Are you ready to stand out in your next interview? Understanding and preparing for Height and Climbing Ability interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Height and Climbing Ability Interview

Q 1. Describe your experience working at heights.

My experience working at heights spans over 15 years, encompassing a wide range of projects in diverse environments. I’ve worked on everything from industrial maintenance and construction projects to telecommunications infrastructure and wind turbine servicing. This experience has exposed me to varying levels of complexity, from straightforward tasks to highly challenging scenarios requiring intricate planning and execution. I’ve consistently prioritized safety and efficiency, leading teams and completing projects on time and within budget. For example, on a recent wind turbine repair, I coordinated a team to replace a damaged blade at a height of 150 meters, requiring meticulous planning and execution of rope access techniques. This project successfully avoided any safety incidents and met all project deadlines.

Q 2. What safety equipment are you familiar with?

I’m proficient in using a wide array of safety equipment, including but not limited to:

- Harnesses: Full-body harnesses, including those with specific features like dorsal D-rings and leg straps for secure anchoring.

- Lanyards: Shock-absorbing lanyards, self-retracting lifelines (SRLs), and various connecting devices.

- Anchors: Understanding different types of anchors (structural, non-structural) and their appropriate usage and limitations.

- Fall Arrest Systems: Experience with various fall arrest systems including engineered systems, and understanding their proper inspection and maintenance.

- Personal Protective Equipment (PPE): Helmets, gloves, high-visibility clothing, appropriate footwear, and eye protection for specific tasks.

- Rope Access Equipment: This includes ropes, ascenders, descenders, carabiners, and other specialized equipment for rope access techniques.

Regular inspection and maintenance of all equipment are crucial and form part of my standard operating procedures before any work at height begins.

Q 3. Explain your understanding of fall protection systems.

Fall protection systems are critical for preventing falls from heights. They involve a combination of equipment and procedures designed to arrest a fall before a worker impacts the ground or lower level. These systems work by catching a falling worker and minimizing the impact forces. My understanding encompasses various types of systems, including:

- Guardrail Systems: These provide a physical barrier around the work area.

- Safety Nets: Nets placed below the work area to catch a falling worker.

- Personal Fall Arrest Systems (PFAS): These are systems worn by the worker, including harnesses, lanyards, and anchors, designed to arrest a fall.

- Fall Restraint Systems: These systems prevent a worker from reaching a fall hazard in the first place, typically through the use of tethers and anchor points.

Choosing the right system depends on various factors, including the work environment, the height of the work, and the potential fall distance. Regular inspections and training are crucial to ensure the effectiveness and safety of these systems. For instance, ensuring the correct anchorage point, appropriate lanyard length and checking for any signs of wear and tear are paramount. A system failure can have fatal consequences.

Q 4. How do you perform a pre-climb inspection?

A pre-climb inspection is a critical step that ensures the safety and efficiency of any climb. It involves a systematic check of all aspects of the work environment and equipment. My pre-climb inspection follows a structured approach:

- Equipment Check: Thoroughly inspect all PPE and climbing equipment, checking for any wear, tear, damage, or defects. This includes harnesses, lanyards, carabiners, ropes, and ascenders/descenders.

- Anchor Point Inspection: Evaluate the stability and strength of the chosen anchor points, ensuring they’re capable of supporting the anticipated load. This often involves assessing the structural integrity of the anchor point and its connection to the structure.

- Work Area Assessment: Examine the work area for potential hazards, such as loose debris, obstacles, weather conditions, and environmental factors. Any potential hazards are identified, addressed and documented.

- Communication Plan: Establish clear communication protocols among team members, outlining procedures for signaling and emergency response.

- Escape Route Planning: In case of emergency, determine possible escape routes and identify backup anchor points.

Detailed documentation of the inspection is crucial, serving as a record of the pre-climb conditions and mitigating potential liabilities. I always ensure that all team members understand and agree on the results of the pre-climb inspection before commencement of the work.

Q 5. What are the different types of climbing techniques?

Various climbing techniques exist, each suited to specific tasks and environments. The most common ones I’m experienced with include:

- Rope Access Techniques: Utilizing ropes for ascent and descent, including single rope technique (SRT), double rope technique (DRT), and other advanced rope access methods. This is my most commonly used technique.

- Scaffolding and Elevated Work Platforms: Working from pre-assembled scaffolding or elevated work platforms. Often used for large-scale projects or when rope access is impractical.

- Industrial Climbing: A specialized technique used in industrial settings, often involving complex anchor points and specialized equipment. Often used for inspecting and maintaining industrial infrastructure.

- Tree Climbing: Utilizing specialized techniques for climbing trees safely and efficiently. I have specific training and qualifications for this.

