The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Hydraulic Equipment Repair interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Hydraulic Equipment Repair Interview

Q 1. Explain the principle of Pascal’s Law and its relevance to hydraulic systems.

Pascal’s Law is the foundation of hydraulic systems. It states that pressure applied to a confined fluid is transmitted equally and undiminished to all points in the fluid and to the walls of the container.

Think of it like squeezing a tube of toothpaste: the pressure you apply at one end is felt equally throughout the tube, causing the toothpaste to emerge from the opening. In hydraulics, this principle allows us to use a relatively small force to generate a much larger force. This is achieved by applying pressure to a smaller piston, which then transmits that pressure to a larger piston, resulting in amplified force at the larger piston.

This is crucial in hydraulic systems because it allows for the efficient transfer and multiplication of force, enabling the operation of heavy machinery such as excavators, cranes, and presses with relatively small power sources. The ratio of the areas of the pistons determines the mechanical advantage of the system.

Q 2. Describe the different types of hydraulic pumps and their applications.

Hydraulic pumps are the heart of any hydraulic system, responsible for moving hydraulic fluid. Several types exist, each suited to different applications:

- Gear Pumps: Simple and relatively inexpensive, these pumps use intermeshing gears to draw fluid in and force it out. They’re suitable for low-pressure, low-volume applications. Think of a small hydraulic lift or a power steering system.

- Vane Pumps: These use rotating vanes within a circular casing. They offer higher pressure and volume capabilities than gear pumps and are commonly used in mobile equipment like construction machinery.

- Piston Pumps: These are the workhorses of high-pressure hydraulics. They use reciprocating pistons to create pressure, offering the highest pressure and flow rates. You’ll find these in large industrial presses and heavy-duty machinery. There are radial and axial piston pump variations, each with its own performance characteristics.

- Axial Piston Pumps (Variable Displacement): These offer variable flow rates, allowing for precise control and energy efficiency. They’re ideal for applications requiring precise control of hydraulic actuators, like in sophisticated manufacturing processes.

The choice of pump depends heavily on the specific application’s pressure, flow rate, and cost requirements. A low-pressure application might only require a gear pump, while a high-pressure, high-flow application would necessitate a piston pump.

Q 3. What are the common causes of hydraulic system leaks, and how are they diagnosed?

Hydraulic leaks are a major concern, leading to system inefficiency, contamination, and potential safety hazards. Common causes include:

- Hose Failure: Wear and tear, abrasion, improper crimping, or internal degradation can lead to hose leaks. This is often visually apparent.

- Seal Failure: O-rings, seals, and gaskets wear out over time, due to age, chemical degradation, or incorrect installation. These leaks are often subtle and may require pressure testing to detect.

- Fitting Leaks: Loose or damaged fittings can lead to leaks at connection points. Inspecting threads and tightening connections is important.

- Damaged Components: Cracks or holes in cylinders, pumps, or valves can cause leaks. This often requires more significant repair or component replacement.

Diagnosing leaks involves systematic inspection: visually checking hoses and fittings, using pressure testing to pinpoint leaks, and checking fluid levels. A pressure gauge can help pinpoint the location of the leak, and sometimes dye is used to highlight leaks more easily.

Q 4. Explain the function of a hydraulic accumulator.

A hydraulic accumulator acts like a shock absorber and energy storage device in a hydraulic system. It stores pressurized hydraulic fluid, which can then be released to compensate for pressure fluctuations, reduce shock loads, and provide emergency power.

Imagine a water tower: it provides a reservoir of water under pressure. Similarly, the accumulator maintains a reserve of hydraulic fluid under pressure, available when needed. This is especially important in systems experiencing intermittent demands, such as in press applications or where pump cycling needs to be minimized.

Accumulators can smooth out pressure surges, absorb shock loads from impact forces, and serve as an emergency power source in case of pump failure. Different types of accumulators exist, including bladder, diaphragm, and piston accumulators, each with its own operating characteristics and advantages.

Q 5. How do you troubleshoot a hydraulic system with low pressure?

Low pressure in a hydraulic system can stem from several issues. Troubleshooting involves a systematic approach:

- Check the fluid level: Low fluid level is a simple, common cause of low pressure.

- Inspect the pump: Check for leaks, worn components, or insufficient drive power.

- Examine valves: A malfunctioning relief valve or restricted valves can restrict flow and pressure.

- Check for leaks: Leaks anywhere in the system will reduce pressure.

- Verify the filter condition: A clogged filter will severely restrict flow.

- Assess the accumulator (if present): A faulty accumulator might not be storing or releasing fluid properly.

