The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Metals Knowledge and Properties interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Metals Knowledge and Properties Interview

Q 1. Explain the difference between ferrous and non-ferrous metals.

The primary difference between ferrous and non-ferrous metals lies in their iron content. Ferrous metals contain iron as their primary component, often with carbon and other alloying elements. This gives them properties like high strength and magnetic susceptibility. Examples include steel (an alloy of iron and carbon) and cast iron. Non-ferrous metals, on the other hand, do not contain iron as a major component. They typically exhibit higher corrosion resistance, better electrical conductivity, and are often lighter than their ferrous counterparts. Examples include copper, aluminum, zinc, and gold.

Think of it this way: ferrous metals are like the workhorses – strong and capable of bearing heavy loads, but potentially prone to rust. Non-ferrous metals are more like the specialized tools – excellent at specific tasks but potentially less robust.

Q 2. Describe the process of heat treating steel.

Heat treating steel involves precisely controlling the temperature and cooling rate of steel to modify its microstructure and thus its mechanical properties. This is achieved through a series of steps:

- Heating: The steel is heated to a specific temperature, known as the austenitizing temperature, within a controlled atmosphere furnace. This temperature is crucial and depends on the steel grade and desired outcome.

- Soaking: The steel is held at this temperature for a sufficient period to allow the transformation of its microstructure to occur uniformly throughout the component.

- Cooling: This is the most critical step. The cooling rate determines the final microstructure and properties. Rapid cooling (quenching), often in oil or water, results in hard, brittle structures. Slower cooling (annealing) results in softer, more ductile materials. Some processes involve a combination of quenching and tempering for optimal balance of strength and toughness.

- Tempering (optional): If quenching is used, tempering follows to reduce brittleness. The steel is reheated to a lower temperature and cooled slowly to relieve internal stresses and increase ductility.

A classic example is hardening a knife blade. Heating it to a critical temperature followed by rapid quenching in oil leads to a very hard cutting edge, while subsequent tempering ensures that the blade doesn’t become too brittle and prone to breaking.

Q 3. What are the common types of steel and their applications?

There are countless types of steel, categorized by their chemical composition and resulting properties. Here are a few common examples:

- Carbon Steel: The simplest form, primarily composed of iron and carbon. Its properties vary widely based on carbon content: low-carbon steel is relatively soft and ductile, used for car bodies, while high-carbon steel is hard and strong, ideal for tools and springs.

- Stainless Steel: Contains chromium (minimum 10.5%) which forms a protective chromium oxide layer, providing excellent corrosion resistance. Used in kitchen utensils, surgical instruments, and building materials.

- Alloy Steel: Contains other alloying elements besides carbon, such as nickel, molybdenum, or manganese, to improve specific properties like strength, toughness, or corrosion resistance. Used in high-performance applications like aerospace components and pressure vessels.

- Tool Steel: Designed for high hardness and wear resistance, often used to manufacture cutting tools and dies.

The application depends heavily on the desired properties. For instance, a car body requires a strong yet lightweight and formable steel, whereas a surgical scalpel needs a steel that is incredibly hard and resistant to corrosion.

Q 4. Explain the concept of alloying and its effects on metal properties.

Alloying is the process of adding other elements to a base metal to alter its properties. These added elements are called alloying agents. Alloying significantly impacts a metal’s characteristics such as:

- Strength: Adding elements like carbon to iron increases its strength significantly, forming steel.

- Corrosion Resistance: Chromium and nickel additions to iron create stainless steel, greatly enhancing its corrosion resistance.

- Ductility: Certain alloying elements improve the metal’s ability to deform plastically before breaking.

- Hardness: Alloying can increase the hardness and wear resistance of a metal.

- Electrical Conductivity: Alloying can improve or decrease electrical conductivity depending on the added elements.

Think of it like baking a cake. The base ingredients (flour, sugar, eggs) are like the base metal, while added ingredients (chocolate chips, nuts, spices) are the alloying agents that dramatically affect the final product’s taste and texture.

Q 5. How does grain size affect the mechanical properties of a metal?

Grain size refers to the average size of the individual crystals (grains) within a metal’s microstructure. It significantly affects mechanical properties:

- Strength: Smaller grain sizes generally result in higher strength due to increased grain boundary area, which impedes dislocation movement (dislocations are crystal imperfections that affect plastic deformation).

