Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Manage and coordinate work with other operators interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Manage and coordinate work with other operators Interview

Q 1. Describe your experience managing a team of operators.

Managing a team of operators involves more than just assigning tasks; it’s about fostering a collaborative and productive environment. My experience encompasses leading teams of varying sizes, from small, specialized units to larger, more diverse groups. This involved setting clear expectations, providing regular feedback, and creating a culture of open communication. For example, in my previous role at a logistics company, I managed a team of 10 warehouse operators. I implemented a daily huddle to address immediate concerns, review performance, and celebrate successes. This fostered a sense of camaraderie and improved communication, leading to a 15% increase in efficiency within three months. Beyond this, I focused on identifying individual strengths and weaknesses, tailoring training and mentorship programs accordingly. I believe in empowering my team, delegating responsibility appropriately, and creating opportunities for professional development.

Q 2. How do you prioritize tasks among multiple operators?

Prioritizing tasks across multiple operators requires a structured approach. I typically utilize a combination of methods, including urgency, importance, and dependencies. I use a Kanban-style system (visual task board) to track progress, allowing for easy visualization and real-time adjustments. Tasks are categorized by priority (high, medium, low) based on deadlines, impact, and resource requirements. For instance, urgent repairs on critical machinery would always take precedence over less time-sensitive tasks. When dealing with multiple priorities, I clearly communicate expectations to each operator, ensuring everyone understands the overall objectives and their individual roles. This prevents conflicts and promotes efficiency. I also proactively anticipate potential bottlenecks and adjust assignments as needed. Transparency and open communication are crucial in this process.

Q 3. Explain your approach to resolving conflicts between operators.

Conflict resolution is a crucial skill for any team leader. My approach emphasizes active listening and understanding the root cause of the conflict. I encourage open dialogue in a neutral environment, allowing each operator to express their perspective without interruption. I aim to facilitate a collaborative solution, rather than imposing a decision. For instance, if two operators disagree on the best approach to a task, I’ll guide them through a structured problem-solving process, encouraging them to consider the pros and cons of each option. If the conflict involves a violation of company policy or procedure, I apply disciplinary measures accordingly, ensuring fairness and consistency. The goal is not simply to resolve the immediate conflict, but to create a better understanding and prevent future occurrences.

Q 4. How do you ensure operators adhere to safety regulations?

Safety is paramount in any operational environment. Ensuring adherence to safety regulations requires a multi-pronged approach. This starts with comprehensive training programs for all operators, covering both theoretical knowledge and practical application. Regular safety audits and inspections are essential to identify potential hazards and ensure compliance. I also incorporate safety checks into the daily workflow, emphasizing the importance of reporting any near-misses or unsafe practices. Moreover, I foster a culture of safety by consistently reinforcing safety protocols and rewarding safe behavior. This includes providing positive feedback and recognizing operators who actively contribute to a safe working environment. Regular communication and open feedback channels are key to ensuring everyone is aware of and committed to safety procedures.

Q 5. What metrics do you use to track operator performance?

Tracking operator performance is critical for identifying areas for improvement and recognizing high-achievers. The metrics I use vary depending on the specific role and operational context, but generally include:

- Productivity: Units processed per hour, tasks completed, etc.

- Quality: Error rates, defect rates, customer satisfaction scores (if applicable).

- Safety: Number of safety incidents, near misses, adherence to safety protocols.

- Attendance: Punctuality, adherence to schedules.

Q 6. How do you delegate tasks effectively to operators?

Effective task delegation involves matching the right task to the right operator based on their skills, experience, and availability. Before delegating, I ensure the operator understands the task’s objective, required steps, and expected outcome. I also provide the necessary resources, training, and support. I strive for a balance between empowerment and oversight. While I trust my operators to perform their tasks independently, I maintain open lines of communication and provide regular check-ins to monitor progress and address any challenges. Regular feedback is crucial, both to acknowledge achievements and to identify and address any roadblocks or misunderstandings. This collaborative approach fosters ownership and accountability.