- Inspect hydraulic lines: Kinks or blockages in lines can reduce pressure.

Using a pressure gauge at different points in the system can help pinpoint the location of the pressure drop. Working systematically through these steps allows for efficient fault finding. Always remember safety precautions when working with pressurized hydraulic systems.

Q 6. Describe the different types of hydraulic valves and their functions.

Hydraulic valves are control elements that regulate fluid flow, direction, and pressure. Several types are commonly used:

- Directional Control Valves: These valves control the direction of fluid flow. They can be two-way, three-way, or four-way, allowing for various control options.

- Pressure Control Valves: These regulate system pressure. Relief valves limit maximum pressure, while reducing valves maintain a specific pressure level.

- Flow Control Valves: These regulate the flow rate of hydraulic fluid. They can be used to control the speed of actuators or to maintain a constant flow.

- Check Valves: These allow fluid to flow in one direction only, preventing backflow. They are essential for preventing system back pressure.

These valves work together to orchestrate the complex movements of hydraulic machinery. For instance, in a hydraulic excavator, directional control valves direct fluid to different hydraulic cylinders to control the movement of the arm, bucket, and other components, while pressure and flow control valves manage the speed and force of these movements.

Q 7. How do you identify and repair a hydraulic hose leak?

Identifying and repairing a hydraulic hose leak begins with safety – ensure the system is depressurized before attempting any repairs. Once safe:

- Locate the leak: Visually inspect the hose for cracks, abrasions, or damage. Sometimes a leak may be subtle, requiring careful inspection.

- Determine the cause: Is it a simple abrasion? Is the hose crimped improperly? Knowing the root cause aids in selecting the right repair method.

- Repair or replace: For minor leaks and abrasions, a hydraulic hose repair kit with specialized clamps may suffice. However, for significant damage or old hoses, replacement is always the recommended approach.

- Proper crimping (if replacing): If replacing a hose, ensure proper crimping of the new fittings to prevent future leaks. Incorrect crimping is a major source of hydraulic hose failure.

- Post-repair check: After the repair or replacement, repressurize the system and check for any further leaks.

Always use hoses and fittings rated for the pressure and fluid type of the system. Improper repair can lead to catastrophic failure and potential injury. If you’re unsure about any repair, it’s always best to consult a qualified hydraulic technician.

Q 8. What safety precautions should be taken when working on hydraulic systems?

Working with hydraulic systems demands a high level of safety awareness. Hydraulic fluid is under immense pressure, and leaks can result in dangerous high-velocity jets. Failure to observe safety protocols can lead to serious injury or even death.

- Always lock out and tag out the power source before starting any work. This prevents accidental activation of the system.

- Use appropriate personal protective equipment (PPE), including safety glasses, gloves, and possibly hearing protection. High-pressure jets can cause eye injuries, and the fluid itself may be harmful to skin.

- Never attempt to repair a system while it’s under pressure. Always relieve the pressure before disconnecting any components.

- Be aware of potential pinch points in the system, and take steps to avoid getting your hands or fingers caught. Many hydraulic systems have moving components that can unexpectedly move under pressure.

- Work in a well-ventilated area. Some hydraulic fluids are toxic or flammable, and proper ventilation helps mitigate these risks.

- Follow all manufacturer’s instructions and consult relevant safety data sheets (SDS) for the hydraulic fluid being used.

For instance, I once saw a technician get a minor injury because he didn’t use safety glasses. A small amount of hydraulic fluid sprayed into his eye; although it wasn’t serious, it emphasized the importance of always wearing PPE. Never underestimate the power of hydraulic systems.

Q 9. Explain the importance of hydraulic fluid cleanliness.

Hydraulic fluid cleanliness is paramount to the reliable and long-term operation of a hydraulic system. Contaminants such as dirt, water, and metal particles act as abrasives, damaging precision components like pumps, valves, and cylinders. This leads to increased wear, reduced efficiency, and ultimately, premature failure. Think of it like this: imagine trying to run an engine with gritty sand in the oil—it wouldn’t last long!

- Contamination leads to increased wear and tear, necessitating more frequent and costly repairs.

- Reduced efficiency results from increased friction and restricted flow caused by contaminants.

- Premature component failure is a direct consequence of abrasive wear from particulate matter.

- System instability can occur due to contaminants affecting the fluid’s properties.

Maintaining fluid cleanliness involves using clean filters, regularly changing the fluid, and employing proper maintenance procedures to prevent contamination during servicing. Failing to do so can lead to catastrophic system failure resulting in costly downtime and potential safety hazards.

Q 10. How do you interpret a hydraulic system schematic?