- Ductility: Smaller grain sizes typically reduce ductility, making the metal less easily deformed.

- Toughness: The relationship between grain size and toughness is more complex, but finer grain sizes often improve toughness in certain circumstances.

- Hardness: Smaller grain size usually leads to higher hardness.

Imagine a brick wall: a wall with smaller bricks (smaller grains) would be stronger and harder to break compared to a wall with larger bricks. However, the smaller brick wall might be less flexible and more prone to cracking under stress.

Q 6. What are the different types of corrosion and how can they be prevented?

Corrosion is the deterioration of a metal due to its reaction with the environment. Several types exist:

- Uniform Corrosion: Even deterioration across the metal surface, like the rusting of mild steel.

- Pitting Corrosion: Localized corrosion resulting in small pits or holes on the surface.

- Galvanic Corrosion: Corrosion caused by the contact of two dissimilar metals in the presence of an electrolyte (e.g., seawater). The more active metal corrodes preferentially.

- Crevice Corrosion: Corrosion occurring within narrow gaps or crevices where stagnant solutions can accumulate.

- Stress Corrosion Cracking: Corrosion cracking initiated by the combined action of tensile stress and a corrosive environment.

Corrosion prevention techniques include:

- Protective Coatings: Paint, plating (e.g., galvanizing), or anodizing to create a barrier between the metal and the environment.

- Corrosion Inhibitors: Chemicals added to the environment to slow down corrosion reactions.

- Material Selection: Choosing corrosion-resistant materials like stainless steel or titanium.

- Cathodic Protection: Using a sacrificial anode to protect the metal from corrosion (like zinc coating on steel).

For instance, galvanizing steel fences protects them from rusting because the zinc coating acts as a sacrificial anode, corroding instead of the steel.

Q 7. Describe the different methods of metal forming.

Metal forming encompasses various processes that shape metals into desired forms without significantly altering their chemical composition. Common methods include:

- Rolling: Passing metal between rollers to reduce its thickness and increase its length, producing sheets or plates. Think of making a rolling pin from a metal cylinder.

- Forging: Shaping metal by hammering or pressing it, resulting in a strong and dense product. Sword making often uses forging techniques.

- Extrusion: Forcing metal through a die to create a specific cross-sectional shape, such as aluminum tubes or profiles.

- Drawing: Pulling metal through a die to reduce its diameter, creating wires or tubes. Think of making a wire from a thicker metal rod.

- Stamping/Pressing: Using dies to press or punch metal into various shapes, widely used in automotive parts manufacturing.

Each method is tailored to the metal’s properties and desired final shape. For example, rolling is ideal for producing large sheets of steel, while forging creates strong components for heavy machinery.

Q 8. Explain the principles of welding.

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. This means the materials are fused together, forming a strong bond. The process relies on several key principles:

- Heat Input: Welding uses heat, often generated by an electric arc, gas flame, or friction, to melt the base materials and a filler material (sometimes). The heat melts the metals at the joint interface, allowing them to flow together.

- Fusion: Once molten, the base and filler materials mix and then cool, solidifying into a single, continuous piece. The strength of the weld depends heavily on achieving proper fusion – incomplete fusion can lead to defects.

- Metallurgical Bonding: The atoms of the molten metals rearrange themselves as they cool, forming strong metallic bonds across the weld interface. This is different from simply gluing materials together; it’s a true joining at the atomic level.

- Shielding: Often, a shielding gas (like Argon or CO2) or a flux is used to protect the molten weld pool from atmospheric contamination (oxygen or nitrogen), which can weaken the weld by forming oxides or nitrides.

- Control of Cooling Rate: The rate at which the weld cools influences the microstructure and ultimately the mechanical properties of the weld. Too rapid cooling can lead to cracking, while too slow cooling can result in softer, weaker welds. This is why different cooling methods exist, including quenching and tempering post-weld.

Imagine melting two pieces of chocolate together – that’s a simplified analogy to illustrate the fusion aspect. Welding is more complex, involving precise control of heat, material, and the environment to ensure a strong and reliable joint.

Q 9. What are the common types of non-destructive testing methods used for metals?

Non-destructive testing (NDT) methods are crucial for evaluating the integrity of metal components without causing damage. Common techniques for metals include:

- Visual Inspection: A basic but essential method involving visual examination for surface defects like cracks, corrosion, or porosity.

