Unlock your full potential by mastering the most common Ironworking Tools interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Ironworking Tools Interview

Q 1. What safety precautions are essential when using an oxy-acetylene torch for ironworking?

Safety is paramount when working with oxy-acetylene torches. These torches produce an extremely hot flame capable of instantly igniting flammable materials and causing severe burns. Before even lighting the torch, ensure you’re in a well-ventilated area, free from flammable materials. Always wear appropriate safety gear, including flame-resistant clothing, safety glasses with side shields, and heavy-duty leather gloves. Proper footwear is essential to protect your feet from sparks and hot metal.

- Cylinder Handling: Always use a regulator to control the gas flow. Never drop or damage the cylinders. Keep them upright and secured. Oxygen and acetylene cylinders should be stored separately and a safe distance from any ignition sources.

- Flame Control: Practice lighting and extinguishing the torch properly, avoiding flashback (where the flame travels back into the torch). Maintain a stable flame to prevent uneven heating.

- Hot Work Permit: In many professional settings, a ‘hot work permit’ is required before commencing any operation involving open flames. This ensures appropriate safety measures are in place.

- Fire Extinguisher: Always have a fire extinguisher readily available and know how to use it. A Class B or ABC extinguisher is suitable for this type of work.

Think of it like this: treating oxy-acetylene equipment carelessly is like playing with fire – it’s incredibly dangerous and should be handled with the utmost respect and caution.

Q 2. Explain the difference between various types of welding techniques used in ironworking.

Several welding techniques are used in ironworking, each suited to different applications and material thicknesses. The choice depends on factors such as the desired weld strength, appearance, and speed of execution.

- Oxy-Fuel Welding (OFW): This uses an oxy-acetylene torch to melt the base metal and filler rod, creating a weld pool. It’s versatile, suitable for various thicknesses, and relatively inexpensive but requires more skill and precision than some other methods.

- Arc Welding (e.g., Shielded Metal Arc Welding (SMAW) or Stick Welding): An electric arc melts the base metal and electrode (the filler rod). SMAW is robust and relatively portable, ideal for outdoor or construction settings. It produces a strong weld but often has a rougher appearance.

- Gas Metal Arc Welding (GMAW) or MIG Welding: Uses a continuously fed wire electrode and a shielding gas. It’s faster and produces a cleaner weld than SMAW, ideal for production settings or where a smooth, aesthetically pleasing finish is required. It’s less portable than SMAW.

- Gas Tungsten Arc Welding (GTAW) or TIG Welding: Uses a non-consumable tungsten electrode and a shielding gas. It produces very high-quality welds with excellent precision and control, ideal for thin materials and intricate designs, but it’s a more complex technique requiring more experience.

For example, repairing a cast iron component might use oxy-fuel welding due to its control over the heat input, while building a large steel structure might employ GMAW for speed and efficiency.

Q 3. Describe your experience with different types of ironworking tools, such as hammers, chisels, and punches.

My experience encompasses a wide range of ironworking tools. Proper tool selection is crucial for efficient and safe work.

- Hammers: From lightweight ball-peen hammers for delicate work to heavy sledgehammers for rough shaping, the hammer’s weight and head shape dictate its application. A cross-peen hammer, for instance, is excellent for riveting or shaping curved sections. I’ve used various hammer types extensively, understanding the nuances of each for different tasks.

- Chisels: Cold chisels, used for cutting and shaping cold metal, are essential. Different chisel types (e.g., cape, flat, round-nose) allow for varied cuts and shapes. Proper technique is essential to avoid damaging the chisel or workpiece.

- Punches: Center punches for marking holes, and various punches for creating different shapes in the metal, are regularly used. The selection depends on the required hole size and shape. Punching requires controlled force to avoid damaging the workpiece.

- Other tools: This also includes various types of files, rasps, and grinders for refining shapes and smoothing surfaces. Anvil and vise are essential for holding and shaping workpieces.

For instance, creating a decorative scroll might involve using a hammer and various chisels to shape the metal, followed by filing and smoothing to refine the detail. This illustrates how several tools often work together in a sequence.

Q 4. How do you measure and cut iron accurately using various tools?

Accurate measurement and cutting are fundamental in ironworking.

- Measuring: Steel rules, calipers, and measuring tapes are used to precisely measure the dimensions of the workpiece. For complex shapes, templates or digital measuring tools might be necessary.

- Cutting: The cutting method depends on the material’s thickness and the desired cut. For thicker sections, an oxy-acetylene torch or plasma cutter might be used. For thinner sections, a hacksaw, cold chisel, or abrasive wheel can be employed. Always wear appropriate safety gear, including eye protection, during cutting.

- Accuracy: Precise marking using a scriber or marker is essential before cutting. Using a guide or jig ensures straight cuts, and clamps or vises help secure the workpiece while cutting to ensure safety and accuracy.

Imagine you need to cut a precisely sized piece of steel for a structural support. You would carefully measure the dimensions, mark them on the steel using a scriber, then use a cutting tool like a plasma cutter or band saw with a jig for guidance, ensuring the cut is perfectly square and the correct length.

