Unlock your full potential by mastering the most common Material Evaluation and Selection interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Material Evaluation and Selection Interview

Q 1. Explain the difference between tensile strength and yield strength.

Tensile strength and yield strength are both crucial measures of a material’s ability to withstand forces, but they represent different points on its stress-strain curve. Think of it like stretching a rubber band:

Tensile strength represents the maximum stress a material can withstand before it breaks. It’s the ultimate strength – the point where the rubber band snaps. It’s expressed as the maximum load divided by the original cross-sectional area of the material.

Yield strength, on the other hand, indicates the stress at which the material begins to deform permanently. It’s the point where the rubber band starts to stretch beyond its ability to return to its original shape. After yielding, even if the load is removed, the rubber band will remain slightly stretched. It’s often defined as the stress at 0.2% plastic strain.

For example, a high-tensile-strength steel might be ideal for a suspension bridge cable, requiring the material to withstand immense loads without breaking. Conversely, a material with a high yield strength is critical for structural components requiring dimensional stability, preventing permanent deformation under load.

Q 2. Describe the various types of material testing methods.

Material testing methods are broadly categorized into destructive and non-destructive techniques. Destructive testing involves permanently altering or destroying the sample to determine its properties, whereas non-destructive methods evaluate properties without causing damage.

- Destructive Testing: This includes Tensile testing (measuring tensile strength and yield strength), Compression testing (measuring compressive strength), Impact testing (measuring toughness and resistance to impact), Fatigue testing (evaluating endurance under cyclical loading), Hardness testing (measuring resistance to indentation).

- Non-Destructive Testing (NDT): This encompasses methods like Visual inspection (checking for surface defects), Ultrasonic testing (using sound waves to detect internal flaws), Radiographic testing (using X-rays or gamma rays to detect internal defects), Magnetic particle inspection (detecting surface and near-surface cracks in ferromagnetic materials), and Eddy current testing (detecting surface and subsurface flaws using electromagnetic induction).

The choice of testing method depends heavily on the application, the material type, and the specific properties of interest. For instance, a bridge cable would undergo extensive tensile testing, while a weld might be inspected using radiographic testing.

Q 3. How would you select a material for a high-temperature application?

Selecting a material for a high-temperature application requires careful consideration of several factors. The material must maintain its strength, stability, and desired properties at elevated temperatures. Key considerations include:

- Melting point: The material should have a melting point significantly higher than the operating temperature.

- Creep resistance: Creep is the slow, permanent deformation of a material under sustained stress at high temperatures. High creep resistance is essential. Superalloys are often chosen for their excellent creep resistance.

- Oxidation resistance: Materials must withstand oxidation or other forms of chemical degradation at high temperatures. Ceramic coatings are sometimes used to enhance oxidation resistance.

- Thermal shock resistance: Ability to withstand rapid temperature changes without fracturing. Ceramics generally exhibit good thermal shock resistance.

For instance, in gas turbine engines, nickel-based superalloys are preferred due to their excellent high-temperature strength and creep resistance. In furnace applications, refractory materials like alumina or zirconia are used due to their high melting points and resistance to chemical attack.

Q 4. What are the key considerations when selecting a material for corrosion resistance?

Selecting a material for corrosion resistance involves understanding the corrosive environment and choosing a material with appropriate properties. Key considerations include:

- Type of corrosion: Different materials resist different types of corrosion (e.g., uniform corrosion, pitting corrosion, galvanic corrosion, stress corrosion cracking). Understanding the specific type of corrosion expected is critical.

- Environmental conditions: Factors like temperature, pH, presence of specific ions or chemicals, and humidity significantly affect corrosion rates. A material resistant to saltwater corrosion may not be suitable for acidic environments.

- Material properties: Passivation (formation of a protective oxide layer), inherent corrosion resistance (e.g., stainless steels), and electrochemical potential are crucial factors. Noble metals like gold and platinum exhibit superior corrosion resistance.

- Protective coatings: Coatings such as paint, plating (e.g., chrome plating), or anodizing can enhance corrosion resistance.

For instance, stainless steel is widely used in many applications due to its inherent corrosion resistance. However, in highly corrosive environments, more specialized materials like titanium or Hastelloy alloys might be necessary. In marine environments, protective coatings like zinc galvanizing are often applied to steel structures to prevent corrosion.

