Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Lay-Up Techniques interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Lay-Up Techniques Interview

Q 1. Explain the difference between hand lay-up and spray-up techniques.

Hand lay-up and spray-up are both open-mold composite fabrication techniques, but they differ significantly in material application and resulting part quality. Hand lay-up is a manual process where reinforcement materials (usually fabrics) are placed layer by layer onto a mold, with resin applied by brush or roller. It’s precise but labor-intensive and prone to variations in fiber distribution. Think of it like carefully painting a wall, each stroke deliberate. Spray-up, conversely, uses a machine to simultaneously spray chopped fibers and resin onto the mold. This is much faster and better for large parts, but it sacrifices the control and precision of hand lay-up. Imagine a painter using a spray gun instead of a brush; it’s quicker, but less precise.

In short: Hand lay-up offers superior fiber placement and control for smaller, more complex parts, while spray-up prioritizes speed and efficiency for larger, less intricate parts.

Q 2. Describe the process of preparing a mold for lay-up.

Mold preparation is critical for a successful lay-up. It starts with selecting the right mold material based on the part geometry, production volume, and resin system. Materials can range from wood and metal for simple parts to high-precision, temperature-resistant materials like aluminum or epoxy for complex aerospace components. The mold surface must be smooth, clean, and properly sealed to prevent resin leakage and ensure a defect-free part. A release agent is applied to facilitate easy removal of the cured composite part. This agent acts like a non-stick coating on a pan, preventing the composite from adhering to the mold.

Next, any imperfections in the mold are addressed – filled with appropriate fillers and meticulously sanded to achieve a perfect finish. The mold is then thoroughly cleaned, often with solvents, to remove dust, debris, and any residues from the release agent application. Finally, a final inspection confirms the mold’s readiness for lay-up.

Q 3. What are the common types of reinforcement materials used in lay-up?

A wide variety of reinforcement materials are used in lay-up processes, each with its own unique properties. The choice depends on the desired strength, stiffness, weight, and cost considerations. Common types include:

- Glass fiber: The most common and cost-effective option, offering a good balance of strength and stiffness. Available in various forms, such as woven fabrics, mats, and roving.

- Carbon fiber: Provides exceptional strength and stiffness, but is significantly more expensive than glass fiber. Often used in high-performance applications like aerospace and automotive industries.

- Aramid fiber (Kevlar): Known for its high tensile strength and excellent impact resistance. Used where high toughness is needed, such as in ballistic protection.

- Hybrid fibers: Combining different fiber types (e.g., glass and carbon) to optimize the properties of the final composite. This allows for tailoring the material to meet specific requirements.

The selection process usually involves careful consideration of the application’s needs, including strength requirements, desired weight, and budget constraints.

Q 4. How do you determine the appropriate fiber orientation for a specific application?

Fiber orientation is crucial for optimizing the mechanical properties of the composite part. It’s all about aligning the fibers along the expected stress directions. For example, in a component that will experience primarily tensile loads in one direction, the fibers should be oriented primarily along that axis to maximize strength and stiffness in that direction. This is typically represented as a percentage of fibers aligned in a specific direction (e.g., 0°/90° layup, where fibers are oriented 0 and 90 degrees to each other).

For complex loading scenarios, a more sophisticated approach is needed. Finite element analysis (FEA) is commonly used to simulate stress distribution within the component, guiding fiber placement for optimal performance. This is especially critical in high-performance applications where failure analysis and material efficiency are paramount. For example, in an aircraft wing, different layers with varying fiber orientations are used to withstand diverse stress conditions, from tension to compression and shear forces.

Q 5. Explain the importance of proper resin mixing and application.

Proper resin mixing and application are vital for achieving the desired composite properties and avoiding defects. Resins are typically two-part systems (resin and hardener) that need to be mixed in the precisely specified ratio according to the manufacturer’s instructions. Inaccurate mixing can result in incomplete curing, reduced strength, or poor adhesion. Think of it like baking a cake; the right ratio of ingredients is essential for the final product’s quality.

After mixing, the resin should be applied uniformly and thoroughly to ensure complete wetting of the fibers. Insufficient resin can lead to dry spots, which significantly weaken the composite. Excess resin can increase the weight of the part without significantly increasing its strength and might cause resin-rich areas that are more prone to cracking. Proper techniques, such as using rollers or brushes to achieve uniform resin distribution, are crucial to avoid these problems.