- Liquid Penetrant Testing (LPT): A dye is applied to the surface, penetrating any cracks. After cleaning, a developer reveals the dye in the cracks, making them visible.

- Magnetic Particle Testing (MPT): Used for ferromagnetic materials, this method employs magnetic fields and iron particles to detect surface and near-surface discontinuities. The particles cluster at the defect sites, revealing their location.

- Ultrasonic Testing (UT): High-frequency sound waves are transmitted into the material, and reflections from discontinuities are analyzed to detect internal flaws, including cracks and inclusions.

- Radiographic Testing (RT): X-rays or gamma rays are passed through the material; variations in the transmitted radiation reveal internal flaws. This is often used for detecting welds defects.

- Eddy Current Testing (ECT): Electromagnetic induction is used to detect surface and near-surface flaws. This method is particularly useful for detecting corrosion or cracks in conductive materials.

For instance, in the aerospace industry, UT is vital for inspecting aircraft components for hidden cracks to prevent catastrophic failure. Similarly, RT is commonly used in the pipeline industry for checking the integrity of welds in oil and gas pipelines.

Q 10. Describe the different types of metallographic techniques.

Metallographic techniques are used to study the microstructure of metals, revealing details about their composition, processing history, and properties. Key techniques include:

- Sample Preparation: This is a crucial first step, involving sectioning, mounting, grinding, and polishing to create a flat, mirror-like surface free from scratches.

- Optical Microscopy: A polished sample is etched with a chemical reagent, revealing the grain boundaries and different phases present in the metal. The microstructure is then observed using an optical microscope.

- Scanning Electron Microscopy (SEM): SEM uses a focused beam of electrons to create high-resolution images of the sample’s surface, revealing details far smaller than what’s visible with optical microscopy. It can also be coupled with energy-dispersive X-ray spectroscopy (EDS) to analyze the chemical composition of different phases.

- Transmission Electron Microscopy (TEM): TEM is used to study the internal structure of metals at an atomic scale. A very thin sample is prepared, and a beam of electrons is transmitted through it, providing information about the crystal structure, dislocations, and other defects.

Imagine a baker examining the crumb structure of a loaf of bread; metallographers perform similar inspections on metals to understand their properties and identify potential weaknesses.

Q 11. How do you determine the mechanical properties of a metal?

Determining the mechanical properties of a metal involves conducting various tests. The most common methods include:

- Tensile Testing: A specimen is subjected to a uniaxial tensile load until fracture, measuring its yield strength, tensile strength, elongation, and reduction in area. This helps determine the material’s strength and ductility.

- Compression Testing: The specimen is subjected to a compressive load to measure its compressive strength and behavior under compression.

- Hardness Testing: Several methods (Brinell, Rockwell, Vickers) assess the material’s resistance to indentation. Hardness is often correlated with strength.

- Impact Testing: The material’s ability to absorb energy during impact is evaluated using tests like the Charpy or Izod impact test. This determines its toughness and resistance to fracture.

- Fatigue Testing: The specimen is subjected to cyclic loading to determine its endurance limit and resistance to fatigue failure.

- Creep Testing: The specimen is subjected to a constant load at high temperature to measure its creep rate and time to rupture. This is vital for high-temperature applications.

For example, a bridge designer would use tensile test data to select a steel with sufficient strength and ductility to withstand expected loads. An automotive engineer might use impact testing to choose a metal for a car bumper that can withstand collisions without shattering.

Q 12. What is the difference between tensile strength and yield strength?

Both tensile strength and yield strength are measures of a material’s resistance to deformation under tensile stress, but they represent different points on the stress-strain curve:

- Tensile Strength: This is the maximum stress a material can withstand before it begins to neck and ultimately fracture. It represents the material’s ultimate strength capacity.

- Yield Strength: This is the stress at which the material begins to deform plastically (permanently). It marks the transition from elastic (reversible) deformation to plastic (irreversible) deformation. The yield strength is a crucial design parameter as it indicates the stress level below which permanent deformation will not occur.

Imagine stretching a rubber band. The tensile strength is the point at which it breaks. The yield strength is the point where it starts to stretch permanently, even after you release the tension.

Q 13. Explain the concept of fatigue in metals.

Fatigue in metals refers to the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. Even stresses well below the yield strength can cause fatigue failure over many cycles. The process involves several stages:

- Crack Initiation: Micro-cracks form at stress concentrations (e.g., surface imperfections, inclusions). These are often difficult to detect.