Q 7. Describe a time you had to improve operator workflow.

In a previous role, I noticed that the workflow for processing customer orders was inefficient, leading to delays and errors. The process involved multiple handoffs between operators, and the lack of a standardized procedure contributed to inconsistencies. To improve the workflow, I implemented a Lean methodology approach, which involved identifying and eliminating bottlenecks. First, I mapped the current workflow to pinpoint the areas of inefficiency. Then, I collaborated with the operators to design a streamlined process, reducing unnecessary steps and standardizing procedures. This involved introducing a new software system for order tracking and assigning clear roles and responsibilities to each operator. The result was a significant reduction in processing time, a decrease in error rates, and an overall improvement in customer satisfaction. The project demonstrated the value of collaborative problem-solving and data-driven process optimization.

Q 8. How do you handle operator absenteeism or tardiness?

Absenteeism and tardiness disrupt workflow and impact productivity. My approach is multifaceted, starting with proactive measures to prevent them. I begin by fostering a positive and supportive work environment where operators feel valued and respected. This often includes open communication channels and regular check-ins to address any underlying issues that might contribute to absences.

When absenteeism or tardiness occurs, I follow a clear procedure. First, I try to understand the reason. Is it a personal emergency, illness, or a recurring pattern? For infrequent instances, a simple understanding and confirmation of their well-being suffices. For recurring issues, I initiate a more formal process. This might involve a meeting to discuss the concerns and explore potential solutions collaboratively. We might discuss flexible work arrangements or explore if there are any workplace stressors contributing to the problem. Documentation of these discussions is crucial for maintaining records and tracking improvements.

In cases of consistent absenteeism, despite attempts to address the root cause, disciplinary action, as per company policy, is implemented.

Q 9. How do you provide constructive feedback to operators?

Constructive feedback is about improvement, not criticism. I believe in the ‘sandwich method’: starting with positive reinforcement, focusing on specific areas for improvement, and ending with another positive note and encouragement. For instance, I might say: “I’ve noticed your efficiency in handling order X was excellent; however, let’s work on improving your accuracy in data entry for Y, perhaps by using checklist Z. I’m confident you can master this quickly; you’re a valuable asset to the team.”

I make sure the feedback is specific, actionable, and focuses on behaviors, not personality traits. I also create a safe space for the operator to respond and ask questions. Regular performance reviews, combined with ongoing feedback, provide a consistent framework for growth and improvement. Following up on the feedback is crucial to ensure the operator is implementing the suggestions.

Q 10. How do you ensure efficient communication within your operator team?

Efficient communication is the backbone of a well-functioning team. I use a multi-pronged approach. Firstly, we have daily team huddles, lasting about 15 minutes, to address immediate concerns, share updates on ongoing projects, and ensure everyone is on the same page. This fosters a sense of team spirit and allows for immediate problem-solving.

Secondly, we utilize a combination of tools for asynchronous communication, such as a dedicated team chat platform (like Slack or Microsoft Teams) for quick questions and announcements. We also have a shared project management system (e.g., Asana or Trello) where tasks are assigned, progress tracked, and files are centrally stored. This maintains transparency and accountability.

Finally, regular team meetings (weekly or bi-weekly) are held to discuss longer-term goals, address larger issues, and celebrate successes. Open communication channels are paramount; operators know they can approach me at any time with concerns.

Q 11. What strategies do you use to motivate operators?

Motivation stems from feeling valued and making a meaningful contribution. I focus on several key strategies. Recognition and appreciation are vital—a simple ‘thank you’ or publicly acknowledging achievements during team meetings can go a long way. I believe in empowering operators by providing them with autonomy and ownership over their work, allowing them to take initiative and feel a sense of pride in their accomplishments.

I promote a culture of continuous learning and development by providing opportunities for skill enhancement through training sessions, workshops, or mentorship programs. I also try to foster a collaborative and positive work environment where operators feel comfortable sharing ideas and supporting each other. Regular social events, even simple team lunches, can build camaraderie and boost morale.

