Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Magnetic Hysteresis Loop Analysis interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Magnetic Hysteresis Loop Analysis Interview

Q 1. Explain the concept of magnetic hysteresis.

Magnetic hysteresis describes the lagging of the magnetization of a magnetic material behind the applied magnetic field. Imagine trying to push a heavy box across a rough floor. Initially, it takes a lot of effort to get it moving (initial magnetization). Once moving, less force is needed to keep it going. If you stop pushing, the box doesn’t immediately stop; it slides a bit further due to inertia. Similarly, when you remove the applied magnetic field, the material retains some magnetization. This lagging effect is hysteresis.

This phenomenon is crucial because it reveals a material’s ability to store magnetic energy and its response to changing magnetic fields. It’s a non-linear, path-dependent property, meaning the magnetization depends not only on the current field strength but also on the material’s previous magnetic history. This is why we get a loop, rather than a single line, on a B-H curve.

Q 2. Describe the different regions of a typical hysteresis loop.

A typical hysteresis loop, plotting magnetic flux density (B) against magnetic field strength (H), exhibits several key regions:

- Initial Magnetization Curve: As the applied field (H) increases from zero, the magnetization (B) increases initially rapidly, then more gradually, approaching saturation.

- Saturation: The point where further increases in H produce negligible changes in B. The material’s magnetic domains are almost entirely aligned with the field.

- Descending Branch: As H decreases from saturation, B also decreases, but not along the same path. The material retains a significant amount of magnetization even when H is zero.

- Remanence (Br): The amount of magnetization remaining in the material when the applied field is reduced to zero. This represents the ‘memory’ of the material.

- Coercivity (Hc): The reverse magnetic field strength (H) required to reduce the magnetization (B) to zero after saturation. This indicates the material’s resistance to demagnetization.

- Hysteresis Loop Completion: The loop closes as the applied field is reversed and brought back to zero, demonstrating the path-dependent nature of magnetization.

Q 3. What are remanence and coercivity, and how are they determined from a hysteresis loop?

Remanence (Br) is the magnetic flux density remaining in a material after the external magnetic field is removed. It’s determined by finding the y-intercept of the hysteresis loop—the value of B when H=0 on the descending branch. A high remanence indicates that the material retains its magnetization well, suitable for permanent magnets.

Coercivity (Hc) is the magnetic field strength required to completely demagnetize the material after saturation. It’s determined by finding the x-intercept of the hysteresis loop—the absolute value of H when B=0. A high coercivity means the material resists demagnetization strongly, again, a desirable characteristic of strong permanent magnets.

For example, a hard ferrite magnet will have high remanence and high coercivity, while a soft iron core will have low remanence and low coercivity.

Q 4. What is the significance of the area enclosed by the hysteresis loop?

The area enclosed by the hysteresis loop represents the energy lost per unit volume of the material during one cycle of magnetization. This energy is dissipated as heat due to the irreversible movement of magnetic domain walls within the material. A larger loop area signifies greater energy loss. This is crucial in applications like transformers, where minimizing hysteresis losses is vital for efficiency. Smaller loops are desirable in such scenarios.

Q 5. Explain the relationship between hysteresis and energy loss.

Hysteresis is directly related to energy loss because the magnetization process is not perfectly reversible. During magnetization, energy is stored in the material’s magnetic domains. However, not all this energy is recovered when the field is removed. The difference—the energy trapped in the irreversible domain wall movements—is lost as heat. This energy loss is proportional to the area enclosed by the hysteresis loop.

Consider a transformer: the core is constantly being magnetized and demagnetized. Hysteresis losses contribute to inefficiency and heat generation. Therefore, materials with narrow hysteresis loops (low coercivity) are preferred for transformer cores to minimize these losses.

Q 6. How does temperature affect the hysteresis loop?

Temperature significantly affects the hysteresis loop. Generally, increasing temperature leads to a reduction in both remanence (Br) and coercivity (Hc). The loop becomes narrower and the area enclosed decreases, indicating reduced energy loss. This is because higher temperatures increase the thermal energy of the material, making it easier for the magnetic domains to reorient themselves and reducing the magnetic anisotropy.

The Curie temperature is a critical point; above this temperature, the material loses its ferromagnetic properties and the hysteresis loop disappears completely, becoming paramagnetic.

Q 7. Describe different types of magnetic materials and their hysteresis characteristics.

