Unlock your full potential by mastering the most common Heavy Equipment Maintenance and Operation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Heavy Equipment Maintenance and Operation Interview

Q 1. Describe your experience with preventative maintenance schedules.

Preventative maintenance schedules are the backbone of keeping heavy equipment running smoothly and avoiding costly breakdowns. They’re essentially a roadmap of routine inspections, lubrication, and component replacements designed to catch potential problems before they escalate. Think of it like getting regular checkups for your car – far better to address a small issue early than to face a major repair later.

My experience encompasses developing and implementing these schedules for a variety of equipment, from excavators and bulldozers to loaders and articulated dump trucks. This involves consulting manufacturer recommendations, analyzing operational data (such as hours of operation and environmental conditions), and factoring in the specific demands of the job site. For instance, an excavator working in a particularly dusty environment might require more frequent air filter changes compared to one operating in a cleaner setting. I’ve used computerized maintenance management systems (CMMS) to track scheduled tasks, record completed maintenance, and generate reports to optimize maintenance practices and identify trends.

- Example: For a particular fleet of excavators, I implemented a schedule that included daily pre-operational checks (greasing, fluid level checks), weekly lubrication of boom and arm joints, and monthly inspections of hydraulic lines and components. This reduced downtime by 20% in the first year.

- Example: I created a customized preventive maintenance schedule for a mining operation, factoring in the harsh conditions and heavy workload. This included more frequent checks and replacements for high-wear components.

Q 2. Explain the process of diagnosing a hydraulic system failure.

Diagnosing a hydraulic system failure requires a systematic approach, combining visual inspection with careful testing. Think of it as a detective story – you need to gather clues to pinpoint the culprit.

- Visual Inspection: Start by checking for obvious signs of leakage (oil stains, dripping fluid), damaged hoses or fittings, and any unusual noises (whining, knocking).

- Fluid Level Check: Inspect the hydraulic reservoir for proper fluid level and condition. Low fluid could indicate a leak, while discolored or contaminated fluid suggests internal issues.

- Pressure Testing: Use a hydraulic pressure gauge to check the system’s pressure at different points. Readings outside the manufacturer’s specifications point to potential problems within pumps, valves, or actuators.

- Operational Checks: Observe the equipment’s movements and functionalities. Slow movements, jerky operation, or complete failure of a specific function help isolate the problem area.

- Component Testing: Based on the initial findings, further testing might involve checking individual components like pumps, valves, and cylinders. This often requires specialized tools and knowledge.

Example: If an excavator’s boom fails to extend, you might first check the hydraulic fluid level. If the level is low, you’ll investigate for leaks. If the level is normal, pressure testing could reveal low pressure in the boom cylinder line, suggesting a problem with the boom cylinder itself or a valve regulating its function.

Q 3. How do you troubleshoot engine misfires in heavy equipment?

Troubleshooting engine misfires in heavy equipment is a process of elimination, requiring a methodical approach and diagnostic tools. Think of it like figuring out which cylinder in a multi-cylinder engine isn’t firing properly.

- Listen for the Misfire: A misfire often produces a rough running engine with a noticeable irregular sound. It might sound like a ‘pop’ or ‘cough’ in the exhaust.

- Check the Spark Plugs (if applicable): Inspect spark plugs for wear, fouling, damage, or incorrect gap. Replace or clean them as needed.

- Inspect Ignition System (if applicable): Check ignition wires, coils, and the distributor (if applicable) for damage or corrosion.

- Fuel System Check: Verify adequate fuel supply, inspect fuel filters, and check for leaks. A clogged fuel filter can starve a cylinder of fuel, leading to a misfire.

- Compression Test: A low compression reading in a cylinder indicates a potential problem with the piston rings, valves, or head gasket.

- Check for Vacuum Leaks: Leaks in the intake system will affect the air-fuel mixture and can cause misfires.

- Diagnostic Codes (if applicable): Use an electronic diagnostic tool to retrieve any stored error codes from the engine’s control module (ECM). These codes provide crucial information about the possible cause.

Example: If the misfire is intermittent and accompanied by a rough idle and a check engine light, I’d start by checking the fuel filter, as this is a common cause. If that doesn’t solve the problem, I would proceed to more advanced diagnostics.

Q 4. What are the common causes of overheating in diesel engines?

Overheating in diesel engines is a serious issue that can lead to significant damage. Several factors contribute, but they boil down to a simple imbalance: the engine is generating more heat than it can dissipate.

- Cooling System Issues: Low coolant levels, clogged radiators, malfunctioning water pumps, or a faulty thermostat can all impede heat dissipation.