Q 6. What are the potential defects that can occur during the lay-up process and how are they prevented?

Several defects can occur during the lay-up process, affecting the quality and performance of the final product. These include:

- Voids: Entrapped air bubbles during resin application, reducing strength and stiffness.

- Dry spots: Areas where the fibers are not fully wetted by the resin, leading to weakness and potential delamination.

- Resin-rich areas: Excess resin concentration, reducing the strength-to-weight ratio.

- Wrinkles and folds in fabric: Affecting fiber orientation and causing stress concentrations.

- Delamination: Separation between layers of the composite.

Prevention involves meticulous attention to detail. Careful resin mixing, uniform application, proper fiber placement, and the use of techniques like vacuum bagging (discussed below) are critical. Regular inspection of the lay-up during the process helps in early detection and correction of any defects.

Q 7. Describe your experience with vacuum bagging techniques.

Vacuum bagging is a highly effective technique used to improve the quality of lay-up composites. It involves enclosing the lay-up within a vacuum bag, along with a bleeder ply and a breather fabric. A vacuum pump then removes air from the bag, consolidating the composite and removing trapped air bubbles or excess resin. This results in a denser, stronger, and more uniform part with fewer defects, significantly improving mechanical properties.

My experience includes extensive use of vacuum bagging in several projects, ranging from small prototypes to large structural components. I’ve worked with various bagging materials and vacuum pumps, optimizing the process for different composite systems and part geometries. I find that proper sealing of the vacuum bag is crucial for effective consolidation and consistent results. Vacuum bagging is an invaluable tool for creating high-quality composite parts and I’ve consistently relied on this technique in my work.

Q 8. How do you ensure proper consolidation of the laminate during lay-up?

Proper consolidation in lay-up is crucial for achieving the desired mechanical properties of the final composite part. It’s essentially about removing all trapped air and ensuring the fibers are uniformly wetted out by the resin. Think of it like making a perfectly smooth cake – you wouldn’t want air bubbles ruining the texture!

We achieve this through a combination of techniques. Roller de-aeration, using a specialized roller to work out trapped air from the laminate, is a common method. The roller’s pressure forces the air to the edges, allowing it to escape. We also use a vacuum bagging process in many cases. This involves placing the lay-up in a sealed bag and applying vacuum pressure. The vacuum sucks out the air, forcing the resin to fully impregnate the fibers and consolidate the layers. Finally, we might utilize pressure-assisted techniques like autoclaves for high-performance components, where controlled pressure and temperature ensures optimal consolidation.

For example, in laying up a carbon fiber boat hull, vacuum bagging is almost essential to ensure a flawless, strong structure. Without proper consolidation, the finished product would be weaker and more prone to cracking.

Q 9. What safety precautions do you follow when working with resins and hardeners?

Safety is paramount when handling resins and hardeners. These materials can be hazardous, causing skin irritation, respiratory problems, and even fires. Our safety protocol includes using appropriate Personal Protective Equipment (PPE) at all times. This includes gloves (nitrile or neoprene), safety glasses, respirators (often with organic vapor cartridges), and sometimes full-body suits depending on the resin system. Work is always done in a well-ventilated area or inside a fume hood to reduce exposure to harmful vapors.

We also follow strict procedures for handling and mixing. Mixing is done in designated areas with appropriate spill containment and cleanup materials readily available. Mixing ratios are carefully followed to avoid issues with cure and ensure the proper pot-life is achieved. Any spills are cleaned up immediately to avoid contamination and hazards. Finally, we maintain thorough and accurate records of the materials used and any incidents that occur during the process.

Ignoring these safety measures can lead to serious health problems and potentially costly mistakes. A simple lapse could result in skin burns or respiratory distress. Proper training and vigilant adherence to procedures are essential for our safety.

Q 10. Explain the importance of proper surface preparation before lay-up.

Proper surface preparation is the foundation of a successful lay-up. Think of it as priming a wall before painting – without it, the paint won’t adhere properly and will peel off. Similarly, if the surface isn’t properly prepared, the composite material won’t bond effectively, leading to delamination and structural weakness.