Hydraulic schematics are visual representations of the system, using standardized symbols to show the flow path of hydraulic fluid, components, and their interconnections. Understanding these schematics is fundamental for diagnosing and troubleshooting problems.

Let’s break down how to interpret them:

- Identify the components: Look for symbols representing pumps, valves (directional control, pressure relief, check), actuators (cylinders), reservoirs, and filters.

- Follow the flow path: Trace the lines representing the hydraulic fluid’s path, noting the direction of flow indicated by arrows.

- Understand the control logic: Analyze how the valves control the flow of fluid to the actuators, based on the input signals.

- Note pressure and flow information: Schematics often include information about pressure ratings and flow rates at different points in the system.

For example, a typical schematic will show a pump pushing fluid to a directional control valve. This valve directs the flow either to one side of a hydraulic cylinder (extending it) or to the other (retracting it), based on a signal (e.g., from a joystick). Understanding these relationships is essential for effective troubleshooting.

Q 11. Describe the process of bleeding a hydraulic system.

Bleeding a hydraulic system involves removing trapped air from the lines and components. Air in the system can significantly impact performance and can cause erratic operation, noise and component damage. The method depends on the system’s design and complexity, but generally involves opening bleed screws at high points in the system while the pump operates to allow air to escape.

Here’s a general process:

- Identify bleed points: Locate the bleed screws or valves on the system. These are usually found at high points in the lines or on components such as actuators.

- Start the hydraulic pump: Ensure the pump is running at its normal operating speed.

- Open bleed screws one at a time: Slowly open each bleed screw, allowing air to escape. You may see bubbles in the fluid exiting the bleed screw.

- Close bleed screws: Once a steady stream of fluid free from bubbles is observed, close the bleed screw.

- Repeat for all bleed points: Repeat the process for all bleed points in the system.

- Check for leaks: After bleeding, inspect all connections for leaks.

- Verify system operation: After bleeding, test the system to ensure it operates correctly.

Bleeding is crucial for proper system function. Without it, the system might not operate at all, or it could experience erratic movement and damage. Always refer to the system’s specific instructions for the correct bleeding procedure.

Q 12. What are the common types of hydraulic seals, and how are they selected?

Hydraulic seals are critical components that prevent leakage of hydraulic fluid. The selection of the right seal is vital for system efficiency and longevity. Several types exist, each with its own strengths and weaknesses:

- O-rings: These simple, circular seals are widely used due to their cost-effectiveness and ease of installation. They are suitable for static and low-pressure dynamic applications but can extrude under high pressure.

- U-cups (cup seals): These seals offer superior sealing performance than O-rings, particularly in dynamic applications. They are resilient and can handle higher pressures.

- V-rings: These seals offer a compact design and are suitable for reciprocating motions in high-pressure applications.

- Lip seals (radial shaft seals): These seals are designed to prevent leakage along rotating shafts, commonly found in hydraulic pumps and motors. They are effective for high-speed and high-pressure applications.

- Hydraulic piston seals: These are complex seal designs used to seal the piston in a hydraulic cylinder, often combining multiple seal elements. They can handle high pressure and significant side loads.

Seal selection depends on several factors, including:

- System pressure: Higher pressures demand more robust seals.

- Fluid type: The compatibility of the seal material with the hydraulic fluid is crucial.

- Operating temperature: Temperature extremes can affect seal performance.

- Speed of motion: High-speed applications require seals designed to withstand dynamic forces.

Choosing the wrong seal can lead to leakage, reduced efficiency, and premature system failure. Always consult seal selection guides and manufacturer specifications to ensure compatibility and performance.

Q 13. How do you diagnose and repair a faulty hydraulic cylinder?

Diagnosing a faulty hydraulic cylinder often involves visual inspection, pressure testing, and sometimes disassembly. The process is as follows:

- Visual inspection: Examine the cylinder for external damage, such as dents, scratches, or leaks. Check the rod for scoring or bending.

- Pressure testing: Connect a pressure gauge to the cylinder ports to check for pressure loss or leaks. This helps identify the source of the problem (seal failure, rod damage etc.)

- Disassembly (if necessary): If pressure testing reveals internal problems, the cylinder needs to be disassembled to inspect and replace seals, piston, or other internal components. This usually involves removing the end caps, extracting the piston and rod assembly, and inspecting all parts for wear or damage.

- Component replacement: Worn or damaged seals, piston rings, or other internal parts should be replaced with new parts.

- Reassembly and testing: After replacing the necessary components, reassemble the cylinder and test the system to ensure it functions correctly.