Q 5. What are the common types of iron used in construction and their properties?

Various types of iron are employed in construction, each with unique properties:

- Mild Steel: This is the most common type due to its balance of strength, weldability, and cost-effectiveness. It’s used in structural components, reinforcing bars, and various other applications.

- Cast Iron: High compressive strength but brittle and less ductile than steel. Used in applications where high compressive loads are expected like machine bases or some pipe fittings.

- Wrought Iron: A low-carbon iron with fibrous structure, offering good corrosion resistance and ductility. Historically used extensively, now less common due to higher cost but still found in decorative work.

- Stainless Steel: Alloy steel containing chromium and other elements for high corrosion resistance. Used in exterior applications and where corrosion is a primary concern (balconies, railings).

Choosing the right type of iron depends entirely on the intended use and the environmental conditions. A bridge, for example, would require high-strength steel, while decorative fencing might use wrought iron for its aesthetic appeal and corrosion resistance.

Q 6. How do you ensure the structural integrity of ironwork during installation?

Structural integrity in ironwork is crucial for safety and longevity. Several measures ensure this:

- Proper Design: The design must account for all anticipated loads (weight, wind, seismic activity). Calculations and engineering drawings are vital to ensure the structure can withstand these forces.

- Quality Materials: Using approved, certified materials with known strength properties is essential. Inspecting materials for defects before use is a key step.

- Correct Welding Techniques: Employing the right welding technique and ensuring proper weld penetration and fusion avoids weak points in the structure. Weld inspection (visual or non-destructive testing) is often mandated.

- Proper Connections: Secure and strong connections between components are vital. Bolts, rivets, or welds must be appropriately sized and installed according to specifications.

- Corrosion Protection: Protecting ironwork from corrosion is vital for its lifespan. Methods include painting, galvanizing, or other specialized coatings.

For example, a balcony needs to be designed to support the weight of people and withstand wind loads. Weak welds or improperly sized bolts would compromise the safety of the balcony, highlighting the importance of meticulous attention to detail throughout the process.

Q 7. Explain the process of bending and shaping iron using various tools and techniques.

Bending and shaping iron requires skill and the right tools. The technique varies based on the iron’s thickness and the desired shape.

- Hand Bending: For thinner sections, hand tools like bending bars, or a simple vise and hammer can be used. This allows for precise shaping and control, but is labour intensive.

- Machine Bending: For thicker or larger pieces, hydraulic presses or bending machines provide controlled and powerful bending. This is often faster and more efficient for production-scale work.

- Heating: Heating the iron before bending reduces its yield strength, making it easier to manipulate. A forge or oxy-acetylene torch is commonly used for heating. Care must be taken to avoid overheating, which can cause structural weakening.

- Forming Tools: Molds, jigs, or other forming tools can help create precise and consistent shapes. These tools guide the metal during bending and ensure consistent results.

Consider creating a decorative iron gate. Thinner sections for decorative scrolls might be bent by hand, while thicker supports for the gate frame might need a hydraulic press or a bending machine. Proper heating before bending is crucial in both cases to avoid cracking or breaking the metal.

Q 8. What are the different types of rivets and how are they applied?

Rivets are permanent fasteners used to join metal pieces. Different types cater to various needs in terms of strength, material, and application. They’re applied by inserting the rivet into the holes of the joined parts and then deforming the tail end to create a secure connection. Here are some common types:

- Solid Rivets: These are simple rivets made from a single piece of metal. The tail end is deformed using a rivet gun or hammer and punch. Think of these as the workhorses – reliable and versatile.

- Semi-Tubular Rivets: These have a hollow shaft, often with a slightly flared end. They’re easier to set than solid rivets, particularly in hard-to-reach areas. The hollow shaft also allows for expansion, useful in certain applications.

- Blind Rivets: These are designed to be set from only one side of the workpiece. This is invaluable for situations where access to the other side is impossible, like joining panels inside a chassis. They usually consist of a mandrel that expands the rivet body as it is pulled through.

- Countersunk Rivets: These are designed to sit flush or below the surface of the material, providing a smooth finish. Often used for aesthetics or where a protruding rivet would be impractical.

Application involves careful measurement to ensure proper rivet length and hole size. The chosen method – hand tools, pneumatic rivet guns, or hydraulic riveters – depends on the rivet type, material thickness, and project scale. For instance, I’ve used pneumatic rivet guns extensively on large-scale construction projects for speed and efficiency, while hand tools are often more suitable for intricate detailing in smaller projects.

Q 9. Describe your experience with using power tools in ironworking (e.g., grinders, drills).

My experience with power tools in ironworking is extensive and spans various projects, from intricate ornamental work to robust structural installations. I’m proficient in operating grinders, drills (both hand-held and magnetic), and angle grinders. I understand the importance of safety precautions when operating these tools. For example, I always wear appropriate safety glasses, hearing protection, and a respirator when using a grinder, especially with stainless steel which throws off fine particles.

