Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Materials Selection and Design interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Materials Selection and Design Interview

Q 1. Explain the difference between tensile strength and yield strength.

Tensile strength and yield strength are both measures of a material’s resistance to deformation under tensile load, but they represent different points on the stress-strain curve. Tensile strength is the maximum stress a material can withstand before it fractures. Imagine pulling a rubber band – tensile strength is the point where it snaps. Yield strength, on the other hand, is the stress at which the material begins to deform plastically, meaning the deformation is permanent and won’t recover upon removal of the load. Think of bending a paperclip – the yield strength is when it starts to bend permanently rather than springing back.

In simpler terms: Tensile strength tells you the ultimate breaking point, while yield strength indicates the point where permanent deformation begins. Knowing both is crucial in design, as you need to ensure a structure doesn’t break and doesn’t deform excessively under normal operating loads. For instance, designing a bridge requires a material with high tensile strength to withstand extreme loads but also high yield strength to prevent significant sagging under normal traffic.

Q 2. Describe the process of selecting materials for a high-temperature application.

Selecting materials for high-temperature applications requires careful consideration of several properties. The most critical is the material’s melting point; it should be significantly higher than the operating temperature to prevent melting or softening. Oxidation resistance is crucial, as materials exposed to high temperatures often react with oxygen in the air. Creep resistance (resistance to slow, permanent deformation under sustained stress at high temperatures) is also vital, especially for long-term applications. Thermal shock resistance, the ability to withstand rapid temperature changes without fracturing, is important in some scenarios. Finally, strength and stiffness at high temperatures should also be considered.

The selection process usually involves a multi-step approach: First, identify the maximum operating temperature and the required service life. Then, consult material property databases to identify candidate materials that meet the temperature requirements and other necessary criteria. Finally, prototype testing and simulations may be required to validate the selection and ensure the material performs as expected in the specific application. For example, choosing a material for a jet engine turbine blade demands superior creep resistance, oxidation resistance, and high-temperature strength – typically leading to the use of nickel-based superalloys.

Q 3. What are the key considerations for selecting a material for corrosion resistance?

Selecting a material for corrosion resistance depends heavily on the environment the material will be exposed to. Key considerations include:

- The corrosive agent: Is it acidic, alkaline, saltwater, or something else? Different materials resist different corrosive agents.

- Concentration of the corrosive agent: A higher concentration generally leads to faster corrosion.

- Temperature: Higher temperatures often accelerate corrosion rates.

- Presence of other elements: Impurities in the environment can significantly affect corrosion rates.

Material selection strategies include choosing inherently corrosion-resistant materials like stainless steels (which contain chromium for passivation), titanium alloys, or specialized polymers. Alternatively, applying protective coatings, such as paints, galvanization, or anodizing, can enhance corrosion resistance. For example, if designing a marine component, you’d prioritize materials like stainless steel or titanium due to their excellent resistance to saltwater corrosion. Conversely, for a chemical tank handling strong acids, you might select a specialized polymer or a corrosion-resistant alloy like Hastelloy.

Q 4. How do you determine the fatigue life of a material?

Determining the fatigue life of a material involves subjecting it to cyclic loading (repeated stress) and monitoring its response. The most common method is through fatigue testing. A sample is subjected to a controlled cyclic load, usually with a constant amplitude, until failure. The number of cycles to failure is then recorded. This process is repeated at various stress levels to generate an S-N curve (Stress-Number of cycles to failure). This curve shows the relationship between the applied stress amplitude and the number of cycles to failure. The fatigue life at a given stress level can be determined from the S-N curve.

Other techniques, like fracture mechanics, can be used to predict fatigue life by analyzing crack initiation and propagation. Advanced techniques like finite element analysis (FEA) can simulate the cyclic loading and predict fatigue life computationally. The choice of method depends on factors such as the material, the complexity of the loading, and the required accuracy. For example, designing an aircraft wing requires extensive fatigue testing and analysis to ensure it can withstand millions of stress cycles during its service life.

Q 5. Explain the concept of creep and its relevance in material selection.

Creep is the time-dependent plastic deformation of a material under a constant load or stress, especially at elevated temperatures. Imagine a heavy weight hanging from a wire – over time, at high temperatures, the wire will slowly stretch and elongate even though the weight is constant. This is creep.

Creep is especially relevant in high-temperature applications, like gas turbines or power plant boilers, where materials are subjected to high stress and temperatures for extended periods. Understanding creep behavior is vital for predicting the long-term performance and integrity of structures. Material selection for such applications involves choosing materials with high creep resistance, often achieved through alloying or microstructure control. For example, materials used in power plant boilers must demonstrate excellent creep resistance to maintain structural integrity at high operating temperatures for many years. Failure to consider creep could lead to catastrophic structural failure.