Finally, I make sure operators are appropriately compensated and have opportunities for career progression within the company. This demonstrates that their hard work is valued and that there is a path for future growth.

Q 12. How do you handle operator errors or mistakes?

Operator errors are inevitable. My focus is on understanding the root cause and preventing recurrence rather than assigning blame. When an error occurs, I engage the operator in a calm and supportive discussion to understand what happened. Was it a lack of training, a process flaw, a lapse in attention, or a systemic issue?

Based on the root cause analysis, we create a plan for remediation. This might involve additional training, process improvements, or updated documentation. I emphasize learning from mistakes, viewing them as opportunities for growth and improvement. Furthermore, I ensure the operator understands the impact of the error and the steps needed to prevent its repetition. Documentation of the incident, corrective actions, and subsequent follow-up is essential.

The goal is to create a learning environment where operators feel comfortable reporting errors without fear of retribution, promoting a culture of continuous improvement.

Q 13. Describe your experience with operator training and development.

Operator training and development are crucial investments. I have extensive experience designing and delivering training programs tailored to different skill levels and roles. My approach starts with needs assessments, identifying skill gaps and areas for improvement within the team. This is followed by developing structured training materials, including presentations, hands-on exercises, and simulations, that are engaging and easy to understand.

I emphasize a blend of theory and practical application, ensuring operators have ample opportunities to practice and master new skills. On-the-job training, mentoring, and shadowing programs are also utilized to facilitate learning. Regular evaluations and feedback sessions track progress and identify areas where additional support may be needed. I also incorporate continuous learning through online courses and industry certifications to keep skills up-to-date.

I’ve successfully implemented training programs that resulted in improved operator performance, reduced error rates, and increased overall productivity. I regularly measure training effectiveness to ensure it aligns with business objectives and makes a tangible difference.

Q 14. How do you manage operator workload during peak periods?

Managing workload during peak periods requires proactive planning and efficient resource allocation. I begin by forecasting anticipated demand and adjusting staffing levels accordingly, which may involve overtime scheduling or temporary staffing. I ensure that all operators are aware of the peak period and the increased workload in advance. Clear communication about expectations and priorities is critical.

I utilize task prioritization techniques, ensuring that critical tasks are addressed first. This might involve re-allocating resources from less critical projects or temporarily outsourcing some tasks. I also leverage technology to streamline workflows and automate repetitive tasks wherever possible. Regular check-ins and open communication channels allow for quick adjustments and problem-solving as needed.

Fair distribution of workload and ensuring operators have adequate breaks prevent burnout. I focus on maintaining a collaborative atmosphere to foster mutual support and efficient task completion during high-pressure periods.

Q 15. How do you use technology to improve operator efficiency?

Improving operator efficiency through technology involves leveraging tools that streamline workflows, reduce errors, and enhance communication. This isn’t just about implementing new software; it’s a strategic approach to integrating technology seamlessly into daily operations.

Workflow Automation: Implementing software that automates repetitive tasks frees up operators to focus on more complex and value-added activities. For example, in a warehouse setting, a Warehouse Management System (WMS) can automate tasks like order picking, inventory tracking, and shipping, reducing manual errors and speeding up the entire process.

Real-time Data and Analytics: Dashboards and reporting tools provide operators with real-time insights into performance metrics. This allows for proactive adjustments and identification of bottlenecks. Imagine a manufacturing plant using sensors to monitor machine performance. If a machine is underperforming, the data is immediately visible, allowing for quick maintenance and preventing production delays.

Communication and Collaboration Tools: Platforms like Slack or Microsoft Teams can facilitate seamless communication between operators, supervisors, and other teams, reducing misunderstandings and improving coordination. For instance, a quick question about a procedure can be resolved immediately through a chat, rather than causing a delay waiting for a supervisor.

Training and Simulation Software: Investing in virtual reality (VR) or augmented reality (AR) training can significantly enhance operator skill development by providing a safe and engaging learning environment. This is particularly useful for complex or hazardous tasks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with performance management of operators?

