Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of coal industry regulations interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of coal industry regulations Interview

Q 1. Explain the key provisions of the Surface Mining Control and Reclamation Act (SMCRA).

The Surface Mining Control and Reclamation Act (SMCRA) of 1977 is the primary federal law in the United States regulating surface coal mining and reclamation. Its key provisions aim to protect the environment during and after mining operations. Think of it as a comprehensive rulebook for responsible coal mining.

- Regulation of Surface Mining Activities: SMCRA establishes a permitting system requiring operators to obtain permits before commencing surface coal mining. These permits include detailed plans for mine operations, including pre-mining environmental assessments, and reclamation plans.

- Reclamation Requirements: A critical aspect of SMCRA is its emphasis on land reclamation. This involves restoring mined land to a condition capable of supporting its pre-mining use or an alternative use approved by regulatory authorities. This includes topsoil replacement, re-vegetation, and water quality control measures. Imagine returning the land to a productive state, as close to its original condition as possible.

- Enforcement and Penalties: The act empowers federal and state regulatory agencies to inspect mines, enforce regulations, and impose penalties for violations. Non-compliance can result in significant fines and even mine closure.

- Protection of Public Health and Safety: SMCRA addresses potential health and safety risks associated with coal mining, including air and water pollution, and land instability. It mandates environmental monitoring and mitigation strategies.

- State Programs: SMCRA allows states to develop and implement their own regulatory programs, provided they meet or exceed the minimum federal standards. This creates a balance between federal oversight and state-level flexibility.

For example, SMCRA mandates the detailed assessment of potential impacts on water resources before mining starts, and requires comprehensive plans for managing those impacts throughout and after mining operations. This includes techniques like preventing sediment runoff and treating mine drainage.

Q 2. Describe the permitting process for a new coal mine in your state/region.

The permitting process for a new coal mine varies slightly by state, but generally involves several key stages. Let’s imagine a scenario in a state like West Virginia. First, the coal company would need to conduct extensive pre-mining studies including geological surveys, hydrological assessments, and biological inventories to understand the site’s baseline environmental conditions. Then, they’d prepare a detailed permit application that includes the mining plan, reclamation plan, and an environmental impact assessment.

This application is submitted to the state regulatory agency, which reviews it against the requirements of SMCRA and state-specific regulations. This review can take months, or even years, depending on the project’s complexity and the completeness of the application. Public comment periods are often included to ensure community input. Following this, the state agency may request revisions or additional information. Upon approval, the permit is granted. Post-permitting inspections and reporting are a critical part of the process, ensuring continued compliance.

Failure to meet the requirements can lead to permit denial or significant delays. The process requires a thorough understanding of relevant regulations and effective communication with regulatory authorities.

Q 3. What are the main environmental regulations impacting coal mining operations?

Numerous environmental regulations impact coal mining operations, aiming to minimize environmental damage. These regulations often overlap and interact, requiring a holistic approach to compliance.

- Clean Water Act (CWA): This act regulates water pollution, including discharge from coal mines. It requires permits for discharging pollutants into surface waters, and sets limitations on the types and amounts of pollutants that can be discharged. Think of it as setting limits on the ‘amount of dirt’ allowed in the water.

- Clean Air Act (CAA): The CAA addresses air pollution from coal mining activities, including dust and methane emissions. It sets limits on air emissions from mining operations and requires monitoring and reporting of emissions.

- Resource Conservation and Recovery Act (RCRA): RCRA manages hazardous waste generated from coal mining, such as coal ash and other byproducts. It dictates how these waste materials are handled, stored, and disposed of to prevent environmental contamination.

- Endangered Species Act (ESA): If threatened or endangered species are present near a mining site, the ESA requires assessment of potential impacts and the implementation of mitigation measures to protect these species.

It’s vital to note that these regulations are often interconnected. For example, addressing water pollution under the CWA might also require considering air quality impacts under the CAA, especially if dust from mining activities affects water quality.

Q 4. How do you ensure compliance with mine safety regulations?

Ensuring compliance with mine safety regulations is paramount. This involves a multi-faceted approach that integrates proactive measures with rigorous oversight.

- Comprehensive Safety Programs: We implement detailed safety programs that incorporate regular safety training for all employees, hazard assessments, and implementation of engineering controls to minimize risks. Think of this as a proactive approach to identify and mitigate hazards.

- Regular Inspections: Frequent inspections by both company personnel and regulatory agencies are vital for identifying and correcting potential safety hazards. This includes inspections of equipment, ventilation systems, and working conditions.

- Emergency Response Plans: We have comprehensive emergency response plans in place to deal with various scenarios, such as fires, roof collapses, and equipment malfunctions. Regular drills ensure that personnel are well-prepared to handle emergencies. These plans provide a structured response mechanism in case of an incident.