The preparation process typically involves cleaning the surface to remove any dirt, grease, or contaminants. This can be done using solvents, abrasive cleaning, or even blasting depending on the substrate. Once clean, the surface may require etching or roughening to improve adhesion. For example, aluminum components might be treated with an acid etch to create a slightly rough surface to help the resin bond. After cleaning, a release agent is applied to prevent the composite from bonding to the mold or tooling.

In a practical setting, neglecting proper surface preparation could lead to a catastrophic failure. For instance, in an aerospace application, a poor bond between the composite and the underlying structure could compromise the integrity of the aircraft wing.

Q 11. How do you control the fiber volume fraction during lay-up?

Controlling the fiber volume fraction (Vf) is crucial for achieving the desired mechanical properties of the composite. Vf represents the percentage of fibers in the total volume of the composite material. A higher Vf generally leads to a stronger and stiffer composite, but it also increases the viscosity of the mixture, making it harder to work with and potentially leading to air entrapment.

We control Vf through careful lay-up techniques. We use precise measurements of both fibers and resin, and we use techniques like prepreg materials (pre-impregnated fibers) which helps maintain a consistent resin content and fiber alignment. We also carefully control the ply thickness and orientation during layup. Visual inspection, coupled with occasional destructive testing (for quality control) helps to ensure that the fiber volume fraction is within the specified tolerance range for the project.

For instance, in a high-strength application, like a Formula 1 car chassis, precisely controlling the Vf is critical to meeting the rigorous structural requirements. A deviation from the target Vf would directly impact performance and safety.

Q 12. Describe your experience with different types of resins (e.g., epoxy, polyester).

My experience encompasses working with various resin systems, including epoxy and polyester resins. Each has its own unique properties and applications.

Epoxy resins are known for their excellent mechanical properties, chemical resistance, and good adhesion. They’re often preferred in high-performance applications due to their strength and durability, such as aerospace components and high-end sporting goods. They also tend to offer a greater range of curing agents, allowing for flexibility in tailoring the curing process. However, they can be more expensive than other resin systems.

Polyester resins are typically less expensive and offer good processing characteristics, making them suitable for a wider range of applications, including boat building and some structural components. They generally cure faster than epoxies, but they are often less resistant to chemicals and UV degradation compared to epoxy resins.

The choice of resin system depends heavily on the specific requirements of the project. For example, I’d choose epoxy resin for an aircraft part, but polyester resin might be sufficient for a less demanding application like a small boat hull.

Q 13. How do you inspect a cured laminate for defects?

Inspecting a cured laminate for defects is a crucial step to ensure structural integrity. We use a multi-pronged approach for thorough inspection. Visual inspection is the first step, looking for obvious defects like voids, delaminations (separation of layers), resin-rich areas, or dry spots. We also use non-destructive testing (NDT) methods to detect subsurface defects.

Common NDT methods include ultrasonic inspection, which uses sound waves to detect internal flaws. Radiography (X-ray inspection) can also reveal internal defects. Other methods might include tapping the laminate to detect hollow sounds indicating voids. Documentation of these inspections, along with any remedial actions taken, are carefully recorded.

For example, during the inspection of a wind turbine blade, identifying a delamination early in the process could prevent catastrophic failure and costly repairs down the line. A thorough inspection process is essential to ensuring the safety and longevity of the final product.

Q 14. What is the significance of cure cycle parameters in lay-up?

The cure cycle parameters – temperature, pressure, and time – are critical in determining the final properties of the composite. An improperly defined cure cycle can lead to incomplete curing, resulting in a weak, brittle, and potentially unsafe component.

Each resin system has its own optimal cure cycle, which is often provided by the resin manufacturer. This cycle is designed to achieve the desired degree of cure while minimizing stress build-up and potential defects. Factors such as the thickness of the laminate and the type of curing equipment (oven, autoclave) influence the cure cycle parameters.

For example, a slow cure at low temperature might result in a more uniform cure, reducing internal stresses. Conversely, a high-temperature, short cure might be preferable for production efficiency, but could lead to higher residual stresses in the finished part. We carefully select and monitor these parameters to achieve the necessary balance between mechanical properties, processing speed, and cost.

Q 15. Explain the concept of drape and its importance in lay-up.

Drape refers to how easily a composite material, like a fiber-reinforced polymer, conforms to the shape of a mold. It’s crucial in lay-up because achieving good drape ensures proper fiber orientation and minimizes wrinkles or voids in the final part. Poor drape can lead to weak points and reduced performance. Think of it like draping fabric – a stiff fabric is hard to work with and may bunch up, whereas a flexible one drapes smoothly. In composite lay-up, excellent drape ensures consistent fiber alignment and uniform resin distribution, leading to a stronger and more reliable part.