Q 5. Explain the concept of fatigue failure.

Fatigue failure occurs when a material subjected to repeated or cyclic loading fails at a stress level significantly lower than its ultimate tensile strength. Imagine repeatedly bending a paper clip back and forth: eventually, it will break, even though the force applied in each bending cycle is much less than the force required to snap it in a single instance.

This happens because microscopic cracks initiate and propagate with each loading cycle. These cracks accumulate, eventually leading to catastrophic failure. The number of cycles to failure depends on the stress level, material properties, and environmental factors. The S-N curve (stress vs. number of cycles to failure) is used to represent fatigue behavior.

Fatigue failure is a major concern in many engineering applications, especially in aircraft, bridges, and machinery subjected to repetitive loading. Careful design and material selection, along with fatigue testing, are essential to mitigate fatigue failure.

Q 6. How do you determine the appropriate material for a specific application?

Determining the appropriate material for a specific application is a systematic process involving several steps:

- Define the application and requirements: Clearly specify the function of the component, the environmental conditions (temperature, pressure, chemicals), mechanical loads (tensile, compressive, shear, bending), and other relevant factors.

- Identify candidate materials: Based on the requirements, select potential materials based on their known properties and past experience. Material databases and handbooks are valuable resources.

- Evaluate material properties: Analyze relevant material properties for each candidate material. Consider factors like strength, toughness, stiffness, ductility, corrosion resistance, and cost.

- Perform necessary testing: If needed, conduct material testing to verify the properties and suitability of the candidate materials. This might involve tensile testing, fatigue testing, corrosion testing, etc.

- Make a selection: Based on the analysis, select the most suitable material balancing cost, performance, and manufacturability.

This systematic approach ensures that the selected material meets all design requirements and leads to a robust and reliable product.

Q 7. Describe different failure modes of materials.

Materials can fail in various ways depending on the applied load, environment, and material properties. Some common failure modes include:

- Fracture: Sudden separation of a material into two or more pieces. This can be brittle fracture (sudden failure with little or no plastic deformation) or ductile fracture (failure after significant plastic deformation).

- Yielding: Permanent deformation of a material beyond its elastic limit. The material doesn’t break but undergoes a permanent shape change.

- Creep: Time-dependent deformation under sustained stress at high temperatures.

- Fatigue: Failure due to repeated cyclic loading at stress levels below the yield strength.

- Corrosion: Degradation of a material due to chemical or electrochemical reactions with the environment.

- Wear: Gradual loss of material due to surface abrasion or friction.

Understanding these failure modes is crucial for designing reliable components and selecting appropriate materials. Proper material selection, design considerations, and preventative maintenance can help mitigate these failure modes.

Q 8. What is the difference between ductile and brittle fracture?

Ductile and brittle fracture describe two fundamentally different ways materials fail under stress. Ductile fracture is characterized by significant plastic deformation before failure. Think of pulling taffy – it stretches and thins considerably before it finally breaks. This extensive deformation provides warning signs, like necking, before the final rupture. Brittle fracture, on the other hand, involves little to no plastic deformation. It’s like snapping a dry twig – it breaks suddenly without much prior warning. This is often accompanied by a clean fracture surface.

The key difference lies in the material’s ability to absorb energy before fracture. Ductile materials absorb significantly more energy due to plastic deformation, making them safer in many applications. Brittle materials, conversely, fail catastrophically with minimal energy absorption.

Example: Mild steel exhibits ductile fracture, while glass displays brittle fracture. This difference is crucial in engineering design, dictating the choice of materials for different applications. A bridge structure would benefit greatly from the ductile properties of steel, absorbing stress and giving warnings of potential failure, whereas a ceramic insulator can be brittle and still perform well because it’s not subjected to large tensile stresses.

Q 9. How do you interpret a stress-strain curve?

A stress-strain curve is a graphical representation of a material’s response to applied stress. The x-axis represents strain (deformation) and the y-axis represents stress (force per unit area). Interpreting it provides crucial insights into the material’s mechanical properties.

- Elastic Region: The initial linear portion of the curve represents elastic deformation. Here, the material deforms proportionally to the applied stress, and it returns to its original shape once the stress is removed. The slope of this region represents Young’s modulus (E), a measure of the material’s stiffness.