Various magnetic materials exhibit different hysteresis characteristics:

- Soft Magnetic Materials: These materials have narrow hysteresis loops (low Br and Hc), meaning they are easily magnetized and demagnetized. They are used in applications requiring low energy loss, like transformer cores (e.g., soft iron, silicon steel).

- Hard Magnetic Materials: These materials have wide hysteresis loops (high Br and Hc), making them suitable for permanent magnets. They retain their magnetization even after the external field is removed (e.g., Alnico, neodymium magnets, ferrite magnets).

- Ferrites: These ceramic materials offer a balance of good magnetic properties and electrical resistivity. They find applications in transformers, inductors, and permanent magnets.

- Amorphous and Nanocrystalline Materials: These advanced materials have extremely narrow hysteresis loops, minimizing energy loss. Their applications often involve high-frequency applications.

The choice of material depends critically on the specific application. For example, a high-fidelity speaker requires a soft magnetic material in its core to minimize energy loss at varying frequencies, while a refrigerator magnet needs a hard magnetic material to retain its magnetism over time.

Q 8. How is a hysteresis loop measured experimentally?

Measuring a hysteresis loop involves subjecting a ferromagnetic material to a controlled, cyclical magnetic field and simultaneously measuring the resulting magnetization. Imagine stretching and releasing a rubber band – the force applied is analogous to the magnetic field, and the rubber band’s stretch is like the material’s magnetization. This process requires specialized equipment.

Experimentally, this is typically done using a system comprising:

- Electromagnet: Generates a variable magnetic field of known strength (H). This field is often changed smoothly from a high positive value to a high negative value and back, completing a full cycle.

- Sample Holder: Securely holds the magnetic material being tested within the electromagnet’s field.

- Magnetometer: Precisely measures the material’s magnetization (B) in response to the applied magnetic field. Techniques like vibrating sample magnetometry (VSM) or induction methods are commonly employed.

- Data Acquisition System: Records the values of H and B simultaneously, creating the points used to plot the hysteresis loop.

The data from the magnetometer and electromagnet are plotted with magnetic field strength (H) on the x-axis and magnetic flux density (B) on the y-axis. The resulting curve is the hysteresis loop. The process requires careful calibration and control of the experimental parameters to ensure accurate results.

Q 9. What are the common methods for characterizing magnetic materials?

Several methods characterize magnetic materials, each providing different insights. The choice depends on the specific application and the desired level of detail. Common methods include:

- Hysteresis Loop Measurement: Provides information on coercivity, remanence, saturation magnetization, and energy product, crucial for selecting materials in applications like transformers and permanent magnets.

- Initial Magnetization Curve: This curve represents the magnetization behavior of a previously unmagnetized material as the magnetic field strength is gradually increased. It’s helpful in assessing the material’s ease of magnetization.

- Magnetic Permeability Measurement: Determines how easily a material can be magnetized; it’s the ratio of magnetic flux density to the applied magnetic field strength. This is critical for applications such as inductors and magnetic shielding.

- Susceptibility Measurement: Measures the extent to which a material becomes magnetized in an external magnetic field. This is particularly important for paramagnetic and diamagnetic materials.

- Curie Temperature Measurement: Finds the temperature at which a ferromagnetic material loses its ferromagnetic properties and becomes paramagnetic. This information is crucial for designing materials to operate under varying temperature conditions.

Often, a combination of these methods is used to gain a comprehensive understanding of the material’s magnetic properties.

Q 10. Explain the concept of magnetic saturation.

Magnetic saturation refers to the state where a ferromagnetic material cannot be magnetized any further, even with a substantial increase in the applied magnetic field strength. Think of it like filling a container to its maximum capacity; once full, you can’t add any more.

At saturation, essentially all the magnetic domains within the material are aligned with the external field. Increasing the field further will not produce any significant change in magnetization. The saturation magnetization is a characteristic property of the material and is indicated by the upper and lower plateaus of the hysteresis loop.

The value of saturation magnetization (often denoted as Ms or Bs) is an important parameter for choosing materials in high-power applications, where a large magnetization is required.

Q 11. What are the factors affecting the shape and size of the hysteresis loop?

Several factors influence the shape and size of a hysteresis loop. The loop’s area represents the energy lost per cycle (hysteresis losses), and its shape indicates the material’s magnetic characteristics.

- Material Composition: The type of magnetic material (e.g., iron, nickel, alloys) significantly impacts the loop’s shape and size. Different alloys have different magnetic behaviors.

