Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Installing glass shower enclosures interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Installing glass shower enclosures Interview

Q 1. Describe your experience installing various types of glass shower enclosures (frameless, framed, etc.)

My experience spans a wide range of glass shower enclosure installations, encompassing frameless, framed, neo-angled, and curved designs. Frameless enclosures, known for their sleek aesthetic, demand precision in measurement and installation to ensure stability and watertight seals. Framed enclosures, offering more structural support, often involve working with metal frames and hinges, requiring careful alignment and adjustment. Neo-angled and curved enclosures present unique challenges, necessitating specialized cutting techniques and careful consideration of the glass’s structural integrity. I’ve worked with various glass types, including tempered safety glass (essential for shower enclosures), and have experience with different hardware systems, including pivot hinges, sliding doors, and bypass systems. Each type demands a nuanced approach, and I adapt my techniques based on the specific design and materials.

For example, installing a frameless enclosure for a walk-in shower requires meticulous attention to detail in ensuring the glass panels are perfectly plumb and level, preventing water leakage. Conversely, a framed enclosure might necessitate more attention to the alignment and adjustment of the metal framework before glass installation to maintain its structural integrity.

Q 2. What safety precautions do you take when installing glass shower enclosures?

Safety is paramount in glass shower enclosure installation. I always wear safety glasses, gloves, and sturdy closed-toe shoes. Handling glass requires extreme caution to avoid cuts or breakage. I use appropriate lifting techniques and tools to prevent injuries. Before starting any work, I thoroughly inspect the area for potential hazards, such as electrical wiring or plumbing. I also secure the area to prevent accidental entry during the installation process. When cutting glass, I employ a professional glass cutter and wear a face shield to protect myself from flying debris. Finally, I ensure the finished enclosure meets all safety standards, including using tempered glass which is designed to shatter into relatively small, less harmful pieces, in the event of breakage.

Q 3. How do you measure and cut glass for a shower enclosure?

Accurate measurement is crucial for a perfect fit. I use a measuring tape, level, and square to obtain precise dimensions of the shower area. I account for the thickness of the glass, the desired overlap, and the type of hardware being used. Cutting glass requires specialized tools and skills. I use a professional glass cutter to score the glass precisely along the measured lines, followed by a snapping action to separate the cut section. A smooth, clean cut prevents chipping and ensures a professional finish. For complex shapes, a wet saw is typically used. Safety is a top priority during this process. Improper cutting can lead to injuries or damage to the glass, making safety glasses, gloves and a face shield essential.

Q 4. Explain the process of installing shower door hardware.

Installing shower door hardware involves precision and attention to detail. This typically involves hinges, handles, and possibly rollers for sliding doors. I begin by carefully positioning and securing the hinges to the glass panels and the wall or frame. Precise alignment is vital to ensure smooth operation and prevent binding. Handles are attached securely, ensuring they are properly aligned and functioning correctly. Sliding door hardware requires careful adjustment of the rollers to guarantee smooth and effortless sliding. Correctly fitting and adjusting all hardware elements is key to prevent the doors from binding or becoming loose over time. I always follow the manufacturer’s instructions for each specific piece of hardware to ensure correct installation and longevity.

Q 5. How do you ensure a watertight seal in a glass shower enclosure?

A watertight seal is critical to prevent leaks and water damage. I achieve this through a combination of techniques. First, ensure that the glass panels are perfectly fitted and aligned, leaving no gaps. Next, I use high-quality silicone sealant to create a waterproof barrier between the glass, the frame (if applicable), and the surrounding walls. I apply a generous bead of sealant, ensuring complete coverage of all joints. Careful attention is paid to the corners and edges where leaks are most likely to occur. Proper surface preparation is also crucial. The surfaces must be clean and dry for the sealant to adhere effectively. A smooth, even bead of sealant applied correctly will ensure a strong bond and prevent leaks. I usually inspect the sealant to make sure there are no gaps, and often run a wet cloth or sponge along the edges to make sure there is no water penetration.

Q 6. What types of sealants are appropriate for glass shower enclosures?

The type of sealant used is crucial for long-term performance. I typically use a high-quality, mildew-resistant silicone sealant specifically designed for wet environments. This type of sealant provides excellent adhesion to glass and other common shower materials and is resistant to mold and mildew growth. Choosing the right sealant ensures a durable, watertight seal that can withstand the constant moisture in a shower environment. I avoid using caulks, as they generally don’t last as long or provide the same degree of water resistance in this demanding setting.

