Unlock your full potential by mastering the most common Insulating glass interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Insulating glass Interview

Q 1. Explain the process of manufacturing Insulating Glass Units (IGUs).

Manufacturing Insulating Glass Units (IGUs) is a precise process involving several key steps. Imagine building a tiny, perfectly sealed window within a window. First, two or more sheets of glass are carefully cleaned to eliminate any dust or debris that could compromise the seal. These are then spaced apart using a precisely measured spacer, which is crucial for maintaining the gas fill and structural integrity. This assembly is then sealed using a sealant, typically a butyl sealant, which creates an airtight and watertight bond. Finally, a secondary sealant, often polysulfide or polyurethane, is applied for extra protection and durability. The entire unit is then placed in an autoclave, a large pressure vessel, to cure the sealants and ensure a robust, long-lasting bond. The entire process requires meticulous attention to detail, as even small imperfections can lead to IGU failure.

- Cleaning: Thorough cleaning of the glass sheets is paramount.

- Spacer Insertion: Precisely sized spacers are inserted to maintain the air gap.

- Sealant Application: Butyl sealant forms the primary seal, followed by a secondary sealant for reinforcement.

- Autoclave Curing: The autoclave applies heat and pressure to cure the sealants.

Q 2. Describe the different types of sealants used in IGUs and their properties.

Several types of sealants are employed in IGUs, each with unique properties. The choice depends on factors like desired performance, cost, and the intended application. The primary sealant is usually butyl sealant, a flexible, rubber-like material that provides the initial airtight and watertight seal. Its flexibility is critical for accommodating thermal expansion and contraction. The secondary sealant, applied over the butyl, often includes polysulfide or polyurethane. Polysulfide offers excellent adhesion and weather resistance, while polyurethane provides superior strength and UV resistance. Choosing the right sealant combination is essential for the long-term durability and performance of the IGU.

- Butyl Sealant: Primary sealant, known for flexibility and airtight seal.

- Polysulfide Sealant: Secondary sealant providing excellent adhesion and weather resistance.

- Polyurethane Sealant: Secondary sealant, offering high strength and UV resistance.

Q 3. What are the common causes of IGU failure and how can they be prevented?

IGU failure, sadly, is a common occurrence. Think of it like a tiny ecosystem – if one part fails, the whole system is at risk. Common causes include sealant failure (due to UV degradation, chemical attack, or poor manufacturing), spacer corrosion (especially with aluminum spacers), and gas leakage. Prevention strategies include using high-quality materials, meticulous manufacturing techniques, and proper installation. Regularly inspecting IGUs for signs of failure, such as fogging or leaks, is also crucial. Using warm-edge spacers, which minimize edge heat loss and mitigate thermal stress on the sealants, has greatly improved IGU longevity. Additionally, proper handling and installation are vital to prevent damage during transport and installation.

- Sealant Failure: UV degradation, chemical attack, or poor manufacturing.

- Spacer Corrosion: Particularly prevalent with aluminum spacers.

- Gas Leakage: Compromises the insulating properties of the IGU.

Prevention involves using high-quality materials, meticulous manufacturing, proper installation, and regular inspection.

Q 4. How do you measure the U-value and Solar Heat Gain Coefficient (SHGC) of an IGU?

The U-value and Solar Heat Gain Coefficient (SHGC) are crucial metrics for assessing IGU performance. The U-value represents the rate of heat transfer through the unit – a lower U-value indicates better insulation. It’s measured using calibrated equipment that simulates real-world conditions, measuring the temperature difference across the IGU under controlled heat flux. SHGC, on the other hand, measures how much solar radiation passes through the IGU. Lower SHGC values imply better protection against solar heat gain. This is typically measured using a solar simulator that replicates the sun’s spectrum, and measuring the transmitted solar energy.

These measurements are usually performed in accredited testing laboratories according to established standards like ASTM standards. The results are crucial for building designers and energy efficiency calculations.

Q 5. Explain the importance of spacer technology in IGU performance.

Spacer technology plays a vital role in IGU performance. Imagine the spacer as the backbone of the IGU. It maintains the precise air gap between the glass panes, acting as a scaffold for the sealant. The spacer’s material and design significantly influence the IGU’s thermal performance and durability. Traditional aluminum spacers, while inexpensive, conduct heat, leading to increased heat transfer and potential condensation. Modern warm-edge spacers, made of materials like stainless steel or polymer, minimize heat transfer at the edges, improving the IGU’s U-value and reducing the risk of condensation. The choice of spacer technology directly impacts the energy efficiency and longevity of the IGU. For example, a warm-edge spacer can significantly reduce energy consumption compared to a traditional aluminum spacer, resulting in cost savings over the IGU’s lifetime.