Q 6. Describe different material testing methods and their applications.

Numerous material testing methods exist, each designed to evaluate specific properties. Some key examples include:

- Tensile testing: Measures tensile strength, yield strength, and elongation.

- Compression testing: Measures compressive strength and stiffness.

- Hardness testing: Measures the material’s resistance to indentation (e.g., Rockwell, Brinell, Vickers).

- Impact testing: Measures the material’s ability to absorb impact energy (e.g., Charpy, Izod).

- Fatigue testing: Determines the material’s endurance limit and fatigue life under cyclic loading.

- Creep testing: Evaluates the material’s creep behavior at high temperatures.

- Corrosion testing: Assesses the material’s resistance to corrosion in various environments.

The choice of testing method depends on the application and the properties of interest. For example, selecting a material for a car bumper would involve impact testing to evaluate its ability to withstand collisions, while a material for a pressure vessel would necessitate tensile and pressure testing to guarantee its structural integrity.

Q 7. What are the advantages and disadvantages of using composite materials?

Composite materials, which combine two or more materials with different properties, offer several advantages:

- High strength-to-weight ratio: Composites can achieve superior strength and stiffness compared to traditional materials for a given weight, making them ideal for lightweight applications (e.g., aerospace).

- Tailorable properties: The properties of composites can be customized by adjusting the type and arrangement of constituent materials.

- Corrosion resistance: Some composites offer excellent corrosion resistance.

- Design flexibility: Composites can be molded into complex shapes.

However, they also present some disadvantages:

- High cost: Manufacturing composites can be expensive.

- Anisotropy: Composites often exhibit directionally dependent properties.

- Susceptibility to damage: Composites can be susceptible to damage from impact or fatigue.

- Difficult repair: Repairing damaged composites can be challenging.

For example, the use of carbon fiber reinforced polymers (CFRP) in aircraft structures offers a significant weight advantage, but the cost and complexity of manufacturing and repairing these structures must be carefully considered.

Q 8. How do you select materials for biocompatibility?

Selecting materials for biocompatibility requires a meticulous approach, focusing on minimizing adverse reactions within a living system. It’s not just about the material itself, but also its interaction with bodily fluids and tissues. We need to consider factors such as toxicity, degradation products, and the material’s ability to integrate or remain inert within the body.

- Cytotoxicity Testing: This involves exposing cells to the material’s extract or direct contact to assess cell viability and function. A low cytotoxicity rating is crucial.

- Genotoxicity Testing: Evaluates the material’s potential to damage DNA, causing mutations or cancer. This is particularly important for long-term implants.

- Hemocompatibility Testing: For materials in contact with blood, this assesses the material’s impact on blood clotting, platelet activation, and complement system activation. Materials must minimize thrombosis and inflammation.

- Material Degradation and Leaching: We analyze the material’s degradation rate and the toxicity of any released degradation products. Biodegradable materials are carefully chosen to ensure complete and safe absorption.

- Surface Properties: Surface roughness and chemistry can significantly impact biocompatibility. Specialized surface treatments might be necessary to enhance integration or reduce inflammation.

For example, Titanium alloys are widely used in orthopedic implants due to their excellent biocompatibility and high strength. However, even with biocompatible materials, the design is crucial; sharp edges or surface imperfections can lead to irritation and complications.

Q 9. Explain the principles of material failure analysis.

Material failure analysis is a systematic investigation to determine the cause of a material’s failure. It’s a crucial step in preventing future failures and improving product reliability. The process typically involves several stages:

- Visual Inspection: A careful examination of the failed component to identify the fracture surface, cracks, or any other visible damage.

- Macroscopic Examination: Using tools like a magnifying glass or low-power microscope to determine the fracture path and identify potential points of stress concentration.

- Microscopic Examination: Employing techniques like scanning electron microscopy (SEM) and optical microscopy to analyze the microstructure and identify microstructural features contributing to failure.

- Mechanical Testing: Conducting tensile tests, hardness tests, or other mechanical tests on the failed material and/or similar undamaged material to assess its mechanical properties and compare them.

- Chemical Analysis: Determining the chemical composition of the material to rule out material defects or degradation due to environmental factors. Techniques like Energy Dispersive X-ray Spectroscopy (EDS) can be employed.

- Failure Mode Identification: Based on the findings from the above stages, identifying the specific failure mode, such as fatigue, creep, stress corrosion cracking, etc.

For instance, if a bridge cable fails, we’d investigate the microstructure for evidence of fatigue cracks, analyze the cable’s loading history, and assess environmental factors that might have contributed to corrosion.