Q 7. What are the common problems encountered during glass shower enclosure installation?

Common problems include inaccurate measurements leading to ill-fitting panels, improper sealing resulting in leaks, and difficulties with hardware alignment and adjustment causing operational issues. Incorrect glass cutting can result in chips or cracks. Improper leveling of the enclosure can affect the functionality and aesthetic appeal, especially in frameless installations. Occasionally, there can also be challenges with matching existing tiling or ensuring consistent grout lines. Careful planning, precise measurements, and skilled execution are essential to prevent these common problems. If challenges arise, I rely on my experience and knowledge to find creative solutions. For instance, a slight misalignment of a panel can sometimes be corrected with careful adjustment of the sealant or hardware. However, sometimes more drastic steps like replacing a panel may be necessary.

Q 8. How do you handle damaged or cracked glass during installation?

Damaged or cracked glass is unacceptable for installation. Safety is paramount. Upon delivery, I meticulously inspect every panel. If damage is detected, I immediately document it with photos and contact the supplier or the client. We discuss replacement options – either a new panel from the supplier or, if time is critical, exploring alternatives if feasible given the design. I never compromise on safety; a cracked panel is a potential hazard. Replacing a damaged piece early prevents costly delays and potential injuries later on. For minor chips not compromising structural integrity, and with client consent, I might use a specialized glass repair kit as a last resort, but only after thoroughly assessing the damage and ensuring it meets safety standards.

Q 9. Describe your experience working with different types of glass (tempered, laminated, etc.)

I have extensive experience with various glass types. Tempered glass is the industry standard for shower enclosures due to its superior strength and safety features. If broken, it shatters into small, relatively harmless pieces. Laminated glass, composed of multiple layers bonded together, offers even greater impact resistance and is especially useful in areas prone to higher impact risks. I’ve worked with patterned glass, adding aesthetic appeal, and low-iron glass for increased clarity and light transmission. Choosing the right glass is crucial; it affects not only the enclosure’s appearance but also its safety and longevity. I guide clients in selecting the best type based on their budget, style preferences, and the specific requirements of their bathroom environment. For instance, a family with young children might opt for laminated glass for added safety.

Q 10. How do you ensure the proper leveling and plumbness of a shower enclosure?

Precise leveling and plumbness are essential for a properly functioning and aesthetically pleasing shower enclosure. I use a combination of techniques. First, I ensure the walls are plumb and level using a level and plumb bob. Any discrepancies are addressed by shimming or adjusting the framing. Then, during installation, I utilize laser levels to ensure accurate positioning of the glass panels. Small adjustments are made using adjustable shims placed at the base of the enclosure to compensate for minor imperfections in the wall. Regularly checking with a level during each stage, especially when attaching the panels and the door hardware, guarantees a perfectly aligned and functional unit. A misaligned shower door, for example, can lead to difficulty opening and closing and even damage over time.

Q 11. What tools and equipment are essential for installing glass shower enclosures?

The right tools are crucial for a successful installation. My toolkit includes: a measuring tape, level (both standard and laser), plumb bob, shims (various thicknesses), drills (with appropriate bits for the chosen glass and hardware), screwdrivers, putty knives, caulk gun, safety glasses and gloves, a wet/dry vacuum, glass suction cups, and specialized glass cutting tools (if modifications are needed, which are uncommon with pre-fabricated units). Having the proper tools ensures a clean, efficient, and safe installation.

Q 12. Explain your understanding of building codes and regulations related to shower installation.

Understanding building codes is vital. I familiarize myself with local codes regarding shower construction, including requirements for water resistance, ventilation, and safety glass specifications. These codes dictate things like the minimum thickness of the glass (usually 1/4” or 6mm tempered glass), the type of sealing required, and the placement of ventilation to prevent mold and mildew. I always obtain the necessary permits and comply with all regulations to ensure the installation meets the highest standards and avoids any legal issues or safety concerns. For example, some jurisdictions require specific types of seals around the shower base to prevent water leakage.

Q 13. How do you manage customer expectations during the installation process?

Managing expectations is key. Before starting, I thoroughly discuss the project timeline, any potential challenges, and the final look with the client. I provide realistic estimates and keep them informed of progress throughout the installation. Open communication, including prompt responses to questions and addressing concerns promptly, builds trust and ensures a positive experience. For instance, if unforeseen issues arise, like wall irregularities, I discuss the options and their impact on the timeline and cost with the client before proceeding. Transparency is crucial to avoid misunderstandings and ensure client satisfaction.