Q 6. What are the different types of gas fills used in IGUs and their impact on energy efficiency?

Various gases can fill the space between the glass panes of an IGU, significantly impacting its energy efficiency. Air is the simplest option, but using inert gases like argon or krypton enhances insulation. Argon is the most commonly used gas due to its cost-effectiveness and good insulating properties. Krypton, while more expensive, offers even better insulation, leading to lower U-values. These gases are heavier than air, and their low thermal conductivity reduces heat transfer across the air gap. The type of gas fill chosen depends on the desired level of energy efficiency and budget. A krypton fill, for example, can significantly improve energy savings compared to an argon fill, but this comes at a higher initial cost.

Q 7. Describe the process of inspecting and testing IGUs for quality.

Inspecting and testing IGUs for quality involves a multi-step process. Visual inspection is the first step, checking for any visible defects, such as scratches, chips, or sealant imperfections. Testing for gas leakage using specialized equipment, like a pressure decay tester, ensures that the unit maintains its intended gas fill. Furthermore, thermal performance testing, using methods mentioned earlier to measure U-value and SHGC, verifies the IGU’s energy efficiency. These tests are performed to ensure that the IGU meets the specified standards and quality requirements. Finally, air leakage tests might be done to ensure complete sealing. The overall goal is to identify any potential weaknesses before the IGUs are installed, preventing future failures and ensuring customer satisfaction.

Q 8. How do you handle damaged or defective IGUs?

Handling damaged or defective Insulating Glass Units (IGUs) requires a systematic approach prioritizing safety and minimizing waste. First, we carefully assess the extent of the damage. A small crack might be repairable depending on its location and size, while extensive damage often necessitates replacement. For minor damage, we might attempt localized repairs, involving careful cleaning and the application of specialized resins to stabilize the crack and prevent further propagation. However, this is not always possible and depends on the type of damage and IGU construction. Extensive damage, like shattered glass or a complete seal failure, necessitates replacing the entire IGU. Disposal of damaged IGUs follows strict environmental regulations, ensuring proper recycling or disposal of glass and the spacer materials to prevent environmental contamination.

Example: A small chip on a corner might be repaired using a clear resin, but a large crack across the pane usually requires a full replacement. We document all damaged IGUs with photos and reports to ensure appropriate warranty claims or insurance documentation.

Q 9. What are the safety precautions you take when handling IGUs?

Safety is paramount when handling IGUs. These units are heavy and fragile, posing risks of cuts, punctures, and potential structural damage if dropped. We always wear appropriate Personal Protective Equipment (PPE), including safety glasses, gloves, and closed-toe shoes. When handling larger units, we use suction cups or specialized lifting equipment to avoid strain and prevent accidental drops. The work area is carefully secured to prevent any hazards from sharp edges or broken pieces. We also ensure proper handling during transportation, securing the IGUs to prevent shifting and damage.

Example: Before lifting a large IGU, we always inspect the unit, ensure our suction cups are securely attached, and have a second person assist for added safety and balance.

Q 10. Explain the different methods of installing IGUs.

IGU installation methods vary depending on the application and the type of framing system. Common methods include:

- Compression Fitting: The IGU is compressed into a pre-prepared frame using specialized tools and gaskets. This is common in windows and doors with pre-made frames.

- Mechanical Fastening: The IGU is secured to the frame using screws or clips. This method offers more flexibility and is used in various applications.

- Glazing System: In curtain wall systems, specialized glazing systems are used, where the IGU is installed within a supporting structure and secured with various clips and gaskets.

The chosen method relies on factors like the frame material, the IGU size, and the overall building design. Proper installation is crucial for ensuring a long lifespan of the unit and preventing issues like air leakage or condensation.

Example: A typical window installation might use a compression fitting method where the IGU is carefully pushed into the window frame, while a large storefront glass installation might rely on a mechanical fastening system or a specialized glazing system.

Q 11. How do you address issues related to condensation in IGUs?

