflection and utilize a specialized carbide insert with a sharp cutting edge to minimize vibration and maintain the desired groove width. I’d also carefully monitor the cutting fluid temperature and adjust feed rates as needed to maintain optimal cutting conditions.

Q 9. What are the common causes of grooving defects?

Groove defects can stem from various sources, broadly categorized as machine-related, tooling-related, and operator-related issues. Machine-related problems include vibrations, worn bearings, or inaccuracies in the machine’s mechanical components, leading to inconsistent groove depth or width. Tooling issues encompass dull or chipped inserts, improper insert mounting, or incorrect tool geometry, resulting in rough surface finishes or variations in groove profile. Operator errors, such as incorrect feed rates, speeds, or improper workpiece clamping, also frequently contribute to defects. Improper lubrication can also lead to excessive wear and tear on the tooling, resulting in inconsistent grooves. Imagine a poorly sharpened knife – it’s difficult to create a clean, precise cut. Similarly, dull tooling leads to poor surface finish and inconsistent groove dimensions.

- Chatter marks: Caused by vibrations in the machine or cutting process.

- Uneven groove depth: Result of inconsistent feed rates or machine wear.

- Rough surface finish: Due to dull tooling, inappropriate cutting parameters or improper lubrication.

- Burrs: Caused by improper cutting conditions or tool geometry.

Q 10. How do you measure and inspect grooves to ensure quality?

Measuring and inspecting grooves involves using a combination of techniques to ensure they meet the specified tolerances. Optical comparators and profile projectors allow for precise measurement of groove width, depth, and profile. Dial indicators and depth gauges provide accurate measurements of groove depth and dimensions. Surface roughness is assessed using profilometers or surface roughness testers, which quantify the texture of the groove surface. Coordinate Measuring Machines (CMMs) are used for more complex shapes or demanding accuracy requirements. Regular checks using these instruments during the grooving operation allow for real-time adjustments, minimizing waste. Think of it as a quality control checkpoint – verifying the product meets the required specifications at each stage.

For instance, after grooving a series of parts, I would randomly select samples, measure the critical dimensions using a CMM, and analyze the data to ensure that the produced grooves are within the specified tolerances and quality standards.

Q 11. Describe your experience with different types of groove profiles.

My experience encompasses a wide range of groove profiles, including V-grooves, U-grooves, rectangular grooves, and more specialized profiles like dovetail or O-rings grooves. The choice of profile depends on the specific application and functional requirements. V-grooves are commonly used for applications requiring high strength and wear resistance, while U-grooves provide a larger surface area for better contact or sealing. Rectangular grooves are frequently found in applications that require precise dimensional tolerances. I’ve worked with materials ranging from soft metals like aluminum to hard materials like hardened steel and ceramics, requiring adjustments to cutting parameters and tooling selection based on the material’s characteristics. Each profile necessitates a specific tooling configuration and precise control of the grooving parameters to achieve the desired result.

For example, in creating a V-groove in aluminum, I’d select a sharp, diamond-tipped grooving tool with a small radius, use a higher cutting speed and lower feed rate compared to machining a similarly sized groove in a harder material like hardened steel. In the latter case, I’d opt for a carbide-tipped tool with a larger radius, slower cutting speed, and potentially heavier feed rate.

Q 12. How do you maintain and clean a grooving machine?

Maintaining and cleaning a grooving machine is crucial for extending its lifespan, ensuring accuracy, and preventing defects. Regular cleaning involves removing chips and debris from the machine’s working areas using compressed air or brushes. Lubrication of moving parts, such as ways, guides, and bearings, is essential to reduce friction and wear. This involves using the appropriate lubricants, following the manufacturer’s recommendations. Regular inspection of tooling, checking for wear, damage, or sharpness, and replacing them as needed is another important aspect. The machine’s electrical components also need to be checked for any issues. This entire process minimizes unexpected downtime and maintains the machine’s operational efficiency.

Think of it as servicing your car. Regular maintenance extends the life of the vehicle and prevents costly repairs in the long run.

Q 13. What are the different types of lubricants used in grooving operations?