Q 14. Describe your troubleshooting skills related to glass shower enclosure installation.

Troubleshooting is a regular part of the job. Common problems include doors that don’t seal properly, leaking seals, or misaligned panels. For leaking seals, I examine the sealant and reseal if necessary, making sure the surface is clean and dry before application. For misaligned panels or doors, I may need to adjust shims or hardware. If the problem is more complex, I systematically check each component, starting from the wall preparation and moving through to the installation of each glass panel and hardware. I always use a methodical approach, taking measurements and visually inspecting each step to identify the source of the problem. If necessary, I consult technical documentation and manufacturer specifications. I approach each issue with a systematic, problem-solving approach, prioritizing safety and ensuring a functional and aesthetically pleasing result.

Q 15. How do you handle unexpected issues or challenges during an installation?

Unexpected issues are part and parcel of any installation job, especially with glass shower enclosures. My approach is methodical and proactive. First, I always conduct a thorough pre-installation assessment, meticulously measuring and inspecting the site for potential problems like uneven walls or plumbing inconsistencies. This helps prevent many surprises.

However, if a problem arises—say, a wall being more out of plumb than anticipated—I calmly assess the situation. I’ll carefully measure the deviation and determine the best solution. This might involve shimming the frame, using specialized sealant to compensate for minor imperfections, or, in rare cases, discussing alternative solutions with the client. Communication is key; I keep the client informed every step of the way, explaining the issue, the proposed solution, and its potential impact on the timeline or budget.

For example, I once encountered a situation where the existing plumbing interfered with the ideal placement of the shower door. Instead of forcing a solution that compromised safety or aesthetics, I collaborated with the client to slightly adjust the shower’s position, ensuring a perfect fit and a safe, functional result.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with installing custom-sized shower enclosures?

I have extensive experience with custom-sized shower enclosures. It’s a significant part of my work, offering clients the opportunity to personalize their bathroom. The process starts with precise measurements, often involving multiple visits to ensure accuracy. I use high-precision laser measuring tools to account for even minor inconsistencies. Detailed sketches and templates are created, and I work closely with glass suppliers to ensure the glass is cut to the exact specifications.

The installation itself requires meticulous attention to detail. Each fitting needs to be perfectly aligned, ensuring a watertight seal. This involves careful adjustment and often the use of custom-fabricated components. I’ve successfully installed enclosures with intricate designs, curved glass, and unique hardware configurations, showcasing adaptability and precision in my work.

Imagine a recent project where a client wanted a shower enclosure that perfectly matched the unique curves of their bathroom wall. By accurately templating the wall and collaborating closely with the glass fabricator, we created a stunning, bespoke enclosure that flawlessly integrated into the space.

Q 17. How do you ensure the structural integrity of a glass shower enclosure?

Structural integrity is paramount in glass shower enclosure installations. It’s not just about aesthetics; it’s about safety. I achieve this through several key steps. First, I meticulously inspect the wall structure to ensure it can adequately support the weight of the enclosure. This includes checking for stud placement and wall integrity. I then use appropriate anchoring methods, selecting fasteners that are suitable for the wall material (e.g., drywall anchors for drywall, masonry anchors for brick). The type and placement of these anchors are critical to distribute weight evenly.

Next, I ensure the shower enclosure frame is correctly installed and securely fastened to the wall. The frame itself serves as a critical support structure. Finally, I use high-quality silicone sealant at all joints and connections to guarantee a watertight and structurally sound seal. I always use sealant that is specifically designed for wet environments and has excellent adhesion properties.

Consider the importance of proper sealant application. A poorly sealed shower enclosure can lead to leaks, causing water damage and compromising structural integrity over time. My meticulous attention to detail in this step is crucial for long-term durability and safety.

Q 18. Describe your knowledge of different shower enclosure designs and styles.

My knowledge of shower enclosure designs spans a wide range of styles and materials. I’m familiar with framed enclosures, frameless enclosures, neo-angle designs, alcove units, and custom configurations. Each has its own aesthetic appeal and installation requirements. Framed enclosures offer more support and are generally easier to install, while frameless enclosures prioritize a sleek, modern look and require precision installation. Neo-angle enclosures efficiently use corner space, while alcove units are perfect for pre-existing alcove spaces.