For example, a cylinder might exhibit slow extension or retraction. Visual inspection might reveal a leak around the piston rod, indicating a damaged rod seal that should be replaced. Another example could be a cylinder that is completely inoperative. This may require a more thorough investigation and likely disassembly to locate the source of the problem. Thorough analysis is key; sometimes replacing seemingly unrelated components, such as the rod wiper, can solve the problem.

Q 14. What are the common causes of hydraulic pump failure?

Hydraulic pump failure can stem from several causes, and understanding these causes is crucial for preventative maintenance and effective troubleshooting.

- Fluid contamination: Contaminants in the hydraulic fluid act as abrasives, causing wear on the pump’s internal components. This leads to reduced efficiency and premature failure.

- Lack of lubrication: Insufficient lubrication leads to increased friction and wear, ultimately damaging the pump’s bearings and other moving parts.

- Overheating: Excessive heat can damage the pump’s seals and internal components. Overheating is often a symptom of another problem, such as insufficient fluid or restricted flow.

- Cavitation: This occurs when the pump attempts to draw fluid from a low-pressure area, causing the formation of vapor bubbles that implode and damage internal components.

- Improper installation: Incorrect mounting, alignment, or piping can place excessive stress on the pump and lead to premature failure.

- Wear and tear: With age and use, components naturally wear down and eventually require replacement. Regular maintenance can help extend their lifespan.

For instance, I once encountered a pump failure due to cavitation. The suction line was poorly designed, leading to insufficient fluid flow to the pump. Understanding the causes of pump failure is crucial, as they often are interconnected. A thorough investigation is necessary to diagnose the root cause.

Q 15. Explain the difference between open-center and closed-center hydraulic systems.

The core difference between open-center and closed-center hydraulic systems lies in how the hydraulic fluid is managed when actuators (like hydraulic cylinders or motors) are not actively working. Think of it like a water system: open-center is like having a constantly running faucet, while closed-center is more like a precisely controlled valve system.

- Open-center systems: Fluid flows continuously from the pump through a relief valve back to the reservoir when actuators are not engaged. This means the pump is always running, even when there’s no work being done. This is simpler and less expensive but less efficient. Imagine a large irrigation system where the pump is always on, even if only a few sprinklers are in use.

- Closed-center systems: The pump delivers fluid to a control valve. This valve manages the flow, directing it to the actuator only when needed, blocking it back to the reservoir the rest of the time. This is more efficient, leading to less heat generation and lower energy consumption. This is like a sophisticated water management system in a building where the pump only runs when needed to pressurize parts of the system requiring water.

The choice between open and closed-center depends on factors like the application’s complexity, cost, efficiency needs, and required pressure levels. A simple, low-pressure application might use an open-center system, while a complex machine demanding precise control and high efficiency would likely employ a closed-center system.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with hydraulic system testing equipment.

My experience with hydraulic system testing equipment spans a wide range, from basic pressure gauges and flow meters to sophisticated data acquisition systems. I’m proficient in using equipment to measure:

- Pressure: Using various pressure gauges, from simple mechanical indicators to digital transducers, to ensure the system operates within its specified pressure range. I’ve used these to diagnose leaks, pump issues, and valve malfunctions.

- Flow rate: Employing flow meters to assess the volume of fluid moving through the system. Low flow rates can point to blockages or pump problems, while excessive flow may suggest a leak.

- Temperature: Using temperature sensors and thermometers to monitor the hydraulic fluid’s temperature. This is crucial for detecting overheating, which can cause serious damage.

- Particle contamination: I’m experienced in using particle counters and cleanliness analysis equipment to assess the level of contamination in the hydraulic fluid. This helps prevent premature wear and failure of system components.

I also have experience with hydraulic test benches that allow for simulating various operational conditions to diagnose complex issues. These help with the testing of individual components without having to disrupt the operation of a full-scale machine. For example, I have used a test bench to diagnose a problem where the main pump on a large excavator was struggling to achieve required flow rates. Testing it on the bench confirmed a damaged impeller rather than a problem within the system.

Q 17. How do you determine the appropriate hydraulic fluid for a specific system?

Selecting the right hydraulic fluid is critical for optimal system performance and longevity. It’s not a one-size-fits-all approach. The correct fluid depends on several factors:

- Operating temperature: The fluid must withstand the temperature extremes the system will encounter. Extreme temperatures can significantly affect viscosity and performance.

- System pressure: Higher pressures require fluids with higher viscosity indices to prevent cavitation (formation of bubbles in the fluid, which can damage components).

- Component materials: Compatibility between the fluid and the seals, hoses, and other system components is crucial. Incompatible fluids can cause seal swelling, degradation, or leaks.