Q 10. What are the common failure modes in metallic materials?

Metallic materials can fail through various mechanisms. Some common failure modes include:

- Ductile Fracture: This occurs after significant plastic deformation, often exhibiting a cup-and-cone fracture surface. It’s usually associated with high tensile stresses.

- Brittle Fracture: This happens suddenly without significant plastic deformation, often with a relatively flat fracture surface. It’s often associated with low temperatures or high stress concentrations.

- Fatigue Failure: This is caused by cyclic loading, resulting in crack initiation and propagation. Fatigue cracks typically originate at stress concentrators such as surface imperfections or holes.

- Creep Failure: This is a time-dependent deformation under constant load and elevated temperature. It’s common in high-temperature applications, resulting in gradual elongation and eventual fracture.

- Stress Corrosion Cracking (SCC): This occurs when a material is subjected to a corrosive environment and tensile stress simultaneously. It leads to crack initiation and propagation, resulting in unexpected failure.

- Corrosion Fatigue: A combination of fatigue loading and corrosion, leading to accelerated crack growth and premature failure.

Imagine a car axle; fatigue failure could occur due to repeated bending during driving, while stress corrosion cracking could occur if the axle is exposed to salt water.

Q 11. Discuss the importance of material selection in product cost and manufacturability.

Material selection significantly impacts both product cost and manufacturability. Choosing the right material can lead to cost savings throughout the product lifecycle, while poor selection can result in high manufacturing costs and potentially product failure.

- Material Cost: The intrinsic cost of the material itself is a major factor. Some materials, such as titanium alloys, are expensive compared to steel or aluminum.

- Manufacturing Processes: Material selection dictates the feasible manufacturing processes. For example, complex shapes might require more expensive processes like casting or forging, whereas simple shapes might be amenable to more economical methods like stamping or machining.

- Machinability: Some materials are easier to machine than others. Harder materials require specialized tooling and processes, increasing costs.

- Joining Techniques: Different materials require different joining techniques (welding, bonding, etc.). The complexity and cost of these techniques are dictated by material properties.

- Waste and Scrap: The amount of material waste during manufacturing impacts cost. Materials with high yield strength allow for thinner sections, thus reducing waste.

For example, using a cheaper plastic instead of aluminum can significantly reduce material costs but might impact durability and require a redesign to compensate for the lower strength.

Q 12. How do you balance performance requirements with cost constraints in material selection?

Balancing performance requirements with cost constraints is a crucial aspect of material selection. It often involves a trade-off, and the optimal solution depends on the specific application.

- Prioritization: Identify the most critical performance requirements and prioritize them. Compromises might be made on less critical properties.

- Material Property Databases: Use databases like CES EduPack to compare the properties of different materials and their costs to find suitable candidates.

- Value Analysis: Assess the value of each material’s properties relative to its cost. A material might be more expensive but offer significant performance improvements, making it a worthwhile investment.

- Design Optimization: Optimize the design to reduce material usage while maintaining performance. This might involve using composite materials or altering the geometry of the component.

- Alternative Materials: Consider alternative materials that offer comparable performance at a lower cost. For example, using a high-strength steel instead of a more expensive alloy steel.

In designing a bicycle frame, for instance, we might use a high-strength, lightweight aluminum alloy for balance between performance (strength and light weight) and cost, rather than opting for a more expensive carbon fiber.

Q 13. Explain the role of material properties in product design.

Material properties are fundamental to product design. They determine the component’s behavior under different loading conditions and environmental factors.

- Mechanical Properties: Strength, stiffness, hardness, ductility, and toughness dictate the component’s ability to withstand loads and deformations.

- Physical Properties: Density, thermal conductivity, electrical conductivity, and magnetic properties affect the component’s performance in specific applications. For instance, the density affects weight, while thermal conductivity determines heat dissipation.

- Chemical Properties: Corrosion resistance, reactivity, and biocompatibility determine the material’s suitability for different environments and applications. Biocompatibility is crucial for medical implants.

- Manufacturing Properties: Machinability, weldability, and castability influence the manufacturing process and cost.

For example, designing a pressure vessel requires a material with high yield strength and toughness to withstand internal pressure, while designing electronics requires a material with high electrical conductivity and good thermal management properties. Choosing the wrong material properties can lead to product failure or poor performance.

Q 14. Describe your experience with Finite Element Analysis (FEA) in material selection.

Finite Element Analysis (FEA) plays a vital role in material selection by enabling the simulation of a component’s behavior under various loading conditions. This helps in optimizing the design and selecting the most appropriate material based on performance criteria.