- Yield Point: The point where the curve deviates from linearity indicates the yield point. Beyond this point, plastic deformation begins – permanent deformation occurs, and the material will not return to its original shape.

- Plastic Region: This region shows the material’s ability to undergo permanent deformation. The curve may exhibit strain hardening (increased resistance to deformation) or necking (reduction in cross-sectional area).

- Ultimate Tensile Strength (UTS): The highest point on the curve represents the UTS, the maximum stress the material can withstand before failure.

- Fracture Point: The point where the curve ends indicates the fracture point, marking the material’s failure.

By analyzing these features, we can determine a material’s strength, ductility, toughness, and elasticity. This information is essential for selecting appropriate materials for specific engineering applications.

Q 10. Explain the concept of creep and its significance.

Creep is the time-dependent deformation of a material under constant stress or load, typically at elevated temperatures. Imagine a metal wire slowly stretching under its own weight over a long period – that’s creep. It’s a significant concern in high-temperature applications, such as gas turbines and nuclear reactors.

The significance of creep lies in its potential to cause structural failure. Even under a relatively low stress, creep can lead to significant deformation over time, potentially exceeding safe operational limits. This slow, continuous deformation can cause components to lose their shape and functionality, eventually leading to cracking or complete failure.

Several factors influence creep behavior, including temperature, stress level, and material properties. Understanding creep mechanisms is crucial in designing components for high-temperature applications to ensure their long-term reliability and safety. Creep testing is performed to assess a material’s resistance to creep deformation under specific conditions.

Q 11. What are the common material selection databases and software you have used?

Throughout my career, I’ve utilized several material selection databases and software packages. Some of the most prominent include:

- CES EduPack: A comprehensive database providing material properties, processing information, and environmental impact data. It’s excellent for comparing different materials based on various criteria.

- Granta MI: Another robust database offering similar functionality to CES EduPack, with advanced capabilities for material selection and lifecycle assessment.

- MatWeb: A user-friendly online database containing a vast amount of material property data, readily accessible for quick lookups.

I also have experience using specialized software for finite element analysis (FEA) like ANSYS and Abaqus, which allows me to simulate the performance of materials under various loading conditions and refine material selections based on the simulation results.

Q 12. How would you evaluate the cost-effectiveness of different materials?

Evaluating the cost-effectiveness of different materials requires a holistic approach that considers various factors beyond just the initial material cost. Here’s a step-by-step framework I use:

- Initial Material Cost: Determine the cost per unit volume or weight of each candidate material.

- Processing Costs: Account for fabrication, machining, finishing, and any other processing steps required for each material. Some materials are easier and cheaper to process than others.

- Maintenance and Repair Costs: Consider the material’s durability and susceptibility to wear and tear. Materials requiring frequent maintenance or replacement will increase the overall cost.

- Lifecycle Costs: Assess the entire lifecycle of the product, from manufacturing to disposal, accounting for environmental impact and potential recycling costs. A seemingly cheaper material might incur higher long-term environmental costs.

- Performance and Reliability: A more expensive material might be cost-effective if it ensures longer service life and reduced downtime due to failure. This needs careful weighing against the initial cost.

- Risk Assessment: Factor in the potential risks associated with material failure. A brittle material might be cheaper upfront but could lead to catastrophic failure, incurring high costs down the line.

By systematically analyzing these factors, I can create a comparative cost model for different materials and select the most economically viable option that balances performance and longevity.

Q 13. Discuss your experience with different material characterization techniques (e.g., SEM, XRD, TEM).

My experience with material characterization techniques is extensive, encompassing various microscopy and diffraction methods. I’ve worked extensively with:

- Scanning Electron Microscopy (SEM): I’ve used SEM to examine the surface morphology and microstructure of materials at high magnifications. This is particularly useful for analyzing fracture surfaces, identifying defects, and characterizing coatings.

- X-ray Diffraction (XRD): XRD allows for the identification of crystalline phases present in a material and the determination of crystal structure and preferred orientation. I’ve used XRD extensively in phase identification and analysis of residual stresses.

- Transmission Electron Microscopy (TEM): TEM provides high-resolution imaging of the internal microstructure, allowing for the observation of individual atoms and crystal defects. I’ve utilized TEM for detailed analysis of nanomaterials and advanced materials.