- Application type: Some applications may require specialized fluids that provide specific performance characteristics, such as fire resistance or enhanced lubricity.

I always consult the system’s manufacturer’s specifications to determine the recommended fluid type, viscosity grade, and any specific requirements. I’ve seen systems damaged irreparably by using the wrong hydraulic fluid. For instance, a system using a low viscosity fluid at high pressure could experience cavitation, leading to premature component failure.

Q 18. What are the common causes of hydraulic motor failure?

Hydraulic motor failures are often caused by a combination of factors. Common causes include:

- Contamination: Particles in the hydraulic fluid are a leading cause of motor wear and failure. These particles can abrade internal components, leading to reduced efficiency and eventual failure.

- Overheating: Excessive heat can degrade the motor’s seals, bearings, and other internal components. This can be due to excessive load, insufficient cooling, or other problems.

- Lack of lubrication: Insufficient lubrication can cause friction and wear, leading to premature motor failure.

- Improper installation: Incorrect installation can put extra stress on the motor components, leading to premature failures.

- Excessive load: Exceeding the motor’s rated capacity can cause overload and burnout.

Diagnosing a failed hydraulic motor often requires a careful examination of the motor itself, as well as an analysis of the hydraulic system’s overall condition to find the root cause. I’ve often encountered cases where a seemingly failed motor was actually a symptom of a larger systemic issue, such as a clogged filter, a problem with the pump, or contamination.

Q 19. How do you troubleshoot a hydraulic system with overheating issues?

Troubleshooting a hydraulic system with overheating problems requires a systematic approach. The first step is to identify the source of the heat. Possible causes include:

- High operating pressure: Excessive pressure generates heat through friction within the system. This could be due to restrictions in the system.

- Insufficient cooling: Inadequate cooling capacity might not be enough to dissipate the heat generated by the system. This can result from a faulty cooling fan or radiator, or insufficient cooling fluid.

- Fluid viscosity: Using a fluid with too high a viscosity will increase friction and heat generation.

- Leakage: Internal leaks can cause excessive churning and heat generation. This increases the workload of the pump, leading to overheating.

- Contamination: Contaminated fluid can increase friction and heat due to the presence of particles that hinder proper fluid flow.

My troubleshooting approach involves systematically checking each of these areas. I might use thermal imaging to pinpoint areas of excessive heat, check pressure and flow rates, and analyze the hydraulic fluid for contamination. Once the source of the overheating is identified, appropriate corrective actions can be taken, which might include replacing damaged components, improving cooling, or changing the hydraulic fluid.

Q 20. Explain the process of replacing a hydraulic filter.

Replacing a hydraulic filter is a crucial maintenance task to prevent contamination and maintain system health. Here’s the process:

- Safety first: Ensure the system is depressurized and isolated to prevent injury from high-pressure fluid. This involves opening relief valves and disconnecting the system power sources.

- Locate the filter: Identify the filter to be replaced. Often, these are clearly marked.

- Prepare for replacement: Gather necessary tools including filter wrenches (if required), a container to catch the old filter’s contents, fresh hydraulic fluid, and clean rags.

- Remove the old filter: Carefully remove the old filter, letting the fluid drain into the prepared container. Avoid spilling fluid, and take note of the filter’s orientation.

- Clean the area: Thoroughly clean the filter housing and surrounding area to prevent contamination of the new filter.

- Install the new filter: Install the new filter, ensuring it’s correctly oriented (sometimes there are arrows indicating flow direction).

- Tighten the filter: Tighten the filter to the manufacturer’s specified torque. Over-tightening can damage the filter housing.

- Re-pressurize the system: Carefully re-pressurize the system and check for leaks.

- Inspect the old filter: Inspect the old filter for signs of damage or contamination which may indicate a problem elsewhere in the system.

Using the correct filter is essential, and it’s vital to record the filter replacement date and type, to help with future maintenance planning. Skipping this simple maintenance step can lead to catastrophic system failures due to contamination.

Q 21. Describe your experience with different types of hydraulic power units.

My experience encompasses various types of hydraulic power units (HPUs), each with its strengths and weaknesses:

- Electrically driven HPUs: These are commonly used for their compact size, ease of control, and energy efficiency in many applications. They are often preferred in industrial settings requiring precise control and low noise levels.

- Engine-driven HPUs: Often found in mobile equipment like construction machinery or agricultural equipment, where high power output is required in remote locations. They offer high power-to-weight ratios but can be noisy and less efficient than electric options.

- Pneumatically driven HPUs: Used in certain specialized applications, where compressed air is readily available. They’re generally less efficient than hydraulic systems but can be beneficial in explosive environments.

