The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Land Clearing and Demolition interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Land Clearing and Demolition Interview

Q 1. Describe your experience with different land clearing techniques.

Land clearing techniques vary greatly depending on the site’s characteristics, the desired outcome, and environmental regulations. My experience encompasses a wide range, from manual methods to the use of heavy machinery.

- Manual Clearing: This involves using hand tools like axes, saws, and brush cutters for smaller areas or delicate operations near sensitive ecosystems. I’ve used this approach extensively when working near waterways to minimize erosion.

- Mechanical Clearing: This is far more common for larger projects. We utilize bulldozers to push over trees and shrubs, excavators to remove stumps and roots, and feller bunchers to efficiently cut and bundle trees for easier removal. I once used a combination of bulldozers and excavators to clear a dense forest for a large-scale residential development.

- Prescribed Burning: Under strict regulatory oversight and with the necessary permits, controlled burns can be a cost-effective method to clear underbrush and prepare land for reseeding or other land management practices. I’ve personally overseen several prescribed burns, ensuring strict adherence to fire safety protocols and environmental regulations.

- Hydro-Axing: This employs a specialized machine that uses a rotating cutting head to cut vegetation, making it suitable for clearing difficult terrain or areas with dense vegetation. We used this technique on a particularly rocky hillside to minimize soil disturbance.

The choice of technique depends heavily on the specific project requirements and always involves careful assessment of the environmental impact.

Q 2. What safety measures do you implement during land clearing operations?

Safety is paramount in land clearing. We adhere to a comprehensive safety plan that’s tailored to each project. This includes:

- Pre-job Site Assessments: Thorough inspections identify potential hazards like unstable trees, underground utilities, and wildlife presence.

- Personal Protective Equipment (PPE): Mandatory PPE includes hard hats, safety glasses, high-visibility clothing, steel-toe boots, and hearing protection. We also provide specialized equipment like chainsaw chaps and gloves when necessary.

- Equipment Maintenance and Inspections: Regular checks ensure equipment is in optimal working order, preventing breakdowns and accidents.

- Emergency Response Plan: Clearly defined procedures are in place to handle emergencies, including first aid, evacuation procedures, and communication protocols.

- Training and Certification: All personnel are trained and certified in the safe operation of the equipment they use, and in relevant safety regulations.

- Designated Safety Officers: On larger projects, we assign safety officers to monitor operations and ensure compliance with safety protocols.

For example, before starting any mechanical clearing, we meticulously mark utility lines to prevent damage. We also establish clear communication channels between operators and spotters to avoid accidents.

Q 3. How do you handle unexpected environmental findings during site preparation?

Unexpected environmental findings are a significant possibility during site preparation. Our response involves several key steps:

- Immediate Halt to Work: Any unusual discovery, be it an endangered species habitat, an archaeological site, or hazardous materials, triggers an immediate work stoppage in the affected area.

- Notification of Relevant Authorities: We immediately contact the appropriate environmental agencies, archaeologists, or other specialists as required by law and the project’s environmental permits.

- Assessment and Documentation: A thorough assessment is conducted by qualified professionals to determine the nature and significance of the finding. Detailed documentation with photographs and reports are created.

- Mitigation Strategies: Based on the assessment, we develop and implement mitigation strategies, which might involve altering the project plan, employing specialized techniques, or implementing conservation measures.

- Regulatory Compliance: We strictly adhere to all regulatory requirements throughout the process, ensuring the project aligns with environmental protection laws.

For instance, if we uncover an unexpected wetland, we would immediately halt work and consult with the relevant authorities to determine the best course of action, potentially redesigning the project to avoid the wetland entirely.

Q 4. Explain your experience with demolition techniques for various structures.

My demolition experience spans various structures, from residential buildings to industrial complexes, employing a range of techniques depending on the structure’s size, age, and material composition.

- Selective Demolition: This involves carefully dismantling parts of a structure, often used for historic preservation or when certain materials need to be salvaged. I’ve worked on several projects where we selectively demolished sections of older buildings to allow for renovations while preserving historical features.

- High-Reach Demolition: This utilizes specialized equipment like excavators with long reaches and high-reach demolition robots to dismantle tall structures safely and efficiently. I was part of a team that demolished a multi-story industrial building using this method.

- Controlled Implosion: This technique, used for large structures, involves strategically placing explosives to bring the building down in a controlled manner. While not something I’ve directly managed, I’ve worked alongside experts during these operations, focusing on site safety and preparation.

- Mechanical Demolition: This uses heavy machinery like excavators, crushers, and breakers to dismantle buildings. I’ve employed this technique extensively for many projects involving residential and commercial structures.