- Microstructure: The internal structure of the material, including grain size, crystal orientation, and presence of defects, affects domain wall motion and thus the loop’s shape.

- Temperature: Higher temperatures can reduce the strength of magnetic interactions, leading to a smaller loop and lower saturation magnetization. The Curie temperature is a critical point in this regard.

- Stress and Strain: Mechanical stress within the material can alter the magnetic domain arrangement and hence the hysteresis loop. The loop may become wider or narrower depending on the stress type.

- Previous Magnetic History: A material’s past magnetization can influence its subsequent response to an applied field. This explains the “hysteresis” – meaning “to lag behind”.

Q 12. How can you interpret a hysteresis loop to determine material properties?

A hysteresis loop is a rich source of information about a material’s magnetic properties. Key parameters extracted from the loop include:

- Remanence (Br): The magnetization remaining in the material after the applied field is removed. Represents the “memory” of the material. High remanence is desirable in permanent magnets.

- Coercivity (Hc): The magnetic field strength required to reduce the magnetization to zero after saturation. High coercivity is also desired in permanent magnets, indicating resistance to demagnetization.

- Saturation Magnetization (Bs or Ms): The maximum magnetization achievable in the material. Crucial for high-power applications.

- Hysteresis Loss: The area enclosed by the hysteresis loop, representing the energy dissipated as heat during each magnetization cycle. This is a significant factor in applications involving alternating current (AC) magnetic fields, impacting the efficiency of devices like transformers.

By analyzing these parameters, we can select suitable materials for specific applications. For instance, a transformer core material needs low hysteresis loss for efficiency, whereas a permanent magnet needs high remanence and coercivity.

Q 13. How is hysteresis loop analysis used in the design of magnetic components?

Hysteresis loop analysis is fundamental to the design of magnetic components. It guides material selection and performance optimization. Here’s how:

- Transformer Design: The core material choice directly impacts efficiency. Materials with narrow hysteresis loops (low hysteresis loss) are preferred to minimize energy dissipation as heat. The analysis helps to select the right core material for a specific power rating and frequency.

- Permanent Magnet Design: The loop’s remanence and coercivity dictate the magnet’s strength and resistance to demagnetization. Careful selection ensures the magnet meets the required performance criteria in applications like motors and sensors.

- Inductor and Choke Design: Core material with high permeability and low hysteresis losses are important for efficient energy storage. Analysis helps in optimizing the inductor’s performance characteristics.

- Magnetic Shielding Design: Materials with high permeability can be selected based on the hysteresis loop to create effective shielding against unwanted magnetic fields.

In all these cases, the hysteresis loop acts as a critical tool to predict and optimize the performance of magnetic components under various operating conditions.

Q 14. Explain the difference between hard and soft magnetic materials.

Hard and soft magnetic materials are fundamentally different in their magnetic behavior, leading to distinct applications. The differences are clearly visible when comparing their hysteresis loops.

- Soft Magnetic Materials: These materials have narrow hysteresis loops with low coercivity and high permeability. This means they are easily magnetized and demagnetized, making them ideal for applications requiring rapid magnetization changes, such as transformer cores and inductors. Examples include iron, permalloy, and ferrites. Their loops have a small area, indicating low hysteresis losses.

- Hard Magnetic Materials: These exhibit wide hysteresis loops with high coercivity and remanence. They resist demagnetization, making them suitable for permanent magnets used in motors, sensors, and data storage. Examples include Alnico, samarium-cobalt, and neodymium-iron-boron magnets. Their loops have a large area indicating high energy product and resistance to demagnetization.

The key difference lies in the ease with which their magnetization can be reversed. Soft materials reverse easily, while hard materials resist this reversal.

Q 15. What are some applications of magnetic hysteresis loop analysis?

Magnetic hysteresis loop analysis, or simply hysteresis loop measurement, finds widespread application in characterizing the magnetic properties of materials. It’s essentially a fingerprint of a material’s magnetic behavior. Understanding this fingerprint allows us to tailor materials for specific applications.

- Material Selection: Engineers use hysteresis loops to select materials with optimal properties for various applications, such as transformers (requiring low hysteresis losses for efficiency), permanent magnets (needing high remanence and coercivity for strong fields), and magnetic recording media (demanding high squareness for data density).

- Quality Control: The consistency of magnetic properties is critical in manufacturing. Hysteresis loop measurements are routinely used to ensure batches of magnetic materials meet the required specifications.