The choice of technique depends on the specific project requirements, the nature of the access needed, and safety regulations. Selecting the most appropriate technique is critical for ensuring both safety and productivity.

Q 6. Describe your experience with rope access techniques.

My experience with rope access techniques is extensive. I hold certifications in advanced rope access techniques, including SRT and DRT, and have a proven track record of successfully completing complex projects using this method. Rope access allows for efficient and safe access to hard-to-reach areas, minimizing disruption and maximizing safety. I’m comfortable with various ascenders and descenders, and adept at setting up complex anchor systems. For instance, I recently employed SRT techniques to inspect and repair a section of a bridge at a height of 80 meters, where traditional scaffolding was impractical. The rope access technique allowed for precise and efficient work, ensuring the safety of my team and minimizing downtime.

Q 7. How do you handle emergency situations at heights?

Handling emergency situations at heights requires calm, decisive action and adherence to established protocols. My training emphasizes proactive risk mitigation, but I’m also prepared for unforeseen circumstances. My emergency response procedures include:

- Immediate Assessment: Quickly assess the situation, identifying the nature of the emergency and the affected individuals.

- Communication: Establish clear communication with the emergency response team, providing accurate information about the location, the nature of the emergency, and the number of people involved.

- Evacuation Procedures: Implement the appropriate evacuation plan, using established techniques and equipment to ensure the safe retrieval of the affected personnel.

- First Aid and Medical Assistance: Provide immediate first aid if necessary, awaiting arrival of medical professionals.

- Post-Incident Review: Thorough review of the incident to identify the cause, learn lessons, and implement any necessary improvements to safety procedures and protocols.

Regular training and drills are crucial for effective emergency response. Simulated emergencies are an invaluable method to refine response time and efficiency. My emphasis is on preventing accidents in the first place, but this preparation ensures a swift and effective response to any unforeseen events.

Q 8. Explain your experience with different types of harnesses and their applications.

My experience with harnesses spans various types, each suited for specific climbing and height-related tasks. I’m proficient with full-body harnesses, which offer the most comprehensive protection and are essential for rope access and industrial work at height. These typically feature leg loops, waist belt, and attachment points for various safety equipment. I also have extensive experience with chest harnesses, often used in conjunction with full-body harnesses for added security in certain situations, such as rescue operations or when working on steep angles. For specific tasks like confined space entry, I utilize specialized harnesses designed for confined spaces with added features such as dorsal D-rings for better weight distribution and fall arrest points strategically placed for optimal safety. Finally, I’m familiar with simpler harnesses, such as those used for tree climbing or simpler climbing activities, emphasizing the importance of choosing the right harness for the specific job, always prioritizing safety and regulatory compliance.

- Full-Body Harness: Used for most industrial work at height, offering comprehensive protection.

- Chest Harness: Provides added security in conjunction with a full-body harness.

- Confined Space Harness: Specifically designed for confined space entry and rescue.

- Simple Harnesses: Suitable for less demanding climbing activities like tree climbing.

Q 9. What are the limitations of your climbing experience?

While my experience is extensive, certain limitations exist. My experience is primarily focused on industrial rope access and confined space work, meaning I have less experience with traditional rock climbing techniques and free soloing. Also, my experience is limited to specific geographical regions and weather conditions. Furthermore, while I’m proficient in various rescue techniques, my experience with large-scale multi-person rescue operations is less extensive and requires further training and experience. I’m always seeking opportunities for continued professional development to overcome these limitations and expand my expertise.

Q 10. How do you manage your fear of heights?

Managing fear of heights is crucial in my profession. It’s not about eliminating fear entirely – a healthy respect for heights is essential for safety. Instead, I focus on managing the fear through thorough training, meticulous planning, and adherence to safety protocols. This includes ensuring my equipment is always properly inspected and in good working order, double-checking safety lines and anchor points, and systematically working through each step of a job. Knowing I’ve taken every precaution possible helps to significantly reduce anxiety. Furthermore, regular training and practicing emergency procedures helps build confidence and reduce the emotional response to heights. It’s a continuous process of building trust in my skills, equipment, and training.

Q 11. What is your experience with working in confined spaces at height?

Working in confined spaces at height presents unique challenges demanding specialized training and equipment. My experience includes working in various confined spaces such as tanks, silos, and shafts, often involving complex rigging and rescue procedures. I’m proficient in using specialized confined space harnesses, atmospheric monitoring equipment, and rescue techniques specific to these environments. Understanding the risks associated with confined space work, such as oxygen deficiency, hazardous atmospheres, and limited escape routes, is paramount. I always ensure proper permits are obtained before entering a confined space and follow strict entry and exit procedures to guarantee safety. I am also trained in rescue techniques specific to confined spaces and have participated in numerous confined-space rescue simulations.