The technique selection is a critical decision and always involves careful planning and risk assessment to ensure safety and minimize environmental impact. Each project is unique and requires a customized approach.

Q 5. What safety protocols are crucial for demolition projects?

Safety protocols for demolition are extremely rigorous, exceeding those in land clearing. We implement the following:

- Detailed Site Surveys and Structural Assessments: Comprehensive surveys identify potential hazards and determine the best demolition strategy. This includes assessing the structural integrity of the building, identifying asbestos or other hazardous materials, and locating underground utilities.

- Exclusion Zones and Perimeter Control: Establishing secure exclusion zones around the demolition site restricts unauthorized access, minimizing risks to the public and workers.

- Debris Management Plan: A thorough plan is created to manage demolition debris safely and efficiently, preventing accidents and protecting the environment.

- Dust and Air Quality Control: Measures to control dust and air pollution, such as water spraying and air filtration, are implemented to protect workers and the surrounding community.

- Emergency Response Plan: Detailed emergency plans, including procedures for evacuations and medical emergencies, are developed and practiced.

- Worker Training and Supervision: Rigorous training programs ensure all workers understand and follow safety protocols, and on-site supervision guarantees compliance.

For example, before any demolition begins, we’ll establish a detailed communication plan and designate safety personnel specifically trained in emergency response procedures.

Q 6. How do you manage waste disposal during demolition projects?

Waste management during demolition is crucial for environmental responsibility and regulatory compliance. Our process is as follows:

- Material Segregation: We meticulously segregate demolition waste into different categories—wood, concrete, metal, etc.—for recycling and proper disposal.

- Hazardous Waste Handling: Materials such as asbestos, lead paint, and other hazardous substances are carefully handled and disposed of according to strict regulations. We always engage certified hazardous waste removal companies.

- Recycling and Reuse: Wherever feasible, we prioritize recycling and reusing materials to minimize landfill waste. For example, we might crush concrete for use as aggregate in new construction.

- Waste Transfer Stations and Landfill Disposal: Non-recyclable materials are transported to licensed waste transfer stations and landfills, complying with all environmental permits and regulations.

- Documentation and Reporting: Detailed records of waste generation, disposal methods, and recycling efforts are meticulously maintained and reported to the relevant authorities.

We aim for zero landfill waste whenever possible, and actively seek out innovative solutions for recycling and reusing materials. This not only helps the environment but also reduces project costs.

Q 7. Describe your experience with operating heavy equipment (specify equipment).

My experience operating heavy equipment is extensive, covering a wide range of machinery essential for both land clearing and demolition projects.

- Bulldozers: Proficient in operating various bulldozer models for land clearing, grading, and earthmoving operations. I’m experienced in using them for pushing over trees, moving soil, and preparing sites for construction.

- Excavators: I’m skilled in operating excavators for digging, trenching, demolition, and material handling. I’ve used excavators with both standard and long-reach arms for various applications.

- Wheel Loaders: Experienced in using wheel loaders for loading and transporting materials, especially during demolition projects. This includes loading debris into dump trucks and managing the flow of materials on-site.

- Hydraulic Breakers and Crushers: I’m proficient in operating hydraulic attachments on excavators for demolition work, including breakers for dismantling concrete structures and crushers for reducing material size.

- Skid Steer Loaders: I have experience using skid steer loaders for smaller tasks on site such as grading and cleanup.

I hold all necessary certifications and licenses for operating this heavy equipment and strictly adhere to all safety regulations. I’m also adept at selecting the appropriate equipment for specific tasks, optimizing efficiency and minimizing environmental impact.

Q 8. How do you ensure the safety of workers and the public during demolition?

Worker and public safety is paramount in demolition. We implement a multi-layered approach, starting with rigorous pre-demolition surveys to identify potential hazards like underground utilities, asbestos, or unstable structures. This informs our safety plan, which includes:

- Detailed site security: Perimeter fencing, signage, and 24/7 security personnel to prevent unauthorized access.

- Comprehensive worker training: All personnel receive training on safe demolition practices, equipment operation, hazard recognition, and emergency procedures, with certifications tracked and updated.

- Personal Protective Equipment (PPE): Mandatory use of hard hats, safety glasses, high-visibility clothing, and appropriate respiratory protection, depending on the task.

- Traffic management: Road closures, traffic diversions, and flag persons manage pedestrian and vehicle movements around the site.

- Emergency response plan: A detailed plan outlines procedures for medical emergencies, equipment malfunctions, or unexpected events, including emergency contact information and designated assembly points.