- Research and Development: Scientists use hysteresis loops to study the effects of alloying, processing, and microstructure on magnetic properties. This helps in designing new materials with improved performance.

- Non-destructive Testing: Hysteresis loops can be used for non-destructive evaluation of magnetic components to detect defects or changes in magnetic properties that might indicate material degradation.

For example, in the automotive industry, hysteresis loop analysis helps select optimal materials for electric vehicle motors, balancing magnetic performance with cost and weight constraints.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you deal with noise and artifacts in hysteresis loop measurements?

Noise and artifacts are inevitable in hysteresis loop measurements, stemming from sources like electronic noise in the measurement system, environmental magnetic fields, and sample imperfections. Dealing with them requires a multi-pronged approach:

- Shielding: Employing magnetic shielding reduces the influence of external fields. This is crucial for accurate measurements, especially for materials with low coercivity.

- Signal Averaging: Repeating the measurement multiple times and averaging the results effectively reduces random noise. The more measurements averaged, the better the signal-to-noise ratio.

- Filtering: Digital filtering techniques can smooth the data, removing high-frequency noise without significantly distorting the hysteresis loop’s shape. Appropriate filter types (e.g., moving average, Savitzky-Golay) need to be selected based on the noise characteristics.

- Calibration: Regular calibration of the measurement system ensures accuracy and minimizes systematic errors. This involves using known reference materials with well-defined hysteresis loops.

- Data Pre-processing: This may include techniques like baseline correction to remove offsets or fitting algorithms to model and subtract background noise.

Imagine measuring the hysteresis loop of a tiny magnetic particle. The signal will be weak and easily overwhelmed by noise. Careful shielding, averaging, and filtering are essential to extract a meaningful result.

Q 17. Describe different models used for predicting hysteresis behavior.

Several models exist for predicting hysteresis behavior, each with its strengths and limitations. The choice depends on the complexity of the material and the accuracy required.

- Preisach Model: A widely used phenomenological model that represents the hysteresis behavior as an ensemble of independent elementary hysteresis operators. It can capture complex shapes but requires extensive parameterization.

- Jiles-Atherton Model: Another popular phenomenological model based on the interaction between magnetic domains. It’s computationally efficient and can capture many features of hysteresis, including the effects of magnetic field and temperature.

- Vector Preisach Model: This is an extension of the Preisach model that can effectively model rotational hysteresis and three-dimensional effects in anisotropic materials.

- Micromagnetic Models: These are based on solving the Landau-Lifshitz-Gilbert equation numerically, providing a more fundamental understanding of hysteresis at the microscopic level, but are computationally intensive and require extensive resources.

For instance, the Jiles-Atherton model is often preferred for its balance between accuracy and computational efficiency in industrial applications. However, for advanced research on novel magnetic materials, micromagnetic simulations are often necessary for a comprehensive understanding.

Q 18. How can you use hysteresis loops to assess the quality of magnetic materials?

Hysteresis loops provide crucial insights into the quality of magnetic materials. Several parameters derived from the loop are key indicators:

- Remanence (Mr): The magnetization remaining after the applied field is removed. A high remanence signifies a strong permanent magnet.

- Coercivity (Hc): The applied field needed to reduce the magnetization to zero. High coercivity indicates resistance to demagnetization, vital for permanent magnets.

- Saturation Magnetization (Ms): The maximum magnetization achievable. It reflects the material’s potential magnetic strength.

- Squareness Ratio (Mr/Ms): The ratio of remanence to saturation magnetization. A higher ratio (closer to 1) indicates a more ‘square’ loop, often desirable for memory storage applications.

- Hysteresis Loss: The area enclosed by the loop represents the energy lost as heat per cycle. Lower hysteresis losses are crucial for applications like transformers to minimize energy waste.

Imagine evaluating two batches of permanent magnets. The hysteresis loops will clearly reveal which batch has better magnetic properties, higher remanence, and higher coercivity, thus signifying better quality.

Q 19. Explain the concept of magnetic anisotropy and its effect on hysteresis.

Magnetic anisotropy refers to the dependence of a material’s magnetic properties on the direction of the applied magnetic field. In anisotropic materials, magnetization is easier along certain crystallographic directions (easy axes) than others (hard axes).

