Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Module Cleaning and Maintenance interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Module Cleaning and Maintenance Interview

Q 1. Describe your experience with various module cleaning techniques.

Module cleaning techniques vary greatly depending on the type of module, the nature of the contamination, and the desired level of cleanliness. My experience encompasses a range of methods, from simple manual cleaning to more advanced techniques like ultrasonic cleaning and chemical treatments.

- Manual Cleaning: This involves using soft brushes, swabs, and appropriate cleaning solutions to remove dirt, dust, and other loose contaminants. I’ve used this extensively for delicate modules where aggressive cleaning could cause damage. For example, I’ve successfully cleaned optical modules using isopropyl alcohol and lint-free wipes, ensuring a thorough yet gentle cleaning process.

- Ultrasonic Cleaning: For more stubborn contamination, ultrasonic cleaning is highly effective. This method uses high-frequency sound waves to create cavitation bubbles that dislodge particles from the module’s surface. I’ve employed this technique successfully on modules with complex geometries or intricate components where manual cleaning proved insufficient. The key is choosing the right cleaning solution and carefully controlling parameters like temperature and cleaning time to avoid damage.

- Chemical Cleaning: Certain contaminants require specialized chemical cleaning agents. My experience includes using various solvents and detergents, always ensuring compatibility with the module’s material to avoid corrosion or degradation. For instance, I’ve safely and effectively removed organic residues from electronic modules using appropriate solvents, following strict safety protocols.

Choosing the right technique is crucial. It’s a balancing act between effectiveness and the risk of damaging the module. My approach always prioritizes the least aggressive method that achieves the desired level of cleanliness.

Q 2. What safety precautions do you follow during module cleaning?

Safety is paramount during module cleaning. My procedures always prioritize personal safety and the protection of the modules themselves. This includes:

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, gloves, and a lab coat, to protect myself from chemical splashes, dust inhalation, and potential static discharge. The specific PPE depends on the cleaning agents and module type.

- Proper Ventilation: When using volatile cleaning agents, I ensure adequate ventilation to prevent the buildup of harmful fumes. In some cases, I work in a fume hood.

- Grounding Precautions: For electronic modules, grounding straps are vital to prevent electrostatic discharge (ESD), which can damage sensitive components. I’ve had instances where neglecting this precaution caused costly repairs, emphasizing its importance.

- Chemical Handling: I adhere to the manufacturer’s instructions and safety data sheets (SDS) for all cleaning agents. This includes proper storage, handling, and disposal of chemicals. I always label containers clearly and never mix chemicals unless explicitly allowed by the SDS.

- Waste Disposal: Proper disposal of cleaning solutions and contaminated materials is vital. I follow all relevant regulations and company procedures for waste handling and recycling.

Think of it like this: cleaning modules is like performing delicate surgery. Precision and safety are crucial for a successful outcome.

Q 3. How do you identify different types of module contamination?

Identifying module contamination requires a combination of visual inspection and advanced analytical techniques. The type of contamination dictates the cleaning method. Common types include:

- Dust and Debris: Easily visible under magnification. Often a simple cleaning is sufficient.

- Organic Contaminants: These can be fingerprints, oils, or residues from manufacturing processes. These often require more specialized solvents for removal.

- Inorganic Contaminants: These could include salts, metals, or particulates. Identifying the specific contaminant is crucial for choosing an effective cleaning agent.

- Microbial Contamination: This can involve bacteria, fungi, or other microorganisms. Often requires specialized cleaning agents and sterilization techniques.

For accurate identification, I use a variety of methods:

- Visual Inspection: Using a magnifying glass or microscope to identify the type and location of contamination.

- Spectroscopic Analysis: Employing techniques like Raman or FTIR spectroscopy to identify the chemical composition of contaminants.

- Microscopic Analysis: Using SEM or other microscopy to analyze the morphology and size distribution of particles.

Accurate identification ensures that the most effective and safest cleaning strategy is implemented.

Q 4. What cleaning agents are appropriate for different module materials?

The choice of cleaning agent is critical and depends entirely on the module’s material and the type of contamination. Incompatible cleaning agents can damage or degrade the module’s surface. Here are some examples:

- Isopropyl Alcohol (IPA): Commonly used for cleaning many electronic components and optical surfaces due to its effectiveness and relatively low toxicity. However, it shouldn’t be used on all materials.

- Deionized Water: Often used for rinsing after cleaning with other solvents. Essential for preventing residue.

- Specialized Solvents: For specific types of contamination, specialized solvents, such as acetone or other organic solvents might be necessary, but these must be used carefully and only if compatible with the module material.

- Detergents: Certain low-concentration detergents can effectively remove organic contaminants, but rinsing is crucial to avoid residue.