- Crack Propagation: The cracks gradually propagate through the material under repeated loading, often along crystallographic planes.

- Fracture: The crack eventually reaches a critical size, causing sudden and catastrophic failure, often with little or no plastic deformation.

Imagine repeatedly bending a paperclip back and forth. Eventually, it will break, even though the force applied in each cycle is much less than what’s needed to break it in a single attempt. This is analogous to fatigue failure.

Q 14. What is creep and how does it affect metal performance at high temperatures?

Creep is the time-dependent permanent deformation of a material under a constant load at elevated temperatures. It’s a significant concern for components operating in high-temperature environments like gas turbines and power plant boilers.

At high temperatures, the atoms in the metal gain enough energy to overcome the atomic bonds more easily, allowing them to slowly slide past one another under stress. This slow, continuous deformation can lead to significant dimensional changes and ultimately failure.

Several factors influence creep:

- Temperature: Higher temperatures accelerate creep.

- Stress: Higher stresses result in faster creep rates.

- Material properties: Some metals are more susceptible to creep than others.

- Time: Creep is a time-dependent process; the longer the material is under stress, the more it creeps.

Think of a very viscous liquid slowly flowing under gravity. Creep is similar – the metal slowly “flows” under the influence of stress and high temperature.

Q 15. Describe the different types of casting processes.

Casting is a fundamental metalworking process where a molten metal is poured into a mold, allowed to solidify, and then ejected or broken out to reveal the final shape. Different casting processes vary primarily in the mold material, the method of pouring the molten metal, and the complexity of shapes achievable.

- Sand Casting: This is the oldest and most common method. A mold is created using sand packed around a pattern (the shape of the final casting). Molten metal is poured into the mold cavity. Sand casting is versatile and inexpensive but produces less precise castings with rougher surface finishes.

- Die Casting: This process uses reusable metal molds (dies) to produce high-volume, precise castings. Molten metal is injected under high pressure into the die. Die casting results in superior surface finish and dimensional accuracy but requires significant upfront investment in tooling.

- Investment Casting (Lost-Wax Casting): This method allows for intricate shapes. A wax pattern is created, coated in a ceramic material, and then the wax is melted out, leaving a cavity. Molten metal is poured into the cavity. Investment casting is expensive but ideal for complex geometries.

- Centrifugal Casting: Molten metal is poured into a spinning mold. Centrifugal force distributes the metal evenly, resulting in dense castings with uniform properties. This is often used for pipes and tubes.

- Continuous Casting: Molten metal is solidified continuously in a mold, producing a long, semi-finished product that is later cut to length. This method is highly efficient for mass production.

The choice of casting process depends on factors such as the required accuracy, volume, complexity of the part, and the cost constraints of the project. For instance, a simple, low-volume part might be suitable for sand casting, whereas high-volume production of a complex part would benefit from die casting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the advantages and disadvantages of using different metal joining techniques?

Metal joining techniques encompass various methods of permanently connecting metallic components. Each method offers a unique set of advantages and disadvantages based on factors like strength, cost, and the types of metals involved.

- Welding: This is a fusion process where the base metals are melted and joined together. It offers high strength and is versatile but requires specialized equipment and skilled operators. Different welding processes, such as arc welding, resistance welding, and laser welding, each have their own pros and cons related to speed, cost, and the type of weld produced.

- Brazing: A filler metal with a lower melting point is used to join the base metals. Brazing provides a strong joint but typically results in lower strength compared to welding. It’s suitable for joining dissimilar metals.

- Soldering: Similar to brazing, but uses a filler metal with an even lower melting point. It produces weaker joints but is ideal for electrical connections.

- Bolting/Riveting: These are mechanical joining methods that use fasteners to connect components. They are relatively simple and inexpensive but may not provide the same level of strength or leak-tightness as fusion methods. Bolting allows for disassembly, which is a key advantage in some applications.

Consider an example: A pressure vessel requires high strength and leak tightness; welding is the preferred method. Conversely, assembling a car chassis where disassembly might be required for repairs, bolting is more appropriate.

Q 17. Explain the phase diagram of an iron-carbon alloy.

The iron-carbon phase diagram is a graphical representation of the phases present in iron-carbon alloys at different temperatures and compositions. Understanding this diagram is crucial for selecting appropriate steels for specific applications. The diagram shows several key phases and transformations:

- Austenite (γ): A face-centered cubic (FCC) solid solution of carbon in iron, stable at high temperatures.