With grinders, I’m skilled in using different abrasive discs for shaping, smoothing, and deburring metal. The selection of the correct abrasive is crucial for achieving the desired finish and preventing damage. For example, a coarse grit is used for rough shaping, and then finer grits are employed for polishing. I’ve used grinders to prepare surfaces for welding, removing rust or old paint. Drills are critical for creating precise holes for bolts, rivets, or welding fixtures. Knowing how to use various drill bits and drill speeds is important to prevent drill bit breakage or material damage. I’ve found that magnetic drills are particularly useful for working on vertical surfaces, as they provide stability and prevent accidents. Regular maintenance and checks on all power tools are critical to ensuring both quality of work and personal safety.

Q 10. How do you handle and mitigate the risks associated with working at heights during ironwork installations?

Working at heights during ironwork installations presents significant risks. My approach centers around a multi-layered safety strategy. First, and foremost, I always ensure that the worksite is properly assessed for potential hazards – ensuring scaffolding is stable, inspecting all equipment, checking that all fall protection systems are in place. I adhere strictly to all relevant safety regulations and utilize appropriate personal protective equipment (PPE), including safety harnesses, fall arrest systems, and safety helmets.

Secondly, I emphasize thorough planning and communication. This means carefully reviewing blueprints to understand the work sequence and identifying potential risks before work begins. Communication with my team is essential to ensure that everyone understands their roles and the safety protocols.

Finally, regular inspections and maintenance of the work area and safety equipment are crucial. This prevents accidents and ensures that the safety systems are always functioning correctly. For example, checking the integrity of ropes and ensuring that harness clips are securely fastened. I always lead by example to instill a strong safety culture amongst my team, as preventing accidents is the most effective safety precaution.

Q 11. How would you troubleshoot a common problem encountered during ironwork assembly?

A common problem during ironwork assembly is misalignment of components. This can be due to inaccurate measurements, material deformation, or improper welding. To troubleshoot this, I start by carefully examining the affected area to identify the specific source of misalignment. This involves checking measurements against the blueprints and inspecting the components for any damage.

Next, I consider the most appropriate solution. Minor misalignments can often be corrected by adjusting fasteners or using shims. For more significant misalignments, it might be necessary to rework or replace the affected components. In some cases, minor adjustments using a grinder or file to correct a slight misalignment is possible. Sometimes, it’s necessary to carefully dismantle and reassemble parts to achieve proper alignment. Finally, I document the problem and its solution for future reference and to prevent the same issue from happening again.

For example, if a structural beam isn’t aligned correctly, the entire structure could be compromised. Thorough problem-solving ensures that the final product is both structurally sound and aesthetically pleasing.

Q 12. What are your methods for maintaining ironworking tools and ensuring they are in proper working order?

Maintaining ironworking tools is critical for safety, efficiency, and the quality of work. My approach is based on a combination of regular cleaning, inspection, and preventative maintenance.

After each use, I clean all tools thoroughly to remove debris, rust, and other contaminants. This not only extends the lifespan of the tools but also prevents damage to the workpiece. For example, I use wire brushes for removing slag from welding tools and solvent for cleaning cutting oils and grease. I inspect tools for wear and tear, paying close attention to cutting edges, handles, and moving parts. Damaged or worn-out tools are immediately repaired or replaced.

Preventative maintenance includes lubricating moving parts, sharpening cutting edges, and storing tools in a dry, safe place. I regularly check and maintain power tools, ensuring that they’re correctly calibrated and functioning optimally to avoid accidents or producing faulty work. Sharp tools are safer and more efficient, and well-maintained equipment simply works better. This commitment to maintenance reflects my professional approach to the craft.

Q 13. Describe your understanding of blueprint reading and how it relates to ironwork projects.

Blueprint reading is fundamental in ironwork projects. Blueprints provide a detailed visual representation of the project, including dimensions, specifications, and the arrangement of components. My understanding of blueprint reading goes beyond simply identifying shapes and sizes; it involves comprehending the structural integrity and the relationships between various parts.

I can interpret different symbols, lines, and annotations used in blueprints to understand the material specifications, the assembly process, and the overall design intent. For example, I can identify different steel grades, types of welding joints, bolt specifications, and the precise location of every element in the structure. This ensures accurate material ordering, efficient fabrication, and precise assembly.

Accurate blueprint reading prevents errors and ensures that the final structure meets the design specifications and safety requirements. It’s essential for efficient project management and successful outcomes. I consistently check my interpretation of blueprints against the physical materials and assembled components to avoid mistakes and maintain quality control.

Q 14. Explain the process of joining different types of iron using various welding techniques.

Joining different types of iron using various welding techniques requires a deep understanding of metallurgy and welding processes. The choice of welding technique depends on the type of iron, thickness, and the desired properties of the joint. Here are some common methods:

- Shielded Metal Arc Welding (SMAW): This is a versatile process suitable for a wide range of iron types and thicknesses. It uses a consumable electrode to create an arc that melts the base metal and the electrode, forming a weld pool. It’s robust and relatively inexpensive, making it suitable for many construction and fabrication tasks.