- Regular safety inspections: Daily site inspections identify potential hazards, ensure compliance with safety protocols, and address any immediate concerns.

For example, on a recent high-rise demolition, we used a phased dismantling approach, ensuring that each section was carefully taken down before moving to the next. This minimized the risk of uncontrolled collapses and kept nearby buildings safe.

Q 9. What are your strategies for managing project timelines and budgets?

Managing project timelines and budgets requires meticulous planning and execution. We use a combination of techniques:

- Detailed project scheduling: We use critical path method (CPM) software to create a detailed schedule that outlines every task, its duration, dependencies, and potential risks. This allows us to identify critical tasks and proactively address potential delays.

- Regular progress monitoring: We conduct weekly progress meetings to review the schedule, identify any deviations, and adjust the plan accordingly. Progress reports are shared with clients to maintain transparency.

- Resource allocation: We carefully allocate resources, including equipment, personnel, and materials, to optimize efficiency and minimize costs. This includes utilizing technology to optimize equipment usage and reduce idle time.

- Contingency planning: We anticipate potential challenges, like weather delays or material shortages, and build contingency time and budget into the project plan. This protects against unforeseen circumstances impacting deadlines and costs.

- Value engineering: We explore alternative methods or materials to achieve the same result at a lower cost without compromising quality or safety.

For instance, on a recent highway expansion project involving land clearing, we implemented a phased approach to minimize disruption to traffic flow, saving both time and potential penalty costs for delays.

Q 10. Explain your experience with site surveying and preparation.

Site surveying and preparation are foundational to any successful land clearing or demolition project. This phase involves:

- Topographic survey: Detailed mapping of the site’s terrain, including elevations, boundaries, and existing structures. This data informs demolition planning and ensures efficient material removal.

- Utility location: Identifying and marking underground utilities (water, gas, electric, sewer lines) to prevent damage and ensure worker safety. We employ ground-penetrating radar and collaborate with utility companies to confirm locations.

- Environmental assessment: Identifying potential environmental hazards such as asbestos, lead paint, or contaminated soil. This helps in selecting appropriate demolition methods and ensures compliance with environmental regulations.

- Site access planning: Determining the best access points for equipment and materials, considering road conditions, weight limitations, and potential traffic disruptions.

- Site clearing and preparation: Clearing vegetation, removing debris, and preparing the site for demolition activities. This might involve grading, excavation, or temporary structures.

In one project, our thorough site survey revealed an unexpected underground tank, which could have caused significant problems if not discovered beforehand. Our team handled the issue quickly and safely, preventing delays and costly repairs.

Q 11. How do you obtain necessary permits and licenses for land clearing and demolition?

Obtaining the necessary permits and licenses is a crucial and complex part of the process. This requires navigating local, state, and sometimes federal regulations. The process typically includes:

- Identifying applicable regulations: Determining the specific permits and licenses required based on the project’s location, scope, and type of demolition (residential, commercial, industrial).

- Preparing application documents: Gathering and submitting the necessary documentation, including detailed site plans, engineering drawings, safety plans, environmental impact assessments, and proof of insurance.

- Submitting applications to relevant authorities: Submitting applications to the appropriate regulatory bodies, typically the local building department, environmental protection agency, and potentially other agencies depending on the project’s characteristics.

- Addressing any deficiencies: Responding to any requests for additional information or clarification from the regulatory authorities, ensuring all requirements are met.

- Obtaining approvals: Receiving official permits and licenses before commencing demolition activities.

We have a dedicated team experienced in navigating these processes, ensuring all documentation is complete and accurate, minimizing delays and ensuring compliance.

Q 12. How do you handle unexpected challenges or setbacks during a project?

Unexpected challenges are inevitable in demolition projects. Our approach involves:

- Proactive risk assessment: Identifying potential risks and developing mitigation strategies before starting the project.

- Flexible project management: Using agile project management techniques to adapt to changes and unforeseen circumstances.

- Effective communication: Maintaining open communication with the client, the project team, and subcontractors to address challenges promptly.

- Problem-solving skills: Employing creative problem-solving skills to find efficient and safe solutions to unexpected issues. This may involve modifying the demolition plan, adjusting the schedule, or sourcing alternative materials.

- Contingency funds: Having contingency funds allocated to handle unexpected costs.

For instance, we once encountered unexpected asbestos during a demolition. Our team immediately halted work, engaged a certified asbestos abatement contractor, and followed all regulatory procedures to safely remove the hazardous material, keeping the project on track though with a slight delay.

Q 13. Explain your understanding of environmental regulations related to land clearing.

