Unlock your full potential by mastering the most common Knowledge of Welding Standards and Codes interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Knowledge of Welding Standards and Codes Interview

Q 1. What are the key differences between AWS D1.1 and ASME Section IX?

AWS D1.1 and ASME Section IX are both prominent welding codes, but they serve different purposes. Think of it like this: D1.1 is a structural welding code, focusing on the design and fabrication of welded structures like bridges and buildings. ASME Section IX, on the other hand, is a boiler and pressure vessel code, concentrating on the qualification of welding procedures and personnel for applications where safety is paramount, such as in power plants or refineries.

- AWS D1.1 (Structural Welding Code): Deals with the design, fabrication, and inspection of welded steel structures. It provides requirements for welding procedures, welder qualification, and inspection criteria to ensure structural integrity.

- ASME Section IX (Welding and Brazing Qualifications): Focuses solely on the qualification of welding procedures and welders. It establishes detailed requirements for performing Procedure Qualification Records (PQRs) and welder performance qualifications, ensuring consistent and reliable welds in high-pressure applications. It doesn’t dictate design aspects.

In short, D1.1 tells you *how to build* a welded structure, while Section IX tells you *how to qualify* the welding process to ensure its reliability for critical applications. Often, projects might use both – D1.1 for overall structural requirements and Section IX for qualifying the welding procedures used to meet those requirements.

Q 2. Explain the importance of WPS (Welding Procedure Specification) and PQR (Procedure Qualification Record).

The WPS (Welding Procedure Specification) and PQR (Procedure Qualification Record) are indispensable for ensuring consistent weld quality. Imagine baking a cake: the WPS is your recipe, detailing every step, while the PQR is the proof that your recipe works and produces a consistently good cake.

- WPS (Welding Procedure Specification): This document outlines the specific parameters for a given welding process. It includes details like the type of welding process, base materials, filler materials, preheat temperature, interpass temperature, welding positions, and other essential variables. It’s a blueprint for consistent welding.

- PQR (Procedure Qualification Record): This is the documented proof that the WPS is valid. It’s created by performing test welds according to the WPS and then subjecting those welds to rigorous testing, including mechanical tests and often Non-Destructive Testing (NDT). The PQR records the results of these tests, demonstrating that the WPS consistently produces welds meeting the required quality standards.

Without a qualified WPS and corresponding PQR, you can’t guarantee the integrity of your welds. This is crucial for ensuring safety and meeting project specifications, particularly in critical applications.

Q 3. Describe the various types of welding defects and their causes.

Welding defects are imperfections that compromise the strength and integrity of a weld. They can be caused by various factors including improper welding techniques, inadequate equipment, or poor material preparation.

- Porosity: Tiny holes within the weld metal, often caused by gas entrapment during welding.

- Cracks: Fractures in the weld metal or the heat-affected zone (HAZ), typically caused by rapid cooling, residual stresses, or hydrogen embrittlement.

- Incomplete Fusion/Penetration: The weld metal doesn’t fully fuse with the base material, creating a weak point.

- Undercutting: A groove melted into the base material at the edge of the weld, reducing the effective weld cross-section.

- Slag Inclusion: Trapped slag (molten flux) within the weld metal, weakening the weld.

- Overlap: Excessive weld metal extending beyond the weld joint.

Identifying and understanding the cause of welding defects is key to preventing them in future welds. Careful procedural control, proper welder training, and thorough inspection are vital.

Q 4. How do you interpret a welding symbol?

Welding symbols are a standardized way to communicate complex weld joint details concisely on engineering drawings. They’re a kind of shorthand for welders and inspectors.

A typical welding symbol includes several elements:

- Reference Line: The horizontal line from which other elements are drawn.

- Arrow: Indicates the location of the weld on the joint.

- Basic Weld Symbol: Represents the type of weld (e.g., fillet weld, groove weld).

- Supplementary Symbols: Indicate additional details, such as weld size, length, spacing, and finish.

- Dimensions and other specifications: Provide exact measurements of the weld and other related details.

- Tail (opposite arrow): Specifies details related to the other side of the joint.

Understanding these elements is crucial for proper weld preparation and execution. Each element conveys precise information, and misinterpreting them can lead to significant errors. Refer to the relevant welding standards (e.g., ANSI Y14.1) for a complete guide to interpretation.

Q 5. What are the common NDT (Non-Destructive Testing) methods used for weld inspection?