The choice of lubricant in grooving operations is dictated by the material being machined and the cutting conditions. Common lubricants include soluble oils, which are water-miscible and provide good cooling and lubrication properties, and straight oils, which offer better lubricity but require more careful disposal. Synthetic cutting fluids, offering improved performance and environmental friendliness, are also frequently used. Selecting the right lubricant minimizes friction, heat buildup, and tool wear, contributing to a better surface finish and increased tool life. The lubricant must also be compatible with the machine and the workpiece material to avoid any adverse reactions.

For example, when grooving aluminum, I’d use a soluble oil to provide good cooling and prevent built-up edge formation. While for grooving hardened steel, a more viscous, heavier-duty cutting fluid might be necessary for better lubrication and to minimize heat generation.

Q 14. How do you interpret engineering drawings and specifications related to grooving?

Interpreting engineering drawings and specifications for grooving requires a thorough understanding of geometric dimensioning and tolerancing (GD&T) principles. I carefully examine the drawing to identify the required groove profile, dimensions (width, depth, and length), surface finish requirements, material specifications, and tolerances. The drawing often specifies the location of the groove, using reference planes or datums. I need to understand these references to accurately position the workpiece and the tooling. Understanding the tolerance specifications is critical to ensure that the final groove meets the required quality standards. This requires understanding symbols such as +/- tolerances, surface roughness indicators, and geometric tolerances.

For example, a drawing might specify a 0.5 mm wide by 1 mm deep V-groove with a surface roughness of Ra 0.8 μm and a positional tolerance of 0.05 mm. My interpretation of this information would guide the selection of tooling, cutting parameters, and the inspection criteria to ensure that the produced groove satisfies all the specifications.

Q 15. Explain your experience with different materials used in grooving operations.

My experience encompasses a wide range of materials used in grooving operations. I’ve worked extensively with ferrous metals like steel and cast iron, non-ferrous metals such as aluminum and brass, and even plastics and composites. Each material presents unique challenges. For instance, harder materials like hardened steel require specialized tooling and slower feed rates to prevent tool wear and breakage. Softer materials like aluminum may require different cutting fluids to prevent built-up edge on the cutting tool. Understanding the material properties – hardness, ductility, machinability – is crucial for selecting the appropriate tooling and parameters for optimal results and surface finish. I’ve successfully grooved components ranging from small precision parts to large industrial castings, adapting my approach to each material’s specific needs.

- Steel: Requires robust tooling, potentially carbide inserts, and precise control to achieve desired groove dimensions and surface finish.

- Aluminum: Machines relatively easily but can be prone to chip welding if the cutting fluid isn’t appropriately selected.

- Plastics: Sensitive to heat; requires lower speeds and specialized tooling to avoid melting or burning.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with automated grooving systems?

I have extensive experience with automated grooving systems, including CNC (Computer Numerical Control) machines. This includes programming, setup, and operation of various CNC lathes and milling machines equipped with grooving tools. My expertise extends to using CAM (Computer-Aided Manufacturing) software to generate efficient toolpaths for complex groove geometries. I’m proficient in troubleshooting automated systems, diagnosing and resolving errors related to tooling, programming, and machine functionality. For example, I once diagnosed and repaired a malfunction in a CNC lathe’s automatic tool changer, resulting in a significant increase in production efficiency. Automation allows for higher precision, repeatability, and increased productivity compared to manual methods.

Q 17. How do you calculate the feed rate and spindle speed for grooving operations?

Calculating feed rate and spindle speed is critical for efficient and accurate grooving. The calculations depend on several factors, including the material being machined, the tool geometry (insert type, number of cutting edges), and the desired surface finish. There isn’t a single formula, but rather a process involving consideration of these factors. I typically use the manufacturer’s recommendations for the cutting tool as a starting point.

For example, a harder material will require a lower feed rate and spindle speed to prevent excessive tool wear and heat generation. A sharper tool can allow for higher speeds and feeds. I frequently use cutting data handbooks and software to optimize these parameters. Fine-tuning is often done through trial and error, closely monitoring the cutting process for signs of tool wear, chatter, or excessive heat. The goal is to achieve a balance between maximizing material removal rate and maintaining tool life and surface finish quality.