- Gas Metal Arc Welding (GMAW): Often called MIG welding, this uses a continuous wire electrode fed into the weld pool, providing a fast and efficient welding process. It’s ideal for joining thinner materials and producing smooth welds. I often use GMAW for smaller, more intricate work.

- Gas Tungsten Arc Welding (GTAW): Known as TIG welding, this process uses a non-consumable tungsten electrode to create an arc. It’s a precise technique that delivers high-quality welds with excellent control over the weld pool. It’s very useful for joining dissimilar metals or for critical applications that require high precision.

Before joining, appropriate preparation is essential, such as cleaning and beveling the edges to ensure proper fusion and penetration. I choose the welding parameters – amperage, voltage, and shielding gas – depending on the base material and the welding process. After welding, inspection of the weld is crucial for ensuring that it meets the required quality and integrity, often using visual inspection or other non-destructive testing techniques. This comprehensive approach guarantees strong, reliable, and safe joints in my ironwork projects.

Q 15. How do you interpret and apply welding symbols in ironwork drawings?

Welding symbols in ironwork drawings are crucial for communicating precise welding requirements to fabricators. They’re a standardized shorthand, avoiding lengthy written descriptions. Think of them as a visual blueprint for the welder.

Understanding them involves recognizing the reference line, the arrow connecting the symbol to the joint, and the various symbols themselves which indicate weld type (e.g., fillet, groove, spot), size, length, and location. For example, a symbol showing a triangular arrowhead pointing to a joint with a number ‘6’ next to it signifies a 6mm fillet weld. The arrow indicates which side of the joint receives the weld. A short dash on the opposite side of the reference line might indicate that this side also receives a similar weld. Other symbols might denote specific weld preparations or finishing requirements.

In applying these symbols, I always meticulously check the drawing’s legend for any project-specific clarifications or deviations from standard symbols. I then translate them into precise instructions for the welding team, ensuring everyone understands the requirements before starting work. This minimizes errors and rework, vital for maintaining project timelines and quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some different types of metal fasteners used in ironworking?

The world of metal fasteners in ironwork is diverse, each type chosen for its specific application. We’re not just talking about simple screws here!

- Bolts: These are incredibly versatile, ranging from standard machine bolts for simpler connections to high-strength bolts used in structural applications requiring extreme tensile strength. Consider the difference between a standard bolt holding decorative railings and a high-strength bolt securing a heavy steel beam.

- Rivets: Permanent fasteners, often used where disassembly is not anticipated. They’re essential in creating robust, durable connections, often seen in historical ironwork and large-scale structures. Different types, like solid rivets and expansion rivets, offer varying levels of strength and installation methods.

- Welding: While not a traditional fastener in the same vein as bolts and rivets, welding acts as a permanent joining method. It’s crucial for ironwork and is chosen when superior strength and a seamless appearance are needed. The choice of weld type itself is a crucial factor, as different welds provide varying strength characteristics.

- Screws: Various screw types exist, from self-tapping screws for thinner materials to larger, more robust machine screws for thicker components. Choosing the appropriate screw for the material and application is paramount.

Selecting the right fastener considers the material’s thickness, strength requirements, aesthetic considerations, and ease of installation. Improper choices can compromise the structural integrity and appearance of the final project.

Q 17. Describe your experience with working on large-scale ironwork projects.

My experience with large-scale ironwork projects is extensive. I’ve been involved in projects ranging from intricate wrought iron gates for prestigious buildings to the structural steel frameworks of modern skyscrapers. One memorable project involved fabricating and installing a massive, ornate steel staircase for a museum. The project demanded precise measurements, detailed shop drawings, and flawless on-site assembly.

The key to success in such projects lies in meticulous planning and coordination. This begins with thorough review of the architectural and engineering plans, often involving close collaboration with architects and engineers. Detailed shop drawings are then prepared, breaking down the project into manageable sections for fabrication and assembly. On-site supervision is critical to ensure the components are correctly installed, adhering to tolerances, and meeting the safety standards. We had regular progress meetings, and employed advanced laser scanning technology for measurement validation before and during installation. The project’s success relied not only on technical skills but also effective communication, team coordination and strict adherence to schedules.

Q 18. How do you ensure the quality control of your ironwork?

Quality control in ironwork is paramount. It’s not just about the final appearance; it’s about ensuring structural integrity and safety. Our quality control measures are multi-faceted and begin even before fabrication.

- Material Inspection: We thoroughly inspect all incoming materials for defects, verifying their compliance with project specifications.

- Fabrication Oversight: We maintain rigorous control over the fabrication process, regularly checking for dimensional accuracy and weld quality using advanced inspection techniques such as non-destructive testing (NDT). This often involves visual inspection, dimensional checks and even specialized techniques such as ultrasonic testing.

- Assembly Checks: During assembly, we conduct detailed checks to ensure proper alignment and secure connections.

- Final Inspection: A final inspection is performed before the project is deemed complete, often involving a third-party inspection agency to ensure independent verification of quality and compliance with safety regulations.