Non-destructive testing (NDT) is vital for evaluating weld quality without damaging the weld. Several methods are commonly used:

- Visual Inspection (VT): The simplest method, involving visual examination for surface defects.

- Radiographic Testing (RT): Uses X-rays or gamma rays to detect internal defects like porosity and cracks.

- Ultrasonic Testing (UT): Employs high-frequency sound waves to detect internal flaws and measure weld thickness.

- Magnetic Particle Testing (MT): Uses magnetic fields to detect surface and near-surface defects in ferromagnetic materials.

- Dye Penetrant Testing (PT): A liquid penetrant is used to reveal surface-breaking defects.

The choice of NDT method depends on the type of weld, material, and the specific defects being investigated. Often, a combination of methods provides the most comprehensive evaluation.

Q 6. Explain the significance of pre-heat and interpass temperature control in welding.

Pre-heat and interpass temperature control are critical for preventing cracking and ensuring good weld quality, especially in thicker sections or with certain materials like high-strength steels.

- Pre-heat: Heating the base material before welding reduces the cooling rate, minimizing the formation of residual stresses and the risk of hydrogen cracking. The required pre-heat temperature depends on the material, thickness, and welding process.

- Interpass Temperature: Maintaining a specific temperature between weld passes helps manage the cooling rate, preventing cracking and ensuring uniform weld properties. This is especially important for multi-pass welds.

Insufficient pre-heat or interpass temperature control can lead to brittle welds susceptible to cracking, significantly reducing the structural integrity of the weldment. Proper temperature monitoring and control are essential for producing high-quality, safe welds.

Q 7. What are the safety precautions you must follow during welding operations?

Welding is inherently hazardous, and safety must always be the top priority. Key precautions include:

- Eye and Face Protection: Always wear appropriate eye protection (e.g., welding helmet with appropriate shade) to protect against intense light and sparks.

- Respiratory Protection: Use a respirator or ventilation system to avoid inhaling welding fumes, which can be toxic.

- Clothing Protection: Wear flame-resistant clothing to protect against burns and sparks.

- Fire Prevention: Ensure the welding area is free of flammable materials and have a fire extinguisher readily available.

- Electrical Safety: Use properly grounded equipment and avoid contact with energized components.

- Confined Space Safety: If welding in confined spaces, ensure adequate ventilation and monitor oxygen levels.

- Proper Housekeeping: Keep the welding area clean and organized to prevent tripping hazards.

Following these safety measures is crucial to prevent injuries and ensure a safe working environment. Regular safety training and adherence to safety protocols are paramount.

Q 8. What is the role of a Welding Inspector?

A Welding Inspector plays a crucial role in ensuring the quality, safety, and integrity of welded structures. Think of them as the ‘quality control’ experts for welding. Their primary responsibility is to verify that welding procedures are followed correctly, and that the final welds meet the required standards and codes. This involves inspecting welds visually, using non-destructive testing (NDT) methods, and reviewing welding procedures and documentation. They’re essentially the gatekeepers, ensuring that a structurally sound and safe product is delivered.

Their tasks include:

- Visual Inspection: Checking for surface defects, cracks, porosity, and other visual imperfections.

- Non-Destructive Testing (NDT): Employing methods like radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), and liquid penetrant testing (PT) to detect internal flaws.

- Procedure Qualification: Reviewing and approving welding procedures to ensure they comply with relevant codes and standards.

- Welder Qualification: Overseeing welder qualification tests to ensure welders possess the necessary skills.

- Documentation Review: Checking welding records, logs, and other documentation for accuracy and completeness.

In essence, a Welding Inspector acts as a critical link between the welding process and structural integrity, guaranteeing safety and reliability.

Q 9. How do you handle non-conformances discovered during welding inspection?

Discovering a non-conformity during welding inspection requires a systematic approach. Imagine finding a crack in a crucial weld – you can’t just ignore it! My approach involves these key steps:

- Identification and Documentation: Thoroughly document the non-conformity, including its location, type, size, and any other relevant details. High-quality photographs are essential.

- Severity Assessment: Determine the severity of the non-conformity based on applicable codes and standards (e.g., ASME Section IX, AWS D1.1). This dictates the necessary corrective action.

- Notification: Inform the relevant personnel, including the welding supervisor and project manager, about the non-conformity. This ensures timely and appropriate action.

- Corrective Action: Decide on the appropriate corrective action, which might range from minor repairs to complete weld removal and replacement. This decision is always made considering safety and structural integrity.

- Re-inspection: Once the corrective action is complete, the weld must be thoroughly re-inspected to ensure the non-conformity has been successfully addressed.