Example: Feed Rate (mm/rev) = f * (Number of Teeth)Where ‘f’ is a constant derived from the material and tool data.

Q 18. Describe your experience with different types of cutting fluids.

My experience encompasses various cutting fluids, each suited for specific materials and machining conditions. I’ve worked with soluble oils (emulsions), synthetic fluids, and even straight oils. The choice of cutting fluid significantly impacts tool life, surface finish, and chip disposal. Soluble oils are widely used for their cost-effectiveness and ease of use, but synthetic fluids offer better cooling and lubrication properties, particularly for demanding applications. Straight oils are often preferred for deep grooving operations where good lubrication is critical.

For example, when grooving stainless steel, I’d choose a synthetic fluid to minimize built-up edge and improve surface finish. For aluminum, I might opt for a fluid with good chip-breaking characteristics to prevent long stringy chips from interfering with the cutting process. Regular monitoring and maintenance of cutting fluid is crucial to maintain its effectiveness and prevent bacterial growth.

Q 19. How do you deal with machine malfunctions or breakdowns?

Dealing with machine malfunctions is a critical part of the job. My approach involves a systematic troubleshooting process. First, I ensure the machine is safely shut down. Then I carefully inspect the machine for obvious problems, such as tool breakage, coolant leaks, or loose connections. I consult the machine’s maintenance manual and any relevant error codes displayed on the control panel. I use diagnostic tools where necessary to identify the root cause of the problem. Often, simple issues like a clogged coolant line or a loose wire can be quickly resolved. More complex problems may require specialized knowledge or the assistance of a maintenance technician.

One memorable instance involved a sudden stop in the middle of a critical grooving operation. I systematically checked the tool, coolant, and electrical connections. Eventually, I traced the issue to a faulty sensor in the machine’s feedback loop. Replacing the sensor quickly resolved the issue, minimizing downtime and preventing further damage.

Q 20. What is your experience with preventative maintenance for grooving machines?

Preventative maintenance is crucial for ensuring the longevity and reliability of grooving machines. My experience includes performing regular inspections, lubrication, and cleaning of machine components. This includes checking for wear on bearings, belts, and other moving parts, as well as ensuring proper coolant flow and filter maintenance. I adhere to the manufacturer’s recommended maintenance schedule, keeping detailed records of all preventative maintenance tasks. This proactive approach reduces the likelihood of unexpected breakdowns and extends the operational life of the machine, minimizing costly repairs and downtime.

Q 21. How do you manage your time effectively during grooving operations?

Effective time management during grooving operations is critical for productivity. I prioritize tasks based on urgency and importance. I carefully plan each operation, considering factors such as setup time, machining time, and inspection time. I use job scheduling software to optimize production workflow. I avoid unnecessary delays by ensuring that all necessary tooling, materials, and fixtures are readily available before commencing work. I also regularly monitor the progress of the operation and make adjustments as needed to stay on schedule. Effective time management is a key skill that reduces waste and ensures that projects are completed on time and within budget.

Q 22. Describe your experience with quality control procedures in grooving operations.

Quality control in grooving operations is paramount for ensuring product consistency and meeting customer specifications. It’s a multi-faceted process that begins even before the machine starts running. My approach involves a rigorous system encompassing several key stages:

- Pre-operation checks: This includes verifying the accuracy of the CNC program, checking tooling for wear and tear, and ensuring the machine is properly lubricated and calibrated. I meticulously inspect the raw material for defects like cracks or inconsistencies in material properties that could affect the final groove quality.

- In-process monitoring: During operation, I closely monitor the machine’s performance, paying close attention to factors such as spindle speed, feed rate, and cutting depth. Regular checks on the groove dimensions using precision measuring instruments are crucial. Any deviation from the programmed parameters triggers immediate investigation and adjustment.

- Post-operation inspection: Once the grooving is complete, a comprehensive inspection is carried out on a sample of the finished parts. This involves using various measuring tools (e.g., calipers, micrometers, optical comparators) to check the accuracy of groove dimensions, surface finish, and overall part geometry. Statistical Process Control (SPC) charts are utilized to track process variations over time.