- Fan Problems: A broken or malfunctioning fan will reduce airflow through the radiator, causing the engine to overheat.

- Blocked Radiator: Debris or other obstructions can restrict airflow through the radiator.

- Engine Problems: A malfunctioning fuel injection system can cause the engine to run rich, leading to inefficient combustion and increased heat generation. Similarly, problems with the turbocharger, such as oil leaks or bearing failures, can increase heat.

- Ambient Temperature: High ambient temperatures can also contribute to overheating if the cooling system is not adequately sized or efficient.

Example: A constantly overheating engine might indicate a problem with the radiator. A visual inspection might reveal a clogged radiator, requiring cleaning or replacement. If the cooling system is intact but still overheating, I would investigate possible issues within the engine itself.

Q 5. Describe your experience with different types of welding techniques used in heavy equipment repair.

Welding is a crucial skill for heavy equipment repair. I’m proficient in several techniques, each suited to different materials and repair situations. Think of it as having different tools for different jobs.

- Shielded Metal Arc Welding (SMAW): This is a versatile and widely used technique, particularly useful for repairs in the field. It employs a consumable electrode to create the weld, and shielding gas comes from the electrode coating.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, this method is fast and produces high-quality welds, ideal for thicker materials. It uses a continuously fed wire electrode and a shielding gas, usually Argon or CO2.

- Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, this technique creates highly precise and clean welds, perfect for delicate work or when high weld quality is critical. It utilizes a non-consumable tungsten electrode and a shielding gas.

- Flux-Cored Arc Welding (FCAW): Similar to MIG welding, but the wire electrode contains flux that serves as both shielding and filler material, making it suitable for outdoor use.

Example: For repairing a cracked excavator bucket, I’d likely use GMAW due to its speed and ability to handle thicker steel. For welding a hydraulic line, TIG welding would provide the precision needed for a leak-free repair.

Q 6. How do you interpret and utilize equipment manuals and schematics?

Equipment manuals and schematics are essential for effective maintenance and repair. They are the roadmaps that guide diagnosis and repair procedures.

I’m adept at interpreting both. Manuals provide operational instructions, maintenance schedules, troubleshooting guides, and parts diagrams. Schematics (wiring diagrams, hydraulic schematics, etc.) show the layout and connections of various systems. They’re like blueprints, enabling me to trace the flow of fluids, electricity, or signals to pinpoint problem areas.

My process usually involves:

- Identifying the specific model and serial number of the equipment. This ensures I’m consulting the correct manual.

- Locating the relevant section of the manual that addresses the issue at hand. This might be a troubleshooting guide, a parts diagram, or a detailed explanation of a system’s operation.

- Careful reading and interpretation of the information, paying close attention to diagrams, charts, and specifications.

- Using schematics to trace electrical circuits, hydraulic lines, or pneumatic systems to identify potential points of failure.

Example: If a component isn’t functioning correctly, I’d consult the schematic to trace the electrical or hydraulic lines that supply that component. This helps me isolate whether the problem lies within the component itself or in the system that feeds it.

Q 7. Explain your experience with different types of heavy equipment (e.g., excavators, loaders, bulldozers).

My experience with various types of heavy equipment is extensive. I’ve worked with and maintained many different machines throughout my career, and each type presents its unique challenges and maintenance requirements.

- Excavators: I’m experienced in maintaining hydraulic systems, undercarriage components, and engine systems on various sizes of excavators. I understand the importance of regular undercarriage inspection and lubrication to avoid premature wear.

- Loaders: My work with loaders has included preventative maintenance, troubleshooting hydraulic issues, and repairing or replacing components like buckets and tires. I’m familiar with different types such as wheel loaders and skid steer loaders.

- Bulldozers: Bulldozers demand a focus on the undercarriage, blade, and power train. I’ve managed scheduled maintenance, including track tension adjustments, blade sharpening, and troubleshooting transmission issues.

- Articulated Dump Trucks: These large haulers demand attention to tire condition, hydraulic systems, and the articulation joint. My experience includes servicing these vehicles’ robust engines and maintaining their heavy-duty braking systems.

Example: On one job site, I identified a pattern of premature wear on excavator tracks. By carefully analyzing operating conditions and adjusting maintenance procedures, I reduced track replacement costs by 15%.

Q 8. What safety procedures do you follow when working on heavy equipment?

Safety is paramount in heavy equipment maintenance. My approach is based on a layered safety system, encompassing pre-job planning, personal protective equipment (PPE), and adherence to strict lockout/tagout procedures. Before beginning any work, I conduct a thorough risk assessment, identifying potential hazards such as moving parts, high voltage, and hazardous materials. This involves checking the equipment’s operational manual for specific safety precautions and ensuring the work area is properly secured.