- Documentation of Corrective Action: All actions taken must be meticulously documented, including the initial non-conformity report, the corrective action plan, and the results of the re-inspection.

This structured approach ensures consistent quality control and prevents potential safety hazards. Clear communication and meticulous documentation are paramount throughout this process.

Q 10. What are the different types of welding processes and their applications?

There’s a wide array of welding processes, each with its strengths and weaknesses. Think of it like having a toolbox full of different tools – each one is best suited for a particular job.

- Shielded Metal Arc Welding (SMAW): A versatile process using a consumable electrode coated with flux. Great for various materials and applications, especially in field work where portability is key. Example: Repairing pipelines in remote locations.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, this process uses a continuous wire electrode fed into the weld pool. Efficient and productive for high-volume applications. Example: Automotive manufacturing.

- Gas Tungsten Arc Welding (GTAW): Often called TIG welding, this process uses a non-consumable tungsten electrode and a shielding gas. Ideal for high-quality welds requiring precision and excellent control. Example: Aerospace components.

- Submerged Arc Welding (SAW): This process uses a consumable electrode submerged under a layer of granular flux. Excellent for high-speed, automated welding of thick materials. Example: Pipeline construction.

- Resistance Welding: This process utilizes electrical resistance to generate heat, creating a weld joint. Common for joining thin sheets of metal. Example: Automotive body panels.

The choice of welding process depends on several factors: material thickness, joint design, required weld quality, and production environment.

Q 11. Explain the concept of weldability.

Weldability refers to a material’s ability to be welded and produce a sound, acceptable weld. It’s not simply about whether you *can* weld it; it’s about whether you can weld it *well*. A material with good weldability will produce strong, ductile welds with minimal defects. Think of it like baking a cake – some ingredients are easier to work with and consistently produce a good result than others.

Several factors influence weldability:

- Chemical Composition: Elements like carbon, sulfur, and phosphorus can affect the weld’s properties. High carbon steel, for example, can be more difficult to weld than low carbon steel.

- Material Thickness: Thicker materials require more heat input during welding, which can lead to problems like cracking or distortion.

- Preheating and Post-Welding Heat Treatment: These processes can help reduce cracking and improve the weld’s mechanical properties.

- Welding Process: The selected welding process significantly impacts weldability. Some processes are better suited for specific materials or thicknesses.

Understanding weldability is critical in selecting the appropriate welding process, parameters, and pre/post-weld treatments to ensure a high-quality and safe weld.

Q 12. How do you determine the correct filler metal for a specific welding application?

Selecting the correct filler metal is crucial for obtaining a quality weld with the desired mechanical properties. It’s not a case of ‘one size fits all’. The choice depends heavily on the base metal being welded. Think of it like choosing the right paint for a specific surface – you wouldn’t use the same paint for wood and metal.

Key factors to consider:

- Base Metal Composition: The filler metal’s chemical composition should be compatible with the base metal to ensure proper fusion and avoid undesirable reactions.

- Weld Joint Design: Different joint designs may require filler metals with different strengths or ductility.

- Welding Process: The chosen welding process affects the filler metal selection, as different processes require filler metals with specific characteristics.

- Service Conditions: The intended application and environmental conditions (temperature, corrosion, etc.) should be factored in.

Welding codes and standards (like ASME Section IX) provide guidance on selecting appropriate filler metals for various applications. These standards list qualified filler metals for different base materials and welding processes. Careful adherence to these guidelines is essential for ensuring the weld’s structural integrity and safety.

Q 13. What are the common welding codes and standards used in your industry?

My industry utilizes several key welding codes and standards to ensure consistency, safety, and quality. These codes act as blueprints for acceptable welding practices. Some of the most common include:

- ASME Section IX: This standard covers welding and brazing qualifications for pressure vessels. It’s widely used in industries like power generation and chemical processing.

- AWS D1.1: The Structural Welding Code – Steel provides guidelines for structural welding in buildings and bridges. It’s critical for ensuring the safety of large-scale structures.

- ISO 15614: International standards covering welding consumables and their qualifications.

- API 1104: Covers welding of pipelines. This is critical for industries working on large-scale pipeline infrastructure.

These codes specify requirements for welder qualification, welding procedures, inspection techniques, and material properties. They are essential for ensuring that the welds meet the necessary strength, durability, and safety criteria.

Q 14. Describe your experience with different types of welding joints.