Q 12. Describe a time you had to overcome a challenging situation while working at heights.

During a recent inspection of a large industrial chimney, strong winds caused a sudden swaying of the structure. My safety line became unexpectedly taut, and I felt a significant increase in the tension. My immediate reaction was to remain calm and assess the situation. I carefully checked my equipment, ensured my anchor points were secure, and communicated the issue to my ground crew. We decided to temporarily suspend work until the wind subsided to ensure my safety. This situation highlighted the importance of maintaining constant communication, having a thorough understanding of weather conditions, and knowing when to prioritize safety over work deadlines. The experience reinforced the need for adaptability and calm decision-making in unexpected and potentially dangerous circumstances.

Q 13. What are the relevant safety regulations for working at heights in your region?

In my region, working at heights is governed by stringent safety regulations, including adherence to OSHA (Occupational Safety and Health Administration) guidelines. These regulations cover aspects such as fall protection systems (including the use of harnesses, lanyards, and anchor points), rescue plans, confined space entry procedures, regular equipment inspections, and comprehensive training for workers. Specific requirements often depend on the task’s nature and the height involved. For example, fall arrest systems are mandatory above a certain height, and specific training is required for working with specific equipment, such as rope access systems. Failure to comply with these regulations can result in significant penalties and legal repercussions.

Q 14. How do you ensure your equipment is properly maintained and inspected?

Equipment maintenance and inspection are non-negotiable aspects of working at heights. I adhere to a strict routine involving regular visual inspections of all equipment before and after each use. This includes checking for wear and tear, frayed ropes, damaged buckles, and any other signs of degradation. I maintain detailed records of these inspections, noting any issues discovered. Furthermore, all my equipment undergoes periodic professional inspections and certification by qualified technicians to guarantee its compliance with safety standards and to identify any potential problems that might not be visible during routine checks. This proactive approach to equipment maintenance significantly reduces the risks associated with working at heights and contributes to a safer working environment.

Q 15. Explain your understanding of risk assessment in high-altitude work.

Risk assessment in high-altitude work is a systematic process of identifying hazards, analyzing risks, and implementing control measures to minimize the likelihood and severity of incidents. It’s not just about identifying the obvious dangers like falls, but also considering less apparent factors. Think of it like building a sturdy tower – you need a strong foundation (planning), robust supports (equipment), and careful construction (procedures).

- Hazard Identification: This involves meticulously reviewing the worksite, equipment, weather conditions, and potential human errors. For example, identifying loose rocks on a cliff face, deteriorated ropes, or the potential for fatigue amongst the team.

- Risk Analysis: Once hazards are identified, we analyze the likelihood and potential severity of each. A small chance of a minor injury is different from a high chance of a fatal fall. This involves considering the consequences, such as injuries, equipment damage, and delays to the project.

- Control Measures: Based on the risk analysis, we implement control measures. These might involve using appropriate safety equipment like harnesses, lanyards, and fall arrest systems; employing specific work procedures; or adjusting the work schedule due to weather conditions.

- Monitoring and Review: Regular monitoring throughout the work ensures the effectiveness of implemented control measures. We document everything for future reference and improve our risk assessment process over time.

For instance, during a recent bridge inspection, we identified the risk of falling debris as a significant hazard. Our risk assessment led to the implementation of a controlled exclusion zone below, the use of hard hats, and regular debris clearing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively while working at heights with a team?

Effective communication at heights is paramount. It’s not just about shouting instructions; it’s about clear, concise, and unambiguous communication using multiple methods. Imagine working on a construction site high above the ground – a simple misunderstanding could have disastrous consequences.

- Pre-Work Briefing: A comprehensive briefing before commencing work is crucial. This outlines tasks, procedures, potential hazards, communication protocols, and emergency procedures. Visual aids, such as diagrams, are incredibly helpful.

- Designated Communication Channels: We use a combination of methods: radio communication for immediate instructions, hand signals for situations where radio is impractical, and pre-arranged visual signals for emergencies (e.g., a specific number of hand waves indicating a need for assistance).

- Confirmation and Feedback: It’s essential to ensure everyone understands and confirms instructions. Continuous feedback loops prevent misunderstandings. A simple ‘Roger that’ or visual acknowledgement confirms the message has been received and understood.

- Clear and Concise Language: We avoid jargon and use plain language. If specialized terms are necessary, they’re clearly defined before use. Keeping communication simple and direct reduces confusion and improves safety.

During a recent rock climbing project, a sudden change in wind conditions necessitated a quick change of plan. Our pre-arranged hand signals allowed for immediate adjustments without verbal communication which was compromised by the wind.

Q 17. Describe your experience using various anchoring systems.