- Record Keeping and Reporting: Meticulous record-keeping of safety incidents, inspections, and training is crucial for demonstrating compliance and identifying areas for improvement. Accurate and timely reporting to regulatory agencies is also essential.

- Continuous Improvement: We actively seek ways to improve safety performance through data analysis, root cause investigations of incidents, and the implementation of best practices. This allows us to constantly refine our safety programs.

For instance, regular ventilation checks are essential to prevent methane buildup in underground mines, while strict adherence to fall protection protocols is vital in surface mining operations. We also use technologies like gas monitoring systems and proximity detection systems to enhance worker safety.

Q 5. What are the common methods for mitigating water pollution from coal mining?

Mitigating water pollution from coal mining involves a combination of preventative and remedial measures. These methods aim to control the release of pollutants into surface and groundwater.

- Sediment Control: Implementing measures such as sediment basins and check dams to capture and filter sediment runoff from mining areas prevents the clouding of streams and rivers. Think of sediment basins as large traps that catch sediment before it can escape.

- Mine Drainage Treatment: Mine drainage, often acidic and containing heavy metals, requires treatment before discharge. Various treatment techniques are used, including passive systems like constructed wetlands and active systems such as chemical neutralization and filtration. These systems work to remove pollutants and reduce the acidity of the water.

- Groundwater Monitoring: Regular monitoring of groundwater quality is crucial to detect any contamination from mining activities. This allows for prompt remedial action if contamination is found.

- Water Diversion: Diverting surface water away from mining areas prevents the contamination of water sources. This may involve the construction of diversion ditches or other water management structures.

- Land Reclamation Practices: Proper land reclamation after mining helps to restore the natural hydrology and minimize long-term impacts on water quality. This may include re-vegetation and topsoil replacement.

For example, in areas with highly acidic mine drainage, limestone is often added to neutralize the acidity, a common method of passive treatment.

Q 6. Explain the process of mine reclamation and its regulatory requirements.

Mine reclamation is the process of restoring mined land to a stable and productive state. It’s not just about filling holes; it’s about restoring the ecosystem’s functionality. SMCRA mandates detailed reclamation plans as part of the mining permit process. These plans must address several key areas:

- Topsoil Replacement: Replacing the original topsoil is crucial for supporting plant growth and restoring soil fertility. This layer is often carefully removed and stored before mining begins, allowing for later reapplication.

- Contouring and Grading: Reshaping the land to its approximate pre-mining contours helps to improve drainage and stability. This often involves removing highwalls and backfilling trenches.

- Revegetation: Planting native vegetation helps to stabilize the soil, prevent erosion, and restore the aesthetic value of the land. Plant selection is critical to ensure success and biodiversity.

- Water Management: Reclamation plans must address water management to prevent water pollution and erosion. This might include the construction of terraces or swales to control water runoff.

- Monitoring and Maintenance: Post-reclamation monitoring is essential to ensure that the reclaimed land is stable and productive. This often includes regular inspections and vegetation monitoring.

Regulatory requirements for reclamation are stringent and vary by state. Failure to meet reclamation obligations can result in significant penalties and enforcement actions. Reclamation success is often measured by factors such as vegetation cover, soil stability, and water quality.

Q 7. Describe your experience with handling environmental audits and inspections.

Throughout my career, I’ve been extensively involved in handling environmental audits and inspections related to coal mining operations. This experience has provided invaluable insights into regulatory compliance and risk management.

During audits, I’ve worked closely with environmental consultants and regulatory inspectors to review mine plans, environmental monitoring data, and compliance records. I’ve assisted in identifying areas of non-compliance and developing corrective action plans. These audits are not just about finding problems; they are crucial opportunities for improvement. They help us identify weaknesses in our environmental management system and refine our approach to reduce environmental risk.

Furthermore, I’ve participated in numerous regulatory inspections. These inspections assess our adherence to SMCRA and other relevant regulations, including water quality standards and air emission limits. Proactive collaboration with inspectors ensures that any issues are addressed promptly and efficiently. A strong understanding of the regulations is critical to ensuring a positive inspection outcome.

My experience with audits and inspections has significantly shaped our environmental management practices. It has strengthened our commitment to environmental compliance and enabled us to proactively mitigate environmental risks, ensuring sustainable and responsible coal mining operations.

Q 8. How do you manage and report on environmental data from a coal mine?

Managing and reporting environmental data from a coal mine is a multifaceted process crucial for compliance and environmental stewardship. It begins with meticulous data collection at the source. This involves continuous monitoring of various parameters such as water quality (pH, suspended solids, heavy metals), air quality (particulate matter, sulfur dioxide, nitrogen oxides), and noise levels. We utilize a combination of automated monitoring systems and manual sampling, ensuring data accuracy and reliability.