Environmental regulations related to land clearing are stringent and vary by location. Our understanding encompasses:

- Hazardous materials identification and removal: Identifying and properly handling hazardous materials like asbestos, lead paint, PCBs, and contaminated soil, in compliance with local, state, and federal regulations (e.g., EPA guidelines).

- Waste management: Properly managing and disposing of demolition waste, including recycling and reducing landfill waste. This might involve sorting materials on-site, utilizing specialized waste haulers, and obtaining necessary waste disposal permits.

- Erosion and sediment control: Implementing measures to prevent soil erosion and sedimentation during land clearing, protecting waterways and surrounding environments. This might include silt fences, erosion control blankets, and best management practices.

- Protection of endangered species and habitats: Identifying and protecting endangered species and their habitats, following local and federal environmental protection laws.

- Air quality control: Implementing measures to minimize dust and air pollution during demolition and land clearing activities, complying with air quality standards.

We always conduct thorough environmental site assessments and prepare detailed environmental management plans that comply with all applicable regulations. This is crucial for obtaining necessary permits and ensuring our projects are environmentally responsible.

Q 14. Describe your experience with different demolition methods (e.g., implosion, dismantling).

We have extensive experience with various demolition methods, choosing the most appropriate technique based on factors such as structural integrity, site constraints, and environmental concerns.

- Implosion: Used for large structures, this method involves strategically placed explosives to bring down the building in a controlled manner. It is effective for large structures in confined spaces but requires extensive planning and stringent safety measures.

- Dismantling: A more controlled and precise method, dismantling involves systematically taking apart a structure piece by piece. This method minimizes debris and is suitable for structures with valuable reusable materials or those located in densely populated areas. It also reduces the risk of unexpected collapses.

- Selective demolition: Targeting specific parts of a building for removal, rather than the whole structure. This is a common method for renovations or when only certain sections are unsafe or need to be updated.

- Mechanical demolition: Employing heavy machinery like excavators, cranes, and demolition balls to deconstruct structures. This is a versatile method suitable for a wide range of projects and generally less expensive than implosion.

For example, on a recent project involving a historic building, we employed careful dismantling to salvage reusable materials and minimize environmental impact. On another project, implosion was the most efficient method to remove a large, obsolete industrial building within a short timeframe and with minimal disruption to surrounding businesses.

Q 15. How do you ensure compliance with safety and environmental regulations?

Ensuring compliance with safety and environmental regulations is paramount in land clearing and demolition. It’s not just about following the rules; it’s about protecting workers, the environment, and our reputation. We begin by thoroughly researching and understanding all applicable federal, state, and local regulations. This includes permits, safety standards (like OSHA guidelines), and environmental protection laws (like those concerning soil erosion, water contamination, and hazardous waste disposal).

- Permitting: Before we even touch a site, we secure all necessary permits. This often involves detailed site plans, environmental impact assessments, and traffic management plans. For example, a project involving demolition near a waterway requires a detailed plan to prevent erosion and water contamination.

- Safety Protocols: We implement stringent safety protocols, including daily safety meetings, regular equipment inspections, and mandatory personal protective equipment (PPE) use. This could include hard hats, safety glasses, high-visibility vests, and hearing protection.

- Environmental Monitoring: We conduct regular environmental monitoring to ensure compliance with regulations. This often involves soil testing, air quality monitoring, and water sampling, especially when dealing with potential contaminants.

- Waste Management: We develop a detailed waste management plan that outlines how debris, hazardous materials, and other waste will be properly handled, transported, and disposed of, ensuring compliance with environmental regulations. We often partner with licensed hazardous waste disposal companies to handle materials such as asbestos or lead paint.

Our commitment to compliance extends beyond simply checking boxes. It’s woven into our company culture, and our project managers are trained to proactively identify and address potential compliance issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with working with different types of soil and terrain.

My experience encompasses a wide range of soil types and terrains. Understanding these variations is crucial for selecting the right equipment and techniques. For instance, rocky terrain requires specialized equipment like rock breakers and excavators with heavy-duty attachments, whereas sandy soil might require different excavation techniques to prevent collapse.

- Clay Soil: This heavy, dense soil can be challenging to excavate, requiring more powerful equipment and careful planning to prevent compaction.

- Sandy Soil: Sandy soil is easier to work with but can be unstable, requiring shoring or other support systems during excavation.

- Rocky Terrain: Demolition and excavation in rocky areas require specialized equipment such as rock breakers, and careful planning to avoid damage to underground utilities.

- Swampy or Waterlogged Areas: These challenging environments often require specialized equipment, like amphibious excavators and dewatering techniques.