- Ferrite (α): A body-centered cubic (BCC) solid solution of carbon in iron, stable at lower temperatures. Ferrite is relatively soft and ductile.

- Cementite (Fe3C): An iron carbide (iron and carbon compound) that is hard and brittle.

- Pearlite: A lamellar mixture of ferrite and cementite, formed upon cooling austenite. Pearlite’s properties are intermediate between ferrite and cementite.

- Ledeburite: A eutectic mixture of austenite and cementite.

The diagram illustrates the transformations that occur as an iron-carbon alloy cools, showing the formation of different microstructures (pearlite, etc.) that significantly affect the mechanical properties of the steel. For instance, the carbon content directly influences the hardness and strength of steel; higher carbon content generally means higher hardness and strength but reduced ductility.

Q 18. How does temperature affect the properties of metals?

Temperature significantly impacts the properties of metals. Changes in temperature alter the atomic structure and vibrational energy within the metal lattice, leading to changes in mechanical, electrical, and other properties.

- Strength and Ductility: Generally, increasing temperature reduces the strength and increases the ductility of metals. This is because the increased atomic vibrations make it easier for dislocations (crystal lattice defects) to move, leading to plastic deformation.

- Electrical Conductivity: The electrical conductivity of most metals decreases with increasing temperature. The increased thermal vibrations interfere with the flow of electrons.

- Phase Transformations: As mentioned in relation to the iron-carbon diagram, temperature changes can induce phase transformations, fundamentally altering the microstructure and consequently the properties of the metal. For example, heating steel to austenite phase and then cooling it at specific rates can control its hardness through processes like annealing and quenching.

For example, imagine a bridge made of steel. At extremely low temperatures, the steel becomes brittle and more susceptible to fracture. Conversely, at high temperatures, the steel loses strength and could sag under load.

Q 19. What are the effects of impurities on the properties of metals?

Impurities in metals significantly affect their properties. Even small amounts of impurities can dramatically alter strength, ductility, conductivity, and other characteristics. The effect depends on the type and concentration of the impurity and its interaction with the base metal.

- Solid Solution Strengthening: Impurity atoms can dissolve into the crystal lattice of the base metal, creating lattice distortions that hinder dislocation movement, thereby increasing strength and hardness. This is commonly seen in alloying elements added to enhance the properties of a base metal.

- Grain Boundary Segregation: Impurities can segregate to grain boundaries, weakening them and making the metal more susceptible to intergranular fracture. This can reduce the overall ductility and toughness of the material.

- Formation of Precipitates: Impurities can react with the base metal to form precipitates (small particles of a different phase) within the grain structure. These precipitates can either strengthen or weaken the metal, depending on their size, distribution, and type. For instance, many high-strength aluminum alloys utilize controlled precipitation to achieve high strength.

- Changes in Electrical and Thermal Conductivity: Impurities can scatter electrons, reducing the electrical and thermal conductivity of metals.

For example, adding small amounts of carbon to iron produces steel, which is significantly stronger and harder than pure iron. However, excessive carbon can make the steel brittle.

Q 20. Explain the concept of recrystallization.

Recrystallization is a process that occurs in metals after they have been plastically deformed (cold worked). Cold working introduces dislocations, which increase the strength and hardness of the metal but also reduce its ductility. Recrystallization is the formation of new, strain-free grains at elevated temperatures, effectively reversing the effects of cold working.

The process involves the nucleation and growth of new grains within the deformed microstructure. These new grains are free of dislocations, resulting in a softer, more ductile material with improved formability. The temperature required for recrystallization depends on several factors including the material, the extent of prior deformation, and the presence of impurities.

Recrystallization is crucial in many metalworking processes. For example, after cold rolling a metal sheet to a specific thickness, a recrystallization anneal is often performed to soften the metal, making it easier to form into complex shapes without fracturing.

Q 21. Describe the process of powder metallurgy.

Powder metallurgy is a manufacturing process that uses metal powders to create parts. It is distinct from casting or machining because it involves compacting and sintering metal powders into the desired shape. This process offers unique advantages in producing parts with specific properties and complex geometries.

- Powder Production: Metal powders are produced by various methods, including atomization (spraying molten metal into a fine mist), mechanical alloying, or chemical reduction.