Materials also vary: tempered glass is always a requirement for safety, but the style of the hardware—from brushed nickel to sleek chrome—can dramatically alter the look. I also stay updated on new designs and materials, such as the increasing use of patterned or textured glass, to provide clients with the widest possible choice.

For instance, a client might want a frameless glass enclosure for its contemporary style, whereas another might prefer a framed enclosure for increased durability and ease of cleaning. I work to understand these preferences and provide advice tailored to their needs and the practical aspects of their bathroom.

Q 19. What is your process for cleaning up after a glass shower enclosure installation?

Clean-up is an integral part of professional installation. It’s crucial for ensuring client satisfaction and maintaining a positive reputation. My process is systematic and comprehensive. I start by carefully removing all debris, including glass shards, construction waste, and packaging materials. A shop vacuum is extremely useful in this phase for removing fine dust and debris.

Next, I thoroughly clean the shower enclosure and surrounding areas, removing any remaining silicone residue or smudges. I use appropriate cleaning solutions that won’t damage the glass or hardware. Finally, I inspect the entire area one last time to ensure everything is spotless and in perfect working order. Leaving the client’s bathroom clean and organized is as important as the installation itself.

Imagine leaving a customer with a beautiful, new shower enclosure, only to have them find dust and debris everywhere. It ruins the experience. My meticulous cleaning process is part of what sets my work apart.

Q 20. How do you maintain your tools and equipment?

Maintaining my tools and equipment is critical for safety and efficiency. After each job, I carefully clean all tools, removing any debris or residue. I lubricate moving parts on drills and other power tools to ensure smooth operation and longevity. Sharp tools like blades and cutters are stored securely and separately to prevent damage and accidents.

Regular inspection is crucial; I check for damage or wear and tear and replace any components that show signs of malfunction. This proactive maintenance reduces the risk of accidents and downtime. My tools are stored in well-organized and secure storage cases, ensuring they’re always ready for use and remain in optimal condition.

A well-maintained tool is not just more efficient; it’s much safer. A dull blade is more likely to slip, leading to injury. This commitment to maintenance reflects my commitment to both my safety and the quality of my work.

Q 21. How do you prioritize safety when working at heights during shower installation?

Safety at heights is a paramount concern. I never compromise safety, especially when working above floor level. My approach is based on several key principles. First, I always use appropriate fall protection equipment, such as harnesses and safety lines, whenever working at heights. This minimizes the risk of serious injury in case of a fall.

Secondly, I ensure a stable and secure work platform. This may involve using scaffolding, ladders, or other stable structures. Before beginning any work at height, I carefully inspect the stability of the chosen platform. Third, I never overreach or work in an unstable position. I take breaks if needed to avoid fatigue, a significant contributor to accidents.

Finally, I always follow all relevant safety regulations and guidelines. This includes regularly inspecting my equipment and ensuring that it is properly maintained and meets all safety standards. Safety isn’t just a checklist; it’s a mindset that’s integrated into every step of the installation process.

Q 22. Describe your experience working with different types of shower bases.

My experience with shower bases spans a wide range of materials and designs. I’ve worked extensively with acrylic, fiberglass, and porcelain bases, each presenting unique installation challenges. Acrylic bases, for instance, are lightweight and relatively easy to install, requiring careful leveling and sealing to prevent leaks. Fiberglass bases, while durable, can be more prone to cracking during installation if not handled gently. Porcelain bases, though heavier and more demanding to install, offer superior strength and aesthetic appeal. In each case, proper preparation of the subfloor is paramount – ensuring a level surface is critical for preventing future problems like cracking or tilting of the base. I always check for proper drainage before grouting to ensure the base is correctly sloped.

For example, I recently installed a low-profile acrylic base in a small bathroom. Because of the limited space, precise leveling was critical. I used shims strategically to ensure the base was perfectly level, and a high-quality sealant to prevent water penetration around the perimeter.

Q 23. What are the different types of shower door tracks and their installation methods?

Shower door tracks come in several varieties, each with its own installation approach. The most common types are:

- Bypass tracks: These allow doors to slide past each other, ideal for wider openings. Installation involves carefully aligning the tracks to the wall and ensuring smooth operation. Precision is key to prevent binding.

- Pivot tracks: These use hinges on the door itself, which pivot around a fixed point. The installation is more straightforward, centering on proper hinge placement and door alignment for a secure and leak-proof seal.

- Semi-frameless tracks: These offer a sleek modern look with minimal visible hardware. Careful measurements are crucial to ensure proper fit and alignment. These often require more precision and attention to detail during installation.