- Documentation and Reporting: Detailed records of all inspection results, including any anomalies, corrective actions, and preventive measures, are meticulously documented. This data provides valuable insights for continuous improvement and helps identify potential problems before they escalate.

For example, I once identified a subtle variation in the groove depth during a large batch production run. By analyzing the data collected from in-process monitoring and post-operation inspection, I pinpointed the cause to a slightly worn cutting tool. Replacing the tool immediately prevented further defects and ensured that the rest of the batch met the required quality standards.

Q 23. What software or programming languages are you familiar with regarding CNC grooving machines?

My experience with CNC grooving machines extends to several software packages and programming languages. I’m proficient in using:

- CAM software: Mastercam, FeatureCAM, and SolidCAM are among the CAM software packages I utilize for creating CNC programs. These allow me to generate precise toolpaths for various grooving operations.

- CNC machine control systems: I’m familiar with Fanuc, Siemens, and Heidenhain control systems, which are common in the industry. Understanding the specific nuances of each control system is essential for efficient programming and troubleshooting.

- G-code programming: I possess a strong understanding of G-code, the standard programming language for CNC machines. This includes writing and modifying G-code programs to control various aspects of the grooving process.

- Data acquisition and analysis software: I utilize software to collect and analyze data from the machine’s sensors, allowing me to monitor key parameters and optimize the grooving process. This includes software for creating SPC charts and other statistical analyses.

For instance, I recently utilized Mastercam to create a complex 3D grooving program for a challenging component. The software’s advanced features allowed me to optimize toolpaths for efficient material removal and surface finish.

Q 24. How do you handle variations in material properties during grooving operations?

Variations in material properties are a common challenge in grooving operations. Different materials exhibit varying hardness, toughness, and machinability, affecting the cutting process. My approach to handling these variations involves:

- Material identification and testing: Before initiating the grooving process, I carefully identify the material type and conduct necessary tests (e.g., hardness testing) to ascertain its properties. This data guides the selection of appropriate cutting tools and parameters.

- Adaptive control strategies: Modern CNC machines often feature adaptive control systems that automatically adjust cutting parameters based on real-time feedback from the machine’s sensors. These systems help to compensate for variations in material properties, maintaining consistent groove quality.

- Tool selection and optimization: Different materials require different cutting tools. I select tools specifically designed for the material being machined, paying attention to their geometry, coating, and material composition. Optimized cutting parameters, including spindle speed, feed rate, and depth of cut, are crucial to avoid tool breakage and ensure consistent results.

- Process monitoring and adjustment: Constant monitoring of the cutting process allows for early detection of any issues arising from material variations. Adjustments to cutting parameters are made as needed to maintain optimal performance and groove quality. Regular tool changes are implemented to avoid tool wear impacting the final product.

For example, when working with a harder material than originally anticipated, I modified the cutting parameters—reducing the feed rate and increasing the spindle speed—to prevent tool breakage while maintaining the required groove quality.

Q 25. Describe a time you had to troubleshoot a complex grooving machine issue.

During a high-volume production run, we experienced a recurring problem with inconsistent groove depths. The issue was intermittent, making it difficult to diagnose. After a thorough examination, we ruled out factors such as faulty tooling or programming errors.

My troubleshooting strategy involved a systematic approach:

- Data analysis: I meticulously reviewed the machine’s operational logs, identifying patterns in the inconsistencies.

- Visual inspection: I carefully inspected the machine for any signs of mechanical wear or misalignment.

- Component testing: We isolated and tested each component of the machine’s feed mechanism.

- Calibration check: The machine’s linear scales were checked for accuracy.

Ultimately, we discovered a minute amount of play in the linear bearing assembly of the Z-axis (responsible for depth control). This resulted in inconsistent movement, leading to inconsistent groove depth. Replacing the faulty bearing resolved the issue and prevented further production delays. This experience highlighted the importance of thorough investigation and meticulous data analysis in troubleshooting complex CNC machine issues.

Q 26. What are the key performance indicators (KPIs) you monitor during grooving operations?