- Blending and Mixing: The powders are blended to achieve the desired chemical composition and properties.

- Compaction: The powder mixture is compacted under high pressure in a die to form a green compact (a pre-sintered part). The green compact retains the shape but has limited strength.

- Sintering: The green compact is heated in a controlled atmosphere to a temperature below the melting point of the metals. This causes the powder particles to bond together, resulting in a solid part with improved strength and density.

- Finishing Operations: After sintering, further operations may be performed such as machining, heat treatment, or infiltration to enhance the properties and dimensional accuracy of the final product.

Powder metallurgy is particularly useful for producing parts with complex shapes, porous structures, or precise compositions that are difficult to achieve using other methods. It is also efficient for producing parts with very fine microstructures, resulting in improved mechanical properties. This technique is widely used in the production of bearings, cemented carbides, and other advanced metal components.

Q 22. How do you select a suitable material for a given application?

Selecting the right material for an application is a crucial step in engineering design. It involves a systematic process of considering various material properties and matching them to the specific demands of the intended use. This requires a deep understanding of the application’s operating conditions, including the stresses (mechanical, thermal, chemical), the environment (temperature, humidity, corrosive agents), and the required lifespan.

For instance, consider designing a car engine component. We need a material with high strength to withstand the intense forces, high temperature resistance to survive combustion temperatures, and good fatigue resistance to prevent failure over time. Steel alloys are often chosen for this purpose due to their excellent combination of properties, though the precise alloy will depend on the specific component and its operating conditions. A connecting rod might use a high-strength, low-alloy steel, while a piston might use a steel alloy with improved thermal resistance. Factors such as cost, manufacturability, and availability also influence the final decision. A thorough material selection process might involve consulting material property databases, performing simulations, and conducting experimental tests to validate the choice.

- Identify the application requirements: What are the critical operational parameters (stress, temperature, corrosion environment)?

- Consult material property databases: Compare the required properties with available materials.

- Consider cost and manufacturability: Is the material readily available and cost-effective to process?

- Perform simulations and tests: Verify the chosen material’s performance under realistic conditions.

Q 23. What are the environmental concerns related to metal production and processing?

Metal production and processing are major contributors to environmental pollution. The processes often involve significant energy consumption, greenhouse gas emissions, and the generation of hazardous waste. Mining, the first step, can lead to habitat destruction, soil erosion, and water pollution from tailings (waste rock). Smelting, where ores are refined, releases harmful gases like sulfur dioxide (SO2) and particulate matter into the atmosphere, contributing to acid rain and respiratory problems. Furthermore, many metal extraction processes use large amounts of water, potentially depleting local resources.

For example, aluminum production is notoriously energy-intensive, relying heavily on electricity generated from fossil fuels in many regions. The mining and processing of rare earth elements for electronics and other high-tech applications also raises significant environmental concerns due to the potential for toxic waste generation and habitat damage. Addressing these issues requires a multifaceted approach, including developing cleaner production technologies, improving waste management practices, and promoting the recycling of metals.

Q 24. Explain the concept of stress corrosion cracking.

Stress corrosion cracking (SCC) is a serious form of environmental cracking that occurs when a metal is subjected to a combination of tensile stress and a corrosive environment. It’s a failure mechanism where the combined action of these two factors causes cracking and eventual fracture, even at stresses significantly below the material’s yield strength. The crack initiation and propagation are assisted by the corrosive environment, making it more dangerous than simple tensile failure.

Imagine a stainless steel pipe carrying saltwater. If the pipe is under tension (due to pressure or other loads) and is exposed to the corrosive saltwater, it might experience SCC. The chloride ions in the saltwater can attack the passive layer (a protective oxide film) on the stainless steel, initiating cracks. These cracks will then propagate under the combined action of the stress and the corrosive environment, ultimately leading to failure. SCC is a time-dependent phenomenon; the cracks grow slowly over time, often without any visible signs until catastrophic failure occurs. Understanding and mitigating SCC often requires careful material selection, stress control, and environmental protection.

Q 25. What are the common failure mechanisms in metals?

Metals can fail through various mechanisms, each dependent on the material, the loading conditions, and the environment. Some common failure mechanisms include:

- Ductile fracture: Characterized by significant plastic deformation before failure, often with necking and cup-and-cone fracture surfaces.