Before selecting a cleaning agent, I always consult the material’s data sheet to ensure compatibility and follow all safety protocols.

For example, cleaning a glass lens requires different agents than cleaning a metallic housing. I have extensive experience consulting material safety data sheets to determine the appropriate cleaning agents and procedures.

Q 5. Explain your process for documenting module cleaning procedures.

Comprehensive documentation is crucial for maintaining consistency and traceability in module cleaning procedures. My process involves:

- Detailed Cleaning Procedure: This includes a step-by-step guide outlining all procedures, including PPE requirements, cleaning agents used, and equipment involved. It’s like a recipe that guarantees consistent, successful results.

- Module Identification and History: Each cleaning process includes the module’s serial number and a record of its previous cleaning history. This helps monitor cleaning frequency and identify potential issues.

- Cleaning Agent and Solution Details: A clear record of the cleaning agents and their concentrations used during each cleaning is vital. This includes batch numbers and expiration dates.

- Cleaning Results and Observations: After each cleaning, the results are documented. This includes visual assessments, any contamination remaining, and any unusual observations.

- Photographs or Videos: Visual documentation, including before-and-after photos or videos, can be invaluable in demonstrating the effectiveness of the cleaning process and identifying any issues.

- Database System: I often use database systems to keep track of all cleaning records, ensuring easy access and efficient data retrieval.

This meticulous documentation is essential not only for quality control but also for regulatory compliance and troubleshooting potential issues down the line. It’s a critical aspect of establishing best practices in a professional setting.

Q 6. How do you troubleshoot common module cleaning issues?

Troubleshooting module cleaning issues requires systematic investigation. My approach includes:

- Review Cleaning Procedure: Carefully review the documented cleaning procedure to identify any deviations or potential errors. This is the first step, like checking the recipe before troubleshooting a failed dish.

- Analyze Cleaning Results: Examine the cleaning results to identify the nature and extent of any remaining contamination. What went wrong? Was it incomplete removal, residue, or damage?

- Identify Potential Causes: Based on the nature of the issue, identify potential causes, such as using an incorrect cleaning agent, insufficient cleaning time, or inadequate equipment.

- Test Alternative Methods: If the initial cleaning method fails, test alternative techniques or agents, ensuring compatibility with the module material and adhering to safety regulations.

- Re-evaluate Cleaning Parameters: Adjust parameters such as cleaning time, temperature, or concentration of cleaning agents based on experimental findings.

- Consult Relevant Documentation: Refer to the module’s datasheet, the cleaning agent’s SDS, and previous cleaning records for guidance.

For instance, if residue remains after cleaning, I might consider using a more powerful solvent or increasing the cleaning time, but always ensuring that the new method is safe and effective for the module type.

Q 7. Describe your experience with preventive maintenance for modules.

Preventive maintenance is crucial for extending module lifespan and minimizing the need for intensive cleaning. My approach focuses on:

- Regular Inspection: Regular visual inspection of modules for dust, debris, or other contaminants. This is like a yearly car check-up, catching small problems before they become major issues.

- Environmental Control: Controlling the environment in which modules operate by minimizing dust and other airborne contaminants. This includes using appropriate filters and maintaining clean workspaces.

- Protective Enclosures: Using protective enclosures or covers to shield modules from dust and other environmental factors. Similar to using a phone case.

- Scheduled Cleaning: Establishing a schedule for routine cleaning based on the module’s operational environment and the level of contamination expected. This prevents contaminants from building up.

- Handling Procedures: Implementing proper handling procedures to prevent contamination during installation, operation, and maintenance. This involves using appropriate gloves and tools.

My experience shows that consistent preventive maintenance significantly reduces the frequency and intensity of required cleaning, leading to cost savings and prolonged module lifespan.

Q 8. How do you ensure the proper disposal of cleaning waste?

Proper disposal of cleaning waste is paramount for environmental safety and regulatory compliance. It begins with segregation. We separate waste into categories like recyclable materials (e.g., plastic bottles, paper towels), hazardous waste (e.g., certain cleaning solutions), and general waste. Each category is then handled according to its specific requirements. Recyclables go into designated bins, hazardous waste is handled in accordance with local regulations, often requiring specialized containers and disposal firms. General waste is disposed of in standard refuse containers. Documentation is crucial; we maintain detailed records of waste generation, disposal methods, and the companies involved. Think of it like this: proper waste disposal is a multi-step process, similar to a well-organized assembly line, each step ensuring the safety and environmental responsibility of the cleaning process. For example, in one project cleaning server racks, we carefully separated used cleaning wipes from the cleaning solution containers, ensuring the solution was neutralized before discarding to prevent environmental harm.

Q 9. What are the key performance indicators (KPIs) for module cleaning?