This data is then meticulously recorded, often using specialized software designed for environmental management. The software typically includes features for data validation, quality control, and reporting. Regular audits are conducted to ensure data integrity. Finally, comprehensive reports are generated, adhering to regulatory requirements, and submitted to relevant agencies such as the EPA and state environmental protection departments. These reports detail the collected data, any deviations from permitted limits, and corrective actions taken. For instance, if water quality parameters exceed permitted limits, we’d detail the exceedances, the root cause investigation, and the implemented remediation plan, including any water treatment measures implemented.

Think of it like maintaining a detailed health record for the mine – constantly monitoring vital signs and reporting any abnormalities. This systematic approach ensures not only regulatory compliance but also facilitates proactive environmental protection.

Q 9. What are the health risks associated with coal mining, and how are they mitigated?

Coal mining presents numerous health risks to workers, broadly categorized into respiratory illnesses, musculoskeletal disorders, and exposure to hazardous materials. Black lung disease (coal workers’ pneumoconiosis), caused by inhaling coal dust, is a severe and potentially fatal respiratory illness. Silicosis, caused by inhaling silica dust, is another serious lung disease. Musculoskeletal injuries, such as back injuries and strains, are common due to the physically demanding nature of the work. Exposure to methane gas, radon, and other hazardous substances also poses significant health risks.

Mitigation strategies involve a multi-pronged approach: Engineering controls, such as improved ventilation systems to reduce dust and gas concentrations, and the use of safer mining techniques. Administrative controls include implementing strict safety protocols, regular health screenings for workers, and providing mandatory safety training. Personal protective equipment (PPE), including respirators, safety helmets, and protective clothing, is mandatory for all workers. Regular monitoring of air quality within the mine is crucial to ensure effective control measures and early detection of any hazardous gas or dust levels. For example, we might use continuous monitoring systems to track methane levels and implement immediate ventilation adjustments if levels exceed safety thresholds. We also mandate rigorous respiratory protection programs, including fit testing and regular health checks for respiratory issues.

Q 10. Explain the role of the Mine Safety and Health Administration (MSHA).

The Mine Safety and Health Administration (MSHA) is a U.S. government agency responsible for enforcing safety and health regulations in mines. Their role is paramount in protecting the lives and health of miners. MSHA sets mandatory safety and health standards for mines, conducts inspections to ensure compliance, investigates accidents and fatalities, and provides training and education to mine operators and workers. They hold mine operators accountable for maintaining a safe working environment and impose penalties for violations.

Think of MSHA as the ‘safety police’ for the mining industry. Their inspections are thorough and unannounced, covering all aspects of mine safety, from ventilation and ground control to equipment maintenance and emergency preparedness. MSHA’s authority extends to both coal and non-coal mines, ensuring a consistent level of safety across the industry. Their work is essential in reducing workplace accidents and protecting miners’ health.

Q 11. How do you ensure compliance with air quality regulations related to coal mining?

Ensuring compliance with air quality regulations related to coal mining requires a comprehensive approach. We begin by obtaining necessary permits from the EPA and state agencies, which outline specific emission limits for various pollutants. These limits are based on the type of mining operation and its location. Continuous emission monitoring systems are installed at various points in the mining operation to track emissions. Data from these systems is regularly reviewed to ensure compliance. Regular maintenance of equipment, such as dust suppression systems and scrubbers, is crucial to maintain effective emission controls. We also implement strategies to minimize fugitive dust emissions, such as using dust suppressants on haul roads and implementing effective water management practices.

Regular audits are conducted, both internally and by external agencies, to evaluate the effectiveness of our air quality control measures. In case of any exceedances, we conduct a thorough investigation to determine the cause and implement corrective actions. Detailed records of all emissions data, maintenance activities, and corrective actions are kept for submission to the regulatory agencies. It’s a proactive strategy, regularly checking and adjusting our approach to stay within the prescribed limits. For example, if particulate matter emissions exceed limits due to heavy equipment operation, we’d investigate whether our dust suppression system is functioning optimally, and if not, implement necessary repairs and maintenance.

Q 12. Describe your experience with handling regulatory agency interactions.

My experience with regulatory agency interactions is extensive. I have worked closely with the MSHA, the EPA, and various state environmental agencies throughout my career. This has involved submitting permits, responding to inspection findings, negotiating compliance schedules, and participating in agency-led training programs. I’ve developed strong relationships with these agencies built on mutual respect, open communication, and a commitment to compliance. For example, during a recent MSHA inspection, we identified a minor violation related to equipment maintenance records. We immediately addressed the issue, implemented corrective actions, and proactively worked with the inspector to ensure complete compliance.