For example, a highly pliable fabric might drape well onto a complex curved surface, while a stiffer, less flexible material may struggle and require more effort for proper placement and consolidation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle complex geometries during lay-up?

Handling complex geometries during lay-up requires a combination of techniques and materials. For intricate shapes, pre-cut plies or tapes are essential to minimize waste and ensure accurate placement. We often use flexible molds made from materials like silicone rubber that can conform to complex curves. In addition, we may employ specialized techniques such as vacuum bagging or autoclave curing to ensure proper consolidation and resin flow into all areas of the mold. Sometimes, we might use a combination of prepreg materials (pre-impregnated fibers) for simpler sections and hand lay-up for the complex areas to achieve a balance of efficiency and precision.

For instance, I once worked on a project involving a highly contoured aircraft component. We used a flexible silicone mold and pre-cut plies to match the curvature, employing vacuum bagging to remove air pockets and ensure optimal fiber consolidation. This approach allowed us to achieve the required part geometry and structural integrity.

Q 17. Describe your experience with different types of tooling materials.

My experience encompasses a wide range of tooling materials, each with its own strengths and weaknesses. I’ve worked extensively with steel tools for their durability and dimensional stability, ideal for high-volume production runs. However, for more complex geometries and lower-volume production, I prefer using aluminum tools due to their lighter weight and ease of machining. For very complex shapes or prototypes, composite tooling, such as carbon fiber reinforced polymers, provides flexibility and cost-effectiveness. Finally, I’ve used silicone rubber molds for their conformability to intricate shapes, especially when dealing with complex curves.

The choice of tooling material depends heavily on the part geometry, production volume, and budget constraints. Each material brings unique characteristics to the table, and selecting the appropriate one is crucial for achieving the desired outcome.

Q 18. What is the role of release agents in lay-up?

Release agents are crucial in lay-up to prevent the cured composite part from bonding to the mold. They create a thin, non-stick layer that facilitates easy demolding without damaging the part or the mold. Without a release agent, the finished composite would likely be stuck to the mold, making it impossible to remove without destroying either the part or the mold. Common release agents include silicone-based sprays, waxes, and films. The selection of a release agent depends heavily on the type of mold and the composite resin system. The application of the release agent is crucial. It needs to be applied evenly, without leaving too thick of a layer which may impact the surface finish.

For instance, I’ve used a specific silicone-based spray release agent for a carbon fiber part being laid up in a steel mold. A thin even coat ensured a clean release without any surface defects.

Q 19. How do you manage material waste during the lay-up process?

Material waste management is critical for both cost-effectiveness and environmental responsibility. We employ several strategies to minimize waste. This includes careful planning and precise cutting of prepreg materials using computer-aided design (CAD) software and CNC cutting machines. We also implement efficient nesting algorithms to optimize material usage and reduce the amount of scrap generated. Leftover materials, if still usable, are often repurposed for smaller parts or testing purposes. Furthermore, we work closely with our suppliers to explore alternative materials and manufacturing processes that minimize waste generation.

For example, we’ve reduced our prepreg waste by 15% by optimizing our nesting algorithms and implementing a more efficient cutting process. This involved training the team on precision cutting and accurate material estimation.

Q 20. Explain your experience with different lay-up patterns (e.g., unidirectional, cross-ply).

My experience covers various lay-up patterns, each tailored to specific performance requirements. Unidirectional lay-up, using fibers aligned in a single direction, provides maximum strength along that axis, ideal for applications requiring high tensile strength. Cross-ply lay-ups, alternating layers at 90-degree angles, provide balanced strength in two directions. More complex patterns, such as quasi-isotropic lay-ups, achieve near-isotropic strength properties. The choice of lay-up pattern depends entirely on the application’s required mechanical properties and stress distribution.

In one project, we used a unidirectional lay-up for a high-strength structural component, ensuring maximum tensile strength along the primary load direction. In contrast, for a pressure vessel, we opted for a quasi-isotropic lay-up to ensure equal strength distribution in all directions.

Q 21. How do you ensure the consistent quality of your lay-up?