- Variable displacement HPUs: These provide adjustable flow and pressure, enabling efficient control of hydraulic actuators. This offers better precision and energy efficiency than fixed displacement units.

Each type presents different maintenance requirements and potential points of failure. For example, engine-driven HPUs require regular maintenance of the engine and its components, while electrically driven HPUs may need more frequent attention to motor windings and control electronics. I have worked with all these types of HPUs in various applications, from industrial manufacturing systems to mobile heavy equipment, and I understand the nuances of their operation and maintenance.

Q 22. How do you maintain hydraulic system components to prevent failures?

Preventing hydraulic system failures relies heavily on proactive maintenance. Think of it like regularly servicing your car – neglecting it leads to bigger problems down the line. A robust maintenance program focuses on several key areas:

- Regular Fluid Analysis: This is crucial. We analyze the hydraulic fluid for contaminants, such as water, wear particles, and oxidation products. This gives early warning signs of potential issues like leaks, pump wear, or filter degradation. For instance, a sudden increase in water content suggests a leak somewhere in the system.

- Filter Replacement: Hydraulic filters are the system’s first line of defense against contaminants. Following the manufacturer’s recommended replacement schedule is vital. Delaying this can clog filters, leading to restricted flow and increased pressure, potentially damaging components.

- Component Inspections: Regular visual inspections of hoses, fittings, seals, and actuators are necessary to identify any signs of wear, damage, or leaks. Look for cracks, bulges, or weeping fluid. I often use a borescope to inspect hard-to-reach areas.

- Pressure and Temperature Monitoring: Monitoring pressure and temperature gauges during operation allows for detection of anomalies. Consistent high pressure could indicate a blockage, while unusually high temperatures might signify pump or valve problems.

- Leak Detection: Regular leak checks are critical. Even a small leak can lead to significant fluid loss and system degradation over time. Using leak detection dye can be incredibly helpful in pinpointing leaks.

By implementing these preventative maintenance measures, we significantly reduce the risk of catastrophic failures and extend the lifespan of the hydraulic system. I’ve seen systems that were meticulously maintained run for decades without major issues, while poorly maintained systems often require costly repairs or complete overhauls.

Q 23. What are the common types of hydraulic actuators, and how do they work?

Hydraulic actuators are the ‘muscles’ of a hydraulic system, converting hydraulic energy into mechanical motion. There are several common types:

- Hydraulic Cylinders: These are the most common type. They are linear actuators, meaning they provide a pushing or pulling force in a straight line. They work by pressurizing hydraulic fluid into a cylinder, forcing a piston to move. Think of a car’s lift at a service station – that’s a hydraulic cylinder in action.

- Hydraulic Motors: These actuators produce rotary motion. They are similar to internal combustion engines, but instead of burning fuel, they use pressurized hydraulic fluid to turn a shaft. Hydraulic motors are often used in applications requiring continuous rotation, like in a rotating platform or conveyor belt.

- Rotary Actuators: These actuators combine features of both cylinders and motors. They provide controlled rotary motion and can generate significant torque. They find use in applications needing precise angular positioning.

All hydraulic actuators function by utilizing pressurized fluid to create mechanical force. The fluid’s pressure determines the force exerted, while the displacement of the fluid determines the distance or angle of movement. Different types are chosen based on the specific application requirements, like speed, force, and type of movement needed.

Q 24. Describe your experience with hydraulic system troubleshooting software.

My experience with hydraulic system troubleshooting software is extensive. I’m proficient with several industry-standard packages, including [mention specific software names, e.g., FluidSIM, etc.]. These software packages allow me to simulate hydraulic circuits, analyze pressure drops, diagnose flow issues, and even predict potential points of failure. They’re essentially digital versions of the real hydraulic system. For example, I’ve used this software to diagnose a complex problem on a large industrial press. The software allowed me to isolate the faulty directional control valve by simulating different scenarios and observing the pressure and flow changes within the simulated system. This reduced downtime considerably, as it allowed me to focus my attention on the precise failing component.

The ability to visualize the system’s behavior under various conditions is invaluable for troubleshooting. It’s like having a virtual test bench where you can safely experiment without damaging the actual equipment. Furthermore, these tools often integrate with data acquisition systems, allowing me to use real-time data from the hydraulic system to further refine my diagnosis.

Q 25. Explain the function of a hydraulic relief valve.

A hydraulic relief valve is a safety device that protects the hydraulic system from overpressure. Imagine it as a pressure-relief valve in a pressure cooker—it prevents dangerous build-up. It functions by diverting excess hydraulic fluid back to the reservoir when the system pressure exceeds a preset value. This prevents damage to components that might fail under high pressure. The valve opens when pressure exceeds its setpoint and allows the fluid to bypass the actuator and return to the reservoir. This limits the maximum pressure within the system, preventing potential damage from surges or blockages. Without it, even a small blockage could cause a catastrophic pressure spike, rupturing hoses or damaging the pump.