This anisotropy significantly affects the hysteresis loop. Loops measured along easy axes will exhibit lower coercivity and higher saturation magnetization compared to those measured along hard axes. The shape of the hysteresis loop itself will be different depending on the direction of measurement. This leads to variations in magnetic properties like remanence, coercivity and even saturation.

Think of it like pushing a box: it’s easier to push it along a flat surface (easy axis) than up a hill (hard axis). Similarly, it is easier to magnetize an anisotropic material along its easy axis. This directional dependence must be considered in applications, for example, when designing magnets for specific orientations.

Q 20. How does grain size affect magnetic hysteresis?

Grain size significantly impacts magnetic hysteresis. In polycrystalline materials, the magnetic domains interact with grain boundaries, influencing magnetization reversal processes.

Generally, smaller grain sizes lead to increased coercivity and often decreased saturation magnetization. The reason is that the increased number of grain boundaries hinder the domain wall movement which is necessary for magnetization reversal. In contrast, larger grains tend to have lower coercivity, allowing for easier domain wall motion and magnetization reversal.

This is analogous to navigating a city: many small streets (small grains) make it harder to move quickly (higher coercivity), while a few large avenues (large grains) allow for smoother movement (lower coercivity).

Q 21. What are the limitations of hysteresis loop analysis?

Despite its widespread use, hysteresis loop analysis has some limitations:

- Limited Dynamic Information: The standard hysteresis loop shows only the steady-state response. It doesn’t capture dynamic effects, such as eddy currents or domain wall motion at high frequencies.

- Simplified Representation: The loop represents the bulk magnetic behavior, potentially masking inhomogeneities or local variations within the material.

- Temperature Dependence: Hysteresis loops are temperature-dependent, and the measured loop might not be representative at different operating temperatures.

- Non-linearity: Hysteresis is inherently non-linear, and simple models may not accurately capture the behaviour under all conditions. Advanced modeling techniques are required to account for higher-order effects.

- Experimental Challenges: Measurement setup, calibration, and noise reduction can be challenging, particularly for small or delicate samples.

For example, while the hysteresis loop gives a good overview of a transformer’s core loss at low frequencies, it won’t accurately reflect the losses at high frequencies where eddy currents become significant, requiring additional specialized techniques for analysis.

Q 22. Explain the Jiles-Atherton model of hysteresis.

The Jiles-Atherton model is a phenomenological model that describes the hysteresis behavior of ferromagnetic materials. Unlike purely empirical models, it attempts to capture the underlying physics of magnetization processes. It does this by considering three key aspects: magnetization due to the applied field, magnetization due to inter-domain interactions (representing the influence of neighboring magnetic domains on each other), and an irreversible magnetization component related to domain wall pinning and irreversible movement. The model uses several parameters to characterize these processes; these parameters are then used to fit the experimental hysteresis loops. The model’s equations are complex but essentially solve for the magnetization (M) as a function of the applied field (H), incorporating a rate-dependent component to account for hysteresis effects. It’s powerful because it gives a physical interpretation to the observed hysteresis loop, providing insight beyond simple curve fitting.

Imagine a group of tiny magnets (magnetic domains) inside a material. The applied field tries to align these magnets. The Jiles-Atherton model considers both the ease with which they align (related to the material’s intrinsic properties) and the difficulty imposed by their interactions with each other (think of them bumping into and hindering each other). This model is frequently used in simulations to predict hysteresis behavior under various conditions.

Q 23. How can you use hysteresis loop data for material selection?

Hysteresis loop data provides crucial information for material selection in applications where magnetic properties are critical. Key parameters extracted from the loop – such as coercivity (Hc), remanence (Br), saturation magnetization (Ms), and permeability – allow engineers to choose the optimal material for a given application. For example:

- High coercivity materials are needed for permanent magnets, as they retain their magnetization even in the presence of opposing fields.

- High permeability materials are preferred for applications like transformer cores, where efficient magnetization reversal is required to minimize energy loss.

- Low coercivity materials are suitable for applications requiring easy magnetization and demagnetization, such as magnetic recording media.

By comparing the hysteresis loops of different materials, one can directly assess their suitability for specific applications. This avoids trial and error and ensures optimized performance and efficiency.

Q 24. Describe the process of extracting parameters from a hysteresis loop.

Extracting parameters from a hysteresis loop usually involves a combination of graphical and numerical methods. The process generally involves:

- Acquiring the hysteresis loop data: This is done using a hysteresisgraph, which measures the magnetic flux density (B) as a function of the applied magnetic field intensity (H).