PPE is essential and always includes safety glasses, gloves, steel-toed boots, and hearing protection. Depending on the specific task, I might also use a hard hat, respirator, or flame-resistant clothing. Lockout/tagout procedures are strictly followed to prevent accidental energization or startup of equipment during maintenance. This involves physically locking out power sources and tagging them to indicate that work is in progress. For instance, before working on a hydraulic system, I’d lockout the hydraulic pump, ensuring no power reaches the system. Finally, I regularly participate in safety training and refresher courses to stay updated on best practices and new safety regulations.

Q 9. Describe your experience with hydraulic system diagnostics and repair.

I have extensive experience diagnosing and repairing hydraulic systems. My approach starts with a systematic inspection, visually checking for leaks, damaged hoses, and loose connections. I then use diagnostic tools like pressure gauges and flow meters to identify pressure drops, flow restrictions, or other malfunctions. For example, if a hydraulic cylinder isn’t extending properly, I’d first check the pressure at the cylinder inlet. Low pressure might indicate a problem with the pump, relief valve, or a blockage in the hydraulic lines. I’m proficient in troubleshooting various hydraulic components, including pumps, valves, cylinders, and actuators. Repair work ranges from simple hose replacement and seal repairs to more complex tasks such as pump rebuilds and valve replacements. I’m familiar with different types of hydraulic fluids and their properties, ensuring I use the correct fluid for each application. My experience also includes working with both open-center and closed-center hydraulic systems, understanding the nuances of each.

Q 10. How do you handle unexpected equipment breakdowns on-site?

Handling unexpected breakdowns requires a calm and systematic approach. My first priority is safety – ensuring the immediate area is secure and no one is at risk. Then, I perform a preliminary assessment to identify the nature of the breakdown. This often involves checking vital systems, such as engine oil levels, hydraulic fluid levels, and electrical connections. I utilize diagnostic tools to pinpoint the problem. If the issue is minor and I have the necessary parts, I’ll perform on-site repairs. However, if the problem is more complex, I’ll assess the situation, document the issue thoroughly, and communicate it to the appropriate supervisor or dispatch. This involves clear and concise reporting, including photos or videos if necessary. In some cases, I may need to arrange for towing or specialized repair services. Prioritization is key – if the breakdown affects a critical operation, immediate action is paramount. Throughout the process, I maintain accurate records of the breakdown, repair attempts, and any related downtime.

Q 11. What is your experience with electronic diagnostic tools?

I’m proficient in using various electronic diagnostic tools, including scan tools, data loggers, and multimeters. Scan tools allow me to read diagnostic trouble codes (DTCs) from the equipment’s electronic control modules (ECMs), helping to pinpoint the cause of electrical or electronic malfunctions. For instance, a DTC might indicate a faulty sensor or a problem within the engine’s control system. Data loggers capture real-time data from various sensors, enabling me to analyze system performance and identify trends that might indicate a developing problem. Multimeters are essential for testing voltage, current, and resistance in electrical circuits. I’m also familiar with specialized software and diagnostic interfaces used with specific heavy equipment brands. My experience covers various types of electronic systems, including engine control units, transmission control units, and various sensor and actuator networks.

Q 12. How familiar are you with different types of lubricants and their applications?

Understanding lubricants is crucial for maintaining heavy equipment. I’m familiar with various types, including engine oils (conventional, synthetic, and high-mileage), gear oils, hydraulic fluids, and greases. The selection of the correct lubricant depends on factors such as equipment type, operating conditions, and manufacturer recommendations. For example, a high-performance engine oil is needed for a heavy-duty diesel engine operating under extreme loads, while a specific hydraulic fluid is required for a sensitive hydraulic system. I understand the different viscosity grades (e.g., SAE 10W-30, 15W-40) and their impact on performance at varying temperatures. I also understand the importance of lubricant properties like viscosity index, pour point, and additive packages. Regular lubricant analysis, including used oil analysis, is critical to identifying potential issues and adjusting lubrication schedules as needed. This preventative approach minimizes wear and tear, extends equipment life, and reduces costly breakdowns.

Q 13. Explain your understanding of different types of engine systems (e.g., diesel, gasoline).