- Brittle fracture: Sudden failure with minimal plastic deformation, often with a flat, crystalline fracture surface.

- Fatigue failure: Failure due to cyclic loading, even at stresses well below the yield strength. Initiation of cracks at stress concentrations followed by propagation until final failure.

- Creep failure: Time-dependent deformation and failure under sustained high temperature and stress.

- Corrosion: Degradation of material properties due to chemical or electrochemical reactions with the environment.

- Stress corrosion cracking (SCC): Failure due to combined tensile stress and corrosive environment.

- Hydrogen embrittlement: Reduction in ductility and strength caused by hydrogen absorption.

Understanding these mechanisms is crucial for designing reliable metal components and preventing failures. For example, careful design to avoid stress concentrations is crucial for preventing fatigue failure, while using corrosion-resistant materials is key for preventing corrosion-related failures.

Q 26. Describe the principles of metallography.

Metallography is the science and art of preparing and examining the microstructure of metals and alloys. It involves preparing a sample of the metal (sectioning, mounting, grinding, polishing) and then etching it with a chemical reagent to reveal the different phases and microstructural features. The prepared sample is then examined under a microscope (optical or electron) to analyze the grain size, shape, phases, and other structural characteristics.

This microscopic examination provides valuable insights into the material’s properties and processing history. For example, a fine-grained steel will typically be stronger and tougher than a coarse-grained steel. The presence of certain phases might indicate a specific heat treatment or manufacturing process. Metallography plays a critical role in quality control, failure analysis, and materials research. It allows engineers and scientists to relate the microstructure to the macroscopic properties, facilitating improvements in material selection and processing.

Q 27. What is the difference between ductile and brittle fracture?

Ductile and brittle fracture represent two distinct modes of failure in materials. Ductile fracture is characterized by extensive plastic deformation prior to fracture. The material stretches and necks down before finally breaking. The fracture surface often exhibits a cup-and-cone shape, indicative of significant shear deformation. Ductile fracture generally provides warning signs before catastrophic failure, allowing for preventative measures.

Brittle fracture, on the other hand, is sudden and catastrophic, with very little or no plastic deformation before failure. The fracture surface is typically flat and crystalline, often exhibiting cleavage planes. Brittle fractures often occur without warning and are particularly dangerous. The difference lies primarily in the ability of the material to deform plastically before fracture. Ductile materials can absorb more energy during deformation, while brittle materials fail abruptly.

Consider a difference between a mild steel rod and a glass rod. The steel rod will deform significantly before breaking (ductile), while the glass rod will break suddenly with minimal deformation (brittle). The same material can exhibit different fracture modes under different conditions, such as temperature, strain rate, or the presence of defects. Understanding the factors influencing fracture behavior is essential for designing safe and reliable structures.

Q 28. Explain the role of microstructure in determining the properties of metals.

The microstructure of a metal, its arrangement of grains, phases, and defects at a microscopic level, profoundly influences its macroscopic properties – strength, ductility, toughness, corrosion resistance, etc. The size, shape, and orientation of grains, the presence of precipitates or second phases, and the types and distribution of defects (dislocations, grain boundaries) all play a crucial role.

For example, a fine-grained material typically exhibits higher strength and hardness due to increased grain boundary area hindering dislocation movement. Conversely, a coarse-grained material might have improved ductility. The presence of specific phases can significantly influence properties. For instance, the addition of carbides to steel strengthens it but can reduce ductility. Heat treatments alter microstructure by changing the size, distribution, and type of phases present; altering the material’s properties accordingly. Techniques like heat treating, cold working, and alloying are used to manipulate the microstructure and tailor the desired properties for specific applications. Understanding and controlling the microstructure are fundamental aspects of materials science and engineering.

Key Topics to Learn for Metals Knowledge and Properties Interview

- Crystal Structures and Defects: Understanding BCC, FCC, HCP structures and their influence on material properties. Analyzing the impact of point, line, and planar defects on mechanical behavior.

- Mechanical Properties: Comprehending tensile strength, yield strength, ductility, hardness, toughness, fatigue, and creep. Knowing how to interpret stress-strain curves and apply this knowledge to material selection.

- Phase Diagrams: Interpreting equilibrium phase diagrams (e.g., Fe-C diagram) to predict phase transformations and microstructures at different temperatures and compositions. Relating microstructure to mechanical properties.