- Identifying key points on the loop: The loop’s key features (saturation magnetization (Ms), remanence (Br), and coercivity (Hc)) are identified visually or using numerical algorithms.

- Calculating parameters: Parameters such as initial permeability (μi), maximum permeability (μmax), and hysteresis losses (area within the loop) can then be determined using standard formulas or through numerical integration.

- Fitting a model (optional): For a more precise characterization, a model such as the Jiles-Atherton model can be fitted to the measured loop, providing a set of parameters that accurately describes the material’s behavior.

For example, the coercivity (Hc) is the magnitude of the reverse field required to reduce the magnetization to zero. The remanence (Br) is the magnetization remaining after the applied field is removed. These are often determined directly from the loop graph. More advanced parameters require mathematical computations based on the data points of the loop.

Q 25. What software/tools are commonly used for hysteresis loop analysis?

Several software and tools are widely used for hysteresis loop analysis. These include:

- Specialized hysteresisgraph software: Many hysteresisgraph manufacturers provide dedicated software for data acquisition, visualization, and parameter extraction. These packages often include advanced features such as model fitting and report generation.

- MATLAB: MATLAB, with its extensive toolboxes, is a powerful platform for data analysis, signal processing, and curve fitting. The versatility makes it suitable for developing custom algorithms for hysteresis loop analysis.

- Python with SciPy and NumPy: Python, coupled with libraries like SciPy and NumPy, provides a flexible and open-source alternative for hysteresis loop analysis. Libraries such as `matplotlib` are used for plotting and visualization.

- Commercial Finite Element Analysis (FEA) software: Packages such as ANSYS and COMSOL allow for the simulation of magnetic fields and the prediction of hysteresis loops, enabling engineers to design and optimize magnetic components.

The choice of software depends on factors such as the complexity of the analysis, the available resources, and the user’s familiarity with different programming environments.

Q 26. Explain how hysteresis affects the performance of transformers.

Hysteresis significantly impacts the performance of transformers, primarily through the generation of hysteresis losses. In a transformer, the core material is subjected to a cyclical magnetization process, and the energy dissipated during each cycle due to hysteresis contributes to heat generation and reduced efficiency. This energy loss is directly proportional to the area enclosed by the hysteresis loop – a larger loop implies greater losses. The frequency of operation is also important; higher frequencies result in more cycles per second, exacerbating the effects of hysteresis.

To minimize hysteresis losses, transformer cores are usually made from materials with narrow hysteresis loops, exhibiting low coercivity and high permeability. Materials like grain-oriented silicon steel are chosen specifically for their low hysteresis losses at the operating frequencies.

Q 27. Discuss the impact of stress on the magnetic hysteresis loop.

Stress significantly affects the magnetic hysteresis loop. The application of stress – whether tensile, compressive, or shear – alters the magnetic domain structure and the ease with which domain walls move. This leads to changes in the shape and size of the hysteresis loop, affecting parameters such as coercivity, remanence, and permeability.

Generally, tensile stress tends to increase coercivity (making magnetization harder) and decrease permeability, while compressive stress may have the opposite effect. The exact impact depends on the type of stress, the material’s magnetostrictive properties (how much the material’s shape changes with magnetization), and the material’s crystalline structure. This is crucial in engineering applications where the components might experience mechanical stress; the hysteresis behavior under stress needs careful consideration to avoid performance degradation or unexpected failures.

Q 28. How can you interpret a minor hysteresis loop?

A minor hysteresis loop is observed when the magnetizing field is cycled within a limited range, not reaching the saturation magnetization. It provides information about the reversible and irreversible magnetization processes occurring within that specific field range. These loops are smaller than the major loop and do not intersect at the origin. The shape and size of a minor loop reveal the material’s magnetization response to small field changes.

Analyzing minor loops helps assess the material’s domain wall motion behavior in different magnetization states. The slope of the minor loop provides information about the differential permeability within that field range. This information is important for understanding the magnetization dynamics under specific operating conditions and can provide insights into the material’s behavior at different magnetization levels, providing a more comprehensive understanding than just the major loop.

Key Topics to Learn for Magnetic Hysteresis Loop Analysis Interview

- Fundamentals of Magnetism: Understanding magnetic domains, permeability, and the relationship between magnetic field strength (H) and magnetic flux density (B).

- Hysteresis Loop Characteristics: Defining key parameters like remanence, coercivity, saturation magnetization, and hysteresis loss, and their physical interpretations.