I’ve worked on projects involving everything from flat, easily accessible sites to challenging mountainous terrain, and I’m adept at adapting our methods to meet the demands of each unique environment. We always conduct thorough site assessments to account for soil composition and terrain challenges before starting any project.

Q 17. How do you assess the structural integrity of a building before demolition?

Assessing the structural integrity of a building before demolition is a critical safety step. We use a multi-faceted approach that combines visual inspection, engineering analysis, and sometimes, non-destructive testing.

- Visual Inspection: A trained structural engineer conducts a thorough visual inspection to identify visible signs of deterioration, such as cracks, corrosion, and structural damage.

- Engineering Analysis: This involves reviewing building plans, structural calculations, and past maintenance records to understand the building’s design and construction. This helps assess the overall structural integrity and identify potential weak points.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or ground-penetrating radar might be used to detect hidden structural flaws or determine the condition of materials without causing damage. For instance, we might use ground-penetrating radar to locate underground utilities before excavation.

- Asbestos and Hazardous Material Testing: We always include asbestos and hazardous material testing as part of the pre-demolition assessment to ensure the safe handling and disposal of any hazardous materials.

Based on this comprehensive evaluation, we develop a demolition plan that addresses any identified structural weaknesses and ensures worker safety. This might involve selective demolition, controlled implosion, or other specialized techniques. For example, if a wall shows signs of instability, we might reinforce it or use a different demolition approach to minimize the risk of collapse.

Q 18. How do you mitigate risks associated with asbestos or other hazardous materials?

Mitigating risks associated with asbestos and other hazardous materials is a top priority. Our approach adheres strictly to all relevant regulations and involves several key steps:

- Identification and Assessment: We begin by conducting a thorough asbestos and hazardous material survey. This often involves taking samples and sending them to a certified laboratory for analysis. We might use air monitoring to ensure that asbestos fibers aren’t airborne during demolition.

- Contamination Control: If hazardous materials are present, we implement strict containment measures to prevent the spread of contamination. This includes setting up containment barriers, using specialized equipment, and employing trained personnel wearing appropriate PPE.

- Safe Removal and Disposal: Hazardous materials are removed and disposed of according to strict regulatory guidelines. This often involves engaging specialized contractors licensed to handle hazardous waste. We meticulously document every stage of the process.

- Air Monitoring: During and after the removal process, we conduct air monitoring to ensure that hazardous material concentrations remain within safe limits.

- Post-Demolition Cleanup: We thoroughly clean the site to remove any remaining traces of hazardous materials, ensuring the area is safe for future use.

Neglecting these steps can have severe health and environmental consequences. Our commitment to safety and environmental responsibility dictates a proactive and meticulous approach to managing hazardous materials.

Q 19. What are the key factors to consider when estimating costs for land clearing or demolition?

Accurately estimating costs for land clearing or demolition requires careful consideration of many factors. It’s more than just adding up the cost of equipment and labor; it’s about anticipating potential challenges and including contingencies.

- Site Assessment: A thorough site assessment is the foundation of a good cost estimate. This includes analyzing soil conditions, terrain, vegetation density, and the presence of any structures or utilities.

- Labor Costs: Labor costs depend on the project’s size, complexity, and the required skill level of the workforce. The number of workers and the duration of the project impact this cost significantly.

- Equipment Costs: The type and amount of equipment needed vary depending on the site conditions and the scope of work. Rental costs, fuel, and maintenance should be included.

- Material Costs: Costs associated with the removal and disposal of materials, including transportation and potential hazardous waste disposal fees, must be factored in.

- Permits and Licenses: The cost of obtaining necessary permits and licenses is an important consideration.

- Contingencies: It’s crucial to include a contingency for unexpected costs, such as encountering unforeseen underground utilities or encountering difficult-to-remove materials.

We use sophisticated estimating software and our extensive experience to develop accurate and comprehensive cost estimates. Transparency is key; we work closely with clients to explain each cost item and ensure they understand the rationale behind the overall estimate.

Q 20. How do you communicate effectively with clients, contractors, and other stakeholders?

Effective communication is the cornerstone of successful land clearing and demolition projects. We prioritize clear, consistent, and proactive communication with clients, contractors, and all stakeholders.

- Client Communication: We maintain regular contact with clients, providing updates on project progress, addressing concerns, and proactively communicating any potential issues or delays. We strive to keep them fully informed throughout the project lifecycle.

- Contractor Coordination: We work closely with subcontractors, ensuring clear communication of project requirements, deadlines, and safety protocols. Regular meetings and progress reports facilitate seamless collaboration.