Ensuring consistent lay-up quality relies on a combination of meticulous practices and quality control measures. These include precise ply placement, careful resin application to maintain the correct fiber volume fraction, and consistent curing conditions to ensure proper polymerization. We use digital tools to document each step of the process, including digital images and records of material quantities. Regular inspections and thorough quality control checks at various stages, including visual inspections for voids or wrinkles and non-destructive testing (NDT) techniques like ultrasonic inspection, are vital. This meticulous approach guarantees that each lay-up meets the required standards, resulting in high-quality composite parts with consistent properties.

For instance, we regularly calibrate our curing ovens to maintain precise temperature and pressure settings, critical for achieving the desired mechanical properties in the cured composite. Visual inspections, coupled with ultrasonic testing, are employed to identify any internal flaws and ensure the integrity of every component.

Q 22. Describe your troubleshooting experience with common lay-up problems.

Troubleshooting lay-up issues requires a systematic approach. I begin by visually inspecting the laminate for obvious defects like wrinkles, voids, dry spots, or misaligned plies. These visual cues often pinpoint the root cause. For instance, wrinkles often indicate improper ply placement or insufficient consolidation pressure. Dry spots suggest inadequate resin flow or poor prepreg handling.

Beyond visual inspection, I utilize non-destructive testing (NDT) methods such as ultrasonic C-scans to detect internal flaws like delaminations or unbonded regions. These scans provide a detailed internal image of the laminate, guiding further investigation. If the problem is localized, we might be able to repair it; however, widespread defects often necessitate scrapping the part and restarting the lay-up process.

For example, during a project involving the lay-up of carbon fiber prepreg for a high-performance aircraft component, we encountered excessive resin bleed. By carefully analyzing the lay-up process, we identified the cause as using an overly aggressive curing cycle, leading to accelerated resin flow and expulsion. We adjusted the cure cycle, improving the final product’s quality and reducing material waste. Understanding the resin system’s behavior, curing parameters, and the impact of environmental conditions is critical to effective troubleshooting.

Q 23. Explain your experience with different types of prepreg materials.

My experience encompasses a wide range of prepreg materials, including carbon fiber, glass fiber, aramid fiber (Kevlar), and hybrid composites. Each material presents unique characteristics that influence lay-up techniques and final product properties. For instance, carbon fiber prepreg is known for its high strength-to-weight ratio but can be challenging to handle due to its stiffness. Glass fiber prepreg is generally more forgiving but offers lower mechanical properties. Aramid fiber prepreg exhibits excellent impact resistance but lower tensile strength.

I’m proficient in working with various resin systems within prepregs, including epoxy, bismaleimide (BMI), and cyanate ester. Each system has a distinct processing window (a range of temperature and pressure required for proper cure), influencing the lay-up procedures and curing cycles. For example, epoxy prepregs typically require lower cure temperatures than BMI, impacting the energy requirements of the autoclave. Experience with different prepreg systems and fibers allows me to optimize lay-up strategies for specific performance and cost requirements.

I’ve worked extensively with prepregs with different ply orientations, weave styles (plain, twill, satin), and resin content, tailoring material selection to meet specific structural demands of the final component.

Q 24. How do you determine the appropriate number of plies for a given application?

Determining the appropriate number of plies is a crucial aspect of composite design, driven by the intended application’s structural requirements. The process involves several steps:

- Defining the load case: This entails identifying all anticipated loads and stresses, including tensile, compressive, shear, and bending loads. Finite element analysis (FEA) is commonly used to simulate these load cases.

- Material selection: The properties of the chosen prepreg material (e.g., tensile strength, modulus, shear strength) directly influence the required ply count. Stronger materials may require fewer plies to achieve the desired strength.

- Ply orientation: Strategic ply orientation maximizes strength and stiffness in critical directions, reducing the overall ply count. This is also determined through FEA.

- Thickness calculations: Based on FEA results, we can determine the required laminate thickness, which then translates to the necessary number of plies, considering individual ply thickness. Manufacturing constraints and limitations of the curing process can also influence the final ply count.

- Safety factor: A safety factor is usually included to account for uncertainties in material properties, manufacturing imperfections, and unforeseen loads, ensuring the final product exceeds minimum performance criteria.

For example, designing a pressure vessel might require a significant number of plies due to the high internal pressure, while a structural panel could need fewer if the load requirements are less demanding.