I have a strong understanding of different engine systems, primarily diesel and gasoline engines. Diesel engines are commonly used in heavy equipment due to their high torque and fuel efficiency. I understand the principles of diesel combustion, including fuel injection, air intake, and exhaust systems. I’m familiar with various diesel engine components such as fuel injectors, turbochargers, and exhaust gas recirculation (EGR) systems. Gasoline engines, while less common in heavy equipment, are sometimes found in smaller machines. I understand the basics of gasoline combustion, including spark ignition and fuel delivery systems. My knowledge encompasses diagnosing and repairing common engine problems, such as fuel system issues, ignition problems, and engine performance issues. I’m proficient in performing engine maintenance tasks like oil changes, filter replacements, and tune-ups. Furthermore, I understand the environmental regulations related to diesel emissions, including exhaust after-treatment systems such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems.

Q 14. What experience do you have with repairing electrical systems in heavy equipment?

Repairing electrical systems in heavy equipment requires a combination of electrical theory and practical skills. I’m comfortable troubleshooting and repairing various electrical components, including starters, alternators, wiring harnesses, lights, and sensors. I can use diagnostic tools such as multimeters, clamp meters, and wiring diagrams to pinpoint electrical faults. For example, if a machine’s lights are not working, I’d systematically check the bulbs, fuses, wiring, and switches. I understand basic electrical principles such as voltage, current, resistance, and grounding. I’m also familiar with safety procedures related to working with high-voltage systems. My experience includes working with both DC and AC electrical systems, and I’m familiar with various electrical protection devices, such as circuit breakers and fuses. I’m comfortable reading and interpreting electrical schematics to understand the system’s wiring and component interactions. Proper grounding and bonding are always a priority to ensure safety and prevent damage to the electrical systems.

Q 15. Describe your experience with maintaining track systems on heavy equipment.

Maintaining track systems on heavy equipment is crucial for operational efficiency and safety. It involves regular inspections, preventative maintenance, and timely repairs. My experience encompasses a wide range of activities, from daily lubrication and tension checks to complete track replacements and undercarriage overhauls.

- Daily Inspections: I meticulously check for wear and tear on track shoes, rollers, idlers, and sprockets. This includes looking for cracks, excessive wear, and misalignment. I also check for proper track tension using the manufacturer’s specifications to prevent derailment or damage to the undercarriage.

- Preventative Maintenance: This includes scheduled lubrication of all moving parts, cleaning of the track system to remove debris that can cause premature wear, and tightening of bolts and fasteners. Proactive maintenance drastically extends the life of the track system.

- Repair and Replacement: When damage is detected, I assess the extent of the problem. This might involve replacing individual track shoes, repairing damaged rollers or idlers, or in severe cases, a complete track replacement. I’m experienced in using specialized tools and techniques for accurate track removal and installation, ensuring proper alignment and tension.

- Troubleshooting: I’ve successfully diagnosed and solved various issues, from track derailments caused by improper tension to abnormal wear patterns stemming from misaligned components or uneven terrain operation. For example, I once identified a hidden defect in a sprocket that was causing premature wear on a section of track; replacing the sprocket prevented further damage and costly repairs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with EPA regulations concerning heavy equipment emissions?

I’m very familiar with EPA regulations concerning heavy equipment emissions. My understanding covers Tier 4 Final and previous emission standards, including exhaust gas recirculation (EGR), selective catalytic reduction (SCR), diesel particulate filters (DPF), and diesel oxidation catalysts (DOC). Compliance is paramount, and I know how these technologies work, how to maintain them effectively, and identify potential problems that could lead to non-compliance.

- Regular Maintenance: I understand the importance of adhering to the manufacturer’s recommended maintenance schedules for emission control systems. This includes regular DPF cleaning or replacements, checking for proper functioning of SCR systems (including urea injection), and verifying EGR valve performance.

- Diagnostics: I am proficient in using diagnostic tools to monitor emission levels and identify potential issues in the aftertreatment systems. Understanding fault codes and their causes is crucial for efficient troubleshooting and timely repairs.

- Fuel Quality: I’m aware of the impact of fuel quality on emission control systems. Using the correct fuel and adhering to the manufacturer’s specifications is essential to prevent premature wear and failures of sensitive components such as the DPF.

Non-compliance can result in hefty fines and operational restrictions, so staying updated on current regulations and ensuring proper maintenance is crucial. For instance, a malfunctioning DPF can lead to excessive emissions, potentially triggering penalties and requiring immediate attention.

Q 17. Explain your approach to identifying and resolving repetitive equipment failures.

Addressing repetitive equipment failures requires a systematic and data-driven approach. It’s not enough to just fix the immediate problem; you need to understand the root cause. My approach involves several key steps:

- Data Collection: I meticulously record all maintenance activities, repairs, and downtime associated with the equipment. This data includes the nature of the failure, the time it occurred, any environmental factors, and the steps taken to repair it. A CMMS is invaluable for this.