- Stakeholder Engagement: We engage with other stakeholders, such as neighboring property owners or utility companies, to address their concerns and ensure their safety and cooperation.

- Documentation: Comprehensive documentation, including project plans, meeting minutes, and progress reports, ensures everyone remains informed and aligned. We also utilize digital platforms to facilitate efficient and transparent communication.

Our approach is built on active listening and clear, concise communication. We believe that proactive and transparent communication helps to prevent misunderstandings and ensure project success.

Q 21. Describe your experience with project planning and scheduling.

Project planning and scheduling are critical for successful land clearing and demolition projects. We use a phased approach that encompasses detailed planning, scheduling, and monitoring.

- Project Definition: We begin by clearly defining the project scope, objectives, and deliverables. This includes a detailed description of the work to be performed and a comprehensive site assessment.

- Sequencing: We carefully sequence the various tasks involved, considering dependencies and potential conflicts. This often involves creating a critical path method (CPM) schedule to identify critical tasks and potential bottlenecks.

- Resource Allocation: We allocate the necessary resources, including personnel, equipment, and materials, to ensure timely completion of each task. We might utilize resource leveling techniques to optimize resource allocation.

- Risk Assessment: We conduct a thorough risk assessment to identify potential hazards and develop mitigation strategies. This is crucial for ensuring worker safety and project success.

- Monitoring and Control: Throughout the project lifecycle, we closely monitor progress, comparing actual performance to the schedule and making adjustments as needed. We utilize project management software to track progress and identify potential delays.

Our experience allows us to develop realistic schedules and contingency plans to deal with unforeseen challenges. We regularly review and update the schedule to maintain alignment with project goals and minimize potential delays.

Q 22. How do you manage a team effectively during a demanding demolition project?

Effective team management during a demolition project hinges on clear communication, strong leadership, and proactive risk management. Think of it like conducting an orchestra – each member has a crucial role, and the conductor (project manager) ensures harmonious execution.

- Clear Roles and Responsibilities: Before the first swing of a wrecking ball, every team member understands their tasks, responsibilities, and reporting lines. This avoids confusion and overlap.

- Open Communication: Daily briefings, safety meetings, and open channels for feedback are crucial. We use a combination of in-person meetings and project management software to ensure everyone is on the same page and can quickly address emerging issues.

- Motivation and Recognition: A demanding demolition project can be stressful. Recognizing individual contributions, celebrating milestones, and providing support fosters a positive and productive work environment.

- Safety First: Regular safety talks and inspections are paramount. We lead by example, ensuring everyone adheres to safety protocols and uses appropriate PPE (Personal Protective Equipment).

For example, on a recent high-rise demolition, we established a color-coded system to track progress on different demolition stages and areas. This provided a visual representation for the team, enhancing collaboration and keeping the project on schedule.

Q 23. Explain your problem-solving skills with a specific example from a past project.

During a downtown building demolition, we encountered an unexpected issue: a previously undocumented underground utility line running through the planned demolition zone. This could have caused significant delays and safety hazards.

My problem-solving approach involved these steps:

- Immediate Stoppage: We immediately halted all demolition activities in the affected area.

- Assessment and Investigation: We contacted the utility company to confirm the line’s location, type, and status. This involved reviewing old blueprints, contacting local authorities and using ground-penetrating radar (GPR) to verify the line’s exact path.

- Risk Mitigation Strategy: Working with engineers, we developed a revised demolition plan to safely work around the utility line, minimizing disruption to the project timeline.

- Communication and Coordination: We kept all stakeholders (clients, engineers, utility company) informed every step of the way, ensuring transparency and minimizing potential conflicts.

- Implementation and Monitoring: We implemented the revised plan carefully, with increased monitoring to ensure worker safety near the utility line.

This situation highlighted the importance of meticulous pre-planning and the need to adapt quickly and effectively when faced with the unexpected. It also underscored the value of a strong network of contacts and collaboration with external experts.

Q 24. How do you ensure the accuracy of measurements and site plans?

Accuracy in measurements and site plans is fundamental for safety and efficient project execution. It’s akin to building a house – a flawed foundation will compromise the entire structure. We employ a multi-pronged approach:

- Advanced Surveying Techniques: We utilize Total Stations and GPS technology to conduct precise site surveys, capturing detailed topographical data and creating accurate as-built drawings.

- 3D Modeling and BIM (Building Information Modeling): We integrate 3D modeling software like Autodesk Revit to create detailed virtual models of the site and the existing structures. This allows us to visualize the demolition process and identify potential conflicts before they arise.