In my experience, FEA has been instrumental in several projects. I’ve used it to:

- Stress Analysis: Simulate stress distributions within a component under different loads, helping to identify areas of high stress concentration and refine the design to minimize stress levels. This helps choose a material with adequate strength and avoid brittle failure.

- Fatigue Life Prediction: Assess the fatigue life of a component under cyclic loading, predicting the number of cycles to failure. This allows for the selection of materials with high fatigue resistance.

- Thermal Analysis: Simulate temperature distributions within a component subjected to heat loads. This helps to select materials with appropriate thermal properties (like thermal conductivity and coefficient of thermal expansion) to prevent overheating or thermal stress.

- Material Property Optimization: Explore the effect of various material properties on the component’s performance. This allows for a systematic selection of materials based on quantitative predictions, rather than relying solely on empirical data.

For example, in designing a prosthetic limb, FEA helps predict stress distribution and fatigue life under various loading scenarios, enabling the selection of a biocompatible material with sufficient strength and toughness to ensure the implant’s longevity and patient safety.

I am proficient in using various FEA software packages, including ANSYS and ABAQUS, to conduct these analyses.

Q 15. How do you assess the sustainability of different materials?

Assessing the sustainability of materials requires a holistic approach, considering the entire lifecycle from raw material extraction to end-of-life management. It’s not just about the material itself, but its impact on the environment and society.

- Life Cycle Assessment (LCA): This is a crucial tool. An LCA quantifies the environmental impacts associated with a product’s entire life cycle, including material extraction, processing, manufacturing, use, and disposal. It considers factors like energy consumption, greenhouse gas emissions, water usage, and waste generation. For example, a comparative LCA might show that while aluminum is highly recyclable, its initial production is energy-intensive, whereas a bio-based plastic might have lower manufacturing energy but less favorable end-of-life options.

- Embodied Carbon: This refers to the greenhouse gas emissions associated with a material’s entire life cycle. Choosing materials with low embodied carbon is vital for reducing a product’s carbon footprint. For instance, choosing sustainably harvested timber over steel for certain applications significantly lowers the embodied carbon.

- Social Considerations: Sustainability also involves social aspects. This includes fair labor practices in the supply chain, responsible sourcing of materials, and the impact of the material on human health. For example, avoiding materials containing hazardous substances or those sourced from conflict zones is essential.

- Recyclability and Reusability: The ease with which a material can be recycled or reused at the end of its life significantly influences its sustainability. Materials with high recyclability rates, such as aluminum or certain plastics, are preferred over those destined for landfills.

In practice, I utilize LCA software and databases to compare different materials’ sustainability profiles and integrate these findings into the material selection process. This allows for informed decisions that minimize environmental and social impacts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key considerations for material selection in additive manufacturing?

Material selection for additive manufacturing (AM) involves a unique set of considerations beyond traditional manufacturing. The process itself influences the final product’s properties, and not all materials are suitable for all AM techniques.

- Material Properties: AM processes often require materials with specific properties such as high fluidity for melt-based processes (like Fused Deposition Modeling or FDM) or good powder flow characteristics for powder-bed fusion (like Selective Laser Melting or SLM). The desired final properties (strength, ductility, etc.) are also critical.

- Process Compatibility: The chosen material must be compatible with the specific AM technique. For example, certain polymers might degrade at the high temperatures used in selective laser sintering (SLS), while metals need precise laser parameters for successful melting and solidification.

- Build Orientation and Support Structures: The way the part is oriented in the build chamber impacts the final product’s properties. Materials with anisotropy (different properties in different directions) need careful consideration of build orientation and the use of support structures. Support structures must be easy to remove without damaging the part.

- Post-Processing: Some AM parts require post-processing steps like heat treatment or surface finishing. The chosen material’s response to these processes is vital. For example, some metals require specific heat treatments to reach their desired mechanical properties.

- Cost and Availability: The cost of the material and its availability are always major factors. Some AM-compatible materials are still expensive and not readily available compared to traditional materials.

In my experience, careful analysis of these factors, often utilizing material datasheets provided by AM material suppliers, is key to selecting the optimal material for an AM project. A thorough understanding of the limitations and capabilities of different AM technologies is also paramount.

Q 17. Explain the concept of material degradation and its impact on product lifespan.

Material degradation refers to the deterioration of a material’s properties over time due to various factors. This can significantly impact a product’s lifespan, leading to premature failure or loss of functionality.

- Types of Degradation: Several factors contribute to material degradation, including:

- Chemical Degradation: This involves chemical reactions that alter the material’s structure, such as oxidation (rusting), hydrolysis (breakdown by water), or corrosion.

- Physical Degradation: This includes processes like wear and tear, fatigue (repeated stress), erosion (gradual removal of material), and creep (slow deformation under constant stress).