- Pattern Recognition: I analyze the collected data to identify trends and patterns. Are failures occurring at regular intervals? Are certain components consistently failing? This helps isolate potential root causes.

- Root Cause Analysis: Once patterns emerge, I conduct a thorough investigation to identify the root cause. This might involve inspecting components, reviewing operational logs, consulting technical manuals, and even involving specialists when necessary. For example, repeated engine overheating might point to a faulty cooling system or inadequate lubrication.

- Corrective Actions: Based on the root cause analysis, I implement corrective actions. This could involve replacing faulty parts, modifying operating procedures, improving maintenance practices, or redesigning components to prevent future failures.

- Verification and Monitoring: After implementing the corrective actions, I closely monitor the equipment to ensure the problem is resolved and the failure rate has decreased. If issues persist, the process is repeated until the root cause is fully addressed.

A practical example: Repeated hydraulic hose failures on an excavator led me to discover that the hoses were being improperly routed, resulting in constant abrasion. Re-routing the hoses completely eliminated the problem.

Q 18. What is your experience with different types of engine components (e.g., fuel injectors, turbochargers)?

My experience with engine components is extensive. I’m proficient in diagnosing and repairing various components, including fuel injectors, turbochargers, and other essential parts. This knowledge spans different engine types, from naturally aspirated to turbocharged and supercharged engines, across various heavy equipment brands.

- Fuel Injectors: I can test injectors for proper spray pattern and flow rate, identify clogged or leaking injectors, and perform necessary repairs or replacements. I understand how variations in fuel pressure and timing affect engine performance and emissions.

- Turbochargers: I’m experienced in diagnosing turbocharger issues such as shaft play, oil leaks, and wastegate malfunctions. I can perform repairs such as cleaning or rebuilding turbochargers or recommend replacement as needed. I understand the critical role turbochargers play in engine performance and efficiency.

- Other Components: My experience also encompasses other engine components such as pistons, connecting rods, crankshafts, and cylinder heads. I can perform diagnostics, repairs, or recommend replacements as necessary. I’m proficient in using diagnostic tools to accurately assess the condition of engine components.

For example, I once diagnosed a significant loss of power in a bulldozer by identifying a faulty fuel injector. Replacing the injector restored the engine’s performance immediately.

Q 19. Describe your experience with computerized maintenance management systems (CMMS).

I have significant experience using computerized maintenance management systems (CMMS). These systems are essential for tracking maintenance activities, managing parts inventory, scheduling preventative maintenance, and analyzing equipment performance. My experience includes using several different CMMS platforms.

- Preventative Maintenance Scheduling: CMMS allows for efficient scheduling of preventative maintenance tasks, ensuring that equipment is serviced according to the manufacturer’s recommendations, reducing downtime, and extending the lifespan of the equipment.

- Parts Inventory Management: A CMMS helps optimize parts inventory by tracking usage, ordering, and stock levels. This prevents shortages and reduces the risk of downtime due to lack of necessary parts.

- Work Order Management: CMMS streamlines the work order process, from creating and assigning work orders to tracking their completion. This improves efficiency and accountability.

- Data Analysis: CMMS provides valuable data on equipment performance, allowing for identification of trends, patterns, and potential problems. This data is key to proactive maintenance and the optimization of maintenance schedules.

In a previous role, I implemented a new CMMS which resulted in a 15% reduction in equipment downtime and a 10% decrease in maintenance costs. The improved data analysis also allowed us to identify and address recurring problems more efficiently.

Q 20. How familiar are you with different types of transmissions used in heavy equipment?

Heavy equipment utilizes various transmission types, each with its own strengths and weaknesses. My familiarity extends to several types, including:

- Power Shift Transmissions: These are common in heavy equipment and offer smooth shifting under load. I understand their hydraulic operation and can troubleshoot problems related to clutch packs, hydraulic pumps, and control systems.

- Automatic Transmissions: These are becoming more prevalent in some types of heavy equipment, offering ease of operation. I’m familiar with their electronic control systems and diagnostic procedures.

- Manual Transmissions: Although less common in modern heavy equipment, I have experience with their operation and maintenance, including clutch adjustments and gear synchronizer repairs.

- Continuously Variable Transmissions (CVTs): These are increasingly found in some applications, offering optimal power and efficiency. I understand their more complex operation and the specific maintenance requirements they demand.

Understanding the specific type of transmission is crucial for effective troubleshooting. For example, a slipping clutch in a power shift transmission requires a different diagnostic and repair approach compared to a malfunctioning electronic control module in an automatic transmission.