Throughout my career, I’ve worked extensively with various types of welding joints, each possessing unique characteristics and requiring specific welding techniques. Think of it like constructing a building – different joints are needed for different parts of the structure.

- Butt Joint: The simplest joint, where two pieces are joined end-to-end. Requires careful alignment and fusion. Used extensively in pipelines.

- Lap Joint: Two pieces overlap each other. Simpler to weld than butt joints, but potentially weaker. Common in sheet metal work.

- T-Joint: One piece is joined perpendicularly to another. Can be challenging to weld due to potential for undercut or lack of fusion. Frequently found in structural steel fabrication.

- Corner Joint: Two pieces are joined at a corner, forming an ‘L’ shape. Used often in containers and boxes.

- Edge Joint: Similar to a lap joint, but the edges are prepared to allow better penetration. Often utilized in thin sheet metal components.

Understanding the strengths and weaknesses of each joint type is crucial for selecting the appropriate joint design and welding procedure to ensure the desired structural integrity and performance. The joint design greatly influences the choice of welding process and filler metal.

Q 15. What are the limitations of different NDT methods?

Non-destructive testing (NDT) methods are invaluable for assessing weld quality without damaging the workpiece. However, each method has its limitations. For instance, radiographic testing (RT) excels at detecting internal flaws like porosity and cracks but might miss surface flaws or very small discontinuities. Ultrasonic testing (UT) is highly sensitive to internal flaws, but the interpretation of results requires skilled technicians and can be affected by the weld’s geometry. Magnetic particle testing (MT) and dye penetrant testing (PT) are excellent for surface flaws but can’t detect subsurface defects. Each technique has a specific application and is best used in conjunction with others for a comprehensive assessment.

- Radiographic Testing (RT): Limited by access to the weld, dense materials can obscure images, and interpretation requires expertise.

- Ultrasonic Testing (UT): Surface preparation is crucial, skilled operators are needed, and complex geometries can hinder accurate results. It might struggle with very small, fine cracks.

- Magnetic Particle Testing (MT): Only applicable to ferromagnetic materials, surface preparation is essential, and subsurface flaws may be missed.

- Dye Penetrant Testing (PT): Only detects surface-breaking flaws and requires careful cleaning procedures.

Imagine a situation where a critical weld is inspected. Using only RT might miss a small surface crack, leading to potential failure. A combined approach using RT, UT, and PT would provide a more complete picture, mitigating the limitations of individual methods.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of maintaining accurate welding records.

Maintaining accurate welding records is paramount for ensuring traceability, liability, and quality control. These records act as a comprehensive history of the welding process, enabling project managers and inspectors to verify compliance with codes, identify potential issues, and rectify problems quickly. Imagine a scenario where a weld fails in service; without accurate records, pinpointing the cause and preventing future incidents becomes significantly more difficult. Poor records can also lead to costly delays and legal issues.

Accurate records typically include:

- Welder identification and certifications

- Welding procedure specifications (WPS) and procedure qualification records (PQR)

- Base material specifications and heat numbers

- Weld details (e.g., type of joint, size of weld, preheat temperature)

- NDT results

- Inspection reports

Consider a large-scale construction project where hundreds of welds are made. Without detailed records, tracking individual welds, their specifications, and the results of inspections would be nearly impossible. The comprehensive records facilitate efficient quality control, helping avoid costly rework and ensuring structural integrity.

Q 17. How do you ensure compliance with welding codes and standards on a project?

Ensuring compliance with welding codes and standards demands a proactive and multi-faceted approach. This begins with selecting the appropriate code (e.g., ASME Section IX, AWS D1.1) based on the project requirements. This selection dictates the welding procedures, welder qualifications, inspection methods, and acceptance criteria. Then, the key is consistent monitoring and documentation throughout the entire welding process.

- Pre-weld planning: Selecting the right WPS, ensuring welders are qualified according to the code, and specifying the appropriate NDT methods.

- Welding execution: Maintaining proper welding parameters, using approved materials, and following the established WPS meticulously.

- Inspection and testing: Performing thorough visual inspections and NDT as defined in the code, recording all results meticulously.

- Documentation: Maintaining comprehensive records, including WPS, PQR, welder qualifications, inspection reports, and material certifications.

For instance, on a pressure vessel project adhering to ASME Section IX, deviations from the WPS must be documented and approved. Failure to do so could lead to serious safety concerns and regulatory penalties. Regular audits and internal checks help ensure continued compliance and highlight potential issues early on, preventing costly rework and ensuring project safety.