My experience encompasses a range of anchoring systems, each suited for different applications and environments. Choosing the right anchor is crucial for safety; a poorly chosen anchor is as dangerous as no anchor at all.

- Expansion Bolts: Ideal for solid rock and concrete structures, they provide excellent holding power. I’ve extensively used them for setting up top ropes during rock climbing and for anchoring safety lines during building maintenance.

- Mechanical Anchors: These versatile anchors are suitable for various substrates, including wood and steel. Their ease of installation and adaptability make them valuable for temporary setups.

- Natural Anchors: These involve utilizing natural features like large boulders or strong trees. Careful assessment is required to determine their stability and load-bearing capacity. Experience is key to judging their suitability.

- Master Points: These serve as central connection points for several independent anchor points, distributing the load efficiently. Their use is crucial for multi-person work and for tasks requiring significant load capacity.

During a recent rescue operation, we used a combination of expansion bolts and master points to create a highly reliable anchoring system. The redundancy provided by the master point provided crucial redundancy if one of the expansion bolts had failed.

Q 18. What are the signs of equipment failure and how would you react?

Recognizing signs of equipment failure is critical. It’s about constant vigilance and attention to detail. Ignoring subtle warning signs can have catastrophic results.

- Visual Inspection: Regular and thorough visual checks are essential. This includes examining ropes for fraying, cuts, or excessive wear, checking carabiners for deformation or damage, and inspecting harnesses for tears or weakening stitching.

- Unusual Sounds or Behavior: Pay attention to unusual noises, such as creaking or snapping sounds in ropes or carabiners. Unusual behavior, such as a carabiner not closing smoothly, is also a warning sign.

- Load Testing: Some equipment allows for load testing before full weight is applied. This process helps to verify the integrity of the equipment under stress.

Reaction to Failure: My immediate reaction would be to:

- Immediately stop the work and secure the area: Ensure the safety of everyone in the vicinity.

- Report the failure: Inform the team and supervisors immediately.

- Inspect and remove the faulty equipment: Never attempt to use damaged equipment.

- Implement alternative safety measures: If appropriate, establish an alternative anchoring system or use backup equipment.

In one instance, we noticed fraying in a rope during a regular inspection. We immediately replaced it, preventing a potential serious accident.

Q 19. What are the effects of weather conditions on working at heights?

Weather conditions significantly impact high-altitude work, posing additional hazards. Extreme weather can render work impossible or even extremely dangerous. Think of it as adding layers of complexity to an already challenging environment.

- Wind: Strong winds increase the risk of falls, sway work platforms, and affect the stability of anchors. Work may need to be postponed or special wind protection measures implemented.

- Rain and Snow: These can make surfaces slippery, reduce visibility, and add weight to equipment and structures. This increases the risk of falls and equipment failure.

- Temperature: Extreme temperatures can affect equipment performance (e.g., freezing ropes), reduce dexterity, and increase the risk of hypothermia or heatstroke.

- Lightning: Lightning strikes pose a severe danger, necessitating a complete halt to work during thunderstorms. Seeking adequate shelter is crucial.

During a roofing repair project, a sudden unexpected snowfall forced us to cease operations immediately. The added weight of the snow on the roof, combined with the icy conditions, created an extremely dangerous work environment.

Q 20. How do you plan for rescue scenarios at height?

Planning for rescue scenarios is a critical component of any high-altitude work plan. It’s not a matter of ‘if’ but ‘when’ something might go wrong. A well-rehearsed rescue plan can make the difference between life and death.

- Pre-determined Escape Routes: Identifying multiple escape routes is crucial. These routes should be well-marked and easy to follow in an emergency.

- Emergency Contact Information: Emergency contact information for rescue services, supervisors, and designated personnel needs to be readily available and communicated to all team members.

- Designated Rescue Team: Having a well-trained rescue team familiar with the site and rescue equipment is vital. Regular training and drills should be conducted.

- Appropriate Rescue Equipment: Access to appropriate rescue equipment, such as ropes, harnesses, pulleys, and communication devices is essential.

- Communication Protocols: Clear communication protocols for raising the alarm and coordinating a rescue operation need to be established and understood by all team members.

During a recent project, we established a designated rescue team and practiced several rescue scenarios. This training gave us the confidence and skills to react effectively during an actual emergency when a worker sustained a minor injury.

Q 21. Describe your experience with different types of ascenders and descenders.

My experience with ascenders and descenders is extensive. These devices are critical for controlled movement during climbing and rope access work, and proficiency in their use is essential for safety.

- Ascenders: These devices allow controlled upward movement along a rope. I’ve used various types, including cam-based ascenders (like the Petzl Ascender) and rope-clamp ascenders (like the Petzl Tibloc). The choice depends on factors such as rope diameter and the type of work.