Condensation within an IGU indicates a seal failure. The desiccant within the spacer system, which absorbs moisture, has become saturated. The problem needs immediate attention as persistent condensation can lead to deterioration of the spacer, further damage to the unit and potential mold growth. Addressing this involves replacing the IGU. While there are some attempts to repair minor seal failures, this is generally not cost effective and lacks long term reliability. Replacing the unit ensures proper moisture control and restores the IGU’s performance and insulating properties.

Example: If you notice moisture between the panes of an IGU, it’s crucial to contact a professional for an evaluation and replacement. Trying DIY fixes is unlikely to solve the problem and may even worsen the situation.

Q 12. What are the common challenges encountered during IGU installation?

Common challenges during IGU installation include:

- Improper Frame Preparation: Uneven or damaged frames can lead to poor fit and seal failure.

- Difficult Access: Installing IGUs in tight or hard-to-reach spaces requires careful planning and specialized tools.

- Damage during Handling: IGUs are fragile and can easily be chipped or broken during transportation and installation.

- Seal Issues: Improper sealing techniques can lead to air leakage and condensation.

- Alignment Problems: Improper alignment can lead to uneven gaps and stress on the IGU.

Careful planning, the use of appropriate tools, and adherence to installation guidelines help mitigate these issues. Experience and skill are key to successful IGU installation.

Q 13. How do you troubleshoot common IGU problems?

Troubleshooting common IGU problems usually starts with a thorough visual inspection. We check for seal failures, condensation, cracks, and any signs of damage. We assess air leakage using specialized tools. The tools we use are designed to detect minute leaks and pinpoint their source. Following the inspection, we determine the appropriate course of action, which could range from minor repairs to a complete replacement. Documentation of the issue, repair attempts, and the final solution are crucial for warranty claims and future reference.

Example: If an IGU is leaking air, we might use a smoke test to locate the source of the leak, which could be a faulty seal or a damaged spacer.

Q 14. Describe your experience with different types of glass used in IGUs.

My experience encompasses a wide range of glass types used in IGUs, including:

- Annealed Glass: The most common type, relatively inexpensive, but prone to breakage under stress.

- Tempered Glass (Heat-Strengthened): Significantly stronger and safer than annealed glass; ideal for applications requiring higher durability.

- Laminated Glass: Made up of two or more layers of glass bonded with an interlayer; offers improved safety and security.

- Low-Emissivity (Low-E) Glass: Coated to reflect infrared radiation, improving energy efficiency.

- Specialty Glass: This includes tinted glass for solar control, patterned glass for aesthetics, and even self-cleaning glass.

The selection of glass type depends on various factors like budget, energy performance requirements, and aesthetic preferences. For example, a high-performance IGU for a commercial building might include Low-E coated tempered glass to maximize energy efficiency and safety. Residential projects may often use a combination of tempered glass and Low-E coating for a balance of safety and energy performance.

Q 15. Explain the impact of different climate conditions on IGU performance.

Insulating glass units (IGUs) are significantly impacted by climate conditions. Extreme temperatures, humidity, and solar radiation can all affect their performance and longevity. For example, in extremely hot climates, the sealant can degrade faster, leading to potential failure. Conversely, in very cold climates, there’s a higher risk of seal failure due to thermal stress and expansion/contraction differences between the glass and the spacer. High humidity can lead to condensation buildup within the IGU, reducing its insulation value and potentially causing damage. Solar radiation can cause the glass itself to heat up, impacting the overall energy performance of the unit. To mitigate these issues, manufacturers select materials with optimal performance characteristics for specific climatic regions. This includes selecting sealants with high UV resistance and employing low-emissivity (low-E) coatings to reflect solar radiation and maintain consistent internal temperatures. Choosing the right spacer gas (argon or krypton) also plays a crucial role in improving the IGU’s thermal performance in varied climates.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper handling and storage of IGUs?

Proper handling and storage of IGUs are crucial to prevent damage and ensure optimal performance. IGUs are fragile, so careful handling is paramount. They should always be transported upright to avoid stress on the seals and stored in a climate-controlled environment to prevent temperature fluctuations and condensation buildup. Storage areas should be clean, dry, and free of dust and debris. IGUs should be stored on a flat, stable surface and properly supported to avoid bowing or warping. Furthermore, they should be protected from damage by stacking carefully and using appropriate protective materials. Using custom-made racks can help ensure each IGU is protected against impact and other potential damage during storage.