- Frameless tracks: These are completely minimalist, relying on strong hinges and careful glass cutting for flawless operation. Installing frameless tracks demands precision, as any misalignment can cause significant problems.

Regardless of the type, proper sealing around tracks is essential to prevent water damage. I always use high-quality silicone caulk to ensure a watertight seal.

Q 24. Explain your experience with installing shower enclosures in various bathroom layouts.

I’ve installed shower enclosures in a variety of bathroom layouts, from small, cramped spaces to large, luxurious master bathrooms. In smaller bathrooms, space optimization is paramount. I often utilize sliding doors or pivot doors to maximize usable space. In larger bathrooms, I can accommodate more complex designs, such as corner enclosures with multiple doors or custom-shaped units. Each project demands a unique approach to measurements, ensuring a perfect fit within the existing space. I always take careful measurements and consider all existing plumbing and fixtures before ordering materials to avoid unexpected issues.

For example, I recently installed a custom-shaped neo-angle shower enclosure in a bathroom with a sloped ceiling. This required careful measurements and the fabrication of custom glass panels to perfectly match the unique shape of the space. The result was a stunning and fully functional shower.

Q 25. How do you handle the installation of shower enclosures in older homes or buildings?

Older homes often present unique challenges. Uneven walls, outdated plumbing, and potential structural issues are common. Before starting any installation in an older home, I carefully inspect the existing walls and floor for stability. Shims are frequently needed to compensate for uneven surfaces. I might need to reinforce the wall framing or repair damaged areas before proceeding. Careful attention to the existing plumbing is also crucial, ensuring that the new shower enclosure doesn’t interfere with drainage or water supply lines. Often older homes will have non-standard wall construction or unusual configurations requiring extra ingenuity.

I recently worked on a project in a 1920s home where the walls were slightly bowed. I had to meticulously shim the shower base and frame to ensure a perfectly level installation and prevent any leaks or damage to the unit.

Q 26. What is your experience with working with different types of wall materials?

My experience includes working with various wall materials, including drywall, tile, cement board, and even concrete block. Each material requires a different approach to installation. Drywall requires additional support and waterproofing, often using cement board backing for extra protection. Tile provides a solid, waterproof surface, but requires precise drilling for mounting hardware. Cement board is a common choice for its stability and water resistance. Concrete block requires careful preparation, ensuring that the anchoring system is securely fastened.

For instance, when installing a shower enclosure on tiled walls, it’s crucial to avoid damaging the existing tiles. I use specialized drill bits and take extra precautions to ensure a clean and precise installation.

Q 27. Describe your experience with installing niche shelves in glass shower enclosures.

Installing niche shelves in glass shower enclosures requires precision and careful planning. The niche’s size and position must be carefully considered during the initial design phase. The niche frame needs to be securely attached to the wall structure, and the glass shelf must fit snugly and securely within the frame. Waterproofing is crucial to prevent leaks, and I always use a suitable sealant to prevent water from penetrating the wall cavity behind the niche. I use a combination of high quality silicone sealant and waterproof grout to ensure durability and prevent water damage.

One recent project involved creating a custom-sized niche in a frameless shower enclosure. This required meticulous measurements and precise fabrication of the niche frame to ensure it seamlessly integrated with the overall design. The end result was a beautiful and functional addition to the shower.

Q 28. How do you ensure the proper alignment and function of shower doors and hinges?

Ensuring proper alignment and function of shower doors and hinges is critical for both aesthetics and functionality. I always start with precise measurements, ensuring all components are aligned perfectly before final installation. This includes carefully adjusting the door’s vertical and horizontal position to prevent binding or misalignment. Proper hinge adjustment is essential, and it’s key to ensure they work smoothly and securely. I check for proper clearance and sealing between the doors and the frame to prevent water leakage. This requires careful attention to detail and experience in adjusting different types of hinges.

I recently encountered a situation where a shower door was slightly misaligned, causing it to bind against the frame. By carefully adjusting the hinges and shimming the door, I was able to restore perfect alignment and ensure smooth and trouble-free operation.

Key Topics to Learn for Installing Glass Shower Enclosures Interview

- Measuring and Templating: Accurately measuring shower spaces, understanding tolerances, and creating precise templates for glass cutting and installation.

- Glass Handling and Cutting: Safe handling techniques for various glass types, understanding different cutting methods, and preventing damage during the process.