- Descenders: These are used for controlled descent. I’m proficient with various types, including friction-based descenders (like the Petzl I’D) and braking-assisted descenders (like the Petzl Rig). Each device has specific operating procedures to ensure safe descent.

Proper training and practice are key to safe use of these devices. Incorrect usage can lead to serious injury. I always practice proper techniques before using them in real-world scenarios, and always prioritize safety over speed.

Q 22. Explain your knowledge of different knots used in climbing and their applications.

Knots are fundamental in climbing, providing secure anchors and connections. Choosing the right knot depends entirely on the specific situation and the materials being used. Here are a few examples:

- Figure-eight knot: A simple and reliable stopper knot, primarily used to secure the end of a rope to a harness or other anchor point. It’s easy to tie and inspect, making it a favorite for beginners.

[Image of Figure-eight knot would be here] - Bowline: Creates a fixed loop that won’t slip. Excellent for attaching a rope to a ring or other anchor point, or creating a running loop for ascending.

[Image of Bowline would be here] - Clove hitch: A quick and versatile knot used for attaching a rope to a ring, post, or other object. It’s easily adjustable but requires careful attention to ensure it’s properly secured. It’s often used as a temporary anchor.

[Image of Clove Hitch would be here] - Prussik knot: A sliding knot used for ascending ropes. It grips the rope well under tension but can be easily moved when slack is introduced. Crucial for self-rescue techniques.

[Image of Prussik knot would be here]

The choice of knot is critical for safety. Incorrect knot tying can lead to catastrophic equipment failure. Regular practice and thorough understanding of each knot’s strengths and weaknesses are vital for any climber.

Q 23. How do you assess the structural integrity of a climbing surface?

Assessing the structural integrity of a climbing surface requires a multifaceted approach. It’s not just about looking at the surface; it involves understanding the underlying structure and potential risks. My assessment includes:

- Visual Inspection: Checking for cracks, loose rocks, weathering, signs of erosion, and any other visible defects.

- Testing for Stability: Gently applying pressure to potentially unstable areas to evaluate their firmness. This is often done with tools like a rock hammer to gauge soundness.

- Understanding Rock Type: Different rock types have varying strengths and weaknesses. Granite, for instance, is typically more robust than sandstone. Knowledge of geology is vital here.

- Environmental Factors: Considering weather conditions (rain, ice, snow) that might compromise the surface’s stability.

- Experienced Judgement: Years of experience allow for an intuitive assessment, enabling a quick identification of potential problems that may not be immediately obvious.

In complex scenarios, a professional geological survey might be necessary to obtain a comprehensive understanding of the stability and load-bearing capacity of the climbing surface. Safety always comes first.

Q 24. What are the common hazards associated with working at heights?

Working at heights presents numerous hazards, broadly categorized into:

- Falls: This is the most significant risk, leading to serious injuries or fatalities. Falls can be mitigated through proper fall protection systems.

- Slips, Trips, and Falls on the Same Level: Even without a significant drop, a fall at height can result in injury. Good housekeeping and appropriate footwear are crucial.

- Falling Objects: Tools, equipment, or debris falling from above can cause severe injury to those working below. Appropriate safety measures and designated work areas are essential.

- Electrocution: Contact with overhead power lines is a serious threat. Maintaining safe distances and using appropriate non-conductive tools are paramount.

- Environmental Hazards: Extreme weather, such as strong winds or freezing temperatures, can increase the risk of accidents. These conditions need to be monitored and addressed appropriately.

- Exposure to Hazardous Substances: Depending on the work, exposure to chemicals or asbestos is a possibility requiring appropriate respiratory protection and safety protocols.

A thorough risk assessment is crucial before any work commences at heights, identifying specific hazards and implementing appropriate control measures.

Q 25. How do you stay physically fit and mentally prepared for working at heights?

Maintaining peak physical and mental fitness is crucial for safe and efficient work at heights. My approach involves:

- Regular Exercise: A balanced fitness regime incorporating cardiovascular training, strength training, and flexibility exercises. This helps build stamina, strength, and agility, essential for endurance and safety.

- Specific Training: Practicing climbing techniques, rope handling, and rescue scenarios to hone skills and build confidence. This includes regular training on fall protection systems.

- Mental Preparedness: Developing a calm and focused mindset is crucial, especially during challenging situations. Stress management techniques and mindfulness practices are helpful.

- Adequate Sleep: Sufficient rest ensures alertness and optimal cognitive function, reducing the risk of errors.

- Healthy Diet: Nourishing the body with a balanced diet provides the energy and nutrients needed for demanding work.

My commitment to physical and mental well-being extends beyond personal fitness; it’s a critical component of my professional responsibility for ensuring the safety of myself and others.