Q 26. How do you diagnose and repair a hydraulic directional control valve?

Diagnosing and repairing a hydraulic directional control valve (DCV) requires a systematic approach. I would begin by:

- Identifying the Symptoms: Is the actuator not moving? Is it moving erratically? Is there a leak? The symptoms provide valuable clues about the source of the problem.

- Inspecting the Valve: I’d visually inspect the valve for any signs of damage, leaks, or loose connections. I also use specialized tools to check for internal wear or contamination.

- Testing Valve Operation: Using a pressure gauge, I’d measure the pressure at various points of the valve to check for pressure drops or restrictions. This often helps to pinpoint which part of the valve is malfunctioning. I may also use a flow meter to detect flow restrictions or leaks.

- Disassembling and Cleaning (if necessary): If inspection reveals contamination or internal damage, the valve may need disassembly and cleaning. This often involves removing spools, seals, and other internal parts for thorough inspection and cleaning or replacement. This step requires a high degree of precision and cleanliness.

- Reassembly and Testing: After cleaning or replacing components, the valve is carefully reassembled and thoroughly tested to ensure proper function. I’d retest its operation to confirm everything is working correctly.

If the problem persists, advanced diagnostics like using a hydraulic test bench may be required to further investigate. Each step requires careful attention to detail and knowledge of the valve’s internal workings.

Q 27. Describe your experience with hydraulic system commissioning and start-up.

Hydraulic system commissioning and start-up are critical phases, requiring meticulous attention to detail. My experience involves overseeing the entire process, from initial inspection and pre-commissioning checks to final system testing and handover. I typically follow these steps:

- Pre-Commissioning Checks: This involves verifying that all components are installed correctly and that the hydraulic system is properly plumbed. I check for leaks, loose connections, and incorrect wiring.

- Fluid Filling and Purging: The system is filled with the correct type and quantity of hydraulic fluid, then thoroughly purged of air. Air in the system can severely affect performance and cause damage.

- Functional Testing: The system is tested under various operating conditions to verify that it meets the design specifications. I would carefully check the pressure, flow, and movement of all actuators.

- Performance Monitoring and Fine-tuning: Any minor adjustments needed to optimize the system’s performance are made. This could involve adjusting pressure relief valves or fine-tuning the control system.

- Safety Checks and Documentation: Thorough safety checks are conducted to confirm the system’s safe operation. All findings and procedures are documented meticulously.

I’ve been involved in commissioning everything from small agricultural machinery to large industrial presses, always adhering to safety standards and best practices. A successful commissioning ensures the system operates efficiently, safely and reliably for years to come.

Q 28. How do you handle emergency situations involving hydraulic system failures?

Emergency situations involving hydraulic system failures require a calm and methodical response. The priority is always safety. My approach involves:

- Assessing the Situation: First, I quickly assess the situation to determine the nature and severity of the failure. Is there a leak? Is the equipment damaged? Are there any safety risks?

- Securing the Area: I ensure the immediate area is safe and secure, preventing access to anyone who isn’t authorized or trained to handle the situation.

- Shut Down the System: If safe to do so, I shut down the hydraulic system to prevent further damage or injury. The specific method of shutdown varies depending on the system.

- Initiate Emergency Procedures: I follow established emergency procedures, which may include contacting emergency services, notifying relevant personnel, and implementing emergency shut-off procedures.

- Damage Assessment and Repair: Once the situation is under control, I proceed with damage assessment and initiate necessary repairs. This might involve temporary repairs to restore limited functionality or complete system overhauls. The priority is to address safety concerns first, then move to restoration of functionality.

I’ve had to handle various emergency situations, including burst hoses and sudden equipment failures. Swift and decisive action, combined with a thorough understanding of the system and its safety mechanisms, is key in minimizing damage and ensuring everyone’s safety.

Key Topics to Learn for Hydraulic Equipment Repair Interview

- Hydraulic Systems Fundamentals: Understanding Pascal’s Law, hydraulic pressure, flow rate, and their interrelationships. Practical application: Diagnosing pressure drops in a system.

- Hydraulic Components: Detailed knowledge of pumps (gear, vane, piston), valves (directional control, pressure control, flow control), actuators (cylinders, motors), and filters. Practical application: Troubleshooting malfunctioning components based on observed symptoms.