Documentation is crucial throughout the process. We meticulously record all inspection results, enabling traceability and identification of any potential issues. We adhere to industry best practices and relevant standards, and continuous improvement is a core part of our philosophy.

Q 19. What are your methods for calculating material requirements for an ironwork project?

Calculating material requirements for an ironwork project involves a systematic approach, ensuring we procure the correct amount of material to minimize waste and avoid delays. It’s not simply a case of eyeballing it!

The process typically begins with a detailed review of the project drawings and specifications. We then break down the project into individual components, determining the dimensions and material type (steel, wrought iron, etc.) for each. We use specialized software and established formulas to calculate the volume and weight of each component. This often includes factoring in allowances for cutting losses, waste, and potential errors. For example, calculations for steel might involve accounting for factors such as shear strength in welds. Finally, we add a safety margin to account for unexpected issues or material variations. This systematic approach ensures that we order the appropriate quantity of materials, avoiding unnecessary costs or delays caused by shortages.

Q 20. Explain your experience with working with different types of metal (steel, wrought iron, etc.)

My experience encompasses working with a variety of metals commonly used in ironwork, each with unique properties and requiring distinct fabrication techniques.

- Steel: A versatile and widely used material offering excellent strength and weldability. Different grades of steel are chosen based on strength requirements, corrosion resistance, and other factors. Structural steel is prevalent in large-scale projects, while other grades may be more suitable for decorative elements.

- Wrought Iron: Historically significant, wrought iron is prized for its malleability, durability, and distinctive appearance. It is often used in ornate decorative ironwork but requires specialized techniques due to its lower tensile strength compared to steel.

- Stainless Steel: Known for its corrosion resistance, stainless steel is ideal for outdoor applications where longevity and aesthetic appeal are paramount. It’s used extensively in contemporary and modern ironwork designs.

- Cast Iron: Suitable for creating intricate, detailed components, cast iron has excellent compressive strength but is less suited for applications demanding high tensile strength.

Understanding the distinct properties of each material is key to selecting the appropriate one for each aspect of the project, and to employing the correct fabrication and joining methods. I have extensive experience with each of these materials, employing diverse fabrication techniques based on the characteristics of each material.

Q 21. How familiar are you with OSHA regulations related to ironworking?

My familiarity with OSHA (Occupational Safety and Health Administration) regulations pertaining to ironwork is extensive. Safety is non-negotiable. These regulations cover a wide range of aspects of our work, from fall protection to equipment safety and personal protective equipment (PPE).

I understand the requirements for fall protection systems, including the use of harnesses, lifelines, and anchorage points, especially when working at heights, a common situation in ironwork. I’m knowledgeable about the safe use of welding equipment and related personal protective equipment such as welding helmets and gloves. I am familiar with the requirements for lockout/tagout procedures to prevent accidental energization of machinery, and the proper handling and storage of hazardous materials, such as welding gases. We also follow regulations regarding respiratory protection when welding or working with materials that produce harmful fumes. We conduct regular safety training for our team, ensuring everyone is aware of and adheres to these critical regulations. This prevents accidents, and promotes a safe and productive work environment. I regularly stay updated on all changes and new regulations, attending safety courses and reviewing the relevant OSHA publications.

Q 22. Describe your experience with using hand-held power tools in ironworking.

My experience with handheld power tools in ironworking is extensive. I’m proficient with a range of tools, including angle grinders (for cutting and grinding), die grinders (for intricate shaping and finishing), and drills (for creating holes of various sizes). Choosing the right tool for the job is crucial. For example, a thin cutoff wheel on an angle grinder is ideal for precise cuts on thin metal, while a heavier-duty abrasive wheel is better suited for removing significant amounts of material. Similarly, die grinders with different bits allow for intricate detailing and smoothing of welds. Safety is paramount, and I always utilize appropriate safety glasses, gloves, and hearing protection when using these tools.

I’ve used these tools on countless projects, from creating custom gates and railings to intricate metal sculptures. One memorable project involved using a die grinder with a carbide burr to carefully shape the intricate details on a decorative fireplace surround, showcasing the precision these tools allow.

Q 23. What are the steps you take to ensure a safe and efficient workflow in ironworking?

Safety and efficiency are intertwined in ironworking. My workflow always begins with a thorough risk assessment. This includes identifying potential hazards like sharp edges, hot metal, and sparks. I then implement the necessary safety measures, such as wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, a welding helmet (when welding), and hearing protection. Proper ventilation is also crucial, especially when welding or using power tools that generate dust.

Efficient workflow involves careful planning. I always sketch out the project beforehand, ensuring I have all the necessary materials and tools ready. This reduces downtime and improves accuracy. I organize my workspace to optimize workflow, keeping frequently used tools within easy reach and ensuring sufficient space to maneuver. This methodical approach minimizes errors and ensures a smoother, safer, and more productive process.

Q 24. Explain how to determine the correct size and type of bolt for a particular ironwork application.