Effective communication is key in these interactions. Clearly articulating our compliance strategies, actively participating in agency discussions, and demonstrating a proactive approach to safety and environmental protection are crucial. I believe in transparent and collaborative relationships with regulators, viewing them not just as enforcement bodies but as partners in ensuring a safe and environmentally responsible mining operation. Successful interactions are built on mutual trust and a shared commitment to safeguarding both workers and the environment.

Q 13. What are the key differences between state and federal coal mining regulations?

Federal and state coal mining regulations work in tandem, but there are key differences. Federal regulations, primarily established by the MSHA and the EPA, provide a baseline level of safety and environmental protection applicable nationwide. These regulations address issues such as mine safety standards, air and water quality, and reclamation requirements. State regulations often build upon federal regulations, adding more stringent requirements or addressing specific local environmental concerns. States may have different permitting processes, reclamation standards, or water quality criteria, reflecting unique geographical and environmental conditions.

For instance, a state might have stricter limits on water discharge from mining operations due to sensitive local ecosystems. Effective compliance necessitates understanding both federal and state-specific rules, ensuring full compliance with all applicable regulations. This requires navigating different agency procedures, permit applications, and reporting requirements. It’s like following a layered set of instructions – the federal regulations provide the core guidelines, and state regulations add specific regional considerations.

Q 14. How do you manage risks associated with coal mine subsidence?

Coal mine subsidence, the sinking of the ground surface due to underground mining activities, presents a significant risk. Management of this risk requires a multi-pronged approach starting with careful mine planning and design. This involves utilizing advanced geotechnical engineering techniques to assess ground stability and predict potential subsidence areas. Ground control measures, such as backfilling of voids and implementing appropriate support systems within the mine, are crucial in preventing or minimizing subsidence. Pre-mining surveys are conducted to map existing structures and utilities to assess their vulnerability. Surface monitoring systems, utilizing instruments like inclinometers and extensometers, are deployed to detect ground movement and provide early warning signs of potential subsidence.

In addition to these proactive measures, we develop comprehensive subsidence management plans outlining procedures for addressing subsidence events. This includes establishing communication protocols with impacted property owners and designing remediation strategies to repair any damage caused by subsidence. For instance, a plan might include pre-emptive measures like grouting techniques to stabilize the ground before significant subsidence occurs. Regular monitoring of the ground surface and prompt responses to any signs of instability are critical. Proper communication and collaboration with local communities are essential in managing the risks and mitigating the potential impacts of coal mine subsidence.

Q 15. Explain the importance of proper waste management in coal mining operations.

Proper waste management in coal mining is paramount for environmental protection and regulatory compliance. It’s not just about disposing of waste; it’s about minimizing its environmental impact throughout its lifecycle – from generation to final disposal. Improper management leads to water contamination, air pollution, soil degradation, and risks to human health.

- Minimizing Waste Generation: This involves optimizing mining processes to reduce the amount of waste produced in the first place. For instance, using selective mining techniques to extract only the valuable coal seams, leaving behind less overburden to dispose of.

- Waste Characterization and Treatment: Different types of coal mine waste (e.g., overburden, mine tailings, fly ash) require different treatment methods. Overburden, for example, might require re-contouring and revegetation to prevent erosion and land degradation. Tailings ponds need careful design and management to prevent seepage and contamination of water sources.

- Safe Disposal and Monitoring: Waste disposal sites must be designed and constructed to meet stringent regulatory requirements. This includes proper lining, leachate collection systems, and ongoing monitoring of groundwater quality to detect and mitigate any contamination. Regular inspections and reporting are crucial.

Imagine a scenario where a mining company fails to properly manage its tailings pond. A breach could release toxic substances into a nearby river, causing significant environmental damage and potentially harming local communities. This highlights the critical need for meticulous waste management planning and execution.

Career Expert Tips:

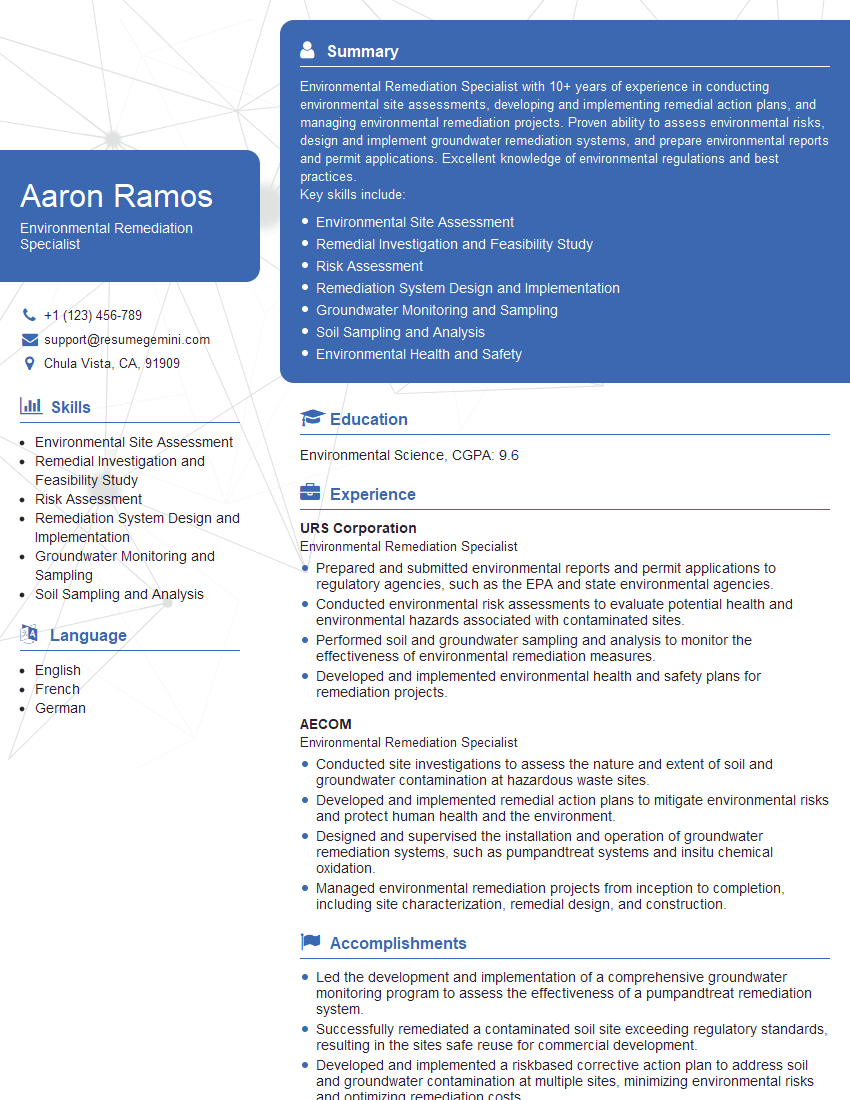

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle non-compliance issues in coal mining operations?

Handling non-compliance in coal mining requires a multi-pronged approach emphasizing immediate corrective action, root cause analysis, and preventative measures. The severity of the non-compliance dictates the response.

- Immediate Corrective Action: If a violation is identified (e.g., exceeding permitted emission limits), immediate steps must be taken to rectify the situation. This might involve shutting down equipment, implementing emergency controls, or modifying operational procedures.

- Root Cause Analysis: A thorough investigation is necessary to determine the underlying cause of the non-compliance. This often involves reviewing operational records, conducting site inspections, and interviewing personnel. The goal is to prevent similar incidents from occurring.

- Corrective and Preventative Actions: Once the root cause is identified, corrective actions are implemented to address the immediate problem. Preventative measures are crucial to ensure future compliance. This could involve implementing new training programs, upgrading equipment, or revising operational procedures.

- Reporting and Documentation: All non-compliance incidents must be properly documented and reported to the relevant regulatory authorities within stipulated timeframes. Transparent communication with authorities is vital.

- Enforcement Actions: Depending on the severity of the violation, regulatory agencies might impose penalties (fines, suspension of operations) or even initiate legal proceedings.

For instance, if a mine consistently exceeds its water discharge limits, the regulatory response might escalate from warnings to significant fines and potential operational restrictions until the problem is resolved and preventative measures are put in place.

Q 17. Describe your understanding of mine closure planning and regulatory requirements.

Mine closure planning is a critical aspect of responsible coal mining. It involves systematically decommissioning a mine and restoring the affected land to a safe and environmentally acceptable condition. Regulatory requirements vary by jurisdiction but generally include:

- Site Characterization: A thorough assessment of the site’s environmental conditions, including soil, water, and air quality, is crucial for developing an effective closure plan.

- Reclamation Plan Development: The plan details the steps involved in restoring the land, such as removing infrastructure, backfilling voids, re-contouring the land, and implementing revegetation programs. It must meet specific regulatory standards.

- Financial Assurance: Mining companies are typically required to demonstrate financial capacity to fund mine closure activities. This is often achieved through bonds, trusts, or other financial instruments.

- Regulatory Approvals: The closure plan must be submitted to and approved by the relevant regulatory authorities before closure activities commence.