In addition to these, I have experience with other techniques like mechanical testing (tensile, compression, hardness), thermal analysis (DSC, TGA), and chemical analysis (EDS, XPS). The choice of technique depends heavily on the specific material and the properties being investigated.

Q 14. How do you handle material selection challenges with conflicting requirements?

Conflicting requirements in material selection are common challenges. For instance, a component might need to be both strong and lightweight, or corrosion-resistant and low-cost – often these are competing properties. I address these challenges using a multi-criteria decision-making (MCDM) approach.

My process involves:

- Identifying Key Requirements: Clearly define all requirements, weighting them based on their relative importance. A strong emphasis on safety might outweigh cost concerns in some applications.

- Material Screening: Initially screen a large pool of candidate materials based on the most critical requirements, eliminating those that clearly don’t meet essential criteria.

- Prioritization and Trade-offs: Create a matrix or scoring system that evaluates remaining materials based on each requirement’s weighted importance. This necessitates making trade-offs. For example, a stronger material might be heavier, so compromises must be considered.

- Iterative Refinement: If necessary, further investigations, such as simulations or experimental testing, might be required to better understand the trade-offs and make a well-informed decision.

- Sensitivity Analysis: Perform a sensitivity analysis to understand how changes in the weighting of criteria would affect the final material selection. This provides insights into the robustness of the selection.

This systematic process helps in objectively evaluating different materials and making the best selection based on the overall balance of conflicting requirements.

Q 15. Explain your understanding of material degradation mechanisms.

Material degradation is the process by which a material’s properties deteriorate over time due to various factors. Understanding these mechanisms is crucial for predicting a material’s lifespan and ensuring its reliable performance. These mechanisms can be broadly categorized as:

- Chemical Degradation: This involves chemical reactions that alter the material’s structure. Examples include corrosion (oxidation of metals), hydrolysis (reaction with water), and biodegradation (breakdown by living organisms). Think of rust on a car – that’s classic chemical degradation.

- Physical Degradation: This is caused by physical forces and includes phenomena like wear and tear (abrasion, erosion), fatigue (repeated stress leading to crack formation), and creep (slow deformation under constant stress). Consider a bicycle chain wearing down due to friction – that’s physical degradation.

- Biological Degradation: This involves the action of living organisms, such as microorganisms or insects, that break down the material. Wooden structures decaying due to fungal growth are a prime example.

Understanding the specific degradation mechanisms relevant to a material in its intended application is vital for selecting appropriate materials and designing for longevity. For instance, when choosing a material for a marine application, corrosion resistance is paramount, thus directing us towards materials like stainless steel or certain polymers.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with finite element analysis (FEA) in material selection.

Finite Element Analysis (FEA) is an invaluable tool in material selection. I’ve extensively used FEA to simulate the behavior of materials under various loading conditions. This allows for the prediction of stress, strain, and deformation, helping to identify potential failure points before physical prototyping.

For example, in a recent project involving the design of a high-performance automotive component, I utilized FEA to compare the performance of aluminum alloy and carbon fiber reinforced polymer (CFRP). By inputting the expected loads and boundary conditions into the FEA software, we could visualize stress distribution and determine which material offered better strength-to-weight ratio and fatigue resistance under real-world driving conditions. The results directly influenced the final material selection and the component’s overall design optimization.

My FEA experience spans various software packages, including ANSYS and Abaqus, and I’m proficient in meshing, boundary condition definition, and result interpretation. This allows me to accurately model complex geometries and predict material behavior with high fidelity.

Q 17. How do you ensure the safety and reliability of materials in a product?

Ensuring material safety and reliability involves a multi-faceted approach that begins long before the product hits the market.

- Material Characterization: Thorough testing is crucial, including mechanical testing (tensile strength, yield strength, fatigue testing), chemical analysis, and physical property evaluations (density, thermal conductivity). This verifies that the material meets the specified requirements.

- Safety Factor: In design, we always incorporate a safety factor to account for uncertainties and variations in material properties. This ensures the product can withstand higher loads than anticipated.

- Quality Control: Strict quality control procedures throughout the manufacturing process are essential to prevent defects and maintain consistency in material properties. This might involve regular inspections and testing of raw materials and finished products.