Q 21. What is your experience with repairing and maintaining undercarriage components?

Repairing and maintaining undercarriage components is a significant part of my expertise. This includes regular inspections, preventative maintenance, and repairs of various parts like tracks, rollers, idlers, sprockets, and even the frame itself.

- Track System: As mentioned previously, I’m proficient in track system maintenance, including tension adjustments, lubrication, and component replacement. I understand the importance of proper track tension to prevent derailments and premature wear.

- Rollers and Idlers: I can inspect rollers and idlers for wear and tear, damage, and misalignment. Replacing these components is a routine procedure for me.

- Sprockets: I can identify and address sprocket wear and tooth damage. I understand how improper sprocket alignment contributes to track wear. Replacing sprockets requires precision.

- Undercarriage Frame: I can inspect the undercarriage frame for cracks, damage, and distortion. Repairing damaged frames can involve welding or other advanced techniques.

A recent example involved repairing a severely damaged undercarriage on a large excavator. By carefully assessing the damage, I developed a repair plan which was both cost-effective and ensured the excavator’s structural integrity, significantly reducing downtime.

Q 22. How do you prioritize maintenance tasks to maximize equipment uptime?

Prioritizing maintenance tasks for maximum equipment uptime requires a strategic approach combining preventative measures with reactive repairs. Think of it like a doctor’s appointment – regular checkups prevent major issues later. I utilize a prioritized system based on several factors:

- Criticality: Tasks impacting safety or major production are top priority. For example, brake system maintenance on a haul truck trumps a minor hydraulic leak on a smaller excavator.

- Frequency: Manufacturer-recommended service intervals dictate the schedule for routine tasks like oil changes, filter replacements, and lubrication. These are scheduled proactively to avoid unexpected failures.

- Cost-benefit analysis: Some repairs might be minor but could lead to significant damage if neglected. Addressing these promptly minimizes downtime and prevents escalating costs. For example, a small crack in a weld on a bucket could become a major structural failure if left unattended.

- CMMS (Computerized Maintenance Management System): Modern CMMS systems are invaluable for tracking work orders, scheduling maintenance, and generating reports on equipment history and potential problems. This allows me to predict potential failures and schedule preventative maintenance accordingly.

By combining these factors, I create a maintenance schedule that optimizes uptime while minimizing costs. It’s not just about fixing things when they break; it’s about anticipating problems and preventing them.

Q 23. What is your experience working with different types of welding equipment (e.g., MIG, TIG)?

I’m proficient in both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, having utilized both extensively for repairs and fabrication on heavy equipment. MIG welding, known for its speed and ease of use, is ideal for thicker materials and fast repairs, particularly in situations where high cosmetic quality is less crucial. I often use MIG for patching worn components or repairing structural elements on excavators or loaders. For example, I recently used MIG to repair a severely damaged bucket tooth on a backhoe.

TIG welding, while slower, provides significantly better precision and superior weld quality, making it my preferred method for critical repairs or when appearance matters. I use TIG when welding thin materials, components with intricate designs, or when high weld strength and integrity are paramount, such as when repairing hydraulic lines or critical structural members.

My experience extends beyond simply knowing how to weld. I understand material compatibility, proper weld techniques for different metals (steel, aluminum, stainless steel), and the importance of pre- and post-weld procedures, such as cleaning and heat treating, to ensure a lasting repair.

Q 24. Explain your understanding of different types of bearings and their applications.

Bearings are crucial components in heavy equipment, minimizing friction and enabling smooth rotation. Different types exist, each suited for specific applications:

- Ball bearings: These are commonly used where high speeds and relatively light loads are involved, like in wheel hubs or smaller rotating components. They’re simple, reliable, and relatively inexpensive.

- Roller bearings: These handle heavier loads and are ideal for applications with slower speeds but higher radial or thrust loads. Think of the bearings in a bulldozer track system.

- Tapered roller bearings: These are designed to withstand both radial and thrust loads simultaneously, making them suitable for applications like axles and gearboxes, where combined stresses are common.

- Spherical roller bearings: These self-aligning bearings tolerate misalignment, which is beneficial in applications where precise shaft alignment is challenging to maintain.

- Needle roller bearings: These compact bearings have long, slender rollers which allow for high load capacity within a limited space. They’re often used in small components within larger assemblies.

Selecting the wrong bearing type can lead to premature failure, equipment damage, and costly downtime. Therefore, understanding the load, speed, and environmental conditions of each application is critical for proper bearing selection.

Q 25. Describe your experience with performing routine inspections on heavy equipment.