- Biological Degradation: Some materials are susceptible to degradation by biological agents like bacteria or fungi, commonly found in biomaterials or applications exposed to the environment.

- Impact on Product Lifespan: Material degradation reduces the product’s strength, durability, and overall functionality, leading to shorter lifespan. For instance, a plastic component exposed to UV light will degrade faster, becoming brittle and eventually failing prematurely. Similarly, a metal component experiencing corrosion will lose strength and become susceptible to failure.

- Mitigation Strategies: Various strategies can mitigate material degradation, such as using corrosion-resistant materials, applying protective coatings, designing for specific loading conditions, and incorporating preventive maintenance.

Understanding the degradation mechanisms of different materials is critical in designing durable and long-lasting products. This often requires material testing and analysis to determine the material’s behavior under anticipated operating conditions.

Q 18. How do you handle material selection challenges in a fast-paced project environment?

In fast-paced project environments, efficient material selection is crucial. I employ a structured approach to streamline the process without compromising quality.

- Prioritization and Screening: I start by clearly defining the key requirements for the material. This includes mechanical properties, chemical resistance, cost constraints, and regulatory compliance. I then use this criteria to quickly eliminate unsuitable materials, focusing on a smaller set of candidates.

- Rapid Prototyping and Testing: Instead of extensive testing on all potential candidates, I might prioritize rapid prototyping using readily available materials to quickly assess feasibility and functionality. This allows us to identify potential issues early on and avoid costly mistakes.

- Leveraging Existing Data: I extensively utilize material databases and online resources to access existing material properties and past project data, significantly reducing the time needed for initial material research.

- Collaboration and Communication: In fast-paced projects, seamless collaboration with design engineers, manufacturers, and other stakeholders is paramount. Open communication and regular updates keep everyone informed and ensure that the material selection process remains aligned with the project timeline.

- Decision Making Frameworks: Using a weighted scoring system based on project priorities can help quantitatively compare multiple materials and make a well-justified selection even under time pressure.

The key is to prioritize efficient decision-making without sacrificing quality or safety. This often involves making informed compromises and accepting a degree of uncertainty in material selection based on risk assessment.

Q 19. Describe your experience with various material databases and software.

I have extensive experience with various material databases and software packages. These tools are indispensable for efficient and informed material selection.

- CES EduPack: This comprehensive software suite provides access to a vast database of materials, allowing for easy comparison based on different properties. It’s particularly useful for life cycle assessment and comparing material sustainability.

- Granta MI: Granta MI is another powerful tool that provides access to detailed material properties and enables users to build custom databases and perform sophisticated material selection analyses. It’s commonly used in industry for complex material selection tasks.

- MatWeb: This online database contains a substantial amount of information on various materials. It’s a convenient resource for quick lookups and property comparisons.

- Manufacturer Datasheets: I regularly consult manufacturer datasheets for detailed information on specific materials, including processing recommendations and limitations. This is crucial for ensuring material compatibility with manufacturing processes.

My proficiency with these tools allows for swift analysis, comparison, and selection of materials, improving efficiency and reducing the risk of selecting unsuitable materials.

Q 20. What are the ethical considerations in material selection and procurement?

Ethical considerations are paramount in material selection and procurement. Decisions must consider the environmental, social, and economic impacts across the supply chain.

- Sustainable Sourcing: Ensuring materials are sourced responsibly and sustainably is crucial. This includes avoiding materials sourced from conflict zones, employing fair labor practices, and minimizing environmental damage during extraction and processing. Certification schemes, like Forest Stewardship Council (FSC) for timber, provide assurance of responsible sourcing.

- Fair Labor Practices: The entire supply chain should adhere to ethical labor practices, ensuring fair wages, safe working conditions, and the absence of child labor. This requires due diligence and often involves verifying supplier compliance with ethical standards.

- Transparency and Traceability: Maintaining transparency in the supply chain is vital. Knowing the origin of materials and their journey to the final product allows for better monitoring of ethical and environmental impacts. Blockchain technology is increasingly used to enhance supply chain traceability.

- Material Health and Safety: Choosing materials that minimize potential health and environmental risks is crucial. This includes avoiding hazardous substances, such as lead or asbestos, and selecting materials with minimal impact on human health and the environment. Regulatory compliance is essential in this area.

- End-of-Life Management: Considering the end-of-life management of materials is an ethical imperative. Promoting recyclability, reusability, and responsible disposal helps minimize waste and environmental pollution.

Ethical sourcing and responsible material selection are not only morally sound but also increasingly critical for brand reputation and customer trust. Companies are increasingly held accountable for the ethical practices throughout their supply chains.