Key Performance Indicators (KPIs) for module cleaning are designed to measure efficiency and effectiveness. These include: Cleaning Time: How long it takes to clean a module or a set number of modules. Faster cleaning times indicate efficiency. Defect Rate: The number of modules that fail post-cleaning inspection due to residual contamination or damage. A low defect rate demonstrates quality control. Cost per Module: The total cost of cleaning divided by the number of modules cleaned. This KPI focuses on cost-effectiveness. Employee Safety Incidents: The number of accidents or near misses during cleaning. A low rate highlights a safe working environment. Client Satisfaction: Feedback from clients on the cleanliness and overall quality of the cleaning service. High satisfaction rates are crucial for ongoing business. We use a data-driven approach. For example, by tracking cleaning time over several projects, we identified process bottlenecks and optimized our workflow, leading to a 15% reduction in cleaning time.

Q 10. How do you maintain cleanliness and organization in your workspace?

Maintaining a clean and organized workspace is essential for efficiency and safety. This involves several strategies: 5S Methodology: We implement the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to systematically organize our workspace. Designated Storage: We use labeled containers and shelves for cleaning supplies, tools, and waste. Regular Cleaning: We dedicate time each day to cleaning the workspace, wiping down surfaces, and discarding trash. Visual Management: We use visual aids like color-coded labels and shadow boards to quickly locate tools and materials. Think of it like a well-stocked and organized kitchen – everything has its place, making the cleaning process smoother and more efficient. In a recent project, the organized workspace allowed us to quickly locate a specialized tool needed for a complex module cleaning, saving valuable time and preventing delays.

Q 11. Describe your experience with specialized cleaning tools and equipment.

My experience with specialized cleaning tools and equipment is extensive. I’m proficient in using various types of vacuum cleaners, including HEPA-filtered vacuums for sensitive environments. I’m also skilled in using ultrasonic cleaners for delicate components, and I understand the principles of selecting the right cleaning agents based on material compatibility. I’m familiar with different types of brushes, swabs, and wipers, and I know how to use them effectively to remove various types of contaminants. I’ve worked with specialized tools for cleaning hard-to-reach areas, such as compressed air and flexible cleaning wands. In a recent project involving cleaning intricate microelectronics, the use of a specialized ultrasonic cleaner with precise frequency control was crucial in preventing damage to the modules.

Q 12. How do you manage multiple cleaning tasks simultaneously?

Managing multiple cleaning tasks simultaneously requires effective prioritization and time management. I employ several techniques: Prioritization: I start by identifying the most urgent and critical tasks and tackle those first. Time Blocking: I allocate specific time slots for each task to ensure efficient completion. Delegation: Where possible, I delegate tasks to other team members to optimize workflow. Workflow Optimization: I constantly look for ways to streamline our cleaning processes, such as developing standardized procedures or using more efficient tools. Imagine juggling multiple balls; it’s about keeping them all in the air by focusing on one at a time, while maintaining an awareness of the overall picture. In a large-scale cleaning operation involving several server rooms, we successfully coordinated the activities of multiple teams by implementing a detailed schedule and employing real-time communication.

Q 13. How familiar are you with various module types and their specific cleaning requirements?

I have extensive familiarity with various module types and their specific cleaning requirements. This includes experience with electronic modules, optical modules, mechanical modules, and more. Each module type presents unique challenges requiring specialized knowledge and techniques. For example, electronic modules are highly susceptible to electrostatic discharge (ESD), necessitating the use of ESD-safe tools and procedures. Optical modules are sensitive to scratches and require careful handling and cleaning with specialized materials. Mechanical modules often have intricate designs that require targeted cleaning approaches. My knowledge encompasses understanding the materials used in each module type, potential contaminants, and the appropriate cleaning solutions and methods. For example, I’ve successfully cleaned delicate fiber optic modules, understanding the crucial role of avoiding damage to the delicate optical fibers.

Q 14. Explain your experience working with complex or sensitive modules.

I have significant experience working with complex or sensitive modules requiring meticulous care and specialized cleaning techniques. These might include modules with intricate internal components, those operating under high voltages, or modules with extremely sensitive surfaces. In such scenarios, detailed documentation of the cleaning procedure is essential. Strict adherence to safety protocols is a must. I carefully select cleaning agents and tools based on material compatibility and potential risks. Thorough inspection and testing post-cleaning are always crucial. For instance, in a recent project involving a large, high-value telecommunications module, we carefully developed a custom cleaning procedure, including detailed photographic documentation, to ensure the integrity of the module throughout the process. The successful completion of this project demonstrated our capabilities in handling challenging cleaning scenarios.

Q 15. How do you prioritize tasks during a module cleaning operation?