- Risk Assessment: A comprehensive risk assessment helps identify potential failure modes and their consequences. This allows us to develop mitigation strategies, such as redundancy or safety systems.

- Regulations and Standards: Adherence to relevant safety regulations and industry standards (like ASTM, ISO) is crucial for compliance and ensures the product meets minimum safety requirements.

For instance, in aerospace applications, where safety is paramount, every material used undergoes rigorous testing and certification to ensure it meets stringent safety requirements before being used in any flight-critical component.

Q 18. What are the environmental considerations in material selection?

Environmental considerations are increasingly important in material selection. We must consider the entire lifecycle of the material, from extraction of raw materials to manufacturing, use, and end-of-life disposal or recycling.

- Toxicity: Some materials release harmful substances during manufacturing or use (e.g., VOCs from certain polymers). Choosing less toxic alternatives is vital.

- Energy Consumption: The energy required for material extraction, processing, and transportation should be minimized. Materials with lower embodied energy are preferred.

- Recyclability: Selecting recyclable or easily biodegradable materials reduces waste and environmental impact.

- Resource Depletion: Using materials made from abundant resources, rather than scarce ones, contributes to resource sustainability.

- Greenhouse Gas Emissions: Considering the carbon footprint associated with material production and transportation is essential for reducing environmental impact. Choosing materials with lower carbon emissions is an important step.

For example, in packaging applications, switching from traditional plastics to biodegradable alternatives like PLA (polylactic acid) can significantly reduce plastic waste and environmental pollution.

Q 19. Describe your experience with material sustainability and lifecycle assessment.

My experience with material sustainability and lifecycle assessment (LCA) includes conducting LCAs for various products, employing software tools like SimaPro. LCAs provide a comprehensive analysis of the environmental impacts associated with a material’s entire lifecycle. This includes evaluating energy use, emissions of greenhouse gases, water consumption, and waste generation.

In a recent project concerning the development of a sustainable building material, we used LCA to compare the environmental impact of different concrete mixes. We found that using recycled aggregates and optimizing cement content significantly reduced the overall carbon footprint of the final product. This helped us choose a more sustainable alternative while maintaining the desired structural properties. The results from our LCA informed material selection, design modifications, and even influenced the product’s marketing and branding, highlighting its environmental benefits to customers.

Q 20. How would you handle a situation where a selected material fails to meet expectations?

If a selected material fails to meet expectations, a systematic approach is required.

- Investigate the Cause: First, thoroughly investigate why the material failed. This involves analyzing the material’s performance in the actual application, conducting further testing to understand the failure mechanism, and reviewing the initial material selection criteria. Was there an unforeseen stress condition? Was the material improperly processed or handled?

- Review the Design: Evaluate whether the design itself contributed to the failure. Could redesign mitigate the problem?

- Explore Alternative Materials: Research and evaluate alternative materials that better meet the required properties and performance characteristics. Conduct comparative analysis of various options, possibly using FEA again to simulate performance.

- Implement Corrective Actions: Based on the findings, implement necessary corrective actions. This might include changing materials, modifying the design, or enhancing the manufacturing process.

- Document Lessons Learned: Document the entire process, including the failure analysis, corrective actions, and lessons learned. This helps prevent similar issues in future projects.

For example, if a plastic component unexpectedly fails due to unexpected heat exposure, we’d investigate the material’s thermal properties, potentially find a higher temperature-resistant polymer, and possibly redesign the system to better manage heat dissipation.

Q 21. Explain the importance of material traceability and documentation.

Material traceability and documentation are critical for ensuring product quality, safety, and liability. Traceability allows us to track the material’s origin, processing history, and handling throughout its lifecycle. This is especially important in regulated industries like aerospace, medical devices, and automotive manufacturing.

Comprehensive documentation includes:

- Material Certificates: These documents provide assurance that the material meets specified standards and properties.

- Manufacturing Records: These records detail the processing steps and parameters used during material production.

- Inspection Reports: These reports document the results of quality control inspections, ensuring conformity to standards.

- Batch Numbers and Identification: Unique batch numbers and identification labels enable easy tracking of individual material batches.