The key performance indicators (KPIs) I monitor during grooving operations are designed to provide a comprehensive overview of efficiency, quality, and cost-effectiveness. These include:

- Groove dimensions: Accuracy of groove width, depth, and profile, measured using precision instruments and compared to specifications. This is a critical metric for product quality.

- Surface finish: Measured using surface roughness parameters (Ra, Rz). A smooth surface finish is often crucial for functionality and aesthetics.

- Cycle time: Time taken to complete one grooving cycle. Optimizing this reduces production time and improves efficiency.

- Tool life: Number of parts produced before tool replacement is needed. Longer tool life reduces tooling costs.

- Material usage: Quantity of material used per part. Efficient material utilization minimizes waste and lowers costs.

- Machine downtime: Percentage of time the machine is not producing parts due to breakdowns or maintenance. Minimizing downtime ensures maximum productivity.

- Defect rate: Percentage of parts rejected due to quality issues. Low defect rates are essential for high product quality and customer satisfaction.

Regular monitoring and analysis of these KPIs allow for proactive identification of areas for improvement and optimization of the grooving process.

Q 27. How do you ensure the efficient use of tooling and materials during grooving?

Efficient use of tooling and materials is crucial for minimizing production costs and maximizing profitability. My strategies for achieving this include:

- Proper tool selection: Choosing tools optimized for the specific material and grooving operation. This includes considering factors like tool geometry, material, and coating.

- Optimized cutting parameters: Setting spindle speed, feed rate, and depth of cut to maximize tool life and minimize material waste. This often involves employing techniques like climb milling or high-speed machining when appropriate.

- Regular tool maintenance and sharpening: Implementing a proactive maintenance program for tools, including regular inspection, sharpening, and replacement as needed. This extends tool life and ensures consistent groove quality.

- Minimizing scrap and waste: Implementing processes to reduce material waste, such as optimizing stock sizes and cutting patterns. This can involve using nesting software or techniques like ‘zero-waste’ cutting.

- Material handling and storage: Proper storage and handling of materials to prevent damage and loss. This can involve using appropriate storage racks or implementing a first-in, first-out (FIFO) inventory system.

For example, by implementing a predictive maintenance program based on tool wear sensors, we were able to extend tool life by 15%, leading to significant cost savings.

Q 28. How do you stay updated on the latest advancements in grooving machine technology?

Staying updated on the latest advancements in grooving machine technology is vital for maintaining competitiveness and improving operational efficiency. I employ several strategies to achieve this:

- Industry publications and journals: I regularly read industry publications, such as trade magazines and technical journals, to keep abreast of new technologies and innovations in CNC machining and grooving.

- Industry conferences and trade shows: Attending conferences and trade shows allows me to network with industry peers, learn about the latest developments, and see new equipment in action. This provides hands-on experience and facilitates direct interaction with manufacturers.

- Online resources and webinars: I utilize online resources, such as manufacturer websites, educational platforms, and online webinars, to learn about new techniques, software updates, and best practices.

- Manufacturer training programs: Participating in training programs offered by CNC machine manufacturers ensures I have in-depth knowledge of the latest machine functionalities and operational procedures.

- Professional networking: Connecting with other grooving machine operators and experts through online forums and professional organizations. This allows for sharing best practices and knowledge exchange.

For example, attending a recent trade show, I learned about a new type of cutting tool with enhanced wear resistance and surface finish capabilities, which I’ve since implemented in our operations with noticeable improvements.

Key Topics to Learn for Grooving Machine Operation Interview

- Machine Setup and Operation: Understanding the various components of the grooving machine, including the spindle, feed mechanism, and coolant system. Knowing the proper procedures for setting up the machine for different jobs, including tool selection and adjustment.

- Tooling and Tool Management: Familiarity with different types of grooving tools, their applications, and maintenance. Understanding how to select the appropriate tool for a specific job and how to properly store and maintain tools to extend their lifespan.

- Material Handling and Processing: Safe and efficient methods for handling and loading materials into the grooving machine. Understanding the properties of different materials and how they affect the grooving process.

- Quality Control and Inspection: Methods for inspecting the quality of grooves produced, including dimensional accuracy and surface finish. Understanding common quality control issues and how to troubleshoot them.