- Material Properties and Hysteresis: Exploring how different materials (ferromagnetic, ferrimagnetic, etc.) exhibit varying hysteresis loop shapes and their implications for applications.

- Practical Applications: Analyzing the role of hysteresis loops in various technologies, including data storage (hard drives), sensors, transformers, and electric motors.

- Measurement Techniques: Familiarizing yourself with methods used to obtain hysteresis loops experimentally, including vibrating sample magnetometry (VSM) and hysteresisgraph techniques.

- Loop Shape Analysis and Interpretation: Developing the ability to interpret different loop shapes to determine material properties and predict performance in specific applications.

- Modeling and Simulation: Understanding basic models for predicting hysteresis behavior and their limitations.

- Advanced Concepts (for Senior Roles): Explore topics such as magnetic anisotropy, exchange bias, and domain wall dynamics.

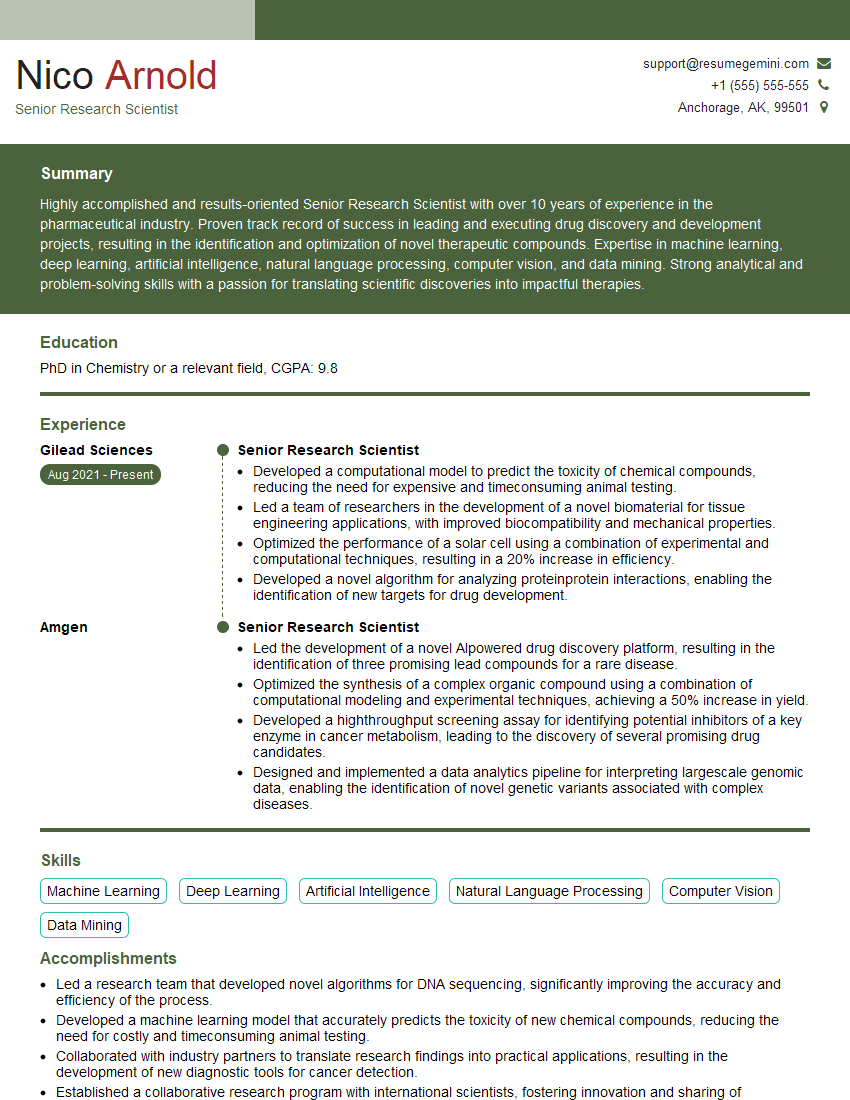

Next Steps

Mastering Magnetic Hysteresis Loop Analysis opens doors to exciting career opportunities in materials science, engineering, and related fields. A strong understanding of this topic demonstrates a solid foundation in magnetism and material characterization, making you a highly competitive candidate. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes tailored to various fields. We provide examples of resumes specifically designed for candidates with expertise in Magnetic Hysteresis Loop Analysis to help you craft a standout application. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.