Routine inspections are the cornerstone of preventative maintenance. My process includes a thorough visual inspection followed by checks of key operational aspects. For example, a typical inspection of a large excavator would involve:

- Visual inspection: Checking for leaks (hydraulic, fuel, coolant), loose bolts, damage to bodywork, wear on cutting edges and tracks, and any signs of unusual wear or damage.

- Fluid levels: Checking engine oil, hydraulic oil, coolant, and transmission fluid levels. Low levels can indicate a leak or other problem.

- Tire pressure: Ensuring correct tire inflation for optimal performance and to prevent premature wear and tear.

- Operational checks: Testing the functionality of all hydraulic functions, controls, and safety systems (emergency stops, warning lights). Listening for unusual noises that could indicate bearing wear or other mechanical problems.

- Documentation: Maintaining detailed records of inspection findings, including any identified issues and the actions taken to address them. This history is invaluable for tracking equipment performance and identifying trends.

This meticulous approach ensures early detection of potential problems, minimizing major breakdowns and maximizing equipment lifespan. It’s about anticipating problems before they become costly crises.

Q 26. How do you ensure the accuracy of your repair work?

Ensuring the accuracy of my repair work is paramount. I employ several strategies:

- Precision measurement: I use accurate measuring tools (calipers, micrometers, laser measuring devices) to ensure all components are correctly sized and aligned. I always double-check measurements to prevent errors.

- Proper torque specifications: Following manufacturer specifications for bolt torque is critical. Over-torquing can damage components, while under-torquing can cause loosening and failure. I utilize torque wrenches to maintain consistent torque values.

- Adherence to repair manuals: I always consult the equipment’s service manual for detailed repair procedures and specifications. This ensures I’m following the correct steps and using the proper parts.

- Testing and inspection: After a repair, I thoroughly test the equipment to confirm the fix was successful. This might involve a functional test, load testing, or other relevant checks. If the repair is related to a safety-critical component, I will thoroughly document the testing procedures.

- Quality control checks: Having a colleague review my work can also help in catching errors before they become significant problems.

By following these procedures, I strive for high-quality, accurate repairs that increase equipment reliability and longevity.

Q 27. What is your experience with using diagnostic software for troubleshooting heavy equipment issues?

I have extensive experience using diagnostic software on a wide range of heavy equipment, from excavators to loaders and haul trucks. These sophisticated systems provide invaluable data for troubleshooting and repair. Specific examples include Caterpillar’s ET (Electronic Technician) and Komatsu’s diagnostic software. These systems allow me to:

- Retrieve diagnostic trouble codes (DTCs): These codes provide clues to the root cause of the problem, narrowing down the possible issues significantly. For example, a specific DTC might indicate a faulty sensor or a malfunctioning component.

- Monitor real-time data: Observing parameters such as engine speed, hydraulic pressure, temperature, and fuel consumption in real time helps identify anomalies and potentially predict problems.

- Perform component testing: Some software allows for active component testing, enabling me to check the functionality of individual systems without having to disassemble everything.

- Access historical data: Analyzing previous diagnostic data can reveal trends and patterns, potentially uncovering underlying issues that weren’t apparent from the current symptoms.

I treat this data as a critical tool, guiding me towards accurate and efficient diagnoses and ensuring a quicker return to service for the equipment.

Q 28. How do you stay current with advancements in heavy equipment technology?

Staying current in this rapidly evolving field is crucial. I employ several methods:

- Manufacturer training courses: I regularly participate in manufacturer-provided training courses to learn about new technologies, updates, and best practices related to specific equipment brands. These often include hands-on experience with new diagnostic tools and technologies.

- Industry publications and journals: I regularly read industry publications and journals to stay abreast of the latest trends and developments in heavy equipment maintenance and repair technologies. This keeps me up to date on emerging issues and best practices.

- Online resources and forums: Online resources, forums, and webinars provide a wealth of information and allow for discussions with other professionals in the field, leading to valuable knowledge sharing.

- Networking and conferences: Attending industry conferences and networking events provides opportunities to learn from experts and share experiences with colleagues.

Continuous learning is vital for staying proficient and adapting to the ever-changing landscape of heavy equipment technology. The industry is constantly evolving, and I am committed to keeping pace with it.

Key Topics to Learn for Heavy Equipment Maintenance and Operation Interview

- Preventive Maintenance Schedules: Understanding and applying preventative maintenance schedules to minimize downtime and extend equipment lifespan. This includes knowing the importance of regular inspections, lubrication, and component replacements.

- Hydraulic Systems: Diagnosing and troubleshooting hydraulic system malfunctions, including leaks, pressure issues, and component failures. Practical application involves understanding hydraulic schematics and using diagnostic tools.