- Safety Procedures and Regulations: Adherence to all relevant safety regulations and procedures when operating the grooving machine. Knowing how to identify and mitigate potential hazards.

- Troubleshooting and Maintenance: Identifying and resolving common problems encountered during grooving operations. Performing basic maintenance tasks to keep the machine in optimal working condition.

- Programming and Setup (if applicable): If the grooving machine utilizes CNC or other programming, understanding the programming language and procedures for setting up and running programs.

- Production Efficiency and Optimization: Understanding techniques to maximize production output while maintaining high quality standards. This includes optimizing cutting parameters and minimizing downtime.

Next Steps

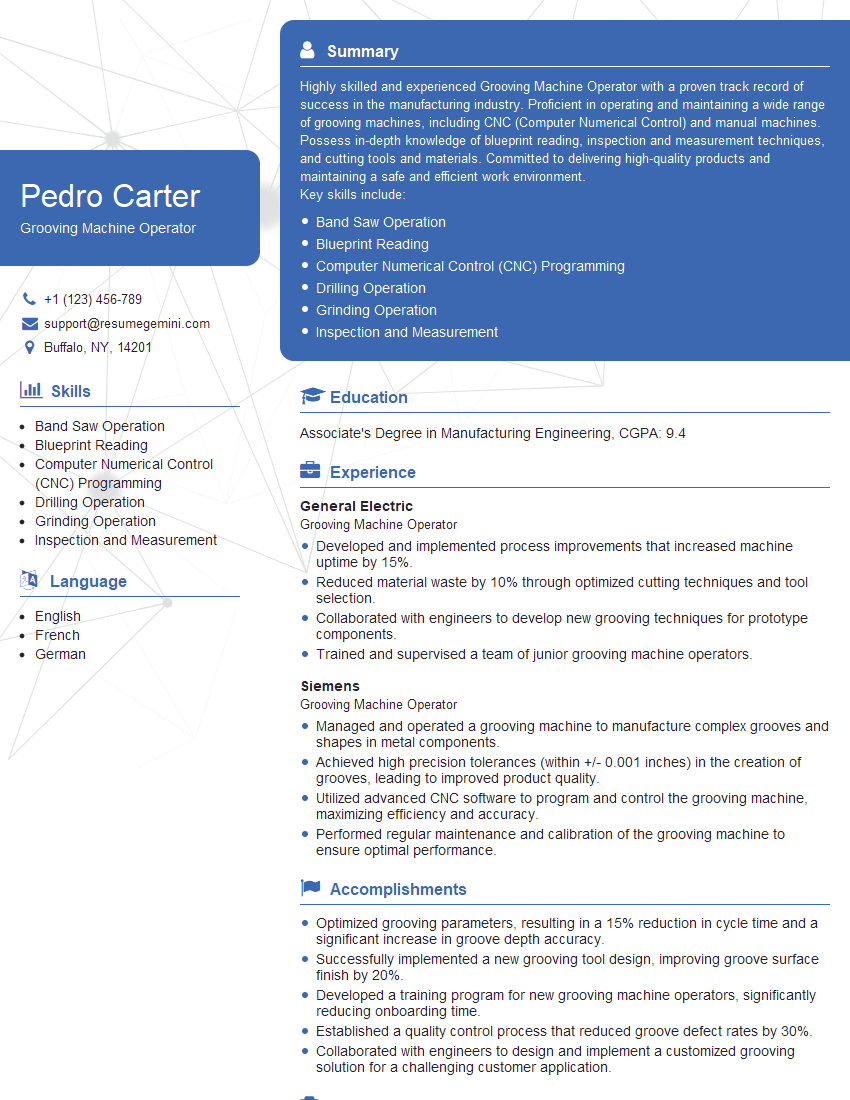

Mastering Grooving Machine Operation opens doors to exciting career opportunities in manufacturing and engineering, offering potential for advancement and higher earning potential. A strong resume is your key to unlocking these opportunities. To make sure your skills shine through to potential employers, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and effective resume that will get noticed. We offer examples of resumes tailored to Grooving Machine Operation to guide you in creating your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.