Q 18. Describe your experience with root pass welding.

Root pass welding is a critical step in multi-pass welds, laying the foundation for subsequent passes. Its quality directly impacts the overall weld integrity. My experience encompasses various root pass techniques, including stringer beads, weaving, and hot-pass techniques. Each method is chosen based on factors such as joint design, material thickness, and welder skill.

I’ve worked extensively with different welding processes like Gas Tungsten Arc Welding (GTAW) or TIG welding, which is commonly used for its precision and control of the root pass, especially in critical applications. I’ve also experience with Gas Metal Arc Welding (GMAW) or MIG welding for root passes in less stringent applications, although it requires more skill to achieve good penetration and fusion. The success of root pass welding depends heavily on careful control of parameters like current, voltage, travel speed, and shielding gas. Proper joint preparation, including consistent root gap and bevel angle, is also paramount to ensuring complete fusion.

In one project, involving a stainless steel pipeline, careful control of the root pass using GTAW was vital to prevent cracking and ensure the long-term integrity of the weld. I focused on achieving full penetration and maintaining a consistent weld bead profile, which was then verified through radiographic testing. The meticulous approach resulted in a flawless root pass, setting the stage for the successful completion of the multi-pass weld.

Q 19. What is the difference between destructive and non-destructive testing?

Destructive testing (DT) and non-destructive testing (NDT) are both crucial for evaluating weld quality, but they differ fundamentally in their approach. DT involves sacrificing the test specimen to determine its properties. NDT, on the other hand, evaluates material properties without causing any damage.

- Destructive Testing (DT): This involves techniques such as tensile testing, bend testing, and impact testing. These methods provide precise quantitative data on strength, ductility, and toughness but require destroying the test sample.

- Non-Destructive Testing (NDT): This encompasses methods like radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), and dye penetrant testing (PT). These techniques allow for the evaluation of multiple welds without compromising the structural integrity of the components.

Think of it like this: DT is like breaking open a container to see its contents directly; NDT is like using a sophisticated scanner to visualize the internal structure without opening it. DT is often used to validate the results of NDT or to determine the mechanical properties of the weld metal. While DT provides detailed quantitative data, NDT enables inspection of the entire weld in its installed condition, making it crucial for ensuring safety and structural integrity.

Q 20. What are the various types of joint preparation techniques?

Joint preparation techniques are crucial for achieving strong, reliable welds. The choice of technique depends heavily on the joint type, material thickness, and welding process. Proper preparation ensures complete penetration, minimizing the risk of defects like incomplete fusion or lack of penetration.

- Square Butt Joint: Simple but requires precise alignment and may need backing.

- Single Bevel Joint: One edge is beveled, suitable for thicker materials.

- li>Double Bevel Joint: Both edges are beveled, offering good penetration.

- Single J-Joint and Double J-Joint: Similar to bevel joints but with a concave shape, providing a more controlled weld pool.

- Single U-Joint and Double U-Joint: Feature a U-shaped groove, ideal for thicker materials and high-strength applications.

- V-Joint and Double V-Joint: Features a V-shaped groove and are popular for thicker materials requiring high penetration.

- K-Joint: A variation of the V-joint, with a smaller root opening.

Each joint preparation type offers advantages and disadvantages based on factors like ease of welding, penetration, and weld geometry. For instance, a double-V joint is preferred for thick plates due to its high penetration capabilities. However, it requires more preparation time. The selection of the optimal technique is a crucial step in ensuring the final weld quality meets the required standards and specifications.

Q 21. What are the acceptance criteria for welds according to relevant codes?

Acceptance criteria for welds vary depending on the applicable code and the specific application. These criteria define the allowable levels of defects, ensuring the weld meets the necessary strength, toughness, and integrity requirements. Codes like ASME Section IX and AWS D1.1 provide detailed acceptance standards, often including visual inspection criteria and NDT acceptance limits.

These criteria typically address:

- Visual inspection: Limits on surface defects like undercuts, cracks, and porosity.

- Radiographic testing (RT): Acceptance standards for the size, number, and location of internal flaws such as cracks, porosity, and inclusions.

- Ultrasonic testing (UT): Acceptance criteria for the size, orientation, and distribution of flaws detected by ultrasonic waves.

- Mechanical testing: Requirements for tensile strength, yield strength, and other mechanical properties.

For example, ASME Section IX might specify maximum allowable flaw sizes for different weld types and thicknesses, ensuring that acceptable levels of defects do not compromise the pressure vessel’s structural integrity. Exceeding these limits would necessitate repair or rejection of the weld. The acceptance criteria are integral in guaranteeing safety, reliability, and conformance with the design specifications.