- Hardware Selection and Installation: Choosing appropriate hinges, handles, clamps, and other hardware based on glass type and shower design; ensuring proper installation for water tightness and structural integrity.

- Sealing and Caulking Techniques: Applying sealant and caulk correctly to ensure a waterproof and aesthetically pleasing finish; understanding different sealant types and their applications.

- Installation Methods for Different Shower Types: Familiarity with installing enclosures in various configurations (e.g., neo-angle, corner, sliding, pivot doors); adapting techniques to different shower pans and wall types.

- Troubleshooting and Problem-Solving: Identifying and resolving common installation issues such as glass misalignment, leaking seals, and hardware malfunctions; applying practical problem-solving skills.

- Safety Regulations and Best Practices: Adhering to safety standards during glass handling and installation; understanding and applying appropriate safety equipment and procedures.

- Understanding Different Glass Types: Knowledge of tempered glass properties, laminated glass, and other specialized glass types used in shower enclosures; understanding their strengths and limitations.

Next Steps

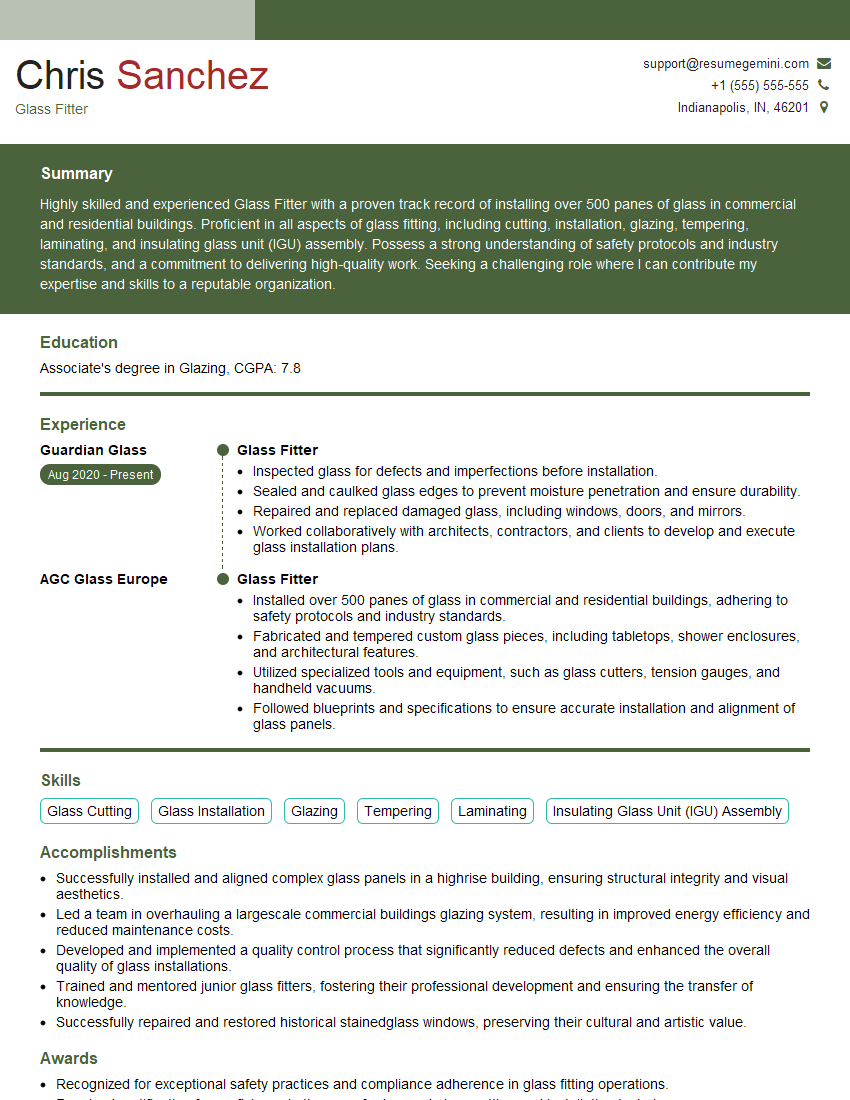

Mastering the installation of glass shower enclosures opens doors to rewarding careers in construction, home renovation, and specialized glass fitting. A strong understanding of these techniques demonstrates valuable skills to potential employers. To increase your job prospects, it’s crucial to create a professional and ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you build a compelling resume showcasing your skills effectively. Examples of resumes tailored to Installing glass shower enclosures are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.