Performance management for operators involves a multi-faceted approach that goes beyond simply tracking numbers. It’s about fostering a culture of continuous improvement while ensuring fair and consistent evaluation. My approach is rooted in setting clear expectations, providing regular feedback, and offering opportunities for growth.

Setting Clear Goals and KPIs: Operators need to understand what constitutes success in their roles. This involves defining clear, measurable, achievable, relevant, and time-bound (SMART) goals and key performance indicators (KPIs).

Regular Performance Reviews: Conducting regular one-on-one meetings allows for open communication, feedback, and addressing any concerns or challenges the operator may be facing. These meetings aren’t just about evaluating past performance; they’re an opportunity for collaborative goal setting and skill development planning.

Data-Driven Feedback: Utilizing performance data from various sources (productivity metrics, error rates, customer feedback) allows for objective and data-backed feedback. This helps move beyond subjective assessments and creates a more transparent performance management system.

Addressing Performance Issues: When performance issues arise, I believe in a supportive yet firm approach. This often starts with identifying the root cause – is it a skill gap, lack of resources, or perhaps a systemic issue? Once the root cause is identified, we can create a tailored development plan to address the problem.

Q 17. How do you identify and address operator skill gaps?

Identifying and addressing operator skill gaps requires a proactive and systematic approach. It begins with accurate assessment and continues with targeted training and development initiatives.

Skills Gap Analysis: This involves a thorough review of operator performance data, conducting competency assessments, and soliciting feedback from supervisors and operators themselves. For example, observing operators during their tasks, reviewing quality control reports, or administering skills tests can highlight areas needing improvement.

Targeted Training Programs: Once skill gaps are identified, customized training programs are developed to address specific needs. This could involve on-the-job training, classroom instruction, or online courses. For instance, if a group of operators struggles with a particular piece of equipment, I’d arrange for hands-on training with an expert.

Mentorship and Coaching: Pairing less experienced operators with more experienced ones can be incredibly valuable. Mentorship provides opportunities for skill transfer and continuous learning in a supportive environment. Coaching focuses on goal setting and performance improvement through regular feedback and support.

Ongoing Assessment and Feedback: Continuously monitoring operator performance after training allows for adjustments and further development opportunities. Feedback is crucial for ensuring that training has been effective and that operators are applying newly acquired skills.

Q 18. Describe your experience with implementing new processes for operators.

Implementing new processes for operators requires careful planning, effective communication, and a strong focus on user adoption. It’s crucial to involve operators in the process to ensure buy-in and a smooth transition.

Needs Assessment and Planning: Before implementing any new process, a thorough needs assessment is conducted to identify the problem the new process is intended to solve. This is followed by detailed planning, including timelines, resource allocation, and potential challenges.

Training and Communication: Clear and comprehensive training is essential to ensure operators understand the new process. This could involve interactive training sessions, videos, or job aids. Frequent communication keeps everyone informed about the implementation timeline and addresses any concerns.

Pilot Testing and Feedback: Piloting the new process on a smaller scale allows for early identification of issues and adjustments before a full-scale rollout. Gathering feedback from operators throughout the process is crucial for fine-tuning the process and ensuring it meets the needs of its users.

Monitoring and Evaluation: Post-implementation monitoring allows for continuous improvement. Tracking key metrics (e.g., efficiency, error rates) helps to evaluate the success of the new process and identify areas needing further refinement.

Q 19. How do you ensure operators understand company policies and procedures?

Ensuring operators understand company policies and procedures is a critical aspect of maintaining a safe and compliant work environment. My approach is multi-pronged, emphasizing accessibility, clarity, and ongoing reinforcement.

Clear and Accessible Communication: Company policies and procedures should be clearly written, easy to understand, and readily accessible to all operators. This could involve a company intranet, employee handbooks, or easily searchable online resources.

Training and Orientation Programs: New employee onboarding should include a thorough review of key policies and procedures. Regular refresher training can help reinforce key information and address any updates.

Interactive Learning Methods: Using interactive methods, like quizzes or simulations, can improve comprehension and retention. Interactive modules can also cater to different learning styles.