- Engine Diagnostics and Repair: Troubleshooting engine problems, performing basic engine maintenance (oil changes, filter replacements), and understanding the principles of internal combustion engines. This also encompasses understanding emission control systems.

- Electrical Systems: Working with electrical wiring diagrams, troubleshooting electrical faults, and understanding the operation of various electrical components in heavy equipment (e.g., starters, alternators, lighting systems).

- Safety Procedures and Regulations: Demonstrating a thorough understanding of all relevant safety protocols, including lockout/tagout procedures, personal protective equipment (PPE) usage, and hazard identification.

- Troubleshooting and Problem-solving: Explaining your approach to diagnosing complex equipment issues systematically, using diagnostic tools effectively, and applying your knowledge to find practical solutions.

- Diesel Engine Technology: A deep understanding of diesel engine operation, including fuel systems, air intake systems, and exhaust systems. This also includes knowledge of different diesel engine types and their applications.

- Welding and Fabrication (if applicable): Demonstrating knowledge of welding techniques and metal fabrication processes if required for the specific role. This includes understanding different welding processes and safety procedures.

Next Steps

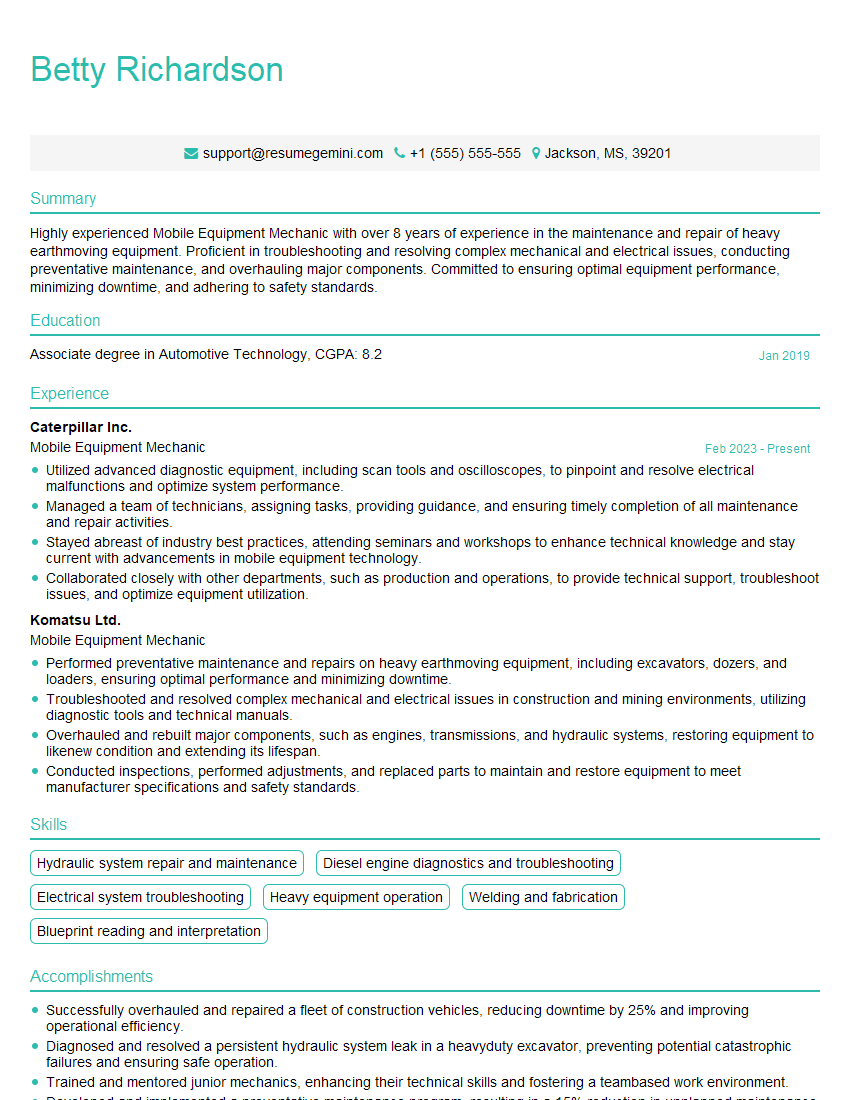

Mastering Heavy Equipment Maintenance and Operation opens doors to a rewarding career with excellent growth potential. Advancement opportunities are plentiful for skilled and knowledgeable technicians, leading to increased responsibility and higher earning potential. To maximize your job prospects, focus on crafting an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Heavy Equipment Maintenance and Operation are available to guide you, ensuring your application stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.