- Hydraulic Fluids: Properties of hydraulic fluids, their selection criteria, and the impact of contamination. Practical application: Identifying and addressing fluid leaks and contamination issues.

- Hydraulic System Diagnostics: Mastering troubleshooting techniques, using diagnostic tools (pressure gauges, flow meters), and interpreting schematics. Practical application: Effectively identifying the root cause of hydraulic system failures.

- Hydraulic System Maintenance: Preventive maintenance procedures, including filter changes, fluid level checks, and component inspections. Practical application: Developing and implementing a preventative maintenance schedule.

- Safety Procedures: Understanding and adhering to safety protocols related to high-pressure systems, hazardous fluids, and potential hazards. Practical application: Demonstrating safe practices during repair and maintenance.

- Electrical Systems Integration: Understanding the interaction between hydraulic and electrical systems, including control circuits and sensors. Practical application: Troubleshooting issues involving both electrical and hydraulic components.

- Common Hydraulic System Problems: Experience with identifying and resolving common issues such as leaks, malfunctions, and performance degradation. Practical application: Quickly assessing and fixing problems in various hydraulic equipment.

Next Steps

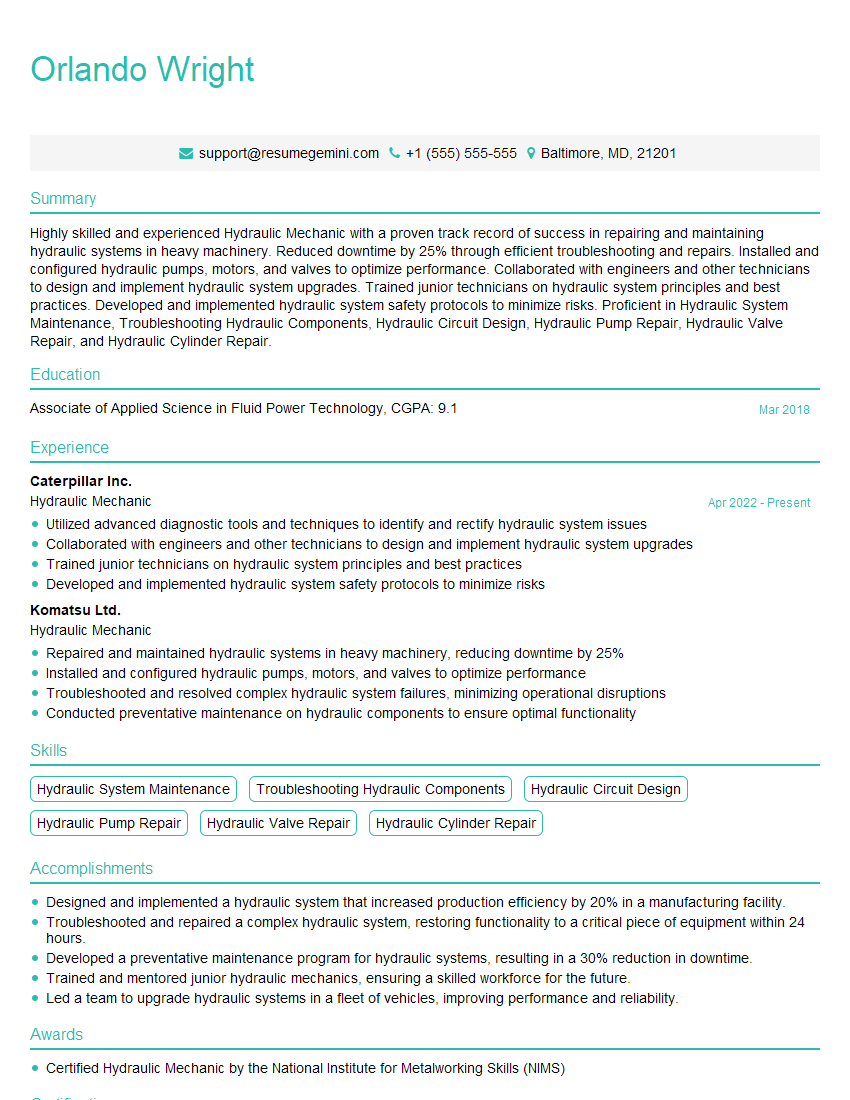

Mastering Hydraulic Equipment Repair opens doors to a rewarding and in-demand career with excellent growth potential. Advancement opportunities abound for skilled technicians, offering higher pay and increased responsibility. To maximize your job prospects, a well-crafted, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume, highlighting your skills and experience in the best possible light. Examples of resumes tailored specifically to Hydraulic Equipment Repair are available to help guide you. Invest the time to create a compelling resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.