Open Communication and Feedback Channels: Creating a culture where operators feel comfortable asking questions and providing feedback ensures that any confusion or misunderstandings are quickly addressed.

Q 20. How do you handle complaints or issues from operators?

Handling complaints or issues from operators requires a fair, consistent, and empathetic approach. My priority is to address the underlying issue and to ensure the operator feels heard and understood.

Active Listening and Empathy: Begin by actively listening to the operator’s concerns without interruption. Show empathy and acknowledge their perspective.

Investigating the Issue: Thoroughly investigate the issue to determine the facts and identify the root cause. This may involve reviewing relevant documentation, interviewing other involved parties, or conducting a site visit.

Finding a Solution: Collaboratively develop a solution with the operator, taking into account their input and suggestions. The goal is to find a fair and equitable solution that addresses the underlying problem.

Follow-up and Documentation: Document all communications, actions taken, and the final resolution. Follow up with the operator to ensure that the issue has been resolved to their satisfaction.

Q 21. How do you track operator productivity and efficiency?

Tracking operator productivity and efficiency is crucial for identifying areas of improvement and for making data-driven decisions. This involves a combination of quantitative and qualitative data collection.

Key Performance Indicators (KPIs): Define relevant KPIs that align with organizational goals. These could include units produced, tasks completed, error rates, customer satisfaction scores, or adherence to safety protocols. The choice of KPIs should be specific to the operator’s role and responsibilities.

Data Collection Methods: Implement systems for collecting data, such as time-tracking software, production tracking systems, or quality control reports. This may involve manual data entry or automated data collection through sensors and software.

Data Analysis and Reporting: Regularly analyze the collected data to identify trends, patterns, and potential areas for improvement. Generate reports that clearly communicate performance insights to operators and management.

Regular Review and Adjustment: KPIs and data collection methods should be reviewed and adjusted periodically to ensure that they remain relevant and effective. Regular calibration of the system prevents data drift and ensures that the metrics accurately reflect operator performance.

Q 22. How do you ensure compliance with relevant regulations among operators?

Ensuring compliance among operators starts with a robust training program covering all relevant regulations. This includes regular refresher courses and updates whenever legislation changes. We utilize a combination of methods: initial onboarding with comprehensive materials, interactive modules for online learning, and regular in-person training sessions led by experienced supervisors. Beyond training, we implement a system of checks and balances. This includes regular audits of operator work, utilizing checklists and documented procedures to ensure adherence to regulations. Any non-compliance is addressed immediately through retraining, corrective actions, and potentially disciplinary measures. We also establish clear lines of communication, encouraging operators to report any concerns or ambiguities regarding regulations. Think of it like a layered security system: training is the first layer, audits are the second, and open communication forms the third, ensuring compliance is consistently maintained.

For example, in my previous role managing a team of warehouse operators, we had to ensure strict adherence to OSHA safety regulations. We implemented a rigorous training program covering all aspects of safe warehouse operation, from forklift safety to proper lifting techniques. Regular audits and spot checks ensured consistent application of these guidelines, leading to a significant reduction in workplace accidents.

Q 23. Describe a situation where you had to resolve a conflict between an operator and a customer.

In one instance, a customer complained about a delayed delivery due to an operator’s oversight in incorrectly loading the shipment. The operator felt unfairly blamed, citing a lack of clear instructions. The conflict arose because both sides felt misunderstood. To resolve this, I initiated a three-step process. First, I listened to both parties empathetically, acknowledging their respective perspectives. This helped diffuse the immediate tension and create a safe space for discussion. Second, I reviewed the relevant documentation, the operator’s training records, and the delivery instructions to determine where the breakdown in communication occurred. We discovered that the instructions were indeed ambiguous, highlighting a training gap. Finally, I facilitated a joint problem-solving session. This led to clearer instructions being drafted and the operator receiving additional training on proper shipment loading procedures. The customer received a sincere apology and a revised delivery schedule, while the operator received support and improved understanding. The situation highlighted the importance of clear communication and continuous improvement in training materials.