Selecting the right bolt is critical for structural integrity. The process involves considering several factors:

- Load: Determine the tensile strength needed to withstand the forces the joint will experience. This depends on the weight being supported and any dynamic forces (vibration, movement).

- Material: The bolt material must be compatible with the ironwork and the environment. For example, stainless steel bolts are ideal for outdoor applications to resist corrosion.

- Diameter and Length: The bolt diameter should be sufficient to provide adequate shear strength, while the length ensures proper engagement with the joined materials. A general rule is to have at least a few threads extending beyond the nut.

- Thread Type and Pitch: The thread type and pitch (spacing between threads) should be appropriate for the application and ensure a secure grip. Fine threads offer better grip in softer materials.

For instance, a heavy-duty gate might require high-tensile bolts with a significant diameter, whereas a smaller, less stressed component might only need a standard bolt of smaller diameter.

Q 25. How do you ensure proper alignment and fitting of ironwork components?

Precise alignment and fitting are vital for both aesthetics and structural integrity. My approach involves a combination of techniques:

- Jigging and Fixtures: For complex assemblies, I use jigs and fixtures to hold components in the correct position while welding or bolting. This ensures accuracy and repeatability.

- Clamping and Support: When welding, I use clamps to hold pieces firmly in place, preventing warping or misalignment during the welding process.

- Measuring and Verification: Throughout the process, I use measuring tools like calipers, squares, and levels to verify alignment. This iterative checking ensures the final product meets specifications.

- Shimming: To correct minor misalignments, I use shims – thin pieces of metal – to create the necessary gap or offset.

Consider building a square frame. Using jigs, clamps and precise measuring will ensure the sides are perfectly square and the corners are at 90 degrees.

Q 26. What are the different types of welding processes suitable for ironwork, and when is each most appropriate?

Several welding processes are suitable for ironwork, each with its strengths and weaknesses:

- Shielded Metal Arc Welding (SMAW or Stick Welding): Versatile, relatively inexpensive equipment, good for outdoor use, but can produce less aesthetically pleasing welds compared to other methods.

- Gas Metal Arc Welding (GMAW or MIG Welding): Produces high-quality welds quickly, suitable for both thin and thick materials, but requires more expensive equipment and specialized shielding gas.

- Gas Tungsten Arc Welding (GTAW or TIG Welding): Ideal for high-quality, aesthetically pleasing welds, excellent control over the weld, but requires more skill and is generally slower than MIG welding.

The choice depends on the project’s requirements. For example, stick welding might be suitable for a robust outdoor fence, while TIG welding would be preferred for intricate metalwork requiring a high-quality finish. MIG welding is often the workhorse for general fabrication because of its speed and quality.

Q 27. Describe your experience in troubleshooting welding problems.

Troubleshooting welding problems requires a systematic approach. I first identify the problem by examining the weld visually. Common issues include porosity (small holes in the weld), lack of penetration (incomplete fusion of the base materials), excessive spatter, and undercut (a groove at the weld toe).

The cause is then investigated. Porosity can result from moisture in the welding wire or improper shielding gas coverage. Lack of penetration might be due to insufficient amperage, incorrect travel speed, or improper joint preparation. I adjust welding parameters like amperage, voltage, and travel speed according to the issue. If the problem persists, I check the condition of the welding equipment, inspect the filler material, and ensure proper joint preparation and cleanliness. Sometimes, a change in welding technique or the use of a different filler metal is necessary.

Q 28. How do you stay updated on the latest advancements and best practices in ironworking techniques and tools?

Staying current in ironworking involves continuous learning. I regularly attend industry conferences and workshops to learn about new techniques and tools. I also subscribe to trade publications and online forums, which provide valuable insights into best practices and emerging technologies. Furthermore, I actively seek opportunities to work on diverse projects, which allows me to expand my skills and adapt to new challenges. Online courses and manufacturer’s training resources are also invaluable for deepening my technical expertise.

A recent example was learning about new Flux-cored wire welding techniques that can increase speed and reduce spatter, resulting in significant time savings on a large project. Constant learning keeps my skills sharp and enhances my efficiency.

Key Topics to Learn for Ironworking Tools Interview

- Safety Procedures and Regulations: Understanding and applying relevant safety protocols for all ironworking tools, including PPE and hazard identification.

- Tool Selection and Usage: Knowing which tools are appropriate for specific tasks and demonstrating proficiency in their safe and effective operation. This includes understanding the limitations of each tool.

- Maintenance and Repair: Proficiency in inspecting, maintaining, and performing minor repairs on common ironworking tools. Knowing when to replace worn or damaged tools is crucial.

- Material Properties and Selection: Understanding the properties of various metals and how tool selection impacts the shaping and fabrication process. This includes considerations for different types of steel and other iron-based alloys.

- Measuring and Layout Techniques: Accurate measurement and marking techniques are essential for precise ironwork. Understanding different measuring tools and their applications is key.

- Welding and Cutting Techniques (as applicable): If relevant to the position, demonstrate knowledge of welding processes (e.g., MIG, TIG, stick) and cutting techniques (e.g., plasma, oxy-acetylene) related to ironwork.