Q 21. How do you stay updated on the latest advancements in materials science and engineering?

Staying updated on the latest advancements in materials science and engineering is essential for remaining competitive and at the forefront of the field. I employ a multi-faceted approach to ensure continuous learning.

- Academic Journals and Conferences: I regularly read leading journals like “Nature Materials,” “Advanced Materials,” and “Acta Materialia.” Attending conferences and workshops allows me to engage directly with researchers and learn about cutting-edge discoveries.

- Industry Publications and Trade Shows: Industry publications and trade shows provide insights into the practical applications of new materials and technologies. This is vital for understanding the challenges and opportunities in different sectors.

- Online Resources and Webinars: Online resources, such as material databases, online courses, and webinars offered by professional organizations, supplement my learning and provide up-to-date information.

- Networking and Collaboration: I maintain strong professional networks, engaging with colleagues, researchers, and industry professionals. Collaboration and knowledge sharing are vital for staying informed about new developments.

- Continuous Professional Development: I actively participate in professional development activities, such as attending workshops and short courses, to enhance my knowledge and skills in specific areas.

This commitment to lifelong learning ensures that I remain informed about the latest developments and can apply the most suitable materials and techniques to meet the evolving needs of projects. I continuously adapt my approach to utilize the most advanced materials and technologies.

Q 22. Explain the difference between ductile and brittle materials and their failure mechanisms.

Ductility and brittleness describe a material’s ability to deform before fracture. Ductile materials, like copper or mild steel, can undergo significant plastic deformation (permanent change in shape) before breaking. This deformation usually involves necking, where the material thins down before failure. Their failure mechanism is typically ductile fracture, characterized by extensive plastic deformation and a cup-and-cone fracture surface. Brittle materials, such as ceramics or cast iron, on the other hand, fracture with little to no plastic deformation. Their failure is sudden and catastrophic, often with a flat, cleavage fracture surface. The failure mechanism is brittle fracture, initiated by crack propagation.

Think of it like this: pulling taffy (ductile) versus snapping a chalk stick (brittle). The taffy stretches and thins before it breaks, while the chalk breaks instantly without much deformation.

- Ductile Failure: Necking, cup-and-cone fracture, significant plastic deformation before failure.

- Brittle Failure: Sudden fracture, little to no plastic deformation, flat fracture surface, often initiated by pre-existing flaws.

Q 23. Discuss your experience with different types of joining techniques for various materials.

My experience encompasses a wide range of joining techniques, tailored to the specific materials involved. For metals, I’ve extensively used welding (MIG, TIG, spot welding), brazing, and soldering. The choice depends on factors like the base metal properties, required joint strength, and aesthetic considerations. For example, TIG welding is ideal for high-quality, corrosion-resistant joints in stainless steel, while spot welding is efficient for mass production of sheet metal components.

For polymers, I have experience with adhesive bonding, ultrasonic welding, and thermal welding. The selection here depends on factors like the polymer type, the required bond strength, and the operating temperature. For instance, cyanoacrylate adhesives are excellent for rapid bonding of many polymers, but may not be suitable for high-temperature applications.

Joining ceramics is more challenging due to their inherent brittleness. Techniques like brazing, diffusion bonding, and adhesive bonding are often employed, but careful control of the joining process is crucial to avoid thermal shock or stress concentrations that can lead to cracking.

In composite materials, I’ve worked with techniques like bonding, riveting, and mechanical fastening, again with the selection driven by the specific materials in the composite and the desired joint properties.

Q 24. How do you ensure the selected materials meet safety and regulatory requirements?

Ensuring material selection meets safety and regulatory requirements is paramount. This involves a multi-step process:

- Identify Applicable Standards: First, I identify all relevant safety standards and regulations. This may include international standards (like ISO), national standards (e.g., ASTM, ASME), and industry-specific guidelines. The specifics depend heavily on the application and intended use of the material. For example, materials for aerospace applications will have far more stringent requirements than those used in consumer goods.

- Material Certification: I obtain material certifications (e.g., mill certificates for metals) that confirm the material properties meet the required specifications. These certifications provide verifiable proof of compliance.

- Testing and Validation: Often, rigorous testing is required to validate the material’s performance under anticipated conditions. This could include mechanical testing (tensile, fatigue, impact), chemical analysis, and environmental testing (corrosion, temperature cycling).

- Documentation: Comprehensive documentation is essential, tracing the material selection and verification process from initial requirements to final testing results. This ensures traceability and facilitates future analysis.

A real-world example: Selecting a material for a medical implant requires compliance with stringent biocompatibility standards (like ISO 10993) and rigorous testing to ensure the material doesn’t cause adverse reactions in the body.