Q 24. How do you maintain a positive and productive work environment for operators?

Maintaining a positive and productive work environment for operators involves fostering a culture of respect, open communication, and mutual support. This includes regularly scheduled team meetings to discuss challenges, celebrate successes, and solicit feedback. We use anonymous suggestion boxes and regular employee satisfaction surveys to gather input and address concerns proactively. Fair and transparent performance evaluations are crucial, along with a system of recognition and rewards for outstanding performance. Regular team-building activities, whether informal coffee breaks or organized events, can help build camaraderie and reduce stress. Finally, promoting work-life balance through flexible scheduling options (where possible) and encouraging breaks contributes significantly to a healthier and more productive team. Think of it as cultivating a garden: you need to nurture and tend to it regularly to ensure healthy growth.

Q 25. What is your experience with budgeting and resource allocation for operator teams?

My experience with budgeting and resource allocation involves a multi-stage process. It begins with forecasting anticipated workload and operator requirements, considering factors such as seasonal fluctuations and project deadlines. This forecast helps determine the necessary personnel and equipment. Then, I develop a detailed budget outlining labor costs, equipment maintenance, training expenses, and other relevant expenditures. I use various software tools for budget management and tracking expenses against projections. When resources are limited, prioritization becomes key. I employ a system that analyzes the impact of each task and allocates resources based on their criticality and potential return on investment. Regular monitoring and adjustments are essential. For example, in a previous role, I successfully reduced operational costs by 15% by optimizing staffing levels based on real-time data analysis and implementing a preventative maintenance program for equipment.

Q 26. How do you adapt to changing priorities and demands when managing operators?

Adapting to changing priorities and demands requires flexibility and strong communication. When priorities shift, I first communicate the change clearly and transparently to the team, explaining the reasons behind it and the impact on individual tasks. We then collaboratively reassess the existing workload, re-prioritizing tasks based on the new demands. This involves open discussion with operators to understand any potential roadblocks and collaboratively devise solutions. If necessary, we may need to adjust schedules, delegate tasks differently, or seek additional resources. Regular check-ins throughout the transition period are essential to monitor progress and address any emerging challenges. Think of it like navigating a ship: you must constantly adjust your course based on changing winds and currents.

Q 27. How do you measure the success of your team’s performance?

Measuring team success involves a balanced scorecard approach, encompassing both quantitative and qualitative measures. Quantitative metrics include things like on-time delivery rates, error rates, productivity levels, and customer satisfaction scores. These provide concrete data on the team’s efficiency and effectiveness. However, these numbers alone don’t tell the whole story. Therefore, we also incorporate qualitative measures, such as employee morale, team cohesion, and adherence to safety protocols. Regular feedback sessions, both individual and team-based, help to identify areas for improvement. We track these metrics over time to identify trends and measure the impact of implemented strategies. For example, a decrease in error rates coupled with an increase in employee satisfaction shows that improvements are not only efficient but also sustainable.

Q 28. Explain your experience with implementing and using scheduling software for operators.

I have extensive experience implementing and utilizing scheduling software for operators, specifically using programs like [mention specific software, e.g., scheduling software]. The implementation process involves several key steps: first, understanding the specific needs of the team and the type of work. This informs the choice of features the software should have. Then, data migration from existing systems is critical, ensuring accuracy and consistency. Next, we train the team on how to use the software effectively, providing ongoing support. Finally, we continuously monitor and optimize the schedules using the software’s analytics capabilities. The software allows for efficient scheduling, reduced manual intervention, automated alerts for conflicts, and improved transparency in assigning tasks. It facilitates better communication and enhances overall operational efficiency.

Key Topics to Learn for Manage and Coordinate Work with Other Operators Interview

- Effective Communication Strategies: Understanding various communication methods (verbal, written, digital) and adapting your approach to different team members and situations. Practical application: Describing how you’ve successfully resolved conflicts or facilitated collaboration through clear and concise communication.