Q 26. Describe your experience with using personal protective equipment (PPE).

My experience with personal protective equipment (PPE) is extensive and encompasses a wide range of equipment. I am proficient in the use, inspection, and maintenance of:

- Harnesses: I can correctly fit and inspect harnesses, ensuring they are properly adjusted and free from defects. I understand the different types of harnesses for various climbing situations.

- Helmets: I regularly wear and inspect helmets, ensuring they are securely fastened and provide adequate head protection.

- Fall Arrest Systems: I am experienced in the safe use of lanyards, shock absorbers, and self-retracting lifelines, understanding their limitations and appropriate applications. This includes regular inspection and testing of these systems.

- Rope and Carabiners: I know how to select appropriate ropes and carabiners for the task, ensuring they are in good condition and properly connected.

- Respiratory Protection: When working in environments with hazardous substances, I use appropriate respiratory protection, following all safety guidelines for fitting and use.

I meticulously check all PPE before each job, ensuring it’s in optimal condition and correctly used to mitigate risks. My understanding extends to the limitations of PPE and the importance of other safety measures.

Q 27. Explain your understanding of the hierarchy of controls for working at heights.

The hierarchy of controls for working at heights prioritizes the elimination of hazards, progressing to progressively less effective controls if elimination isn’t feasible. The order is:

- Elimination: The most effective method, involving removing the hazard altogether, if possible. For example, designing a building that eliminates the need for working at heights.

- Substitution: Replacing the hazardous task with a safer alternative. This might involve using robots or remote-controlled equipment.

- Engineering Controls: Implementing physical changes to minimize risk, such as installing guardrails, safety nets, or using scaffolding.

- Administrative Controls: Implementing procedures and training to mitigate the risk. This includes risk assessments, work permits, and safety training.

- Personal Protective Equipment (PPE): The last line of defense, providing personal protection against hazards. This is always used in conjunction with other control measures, never as the sole method of risk reduction.

It’s crucial to implement the highest level of control feasible, working down the hierarchy only when higher-level controls are impractical or ineffective.

Q 28. How do you ensure compliance with all relevant safety standards and regulations?

Compliance with safety standards and regulations is paramount. My approach involves:

- Knowledge of Regulations: I maintain up-to-date knowledge of all relevant national and industry-specific regulations and standards relating to working at heights.

- Risk Assessments: I actively participate in and contribute to comprehensive risk assessments before any project, identifying and mitigating potential hazards.

- Permit-to-Work Systems: I follow established permit-to-work systems, ensuring all necessary approvals are obtained before commencing work.

- Regular Inspections: I regularly inspect equipment and work areas to identify and rectify potential safety issues.

- Training and Documentation: I participate in ongoing training to maintain my competence and keep records of all training and inspections.

- Reporting and Investigation: I report all incidents and near misses, participating in thorough investigations to identify root causes and prevent future occurrences.

Safety isn’t just a checklist; it’s a continuous process demanding vigilance, proactive measures, and a commitment to best practices.

Key Topics to Learn for Height and Climbing Ability Interview

- Understanding Height Measurements and Conversions: Mastering various units (meters, feet, etc.) and performing accurate conversions is crucial for precise calculations and communication.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of safety protocols, regulations, and best practices related to working at heights and climbing.

- Equipment Knowledge and Selection: Familiarize yourself with various climbing and height-access equipment, their applications, and how to choose the appropriate gear for different scenarios.

- Risk Assessment and Mitigation: Explain your approach to identifying potential hazards, assessing risks, and implementing effective mitigation strategies in height-related work.

- Physical Fitness and Endurance: Be prepared to discuss the physical demands of the role and how your fitness level aligns with the requirements. This might include stamina, strength, and agility.

- Emergency Procedures and Response: Describe your knowledge of emergency response procedures, including rescue techniques and communication protocols in case of accidents.

- Legal and Compliance Aspects: Understand relevant health and safety legislation, permits, and reporting requirements for working at heights.

- Problem-Solving and Decision-Making under Pressure: Showcase your ability to think critically and make sound judgments in challenging or stressful situations involving heights.

- Communication and Teamwork: Highlight your ability to communicate effectively with colleagues and supervisors, especially in collaborative height-related tasks.

- Specific Climbing Techniques (if applicable): Depending on the role, you may need to demonstrate knowledge of specific climbing techniques (e.g., rope access, industrial climbing).