- Heat Treatments: Understanding the principles and applications of annealing, quenching, tempering, and other heat treatment processes. Explaining their effects on microstructure and mechanical properties.

- Corrosion and Degradation: Identifying different types of corrosion (e.g., galvanic, pitting, stress corrosion cracking). Discussing methods for corrosion prevention and protection.

- Material Selection: Applying knowledge of metal properties to select appropriate materials for specific engineering applications, considering factors like cost, performance, and environmental impact.

- Alloying and Strengthening Mechanisms: Explaining the effects of alloying elements on the properties of metals. Describing various strengthening mechanisms such as solid solution strengthening and precipitation hardening.

- Testing and Characterization: Familiarity with common material testing methods (e.g., tensile testing, hardness testing, impact testing) and characterization techniques (e.g., microscopy, diffraction). Understanding how to interpret test results.

- Manufacturing Processes: Basic understanding of metal forming processes (e.g., casting, forging, rolling, extrusion) and their influence on the final properties of the material.

Next Steps

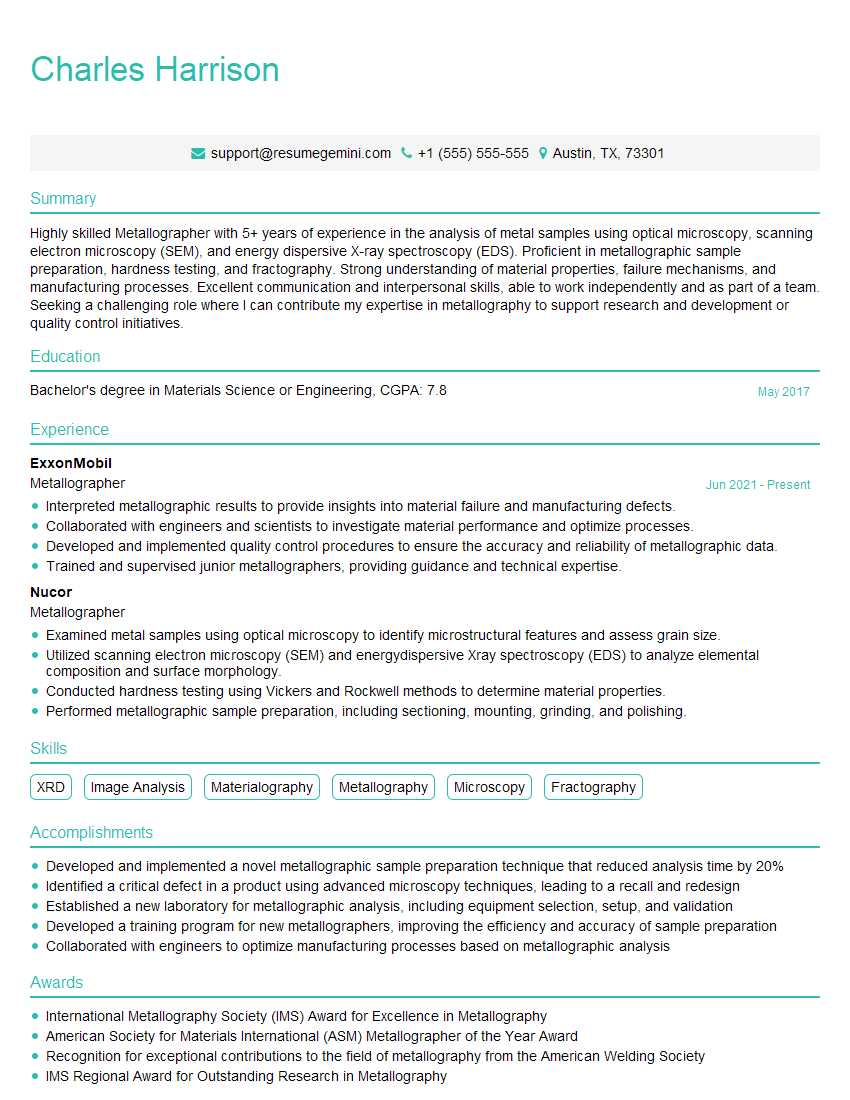

Mastering Metals Knowledge and Properties is crucial for career advancement in numerous engineering and materials science fields. A strong understanding of these concepts demonstrates technical expertise and problem-solving skills highly valued by employers. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Metals Knowledge and Properties to guide you in crafting your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.