- Teamwork and Collaboration: Demonstrating your understanding of collaborative work environments and your ability to contribute positively to a team. Practical application: Providing examples of projects where you successfully coordinated tasks, delegated responsibilities, and leveraged team members’ strengths.

- Task Prioritization and Time Management: Explaining your methods for prioritizing tasks, managing deadlines, and allocating resources efficiently, especially in high-pressure situations. Practical application: Sharing a scenario where you had to prioritize competing demands and the successful outcome.

- Conflict Resolution and Negotiation: Demonstrating your ability to identify and address conflicts constructively, mediating disputes, and finding mutually agreeable solutions. Practical application: Describing a situation where you successfully negotiated a solution to a disagreement within a team.

- Problem-Solving and Decision-Making: Illustrating your ability to analyze problems, identify solutions, and make informed decisions, even with incomplete information. Practical application: Providing examples of how you approached complex problems, considering various perspectives, and choosing the most effective course of action.

- Performance Monitoring and Evaluation: Understanding methods for tracking team progress, identifying areas for improvement, and providing constructive feedback. Practical application: Explaining how you’ve monitored team performance and used data to improve efficiency or productivity.

- Workflow Optimization: Demonstrating your knowledge of improving processes and workflows to enhance efficiency and productivity within a team. Practical application: Describing instances where you identified bottlenecks or inefficiencies and implemented changes to improve the overall workflow.