Next Steps

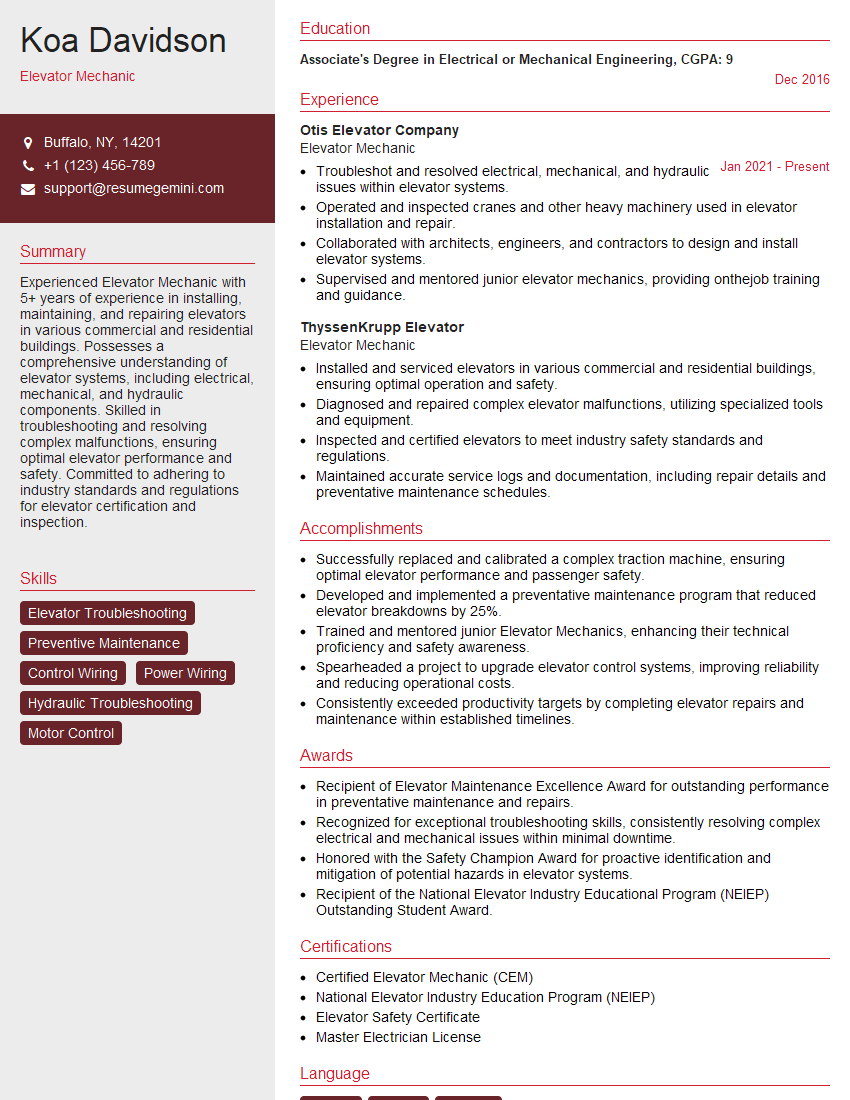

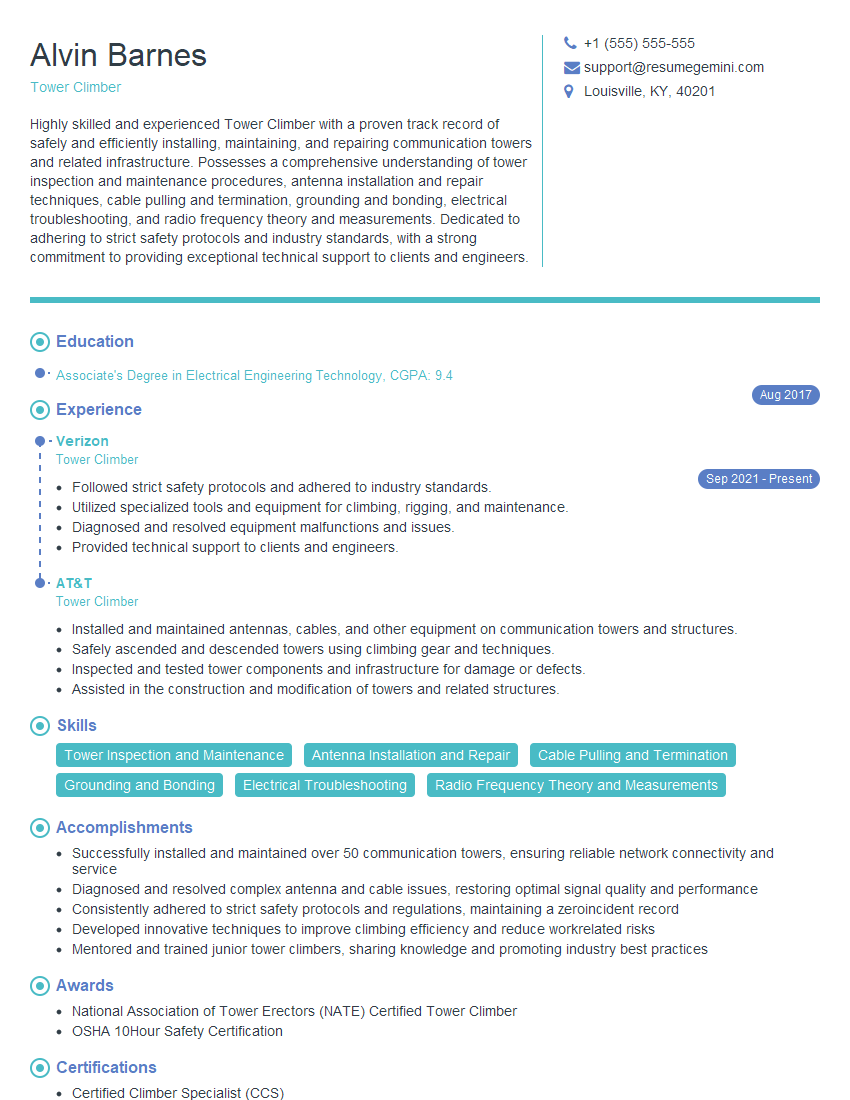

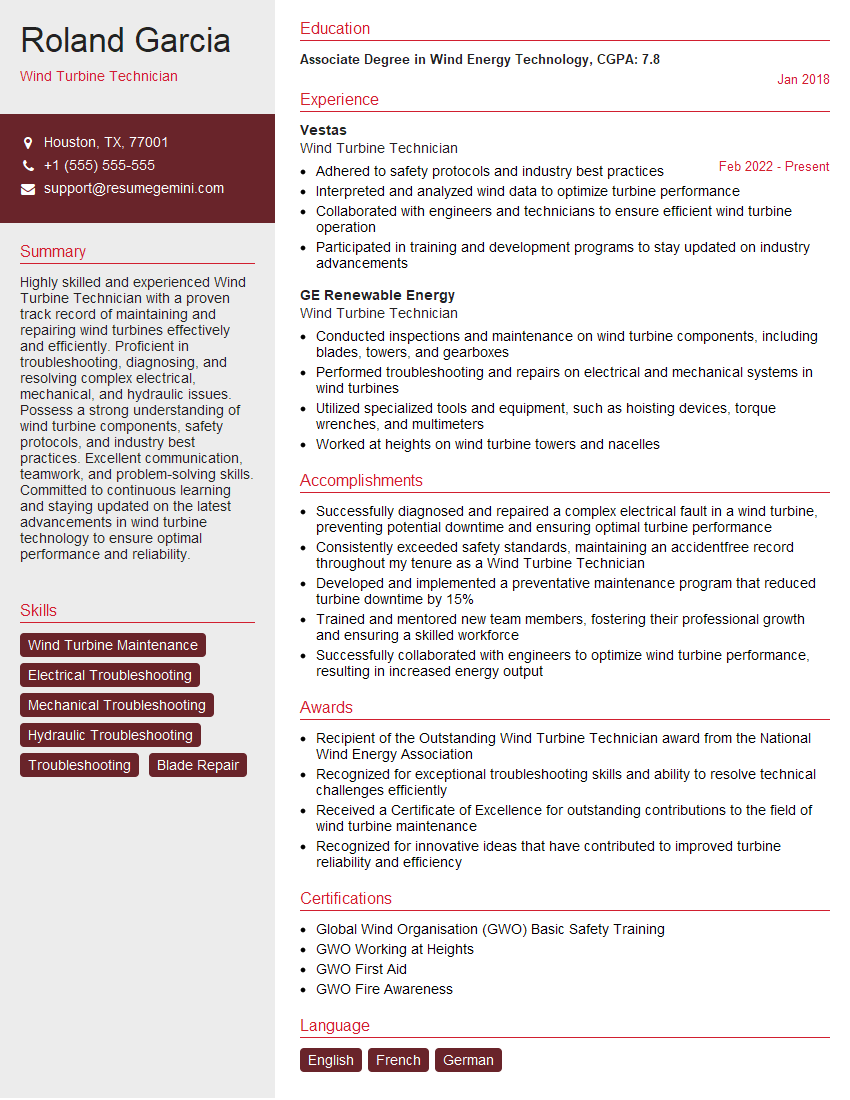

Mastering Height and Climbing Ability is vital for career advancement in many sectors, opening doors to specialized roles and higher earning potential. A strong resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to maximize your chances of getting noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your skills and experience. Examples of resumes tailored specifically for Height and Climbing Ability roles are available to help guide you. Invest time in crafting a compelling resume – it’s your first impression.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.