I’ve personally seen several projects delayed or even jeopardized due to improperly stored IGUs that arrived on site damaged. This underscores the importance of carefully following manufacturer guidelines and implementing a rigorous handling and storage procedure. For example, when working on a skyscraper project once, using a dedicated lifting system with vacuum cups significantly reduced the risk of damage to the IGUs during installation.

Q 17. What are the latest advancements in IGU technology?

Advancements in IGU technology continuously improve energy efficiency and durability. Recent innovations include the use of advanced low-E coatings with multiple layers and variable spectral selectivity. These coatings optimize the control of visible light transmission, solar heat gain, and thermal radiation. Improved spacer technologies offer better edge sealing and insulation, further reducing heat transfer. The development of warm-edge spacers, such as those using flexible materials or incorporating conductive elements, minimizes heat transfer through the IGU edges, leading to further efficiency gains. There’s also increasing use of gas fills beyond argon, such as krypton, which provides enhanced insulation. Furthermore, we are seeing the integration of smart technologies like integrated sensors that monitor IGU performance and alert maintenance personnel to potential issues. This proactive approach enables early detection and mitigation of problems before they escalate into significant repairs.

Q 18. Describe your experience with different IGU manufacturing equipment.

Throughout my career, I’ve worked with a variety of IGU manufacturing equipment, from automated production lines to smaller, more specialized machines. This includes:

- Automated glass washing and cleaning systems

- Spacer application and sealing robots

- Gas filling machines

- Automated sealing and curing systems

- Quality control inspection systems

Q 19. How do you maintain and repair IGU manufacturing equipment?

Maintaining and repairing IGU manufacturing equipment requires a preventative and proactive approach. Regular preventative maintenance, including cleaning, lubrication, and calibration, ensures equipment operates at peak efficiency and extends its lifespan. We use a scheduled maintenance plan, checking critical components and making necessary adjustments or repairs to prevent breakdowns. This schedule takes into account the operating hours and the specific requirements of each piece of equipment. Troubleshooting is crucial; when a malfunction occurs, a methodical approach involving checking sensor readings, inspecting mechanical parts, and verifying programming parameters is key to identifying and addressing the problem quickly. Training personnel in basic equipment troubleshooting is paramount, reducing downtime and the need for outside technicians. Our team maintains a detailed inventory of spare parts to expedite repairs when necessary.

Q 20. What are the environmental considerations related to IGU manufacturing and disposal?

Environmental considerations are paramount in IGU manufacturing and disposal. The manufacturing process involves the use of energy and resources, and generating waste materials. Choosing energy-efficient manufacturing methods and utilizing renewable energy sources can greatly reduce the carbon footprint. The use of recycled materials in spacer frames or in the manufacturing of the glass itself is crucial to minimize environmental impact. Furthermore, efficient waste management systems are essential to minimize the amount of waste sent to landfills. End-of-life disposal of IGUs requires careful planning to minimize environmental consequences. While the glass itself can be recycled, the sealants and spacers are more complex to recycle. The industry is actively developing better methods for recycling these components. We are constantly evaluating new technologies and partnering with recycling companies to improve the environmental sustainability of the entire process, from manufacturing to disposal.

Q 21. Explain the importance of quality control in IGU manufacturing.

Quality control is crucial for the consistent performance and longevity of IGUs. Throughout the manufacturing process, rigorous quality checks are implemented at various stages. These checks involve verifying the quality of the raw materials (glass, spacers, sealants), monitoring the manufacturing process (gas filling, sealing, and curing), and performing final inspections to ensure the IGUs meet predetermined specifications. This includes checks for seal integrity, gas pressure, and optical clarity. We use advanced optical inspection systems and specialized tools to identify defects and maintain consistently high standards. Any deviations from our stringent quality standards will result in the rejection of defective units. Having a rigorous quality control system not only protects the end-user but also builds confidence and trust in our products. This also includes maintaining detailed records and documenting the manufacturing process, which is vital for traceability and accountability.

Q 22. How do you ensure compliance with building codes and standards regarding IGUs?

Ensuring compliance with building codes and standards for Insulating Glass Units (IGUs) is paramount. This involves a multi-faceted approach beginning with a thorough understanding of the relevant codes, such as the International Energy Conservation Code (IECC) and local building ordinances. These codes specify requirements for U-factors (heat transfer), SHGC (solar heat gain coefficient), and air leakage.