- Regular Quality Checks: We implement rigorous quality control checks throughout the measurement and planning process, comparing field measurements with design plans and resolving discrepancies immediately.

- Independent Verification: Where possible, we utilize independent verification of measurements and plans to ensure accuracy and minimize potential errors.

For instance, before demolition of a large industrial facility, we used drone technology to capture high-resolution aerial imagery which we then used to create a precise 3D model of the structure. This allowed us to plan the demolition sequence and identify potential hazardous elements with high accuracy and precision.

Q 25. What software and tools are you proficient in for land clearing and demolition?

Proficiency in relevant software and tools is essential for efficient and safe land clearing and demolition. We utilize a range of technologies, including:

- Autodesk AutoCAD: For precise drafting, site plan development, and as-built drawings.

- Autodesk Revit: For 3D modeling, visualization, and coordination.

- Trimble Total Station: For accurate site surveys and measurement.

- GPS Surveying Equipment: For precise positioning and mapping.

- Heavy Equipment Software (e.g., Caterpillar Product Link): For monitoring equipment performance, tracking usage, and predictive maintenance.

- Project Management Software (e.g., MS Project, Primavera P6): For scheduling, resource allocation, and progress tracking.

We also have extensive experience operating a wide range of heavy machinery, including excavators, bulldozers, and demolition robots, all crucial components of our operations.

Q 26. Describe your experience with post-demolition cleanup and site restoration.

Post-demolition cleanup and site restoration are as critical as the demolition itself. Leaving a site clean and safe ensures compliance and prepares it for the next phase of development. Our approach involves:

- Debris Removal and Sorting: Systematic removal and sorting of demolition waste, separating recyclable materials (metal, concrete, wood) from non-recyclable waste for proper disposal.

- Ground Leveling and Compaction: Ensuring a level and stable site foundation using grading equipment and compaction rollers.

- Environmental Remediation: Addressing any environmental concerns, such as soil contamination or hazardous waste removal, in accordance with all regulations.

- Site Restoration: Depending on the client’s specifications, this might include topsoil replacement, landscaping, and seeding for future development.

In one project, we utilized a specialized sorting system to efficiently separate recyclable materials. This significantly reduced landfill waste and added substantial cost savings to the overall project.

Q 27. How do you handle unexpected weather conditions during a project?

Unexpected weather conditions can significantly impact demolition projects, posing safety risks and causing delays. Our approach focuses on proactive planning and adaptable strategies:

- Weather Monitoring: Continuous monitoring of weather forecasts is crucial. This allows us to anticipate potential disruptions and plan accordingly.

- Contingency Planning: We develop contingency plans for various weather scenarios, outlining alternative work procedures or potential project suspensions.

- Safety Precautions: Implementing enhanced safety measures during inclement weather, such as increased worker supervision, use of specialized equipment, and strict adherence to safety protocols.

- Flexible Scheduling: Building flexibility into the project schedule allows for potential delays caused by weather-related interruptions.

For example, if heavy rain is forecast, we might postpone certain demolition tasks that involve unstable ground conditions and focus on indoor work or other weather-resistant tasks.

Q 28. Describe your experience with emergency response procedures during an incident.

Emergency response procedures are integral to our operations. We adhere to stringent safety protocols and regularly conduct training exercises to prepare for various incidents:

- Emergency Response Plan: A detailed emergency response plan is in place for every project, outlining procedures for various incidents (e.g., fire, equipment malfunction, injury). This plan includes designated roles, communication protocols, and evacuation procedures.

- Regular Safety Training: All team members receive regular training on safety procedures, emergency response protocols, and the use of safety equipment.

- Emergency Communication Systems: We utilize two-way radios, mobile phones, and other communication tools to ensure seamless communication during an emergency.

- First Aid and Medical Assistance: We have trained first aid personnel on-site and immediate access to emergency medical services.

- Post-Incident Review: Following any incident, we conduct a thorough review to identify contributing factors, implement corrective measures, and prevent similar occurrences in the future.

In one instance, a small fire broke out in a demolition site due to sparks from a cutting torch. Thanks to our quick response, utilizing the pre-planned fire suppression system and following evacuation procedures, the fire was contained swiftly and no one was injured. This reinforced the importance of our emergency response plan and training procedures.

Key Topics to Learn for Land Clearing and Demolition Interview

- Site Assessment and Planning: Understanding site surveys, identifying potential hazards (utilities, environmental concerns), and developing safe and efficient demolition plans. Practical application includes creating detailed site maps and risk assessments.