- Troubleshooting and Problem Solving: The ability to diagnose and resolve common problems encountered during ironworking projects, showcasing practical experience and analytical skills.

- Blueprint Reading and Interpretation: Understanding and interpreting blueprints and technical drawings to accurately execute ironworking tasks.

Next Steps

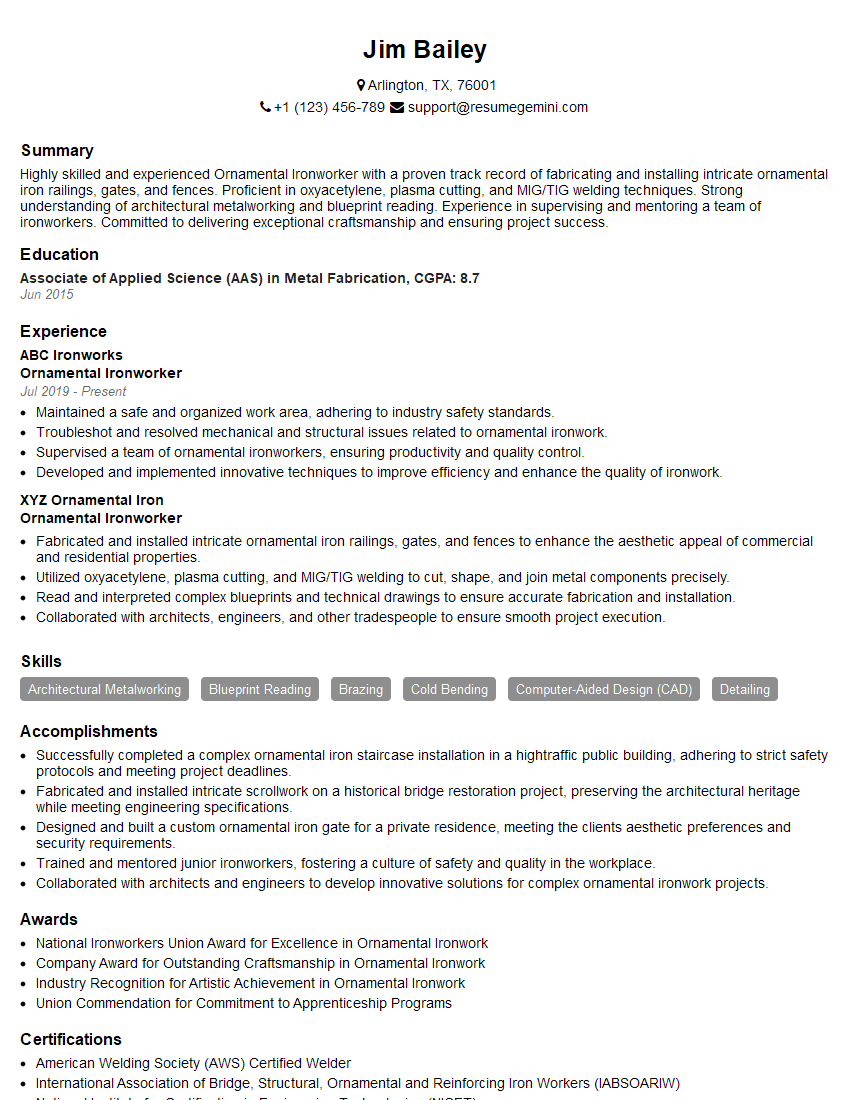

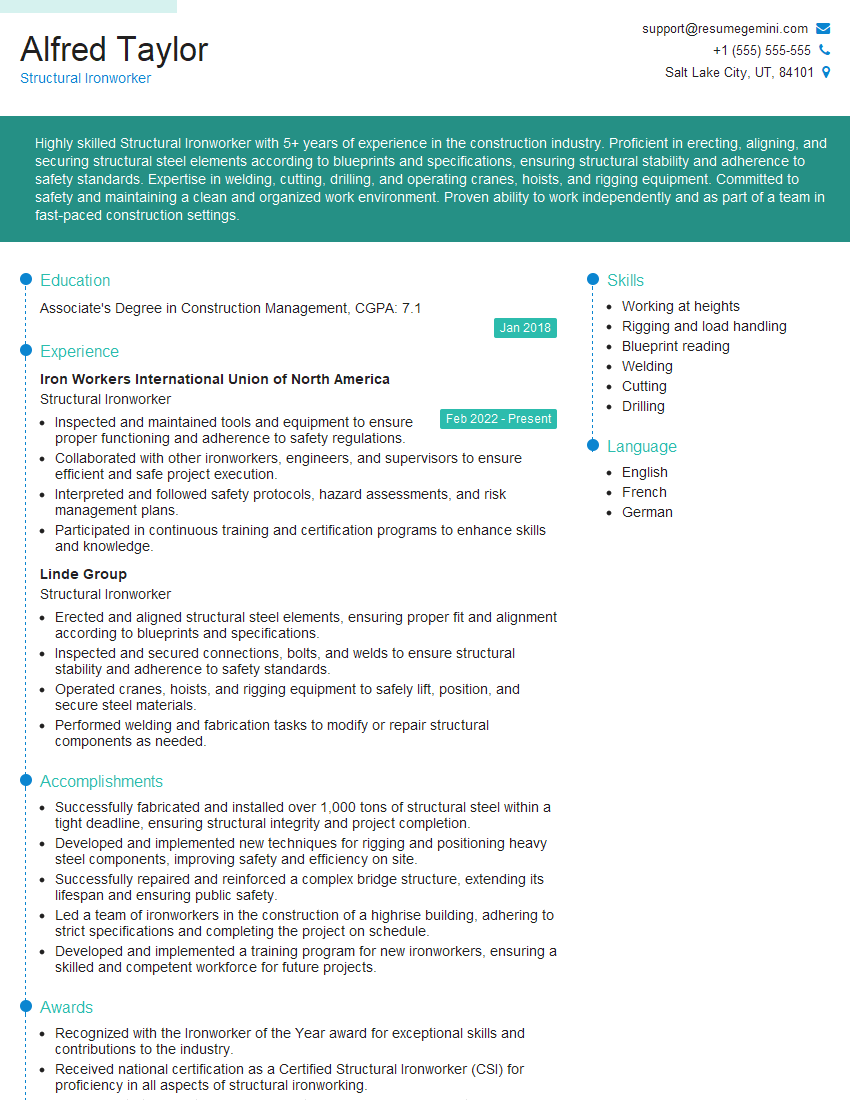

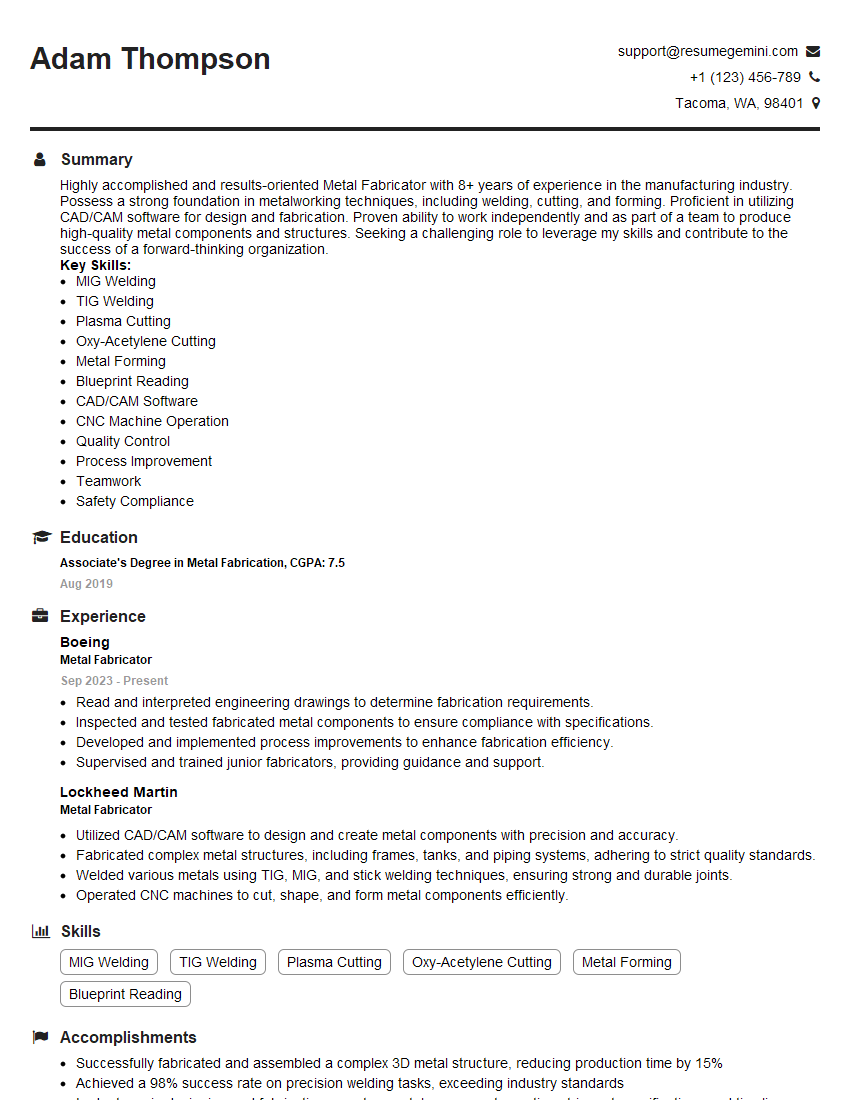

Mastering ironworking tools is essential for career advancement in this field. A strong understanding of these tools translates to increased efficiency, safety, and project success. To stand out to potential employers, creating an ATS-friendly resume is crucial. This will ensure your qualifications are effectively highlighted by applicant tracking systems. We recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides excellent tools and resources, and examples of resumes tailored to the Ironworking Tools field are available to help you get started. Invest the time to craft a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.