In case of a product failure, thorough traceability and documentation allow for quick identification of the root cause. This also ensures compliance with regulatory requirements and helps in avoiding costly recalls. For instance, in the pharmaceutical industry, accurate material tracking is essential for ensuring drug safety and efficacy.

Q 22. Describe your experience with different joining techniques for materials.

Joining techniques are crucial in manufacturing, allowing us to combine different materials to achieve desired functionalities. My experience encompasses a wide range, including:

- Welding: I’ve worked extensively with various welding processes like Gas Metal Arc Welding (GMAW), Tungsten Inert Gas Welding (TIG), and Resistance Spot Welding (RSW). Choosing the right process depends heavily on the materials involved, the required joint strength, and the production scale. For instance, TIG welding offers excellent precision for joining thin sections of stainless steel in aerospace applications, while RSW is ideal for high-speed mass production of automotive body panels.

- Adhesive Bonding: This is a versatile method, especially for joining dissimilar materials where welding might be challenging. I’ve worked with structural adhesives in applications demanding high strength and environmental resistance, such as composite materials in wind turbine blades. Careful selection of the adhesive is crucial, considering factors like temperature, humidity, and the chemical compatibility of the joined materials.

- Mechanical Fastening: This involves using bolts, rivets, screws, and other fasteners to join parts. While seemingly simple, optimizing mechanical fastening for strength, weight, and fatigue resistance requires a deep understanding of material properties and stress analysis. For example, designing a reliable fastening system for a high-vibration engine component involves careful consideration of bolt preload and material selection to prevent loosening or failure.

- Soldering and Brazing: These techniques utilize filler metals with lower melting points to join components. They are particularly useful for joining metals with high thermal conductivity or in electronics assembly. I’ve utilized soldering for circuit board assembly and brazing for joining copper pipes in HVAC systems.

My experience spans various material combinations, from metals and alloys to polymers and composites. The selection of the optimal joining technique is always a critical decision, deeply intertwined with material selection and overall design considerations.

Q 23. How do you assess the manufacturability of a selected material?

Assessing the manufacturability of a material involves evaluating its suitability for various manufacturing processes. It’s not just about whether it *can* be processed, but how *easily* and *cost-effectively*. My approach involves:

- Material Properties Analysis: This includes assessing properties such as machinability (for milling, turning, etc.), formability (for bending, stamping, etc.), weldability, castability, and its response to various heat treatments.

- Process Capability Assessment: I evaluate the availability of suitable manufacturing equipment and the feasibility of achieving the required tolerances and surface finish. For example, a material with poor machinability might necessitate specialized tooling or slower processing speeds, increasing costs.

- Cost Analysis: Manufacturing cost is a critical factor. This involves evaluating raw material cost, processing time, energy consumption, tooling costs, and waste generation. For instance, a high-performance material might be ideal for a specific application, but its high cost and difficult processing could make it economically unviable.

- Risk Assessment: Identifying potential manufacturing challenges and their impact on quality, cost, and delivery timelines. This includes considering factors like material defects, process variability, and potential safety hazards.

For example, when selecting a material for a complex aerospace component, I’d analyze its ability to withstand the stresses of machining, its weldability, and the overall cost versus alternative materials like composites or aluminum alloys. The goal is to find the optimal balance between performance, cost, and production feasibility.

Q 24. Explain your understanding of different material standards and specifications.

Material standards and specifications are essential for ensuring consistent quality, safety, and interoperability. My understanding encompasses a broad range, including:

- ASTM (American Society for Testing and Materials): I’m proficient in using ASTM standards for various materials, including metals, polymers, and composites. These standards define material properties, testing methods, and quality control procedures. For example, ASTM A36 specifies the properties of structural steel.

- ISO (International Organization for Standardization): I regularly refer to ISO standards for international collaboration and consistency. ISO 9001, for instance, focuses on quality management systems, influencing how materials are procured, processed, and tested.

- Industry-Specific Standards: These are crucial and often tailored to particular applications, like SAE (Society of Automotive Engineers) standards for automotive materials or AMS (Aerospace Material Specifications) for aerospace components.

- Material Data Sheets (MDS): I rely heavily on MDS provided by material suppliers, which offer critical information on material properties, chemical composition, and recommended processing methods.