We achieve compliance by:

- Specifying the correct IGU design: This includes selecting appropriate glass types (low-E coatings, thicknesses), gas fills (argon, krypton), and spacer systems to meet the required performance standards. For instance, a project in a cold climate might require a lower U-factor than one in a milder climate.

- Utilizing certified products and materials: We source our components from reputable manufacturers who provide certifications confirming their products meet or exceed relevant standards. This documentation is meticulously maintained for audits.

- Conducting rigorous quality control: This includes regular checks throughout the fabrication process, from glass cutting and cleaning to sealing and gas filling. We employ advanced testing equipment to verify the performance of each IGU, ensuring it meets the specified U-factor and air leakage tolerances. Any unit failing these tests is immediately rejected.

- Maintaining thorough documentation: All project documentation, including material specifications, test results, and installation procedures, is carefully maintained to demonstrate compliance to any auditing body.

Ultimately, compliance ensures the IGU performs as expected, contributing to energy efficiency and occupant comfort, while also avoiding potential legal repercussions.

Q 23. Describe your experience working with different types of window frames.

My experience spans a wide range of window frame materials, each presenting unique challenges and opportunities in IGU integration.

- Aluminum frames: These are known for their strength and durability but can be significant thermal bridges, requiring careful consideration of thermal break design in the IGU spacer system to minimize heat transfer. I’ve worked extensively on projects using thermally broken aluminum frames, where a non-conductive material is incorporated to reduce heat flow.

- Vinyl (uPVC) frames: Vinyl frames offer excellent thermal insulation, reducing the need for overly complex IGU designs to achieve high energy efficiency. My experience includes working with various profile designs and ensuring proper compatibility with the chosen IGU sealants and gaskets.

- Wood frames: Wooden frames provide aesthetic appeal and good insulation, but require precise manufacturing to ensure proper sealing and prevent moisture infiltration around the IGU. I’ve handled projects demanding specific wood finishes and compatibility with various sealants.

- Fiber-reinforced polymer (FRP) frames: FRP frames offer excellent durability and weather resistance, but need specialized attention to the bonding and sealing process with the IGU due to the material’s unique properties. I have developed expertise in successful integration of IGUs into these frames.

Understanding the properties of each frame material is crucial to selecting the appropriate IGU design and installation techniques to optimize performance and longevity.

Q 24. What are the different types of edge sealants used in IGUs and their applications?

Edge sealants are critical for maintaining the integrity of an IGU, preventing gas leakage and moisture ingress. Several types exist, each with specific applications:

- Polyisobutylene (PIB): A common choice for its excellent adhesion to glass and butyl sealants. It’s primarily used as a secondary sealant, providing additional protection against moisture and gas leakage. It’s flexible and can accommodate some movement between the glass panes.

- Butyl sealant: This forms the primary seal in most IGUs, providing a strong and airtight bond between the glass and the spacer system. It’s important for its excellent gas retention properties.

- Polysulfide sealant: Often used as a secondary sealant, offering excellent weather resistance and adhesion to various substrates. It provides enhanced protection against environmental factors and is suitable for more challenging applications. However, it’s less commonly used than PIB due to its longer curing time and potential for staining.

- Silicone sealant: While less common as a primary sealant in IGUs due to its potential for outgassing, silicone is sometimes used for specific applications, such as sealing around the perimeter of the IGU to the frame, where its flexibility and adhesion are advantageous.

The selection of the appropriate sealant depends on factors like climate conditions, the type of glass, spacer system and expected service life. For example, in harsh climates with extreme temperature fluctuations, a polysulfide or high-performance butyl sealant might be preferable.

Q 25. How do you calculate the required quantity of materials for IGU fabrication?

Calculating the required quantity of materials for IGU fabrication involves precise measurements and considerations for waste. This is typically done using software specifically designed for this purpose or through detailed manual calculations.

The process involves:

- Accurate measurement of glass dimensions: These are determined from the window design specifications, accounting for tolerances and cuts.

- Calculation of spacer bar length: The perimeter of each IGU needs to be calculated precisely to determine the amount of spacer bar needed.

- Determination of sealant quantity: The amount of butyl and secondary sealant required is calculated based on the IGU dimensions and the sealant bead size.

- Gas fill volume calculation: The volume of gas required depends on the size of the IGU cavity. This is crucial for ensuring proper insulation performance.

- Accounting for waste: A margin for material waste is always included, usually based on experience and historical data. This helps avoid shortages and delays.