- Demolition Techniques and Equipment: Familiarity with various demolition methods (manual, mechanical, explosive), understanding the capabilities and limitations of different equipment (excavators, bulldozers, crushers), and selecting appropriate tools for specific tasks. Problem-solving involves adapting techniques based on site conditions and project requirements.

- Safety Regulations and Procedures: In-depth knowledge of OSHA regulations and industry best practices for land clearing and demolition, including fall protection, personal protective equipment (PPE), and emergency procedures. Practical application includes developing and implementing comprehensive safety plans.

- Environmental Considerations: Understanding environmental regulations, waste management procedures (e.g., asbestos abatement, soil remediation), and minimizing the environmental impact of demolition projects. Problem-solving includes developing mitigation strategies to address environmental concerns.

- Project Management and Budgeting: Experience with project scheduling, resource allocation, cost estimation, and adhering to project timelines and budgets. Practical application includes creating detailed project timelines and managing project resources effectively.

- Site Restoration and Remediation: Understanding the process of restoring a site after demolition, including grading, landscaping, and potential environmental remediation. Problem-solving includes addressing unforeseen complications during the restoration process.

Next Steps

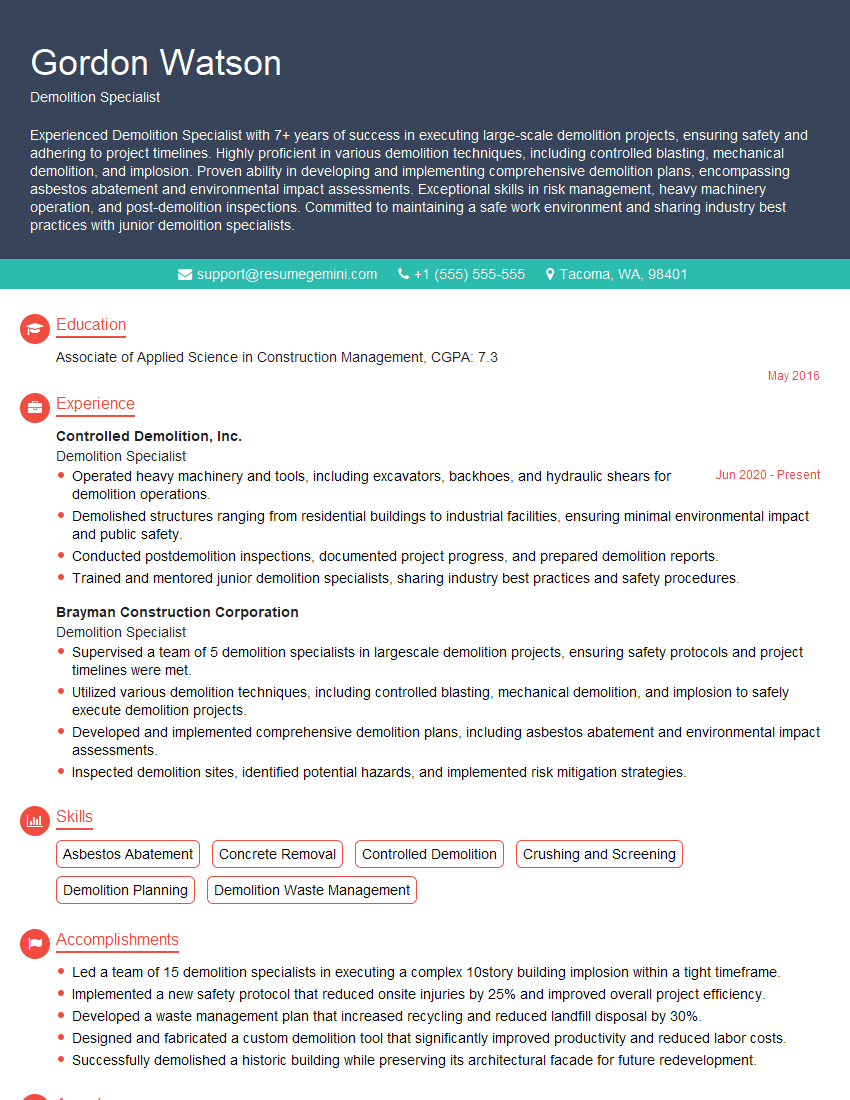

Mastering Land Clearing and Demolition opens doors to rewarding and in-demand careers within the construction and infrastructure industries. Your expertise in safe and efficient demolition practices is highly valued. To maximize your job prospects, it’s crucial to create a compelling, ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your qualifications for Land Clearing and Demolition roles. Examples of resumes tailored to this field are available to further guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.