Q 22. How do you deal with a situation where a weld doesn’t meet the required standards?

Discovering a weld that doesn’t meet standards is a serious matter, demanding a methodical approach. First, I’d meticulously document the non-conformity, including detailed photographs and measurements. This includes noting the specific location, the type of defect (e.g., porosity, cracks, undercut), and its dimensions. Then, I’d consult the relevant welding procedure specification (WPS) and the applicable codes (like AWS D1.1 for structural steel welding) to determine the severity of the defect and whether it’s repairable. A minor defect might be acceptable with a repair, following a documented repair procedure. However, significant defects might require the removal and rewelding of the entire section. The decision will be based on a risk assessment, considering the safety and structural integrity of the component. Communication is key; I’d inform the welding supervisor and quality control personnel immediately, and we’d jointly decide on the best course of action. In a critical application, independent third-party inspection may be necessary to validate the repair or replacement.

For example, if a critical pressure vessel weld shows significant porosity, it’s unacceptable and would require removal and rewelding, potentially necessitating a complete metallurgical examination to understand the root cause. Conversely, a small, superficial undercut on a non-critical weld might be acceptable if it doesn’t compromise the intended function.

Q 23. Explain your understanding of the effects of different welding parameters on the weld quality.

Welding parameters significantly impact weld quality, affecting both the mechanical properties and the appearance of the weld. Think of them as the recipe for a perfect weld. Let’s explore some key parameters:

- Current (Amperage): Higher amperage generally leads to deeper penetration but can also increase the risk of burn-through, porosity, and spatter. Lower amperage results in shallower penetration and might produce a weak weld. The correct amperage depends on the base metal thickness, type of welding process, and electrode diameter.

- Voltage: Voltage controls the arc length and heat input. Higher voltage leads to a longer arc, increasing penetration but also increasing spatter. Lower voltage produces a shorter arc with less penetration.

- Travel Speed: This influences the heat input per unit length. Slower speeds provide more heat input, leading to better fusion but potentially causing excessive heat-affected zone (HAZ) and weakening the weld. Faster speeds reduce heat input, risking insufficient fusion and incomplete penetration.

- Shielding Gas Flow Rate: In gas metal arc welding (GMAW) or gas tungsten arc welding (GTAW), the shielding gas protects the weld from atmospheric contamination. Insufficient flow rate allows atmospheric gases to enter, creating porosity and affecting weld quality. Excessive flow can lead to unnecessary gas consumption.

Finding the optimal combination of these parameters requires experience and often involves testing through weld qualification procedures (WQR) to ensure compliance with the relevant codes and standards. Each welding process has its specific nuances, further emphasizing the need for skilled operators.

Q 24. How do you identify and prevent common welding defects?

Identifying and preventing welding defects is crucial for ensuring structural integrity and safety. Common defects include:

- Porosity: Small holes in the weld caused by gas entrapment. This is often due to poor shielding gas coverage, contaminated base material, or improper welding technique. Prevention involves using the correct shielding gas, cleaning the base material thoroughly, and maintaining proper welding technique.

- Cracks: These brittle fractures can appear in the weld or HAZ. They’re often caused by rapid cooling, high-stress areas, or hydrogen embrittlement. Prevention involves preheating, using low-hydrogen electrodes, and controlling the cooling rate.

- Undercut: A groove at the edge of the weld, caused by excessive current or incorrect travel speed. This weakens the weld. Prevention involves adjusting welding parameters and using proper technique.

- Incomplete Penetration/Fusion: When the weld doesn’t fully fuse with the base metal, weakening the joint. This can be caused by insufficient heat input or improper joint design. Prevention involves adjusting welding parameters, ensuring correct joint fit-up, and using appropriate preheating.

Visual inspection plays a significant role, but advanced techniques like radiographic testing (RT), ultrasonic testing (UT), and liquid penetrant testing (PT) are used to detect internal defects. Regular training and adherence to established welding procedures are critical in defect prevention.

Q 25. What software or tools do you use for welding inspection or documentation?

For welding inspection and documentation, I utilize a range of software and tools. For example, I use:

- Weld inspection software: These programs allow for detailed recording of inspection data, including images, notes, and defect reports. Some programs integrate with data management systems to track traceability and quality control.

- Computer-aided design (CAD) software: CAD is used for reviewing weld joint designs, verifying dimensions, and preparing detailed drawings for welders.