- Post-Closure Monitoring: Once the mine is closed, long-term monitoring is essential to assess the effectiveness of reclamation efforts and to ensure compliance with regulatory requirements.

Imagine a scenario where a company fails to secure adequate financial assurance before mine closure. If the company encounters financial difficulties, the restoration costs might fall on the government or taxpayers, highlighting the importance of robust financial planning for mine closure.

Q 18. What are the legal implications of violating coal mining regulations?

Violating coal mining regulations carries significant legal implications, including:

- Fines and Penalties: Significant financial penalties can be imposed, varying based on the severity and nature of the violation.

- Operational Restrictions: Regulatory agencies might issue cease-and-desist orders, temporarily or permanently suspending mining operations.

- Criminal Charges: In cases of gross negligence, willful misconduct, or serious environmental damage, criminal charges might be filed against company officers and employees.

- Civil Liability: Companies can face civil lawsuits from individuals or groups affected by their non-compliance, leading to substantial financial liabilities.

- Reputational Damage: Environmental violations can severely damage a company’s reputation, leading to decreased investor confidence and market share.

For example, repeated violations of water quality standards could result in hefty fines, temporary closure of the mine, and legal action by environmental groups representing affected communities.

Q 19. How do you integrate sustainability considerations into coal mining operations?

Integrating sustainability considerations into coal mining is no longer optional; it’s a necessity for long-term viability and social license to operate. This requires a holistic approach:

- Minimizing Environmental Impact: Employing best practices in waste management, water conservation, and air quality control is crucial. This includes utilizing advanced technologies to reduce emissions and improve efficiency.

- Rehabilitation and Reclamation: Implementing comprehensive land reclamation plans to restore mined areas to a productive state, minimizing long-term environmental damage.

- Community Engagement: Active engagement with local communities to address their concerns, obtain their support, and mitigate any negative impacts on their livelihoods.

- Climate Change Mitigation: Exploring and implementing strategies to reduce greenhouse gas emissions associated with coal mining and utilization. This could involve carbon capture and storage technologies or investments in renewable energy.

- Economic Sustainability: Ensuring the economic viability of the operation through efficient resource management, diversification of revenue streams, and job creation within the community.

A sustainable coal mine might prioritize the use of renewable energy for its operations, implement advanced dust suppression techniques, and invest in reforestation projects to offset its environmental footprint.

Q 20. Describe your experience with developing and implementing environmental management systems.

Developing and implementing Environmental Management Systems (EMS) like ISO 14001 is crucial for structured environmental performance in coal mining. My experience includes:

- EMS Development: Leading the creation of comprehensive EMS frameworks tailored to the specific operational context and regulatory requirements of various coal mining projects. This involves identifying environmental aspects and impacts, setting environmental objectives and targets, and documenting procedures.

- Implementation and Training: Implementing the EMS across all relevant departments and providing extensive training to personnel to ensure understanding and compliance. This includes conducting regular audits and inspections.

- Performance Monitoring and Reporting: Establishing systems for monitoring environmental performance indicators (KPIs) such as water usage, emissions, and waste generation. This data is used to track progress, identify areas for improvement, and prepare regulatory reports.

- Continuous Improvement: Implementing a continuous improvement process to regularly review and update the EMS based on performance data, audits, and changing regulatory requirements.

In one project, we implemented an EMS that resulted in a 15% reduction in water consumption and a 10% decrease in greenhouse gas emissions, demonstrating the tangible benefits of a well-structured and implemented EMS.

Q 21. Explain the role of stakeholder engagement in managing coal mining impacts.

Stakeholder engagement is vital for responsible coal mining, as it ensures that the operations are aligned with the interests and concerns of all affected parties. Effective stakeholder engagement involves:

- Stakeholder Identification: Identifying all relevant stakeholders, including local communities, indigenous groups, environmental organizations, government agencies, and investors.

- Communication and Consultation: Establishing transparent and open communication channels to share information and actively solicit feedback from stakeholders. This could involve public forums, workshops, and individual consultations.

- Conflict Resolution: Developing mechanisms to address and resolve conflicts that may arise between stakeholders and the mining company.

- Collaboration and Partnership: Building collaborative relationships with stakeholders to develop mutually beneficial solutions that address environmental and social concerns.

- Grievance Mechanisms: Establishing processes for addressing complaints and grievances related to mining operations.

For example, a mining company might partner with a local community to develop a skills training program for former miners, ensuring a smooth transition away from mining and mitigating potential social conflicts during mine closure.

Q 22. How do you assess and mitigate the risks of methane emissions from coal mines?

Methane emissions from coal mines pose a significant environmental and safety risk. Assessing and mitigating these risks requires a multi-pronged approach focusing on prevention, detection, and control.