Understanding and applying these standards is critical for avoiding costly errors, ensuring product reliability, and complying with regulations. It’s common practice to specify materials using these standards in design specifications and purchase orders, such as ‘ASTM A36 steel’ ensuring everyone involved is working with a consistent definition.

Q 25. How do you balance performance, cost, and environmental impact in material selection?

Balancing performance, cost, and environmental impact is a key challenge in material selection. I use a multi-criteria decision-making approach which involves:

- Defining Performance Requirements: Clearly specifying the required mechanical, physical, and chemical properties of the material based on the application’s needs.

- Cost Evaluation: Assessing the raw material cost, processing costs, and lifecycle costs (including maintenance and disposal).

- Environmental Impact Assessment: Considering the material’s life cycle environmental impact, including energy consumption during manufacturing, resource depletion, and waste generation. This often involves using tools like Life Cycle Assessment (LCA).

- Trade-off Analysis: Evaluating the trade-offs between performance, cost, and environmental impact. Sometimes, a slightly less performant but more sustainable and cost-effective material might be the optimal choice.

- Material Selection Software: Using specialized software to assist in the decision-making process. These tools can evaluate multiple materials based on predefined criteria and weighting factors.

For example, in designing a lightweight automotive component, I might consider aluminum alloys for their strength-to-weight ratio. However, I’d also assess the environmental impact of aluminum production and compare it to the use of recycled materials or more sustainable alternatives like bio-based composites, weighting each factor according to its importance in the design specifications.

Q 26. Describe your experience with materials for specific industries (e.g., aerospace, automotive).

I have significant experience with materials in both the aerospace and automotive industries. In aerospace, I’ve worked extensively with high-strength aluminum alloys, titanium alloys, and advanced composites like carbon fiber reinforced polymers (CFRP). The focus here is on high strength-to-weight ratios, fatigue resistance, and the ability to withstand extreme temperature variations and harsh environments. For instance, selecting the appropriate titanium alloy for a jet engine component involves careful consideration of its creep resistance and high-temperature strength.

In the automotive industry, my experience involves a broader range of materials including high-strength steels, aluminum alloys, magnesium alloys, and polymers. Here, the emphasis is often on cost-effectiveness, manufacturability, and recyclability alongside performance requirements. For example, designing a lightweight car body might involve selecting high-strength steel for critical structural components and aluminum alloys for body panels, optimizing both performance and manufacturing costs.

In both industries, material selection is always a collaborative process, involving engineers from various disciplines to consider safety, performance, manufacturability, cost, and environmental factors.

Q 27. What are your preferred methods for communicating technical information about materials?

Communicating technical information effectively is crucial in my role. I prioritize clarity and visual aids to ensure my message is easily understood. My preferred methods include:

- Technical Reports and Presentations: I create well-structured reports and presentations using clear language and visual aids like charts, graphs, and images. These documents are tailored to the audience’s technical level, avoiding unnecessary jargon.

- Data Visualization: I leverage data visualization techniques to present complex material data in a readily understandable manner. Using graphs and charts to illustrate material properties and comparisons is incredibly effective.

- Interactive Tools: I occasionally utilize interactive software tools and simulations to demonstrate material behavior and the implications of material selection decisions.

- Collaboration and Discussions: Open communication and collaboration are essential. I foster interactive discussions and encourage questions to ensure a shared understanding.

For example, when presenting material selection recommendations to a design team, I avoid overwhelming them with excessive data. Instead, I focus on key findings using clear graphs and concise explanations, highlighting the trade-offs and justifications for my choices.

Key Topics to Learn for Material Evaluation and Selection Interview

- Mechanical Properties: Understanding stress-strain curves, tensile strength, yield strength, fatigue, creep, and hardness. Practical application: Analyzing material performance under specific load conditions for a given engineering design.

- Material Characterization Techniques: Familiarity with techniques like microscopy (SEM, TEM), X-ray diffraction, and thermal analysis (DSC, TGA). Practical application: Selecting the appropriate characterization method to identify defects or analyze material composition.

- Material Selection Charts and Databases: Efficient use of databases like CES EduPack to compare and select materials based on multiple criteria. Practical application: Optimizing material selection for cost, performance, and environmental impact.

- Failure Analysis: Identifying failure mechanisms (fatigue, corrosion, creep) and root causes. Practical application: Troubleshooting material failures in existing products or processes.