For larger projects, I usually create a detailed bill of materials (BOM) based on these calculations. This BOM serves as a crucial guide for procurement and helps prevent costly errors in the fabrication process.

Q 26. Explain the concept of thermal bridging in IGUs and how to minimize it.

Thermal bridging refers to the transfer of heat through conductive components in an IGU, reducing its overall insulation efficiency. This usually occurs via the spacer bar, which connects the two panes of glass.

In a traditional IGU, the metal spacer bar acts as a thermal bridge, allowing heat to easily transfer from the warmer side to the cooler side of the unit. This can significantly reduce the IGU’s R-value (insulation resistance). To minimize thermal bridging:

- Utilize low-conductivity spacers: This includes using warm-edge spacers made from materials like stainless steel with a thermal break, or using polymeric spacers which inherently have low thermal conductivity. These reduce the amount of heat transfer through the spacer.

- Optimize spacer design: Designing the spacer bar with a wider width or including insulating materials can reduce the amount of heat flow.

- Employ gas fills with high thermal resistance: Using gases like argon or krypton, which are less conductive than air, can enhance the overall insulation value, compensating for any remaining thermal bridging.

- Improve sealing techniques: Ensuring a tight seal around the spacer bar helps reduce air infiltration and minimize convective heat transfer.

Minimizing thermal bridging is critical for achieving optimal energy efficiency in buildings. A simple analogy would be a coat with metal buttons – the buttons act as thermal bridges, allowing heat to escape more readily. A well-designed IGU uses the equivalent of insulated buttons to prevent heat loss.

Q 27. How do you manage a project involving the installation of a large number of IGUs?

Managing a large IGU installation project requires meticulous planning and execution. My approach is based on a project management framework that encompasses these key elements:

- Detailed project planning: This starts with a thorough review of the project specifications, including the number of IGUs, their dimensions, and the required performance standards. A detailed schedule with clear milestones is created and shared with the team.

- Resource allocation: This involves securing the necessary materials, equipment, and skilled labor well in advance. I utilize software to track material deliveries and ensure timely availability.

- Quality control throughout the process: Stringent quality control measures are implemented at every stage, from the initial IGU fabrication to final installation and inspection. This helps to prevent defects and delays. Regular site visits are conducted to monitor progress and address any issues promptly.

- Effective communication: Maintaining open communication with clients, contractors, and the installation team is essential. Regular updates, progress reports, and problem-solving sessions keep everyone informed and aligned.

- Risk mitigation: Potential risks, such as material delays, weather disruptions, and equipment malfunctions, are identified and contingency plans are developed to mitigate their impact.

For instance, on a recent large-scale project, we implemented a prefabrication strategy, where IGUs were fabricated off-site in a controlled environment and then delivered and installed, drastically reducing site-based delays and improving overall quality.

Q 28. Describe your experience with troubleshooting gas leaks in IGUs.

Troubleshooting gas leaks in IGUs requires a systematic approach to identify the source and implement the appropriate solution. This often involves a combination of visual inspection and specialized testing.

My troubleshooting steps typically include:

- Visual inspection: A careful examination of the IGU for any visible signs of damage, such as cracks or sealant failures. This often reveals the location of the leak.

- Gas leak detection: Specialized equipment, such as a thermal imaging camera or gas detection probes, can pinpoint the leak. A thermal camera can detect temperature differences indicative of gas escaping, while gas detection probes provide more precise detection.

- Pressure testing: The IGU can be pressurized with an inert gas and monitored for pressure loss over a specified period. This helps to determine the leak rate and helps identify the leak location.

- Repair or replacement: Depending on the severity and location of the leak, the IGU may be repaired by resealing the faulty area, or replacement is the more efficient solution. Replacing the whole IGU is usually quicker and cost-effective if the repair is extensive.

Remember, safety is crucial during leak detection and repair. Always follow appropriate safety protocols and use personal protective equipment (PPE) as required.

Key Topics to Learn for Insulating Glass Interview

- Insulating Glass Unit (IGU) Construction: Understand the components of an IGU – glass panes, spacers, sealants, and gas fills. Explore the different types of spacers and their impact on performance.

- Heat Transfer Mechanisms: Master the principles of conduction, convection, and radiation as they relate to heat transfer through an IGU. Be prepared to discuss U-values, SHGC, and visible transmittance (VT).