Assessment involves regularly monitoring methane levels using various technologies, including fixed and portable sensors. We analyze ventilation patterns to identify areas prone to methane accumulation. Geological surveys help to map out potential methane sources within the mine. Data analysis is crucial, allowing us to pinpoint high-risk zones and trends.

Mitigation strategies focus on ventilation improvements to dilute and remove methane. This might involve installing additional ventilation shafts, fans, or adjusting airflow patterns. Methane drainage systems are critical – these systems capture methane before it enters the mine atmosphere, often piping it to the surface for combustion or utilization. Furthermore, we implement strict operational protocols to prevent ignition sources, including regular inspections and maintenance of equipment and proper training for all personnel.

For example, in a previous project, we identified a section of a mine with unexpectedly high methane concentrations. By analyzing ventilation data and geological surveys, we determined that a previously unknown seam was contributing. Installing a new methane drainage system in that specific area significantly reduced emissions and improved mine safety.

Q 23. What are the key regulatory requirements for handling coal ash?

Coal ash, a byproduct of coal combustion, contains heavy metals and other hazardous substances. Regulations governing its handling are stringent and aim to protect human health and the environment. Key requirements vary by jurisdiction but generally include:

- Storage: Coal ash must be stored in lined impoundments or landfills to prevent leaching of contaminants into groundwater. These structures are subject to regular inspections and monitoring to ensure integrity.

- Disposal: Many regulations now prohibit the disposal of coal ash in unlined landfills or surface impoundments. Beneficial reuse options, such as using coal ash in concrete or road construction, are increasingly encouraged.

- Monitoring: Groundwater and surface water around coal ash storage facilities must be regularly monitored for contamination. This often involves collecting samples and analyzing them for specific pollutants.

- Reporting: Facilities must submit regular reports to regulatory agencies detailing their coal ash handling practices, including storage conditions, monitoring results, and any incidents or remediation efforts.

Failure to comply with these regulations can result in substantial fines and legal action. The specifics often depend on the jurisdiction and the nature of the violation, for example, a leak in a lined impoundment would trigger immediate remediation and a stringent investigation from the relevant regulatory body.

Q 24. Describe your experience with conducting environmental impact assessments.

I have extensive experience in conducting Environmental Impact Assessments (EIAs) for coal mining projects. This involves a systematic process to identify, predict, evaluate, and mitigate the potential environmental impacts of a project.

My typical approach involves:

- Scoping: Defining the project boundaries and identifying potential environmental impacts based on the project’s design and the site’s characteristics.

- Baseline Studies: Collecting data on the existing environmental conditions, including air and water quality, biodiversity, and socio-economic factors.

- Impact Prediction: Using various modeling techniques and expert judgment to predict the magnitude and significance of potential impacts.

- Mitigation Planning: Developing plans to avoid, minimize, or compensate for significant negative impacts.

- Reporting: Preparing a comprehensive EIA report summarizing the findings and recommendations.

For example, in a recent EIA for an open-pit coal mine, we identified potential impacts on water resources due to runoff from the mining activities. We developed a mitigation plan involving the construction of sediment ponds, water treatment systems, and a robust monitoring program to minimize water pollution. The report thoroughly documented our assessment and proposed measures for approval, which subsequently guided the project’s development.

Q 25. How do you ensure data accuracy and integrity in regulatory reporting?

Data accuracy and integrity are paramount in regulatory reporting for the coal industry. We employ several strategies to ensure this:

- Data Validation: Implementing rigorous data validation checks at every stage, from data collection to reporting. This includes cross-checking data sources and using automated validation tools to identify anomalies.

- Chain of Custody: Maintaining a clear and auditable chain of custody for all samples and data. This ensures the traceability and integrity of the data.

- Data Management System: Using a robust data management system that incorporates version control and access controls to prevent unauthorized modification of data.

- Regular Audits: Conducting regular internal and external audits of our data management processes and reporting procedures.

- Calibration and Maintenance: Ensuring that all monitoring equipment is properly calibrated and maintained to guarantee accuracy of measurements.

For instance, we use specialized software to manage environmental monitoring data, incorporating automated checks to flag outliers or inconsistencies that could indicate measurement errors or data entry mistakes. These checks are vital for maintaining data integrity and ensuring compliant reporting to regulatory authorities.

Q 26. Explain your understanding of the Clean Air Act’s impact on the coal industry.

The Clean Air Act (CAA) has profoundly impacted the coal industry, primarily by setting limits on air pollutants emitted from coal-fired power plants and other sources. This has led to significant changes in the industry, including:

- Increased Scrutiny: The CAA mandates stringent monitoring and reporting of emissions, leading to greater scrutiny of coal operations.