- Digital imaging and measurement tools: High-resolution cameras and precise measuring devices help in documenting weld imperfections and sizes accurately.

- Data management software: This is crucial for maintaining a complete history of welding procedures, materials, and inspection reports, ensuring full traceability.

- NDT (Non-Destructive Testing) software: This helps process and analyze data from various NDT methods (like UT and RT), allowing for quantitative defect assessment.

The choice of software and tools depends on the project’s scale, the complexity of the weldments, and the specific needs of the client.

Q 26. Describe your experience with different types of base metals and their weldability.

My experience encompasses various base metals, each with unique weldability characteristics:

- Steel: Carbon steel is readily weldable using various processes, but high-carbon steels require preheating to prevent cracking. Stainless steel requires specialized techniques and filler materials to maintain corrosion resistance.

- Aluminum: Aluminum’s high thermal conductivity necessitates high heat input and specialized filler materials (often containing silicon). Good surface preparation is critical to avoid porosity.

- Titanium: Titanium is challenging to weld due to its high reactivity. Specialized inert gas shielding and techniques (like GTAW) are essential to prevent contamination and oxidation.

- Copper: Copper’s high thermal conductivity and tendency to form oxides demand a clean environment and the use of suitable filler metals. Special techniques like brazing are often employed.

Weldability is not only about the base metal but also about the cleanliness, preheating, and the selection of appropriate welding process and filler materials. Understanding the metallurgical aspects of each metal is essential to achieving high-quality welds.

Q 27. How do you interpret and apply welding symbols found on drawings?

Welding symbols on drawings are a concise language that communicates critical weld details. They follow a standardized format (typically based on ANSI/ASME Y14.2M standards). The symbol conveys information about:

- Weld Type: The symbol’s basic form (e.g., a filled arrow for fillet welds, a square for butt welds) indicates the type of weld. A small triangle shows a weld that is made with the groove prepared beforehand.

- Weld Size: The dimensions (leg length for fillet welds, throat thickness for butt welds) are typically indicated near the symbol.

- Weld Location: The arrow’s orientation and location on the drawing indicates the weld’s position on the joint. A reference line is used for this.

- Joint Design: The drawing usually shows the joint preparation (e.g., bevel angle, root opening) that would influence the type of welding process, its procedure and settings.

- Finishing Requirement: Symbols might specify if the weld needs to be ground or other post-weld finishing procedures.

Understanding welding symbols is fundamental for welders and inspectors to ensure that the weld is made according to the design specifications.

For example, a symbol with a filled arrow pointing towards a particular member with dimensions ‘6 mm’ would indicate that a fillet weld of 6 mm leg length is required on that joint. A complete understanding of standards, and the particular application of these standards is essential to properly interpret the symbol.

Q 28. Explain the importance of maintaining traceability in welding procedures and materials.

Traceability in welding is paramount for ensuring quality, accountability, and safety. It involves maintaining a complete and verifiable record of every step in the welding process, from material selection to final inspection. This includes:

- Material Traceability: Every batch of filler material, electrodes, and base metal should be identified with unique identifiers and documented throughout the process. This enables tracking down the source in case of defects.

- Procedure Traceability: The WPS followed for each weld should be clearly documented, including details of the process, parameters, and welder qualifications. Any deviations from the WPS must be recorded and approved.

- Welder Qualification Traceability: Welder qualifications should be carefully documented and readily available, ensuring that only qualified welders are performing the work.

- Inspection Traceability: All inspection records, including NDT reports, visual inspections, and defect repair documents, should be maintained with clear identification of the weld and the inspector. Digital images are a beneficial addition.

Traceability enables effective quality control, facilitates root cause analysis in case of defects, and fulfills regulatory requirements. It is critical in industries such as aerospace, nuclear, and oil & gas where safety is paramount.

Key Topics to Learn for Knowledge of Welding Standards and Codes Interview

- Welding Processes: Understanding the principles and applications of various welding processes (e.g., GMAW, SMAW, GTAW, FCAW) including their strengths, weaknesses, and suitability for different materials.

- Base Metal Properties: Knowledge of how different base metals (steel, aluminum, stainless steel, etc.) affect weldability and the selection of appropriate welding procedures.

- Joint Design and Preparation: Understanding the importance of proper joint design and preparation for ensuring strong and reliable welds. This includes different joint types and their suitability for specific applications.