Q 25. What are the advantages and disadvantages of using prepreg vs. wet lay-up?

Prepreg and wet lay-up represent two distinct approaches to composite fabrication, each with its own set of advantages and disadvantages:

| Feature | Prepreg | Wet Lay-up |

|---|---|---|

| Resin content | Precisely controlled | Variable, potential for inconsistencies |

| Fiber volume fraction | High, consistent | Lower, less consistent |

| Process complexity | Higher | Lower |

| Part quality | Generally higher quality, fewer defects | Potentially lower quality, more defects possible |

| Cost | Higher material cost | Lower material cost |

| Curing | Often requires autoclave | Can use simpler curing methods |

| Handling | Requires careful handling and storage | More forgiving |

Prepreg offers superior control over resin content and fiber volume fraction, leading to higher-quality parts with more consistent properties. However, it’s more expensive and requires specialized equipment and skills. Wet lay-up is simpler and more cost-effective but is more prone to defects and inconsistencies.

The choice between the two depends heavily on the application, budget constraints, part complexity, and required performance characteristics. For high-performance applications where consistent quality is paramount, prepreg is usually preferred. For simpler parts with less stringent requirements, wet lay-up may be a suitable and cost-effective alternative.

Q 26. How do you ensure proper adhesion between plies during lay-up?

Ensuring proper adhesion between plies is essential for achieving the desired mechanical properties of the final laminate. Several factors contribute to good interlaminar adhesion:

- Surface preparation: Cleanliness is crucial. Any contaminants (dust, oil, etc.) on the ply surfaces can hinder adhesion. This often involves wiping the surfaces with a solvent before lay-up.

- Proper resin flow: Sufficient resin must be present to wet out all the fibers in each ply and ensure proper bonding between plies. This often requires applying appropriate pressure during the lay-up and curing process.

- Temperature and pressure: The curing process must provide the necessary heat and pressure to activate the resin and achieve proper polymerization and adhesion. The specifics depend on the chosen resin system.

- Vacuum bagging or autoclave processing: These techniques remove air trapped between the plies and apply even pressure, promoting good interlaminar adhesion. Vacuum bagging is relatively simpler and less expensive than autoclave processing but offers slightly less control over the curing process.

- Proper ply orientation and alignment: Misaligned plies can disrupt the continuous fiber pathways and reduce interlaminar adhesion. Careful handling and lay-up techniques are essential to avoid this.

In practice, we carefully monitor the resin flow during lay-up, paying close attention to wrinkle formation and air bubbles. Any imperfections are addressed immediately to prevent adhesion issues. Regular inspections throughout the curing process help to ensure that the curing conditions are optimal for proper bonding.

Q 27. Describe your experience with automated lay-up equipment.

My experience with automated lay-up equipment includes working with automated fiber placement (AFP) and tape laying (ATL) machines. These systems offer significant advantages over manual lay-up, including increased speed, improved precision, and reduced labor costs. They’re particularly valuable for complex shapes and high-volume production.

AFP machines use a robotic arm to precisely place continuous fibers onto a mold, while ATL machines lay down prepreg tapes in a controlled manner. Both technologies allow for precise control over ply orientation, thickness, and placement, minimizing defects and improving repeatability. Programming these systems requires expertise in CAD/CAM software and a deep understanding of composite materials and lay-up processes.

I’m familiar with operating and troubleshooting various types of automated lay-up equipment, including systems with different head designs, material handling systems, and control software. My experience extends to integrating these machines with other automated processes, such as curing and inspection systems, to achieve a fully automated production line. Furthermore, I’m adept at optimizing automated lay-up parameters to maximize efficiency and quality.

Key Topics to Learn for Lay-Up Techniques Interview

- Material Selection and Properties: Understanding the characteristics of various composite materials (e.g., fibers, resins) and their impact on lay-up quality and final product performance. Consider factors like strength, stiffness, weight, and cost.

- Lay-Up Methods and Techniques: Mastering different lay-up techniques, including hand lay-up, spray lay-up, and automated fiber placement. Understand the advantages and disadvantages of each method and their suitability for different applications.

- Prepreg Handling and Processing: Knowledge of handling prepreg materials, including storage, preparation, and lay-up procedures to ensure optimal fiber alignment and resin flow. Discuss potential challenges like tackiness and shelf life.