- Gas Fills and their Properties: Know the common gas fills used in IGUs (argon, krypton, xenon) and their impact on insulation performance. Discuss the advantages and disadvantages of each.

- Sealant Technology and Failure Modes: Understand the different types of sealants used and their role in preventing moisture ingress and maintaining the IGU’s insulating properties. Be able to identify common sealant failure modes and their causes.

- Manufacturing Processes: Familiarize yourself with the key steps involved in IGU manufacturing, including cleaning, spacer installation, sealing, and quality control.

- Performance Testing and Standards: Understand the various industry standards and testing methods used to evaluate the performance of IGUs. Be prepared to discuss relevant certifications and labels.

- Applications and Design Considerations: Explore the various applications of insulating glass in different building types and climates. Understand how design choices affect the performance and longevity of IGUs.

- Troubleshooting and Problem Solving: Be ready to discuss common IGU issues, such as fogging, leaks, and performance degradation, and how to diagnose and address them.

Next Steps

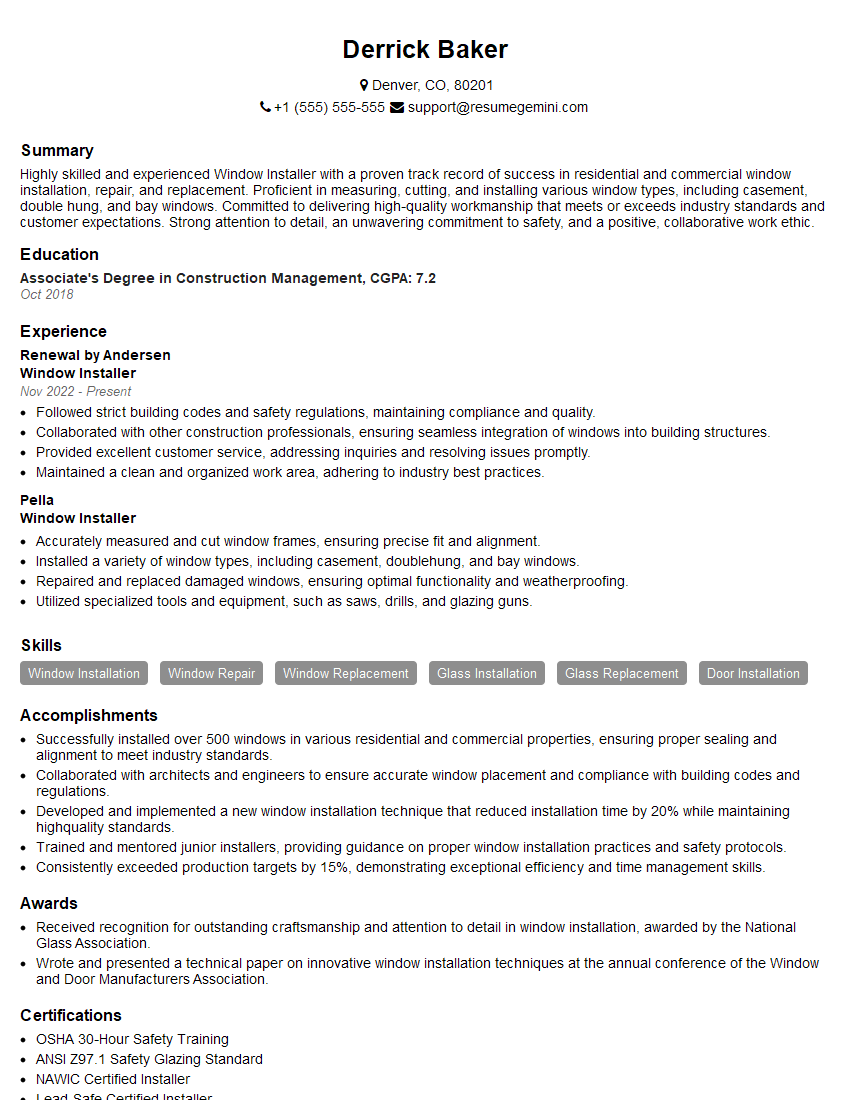

Mastering the intricacies of insulating glass opens doors to exciting career opportunities in the construction, architectural, and manufacturing sectors. A strong understanding of these concepts will significantly enhance your interview performance and increase your chances of securing your dream role. To further boost your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of the Insulating Glass industry. Examples of resumes tailored to Insulating Glass positions are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.