Q 25. Describe your approach to solving a material selection problem involving conflicting requirements.

Conflicting requirements are common in materials selection. My approach involves a structured process to find the optimal compromise:

- Define Requirements: Clearly define all performance requirements (strength, weight, cost, corrosion resistance, etc.) and rank them in order of importance. This often involves collaborating with engineers and designers from different disciplines.

- Material Database Search: Utilize material property databases (like CES EduPack or MatWeb) to identify potential candidate materials.

- Prioritize and Rank: Consider trade-offs between conflicting requirements. For example, a material with high strength may be expensive and heavy. A decision matrix can be very helpful in visualizing and quantifying these trade-offs.

- Prototype and Test: Create prototypes using the shortlisted materials to validate performance. Testing often reveals unexpected behavior or limitations.

- Iterative Refinement: The selection process is often iterative. Initial results might lead to adjustments in the requirements or the exploration of new materials.

For instance, designing a lightweight yet strong component for an aircraft might involve trading off between high-strength aluminum alloys (expensive, potentially heavier) and composite materials (lighter, potentially more expensive, requires careful design to avoid failure modes).

Q 26. What is your experience with different types of polymers and their applications?

Polymers encompass a vast family of materials with diverse properties and applications. My experience includes working with thermoplastics (like polyethylene, polypropylene, and ABS), thermosets (like epoxy and polyester resins), and elastomers (like rubber and silicone).

- Thermoplastics: These can be repeatedly melted and reshaped, making them suitable for processes like injection molding and extrusion. Polyethylene is commonly used in packaging, while ABS is found in many consumer products due to its impact resistance.

- Thermosets: These undergo an irreversible chemical change during curing, forming a rigid structure. Epoxies are widely used as adhesives and coatings due to their excellent adhesion and chemical resistance. Polyester resins are commonly found in fiberglass-reinforced composites.

- Elastomers: These exhibit significant elasticity and flexibility. Rubber is used in tires and seals, while silicones are valued for their biocompatibility and heat resistance.

The selection of a polymer depends on factors like required strength, flexibility, temperature resistance, chemical resistance, and processing methods. Understanding the polymer’s structure-property relationship is crucial for making informed decisions.

Q 27. Explain your understanding of different types of ceramics and their properties.

Ceramics are inorganic, non-metallic materials typically formed from metal and non-metal elements. They are known for their high hardness, high melting points, and chemical inertness, but are usually brittle.

- Oxides: Alumina (Al2O3) is widely used for its high strength, hardness, and wear resistance. It finds applications in cutting tools and structural components.

- Carbides: Tungsten carbide (WC) is exceptionally hard and used in cutting tools and wear-resistant coatings.

- Nitrides: Silicon nitride (Si3N4) exhibits high strength and excellent thermal shock resistance, making it suitable for high-temperature applications.

- Silicates: This broad class encompasses materials like glass and various types of clay, used in a wide range of applications from packaging to construction.

Ceramic properties are strongly influenced by their microstructure and processing methods. Controlling factors such as grain size, porosity, and the presence of impurities is essential to achieve desired properties. For example, a fine-grained alumina will generally be stronger than a coarse-grained one.

Q 28. Discuss your experience with selecting materials for applications under extreme conditions (e.g., high pressure, radiation)

Selecting materials for extreme conditions requires a deep understanding of material behavior under stress. My experience involves carefully considering factors like temperature, pressure, radiation, and corrosive environments.

- High Temperatures: Materials like refractory metals (tungsten, molybdenum), certain ceramics (silicon carbide, zirconia), and some high-temperature alloys are often chosen for high-temperature applications. The selection depends on the specific temperature range, and the presence of oxidizing or corrosive atmospheres.

- High Pressure: Materials with high yield strength and compressive strength are needed. Strong metals, ceramics, or composites with specific microstructures designed to resist crack propagation are often considered.

- Radiation Environments: Materials with high resistance to radiation damage are essential. This often involves specialized alloys or ceramics with specific compositions engineered for radiation resistance.

- Corrosion: In corrosive environments, corrosion-resistant alloys (stainless steels, titanium alloys), coatings, or polymers are often used. The choice depends on the specific corrosive agent and its concentration.

For example, selecting materials for nuclear reactor components involves careful consideration of radiation resistance, high-temperature strength, and corrosion resistance in a high-pressure environment. A multi-material approach, combining different materials with complementary properties, may be adopted for optimal performance in such complex conditions.

Key Topics to Learn for Materials Selection and Design Interview

- Material Properties & Characterization: Understanding mechanical properties (strength, toughness, fatigue), thermal properties (conductivity, expansion), and electrical properties. Consider how these are measured and interpreted.