- Manufacturing Processes and Material Properties: Understanding how manufacturing processes (casting, forging, machining) affect the final material properties. Practical application: Selecting appropriate manufacturing techniques to achieve desired material properties.

- Material Degradation and Corrosion: Understanding different types of corrosion and degradation mechanisms. Practical application: Designing components to resist corrosion in specific environments.

- Sustainability and Life Cycle Assessment: Considering environmental impact throughout the material’s lifecycle. Practical application: Selecting sustainable and recyclable materials for environmentally conscious designs.

- Cost Analysis and Life Cycle Costing: Evaluating the total cost of ownership of materials, considering factors like initial cost, maintenance, and disposal. Practical application: Justifying the selection of a more expensive material based on its long-term benefits.

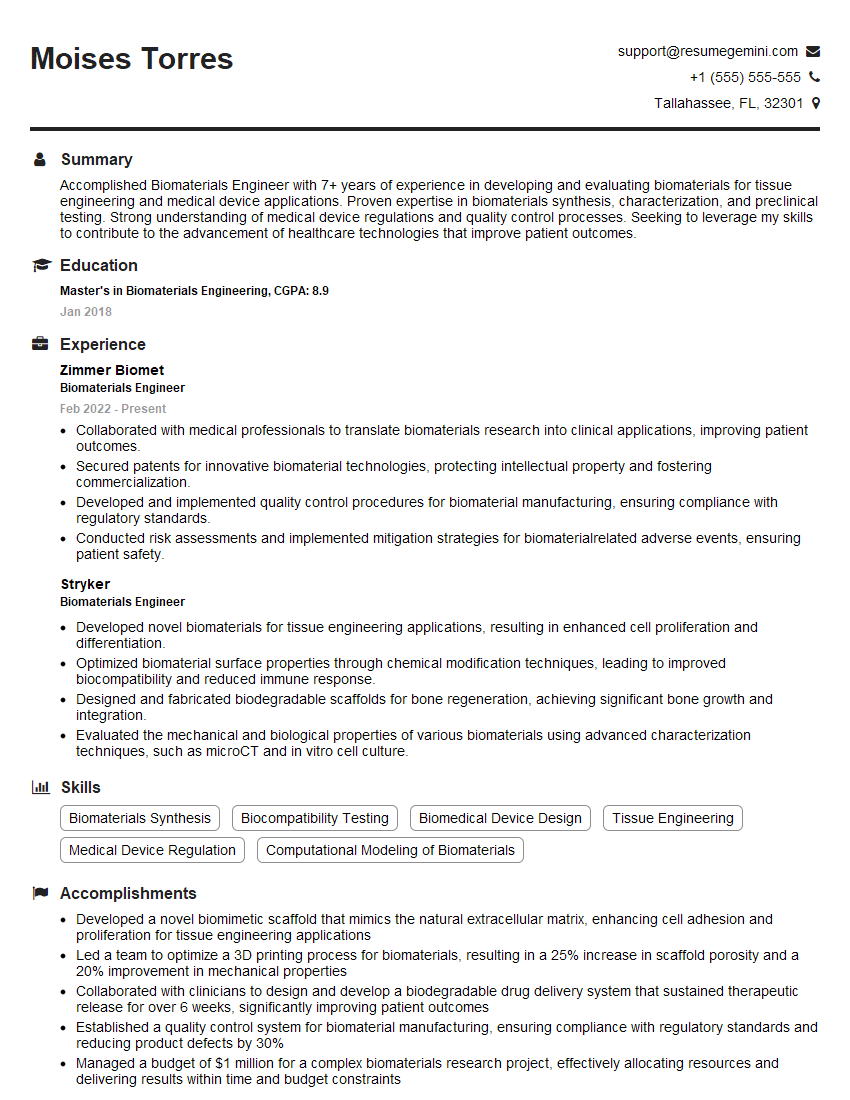

Next Steps

Mastering Material Evaluation and Selection is crucial for career advancement in engineering and related fields. A strong understanding of these concepts demonstrates your ability to design reliable, efficient, and cost-effective products. To significantly increase your chances of landing your dream role, focus on creating a compelling and ATS-friendly resume. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to Material Evaluation and Selection are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.