- Technological Advancements: To comply with the CAA’s emission standards, the industry has invested in technologies like scrubbers and other emission control equipment, which significantly reduces pollutants.

- Shifting Energy Mix: The stricter regulations under the CAA have contributed to a shift towards cleaner energy sources, such as natural gas and renewable energy, impacting the demand for coal.

- Economic Implications: Compliance with the CAA involves substantial capital investment and operating costs for coal companies, impacting their profitability and competitiveness.

The CAA’s impact is ongoing and constantly evolving as new regulations are introduced and technological advancements occur. Understanding these regulations is critical to operating within compliance and navigating the changing landscape of the energy sector.

Q 27. How do you incorporate best practices for mine safety and health into daily operations?

Mine safety and health are paramount. Incorporating best practices into daily operations is not just a matter of compliance but a commitment to our workforce’s well-being. We achieve this through:

- Comprehensive Training: Providing regular and comprehensive safety training to all employees, covering topics like hazard recognition, emergency procedures, and the use of safety equipment.

- Hazard Identification and Control: Implementing a robust hazard identification and control program, identifying potential hazards through risk assessments and implementing effective controls to eliminate or mitigate them.

- Regular Inspections: Conducting routine inspections of mine workings, equipment, and facilities to identify and address safety hazards.

- Emergency Response Planning: Developing and regularly practicing comprehensive emergency response plans to deal with various scenarios, from mine fires to ground control incidents.

- Communication and Feedback: Establishing open channels of communication between management and employees to encourage reporting of safety concerns and feedback on safety practices.

For example, we implemented a near-miss reporting system where employees can report any incident with the potential for injury or damage, without fear of reprimand. Analysis of these reports helps us proactively identify and address potential hazards before they lead to accidents.

Q 28. Describe your experience with emergency response planning and execution in a coal mining context.

Emergency response planning and execution in coal mining is critical due to the inherent risks. My experience includes developing and implementing comprehensive emergency response plans that address various scenarios, such as mine fires, roof collapses, flooding, and methane explosions.

Our plans include:

- Hazard Identification: Identifying potential hazards and assessing their likelihood and potential consequences.

- Emergency Procedures: Developing detailed procedures for dealing with each identified hazard, including evacuation plans, communication protocols, and rescue procedures.

- Training and Drills: Regularly training employees on emergency procedures and conducting drills to ensure that everyone is familiar with their roles and responsibilities.

- Communication Systems: Establishing reliable communication systems for coordinating rescue efforts and keeping personnel informed during an emergency.

- Emergency Equipment: Ensuring that adequate emergency equipment is available and properly maintained, including rescue equipment, first aid supplies, and communication devices.

In one instance, we successfully responded to a mine fire using our pre-planned procedures, minimizing damage and ensuring the safety of all personnel. The effective communication, coordinated rescue efforts, and rapid response directly stemmed from the meticulously planned and rigorously practiced emergency response plan.

Key Topics to Learn for Knowledge of Coal Industry Regulations Interview

- Mine Safety and Health Administration (MSHA) Regulations: Understand the core principles of MSHA regulations, including permissible exposure limits (PELs) for respirable dust and other hazards, ventilation requirements, and emergency response protocols. Consider how these regulations impact daily operations and risk management.

- Environmental Protection Agency (EPA) Regulations: Familiarize yourself with EPA regulations concerning water quality, air emissions (including greenhouse gases), and waste disposal from coal mining activities. Think about how compliance impacts operational costs and environmental stewardship.

- Surface Mining Control and Reclamation Act (SMCRA): Grasp the key provisions of SMCRA, including pre-mining planning, reclamation requirements, and permitting processes. Analyze how these regulations influence land use and long-term environmental responsibility.

- Coal Mine Planning and Design: Explore the regulatory requirements for mine design, including considerations for ground control, ventilation, and water management. Understand the practical application of these regulations in minimizing risks and optimizing production.

- Permitting and Compliance: Develop a strong understanding of the permitting process, reporting requirements, and enforcement actions related to coal industry regulations. Practice problem-solving scenarios related to permit applications and compliance issues.

- Recent Amendments and Updates: Stay abreast of any recent changes or proposed amendments to relevant regulations. This demonstrates your commitment to continuous learning and staying current within the industry.

Next Steps

Mastering knowledge of coal industry regulations is crucial for advancing your career in this sector. A strong understanding of these regulations demonstrates your commitment to safety, environmental responsibility, and regulatory compliance – highly valued attributes by employers. To significantly improve your job prospects, create an ATS-friendly resume that effectively highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the coal industry. Examples of resumes tailored to showcase Knowledge of coal industry regulations are available to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.