- Welding Codes and Standards (AWS D1.1, ASME Section IX, etc.): Familiarity with relevant codes and standards, including their purpose, requirements, and interpretation. This includes understanding the implications of non-compliance.

- Weld Inspection and Testing: Knowledge of various non-destructive testing (NDT) methods (visual inspection, radiography, ultrasonic testing) used to ensure weld quality and integrity.

- Welding Metallurgy: Understanding the metallurgical changes that occur during welding and their impact on the mechanical properties of the weldment. This includes understanding heat-affected zones (HAZ).

- Safety Procedures and Regulations: Familiarity with safety regulations and procedures related to welding, including personal protective equipment (PPE) and hazard mitigation.

- Problem-Solving and Troubleshooting: Ability to identify and troubleshoot common welding defects and issues, applying knowledge of codes and standards to find solutions.

- Documentation and Record Keeping: Understanding the importance of proper documentation and record-keeping for welding procedures, inspections, and quality control.

Next Steps

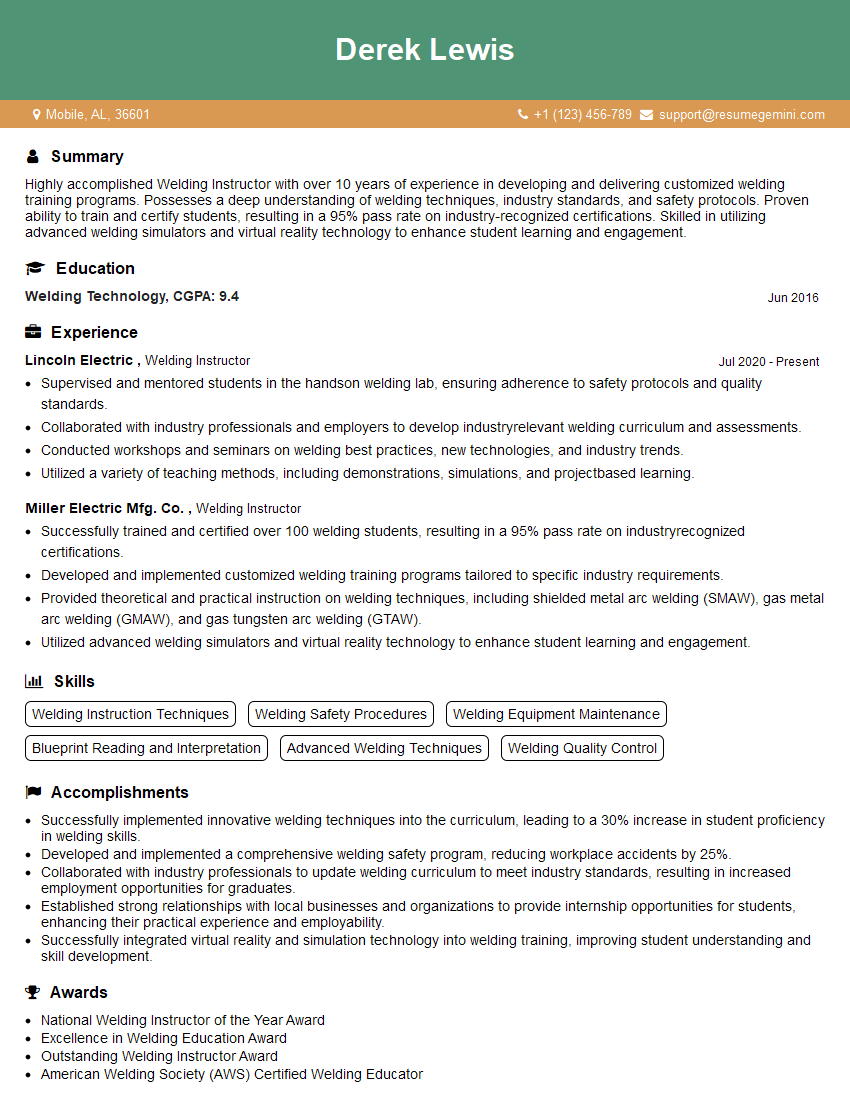

Mastering knowledge of welding standards and codes is crucial for career advancement in the welding industry, opening doors to more challenging and rewarding positions. A strong understanding of these standards demonstrates professionalism, competence, and commitment to safety and quality. To maximize your job prospects, focus on building an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource to help you craft a compelling and effective resume that showcases your skills and experience. We provide examples of resumes tailored to Knowledge of Welding Standards and Codes to help guide you in this process. Invest in your future – build a resume that reflects your capabilities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.