Next Steps

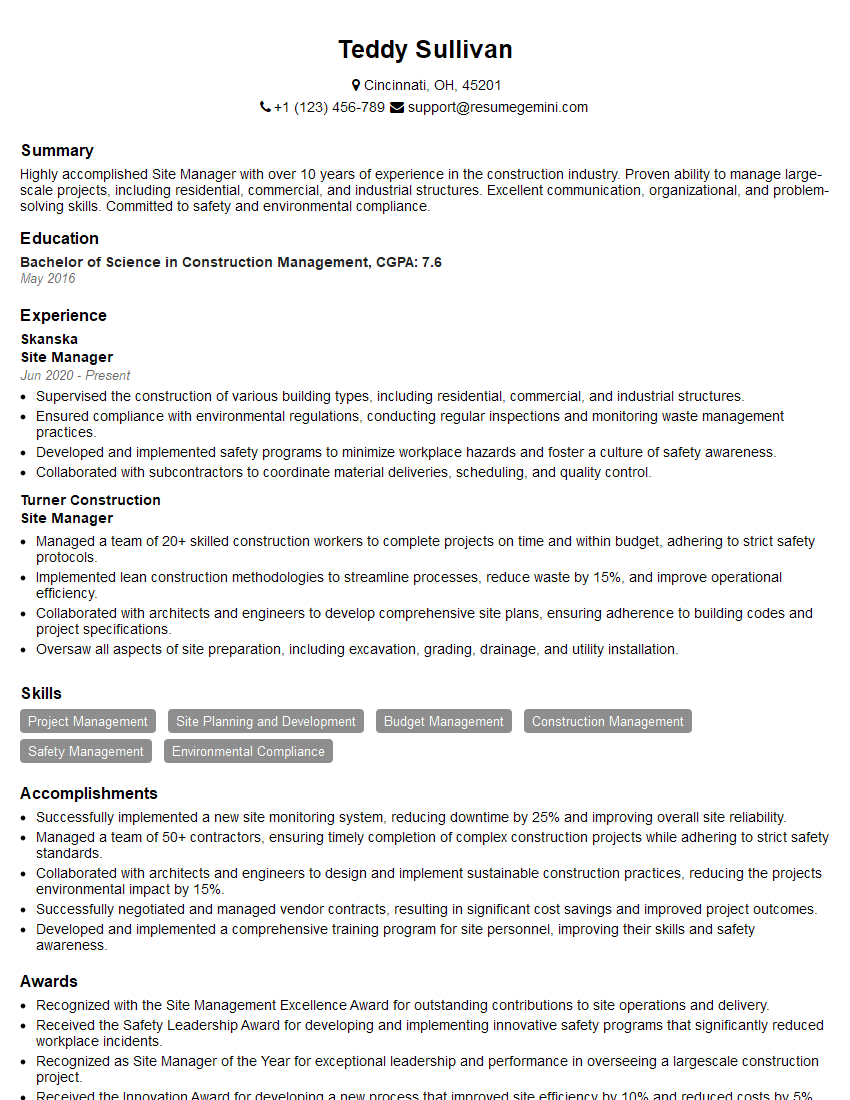

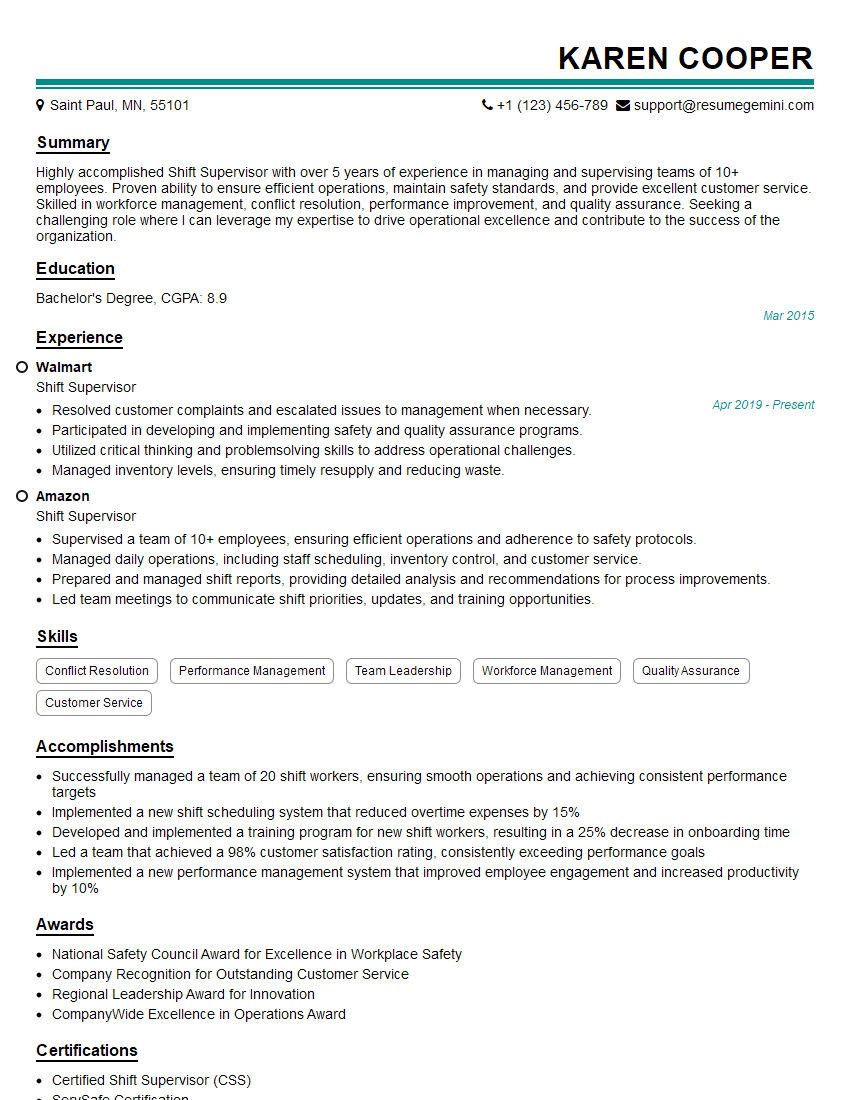

Mastering the art of managing and coordinating work with other operators is crucial for career advancement. It showcases your leadership potential, teamwork skills, and ability to drive results within a collaborative environment. To significantly boost your job prospects, create an ATS-friendly resume that highlights these skills effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We offer examples of resumes tailored to “Manage and coordinate work with other operators” roles to help guide you. Invest the time to craft a compelling resume – it’s your first impression and a key to unlocking your career potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.