- Material Selection Charts & Databases: Learn to effectively utilize Ashby charts and other databases to efficiently compare materials based on desired properties and constraints. Practice selecting materials for specific applications.

- Failure Analysis & Prevention: Understand common failure mechanisms (fatigue, creep, fracture) and how material selection impacts design for reliability and longevity. Be prepared to discuss case studies.

- Manufacturing Processes & Material Limitations: Consider the impact of manufacturing techniques (casting, machining, forging) on material properties and the limitations they impose on design choices. Discuss cost and feasibility.

- Sustainability & Life Cycle Assessment: Understand the environmental impact of material selection and the principles of sustainable design. Discuss eco-friendly materials and circular economy concepts.

- Design for Specific Applications: Be ready to discuss examples of material selection for different engineering applications, such as aerospace, automotive, biomedical, or construction.

- Advanced Materials & Emerging Technologies: Familiarize yourself with advanced materials like composites, nanomaterials, and biomaterials and their potential applications. Discuss their advantages and limitations.

- Material Modeling & Simulation: Understanding the basics of Finite Element Analysis (FEA) and its role in material selection and design optimization.

Next Steps

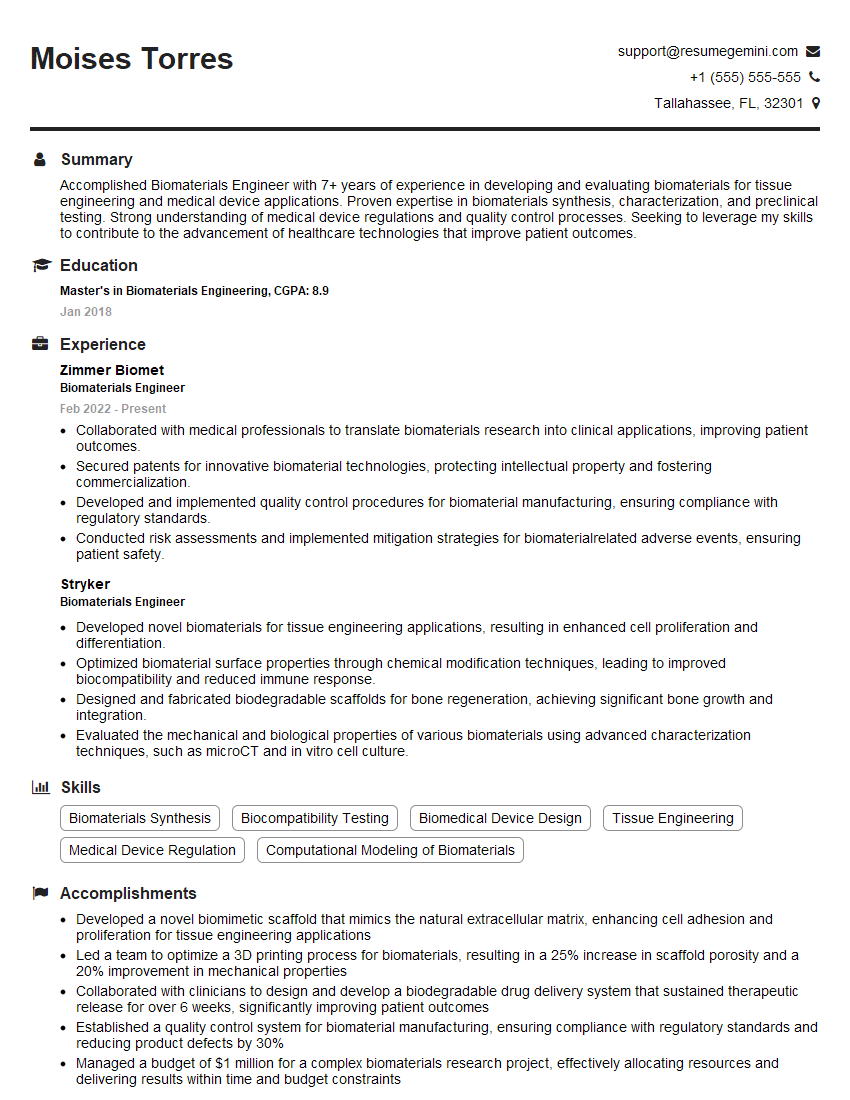

Mastering Materials Selection and Design is crucial for a successful and rewarding career in engineering. It demonstrates a deep understanding of the principles that bridge theoretical knowledge with practical applications, leading to innovative and efficient designs. To significantly boost your job prospects, crafting a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience in this field. Examples of resumes specifically designed for Materials Selection and Design roles are available to guide you through the process. Invest time in creating a resume that showcases your expertise – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.