- Quality Control and Inspection: Implementing quality control measures throughout the lay-up process, including visual inspection, dimensional checks, and non-destructive testing methods to identify and correct defects.

- Tooling and Fixturing: Understanding the role of tooling and fixturing in achieving accurate and repeatable lay-ups. Discuss different tooling materials and their selection criteria.

- Health and Safety Procedures: Familiarity with relevant health and safety regulations and procedures related to handling composite materials and working with lay-up equipment. This includes proper use of personal protective equipment (PPE).

- Troubleshooting and Problem Solving: Ability to identify and resolve common problems encountered during the lay-up process, such as voids, delaminations, and fiber misalignment. Discuss practical approaches to prevent and rectify these issues.

- Advanced Lay-Up Techniques: Explore advanced techniques such as automated tape laying, resin transfer molding (RTM), and vacuum assisted resin transfer molding (VARTM), and their applications in complex composite structures.

Next Steps

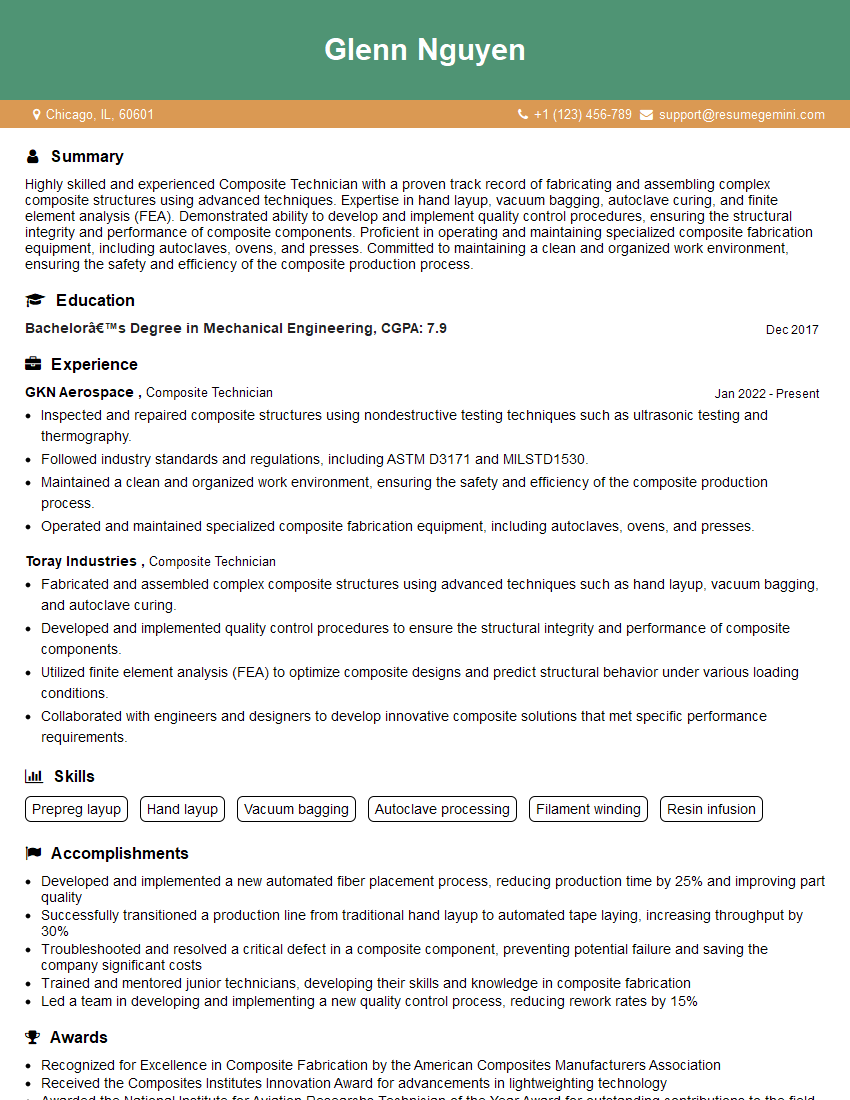

Mastering Lay-Up Techniques is crucial for career advancement in the composites industry, opening doors to specialized roles and higher earning potential. To significantly boost your job prospects, it’s essential to create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the specific requirements of Lay-Up Techniques positions. We provide examples of resumes optimized for this field to guide you in creating your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.