Prioritizing tasks during module cleaning hinges on a risk-based approach combined with operational urgency. I start by identifying modules with the highest risk of failure or those impacting critical systems. For example, modules responsible for power generation in a solar farm would take precedence over those with a less critical function. Then I consider factors like environmental impact (e.g., modules exposed to harsh weather needing immediate attention) and the scheduled downtime. A simple prioritization matrix can be used, listing modules, their criticality, risk level, and environmental factors. This allows for a clear visual representation to decide the order of cleaning tasks.

- High Priority: Modules with critical functionality, significant risk of failure, or exposed to immediate environmental threats.

- Medium Priority: Modules with moderate risk or those where cleaning can be scheduled around other operational needs.

- Low Priority: Modules with minimal risk and non-critical functionalities.

This systematic approach ensures efficient resource allocation and minimizes downtime.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your problem-solving skills in relation to module cleaning challenges.

My problem-solving approach in module cleaning involves a structured five-step process: Identify, Analyze, Plan, Execute, and Review.

- Identify: Accurately pinpoint the problem. For instance, a low energy output from a module could be due to soiling, shading, or internal defects.

- Analyze: Thoroughly examine the problem’s root cause using tools like infrared cameras, visual inspections, and electrical testing.

- Plan: Develop a solution plan, considering factors like safety, cost, and availability of resources. This might involve specialized cleaning techniques or replacement parts.

- Execute: Implement the solution safely and efficiently. Documentation is key here.

- Review: Evaluate the effectiveness of the implemented solution and document the findings to avoid repeating issues.

For example, I once encountered a situation where multiple modules exhibited unexpectedly high temperatures. By systematically analyzing the problem, we identified a blockage in the ventilation system causing overheating. The solution involved cleaning the ventilation system, which resolved the issue. This systematic approach consistently delivers effective solutions.

Q 17. How do you ensure adherence to safety regulations during module maintenance?

Safety is paramount. My approach to ensuring adherence to safety regulations involves a multi-layered strategy:

- Pre-task safety briefings: Before any cleaning or maintenance task, a comprehensive briefing covers all relevant safety protocols, including the use of PPE (Personal Protective Equipment).

- Lockout/Tagout procedures: Strict adherence to lockout/tagout procedures to prevent accidental energization of modules during maintenance.

- Proper PPE usage: Consistent and correct use of safety equipment, including safety glasses, gloves, and protective clothing, is mandatory.

- Environmental monitoring: Regular monitoring of environmental conditions like temperature and wind speed to ensure safe working conditions.

- Regular training and competency assessments: All team members undergo regular safety training and competency assessments to ensure familiarity with the safety procedures.

We use checklists and documentation at every stage to ensure we are adhering to safety regulations. Deviation from safety procedures is never tolerated.

Q 18. Explain your experience with reporting and documenting maintenance activities.

Reporting and documentation are integral parts of my work. I meticulously record all maintenance activities using a standardized reporting system. This typically involves using digital platforms or paper-based logs that capture the following information:

- Date and time of the activity: Precise timestamps provide an accurate timeline.

- Module identification number: Unique identification of the affected modules.

- Type of maintenance performed: Detailed description of the work done (e.g., cleaning, repair, replacement).

- Materials and equipment used: A list of all tools, chemicals, or components used.

- Observations and findings: Any notable observations or issues encountered during the process. This includes photographs or videos to provide visual evidence.

- Signatures and approvals: Confirmation of the work’s completion and approval by relevant personnel.

This detailed record-keeping enables efficient tracking, analysis, and future planning for preventive maintenance and troubleshooting.

Q 19. How do you adapt your cleaning techniques to different environmental conditions?

Adapting cleaning techniques to different environmental conditions is crucial for effective and safe module cleaning. I adjust my methods based on factors like:

- Temperature: Extreme temperatures can affect the effectiveness of cleaning agents and the integrity of the modules. For example, high temperatures might require using cleaning solutions with lower evaporation rates and reduced contact times.

- Humidity: High humidity can lead to longer drying times and increased risk of water spots. Choosing appropriate cleaning agents and utilizing air-drying techniques become critical.

- Precipitation: Rain or snow can necessitate delaying cleaning operations or using water-repellent coatings to facilitate drying.

- Wind speed: High wind speeds can impede cleaning operations and may require postponement until conditions are favorable.

- Soiling type: Different soiling types (e.g., dust, pollen, bird droppings) may require specialized cleaning agents and methods.

A thorough understanding of the environmental conditions allows for optimizing the cleaning process, resulting in superior results while maintaining safety standards.

Q 20. What are the potential risks associated with improper module cleaning?

Improper module cleaning carries several risks:

- Reduced energy output: Inadequate cleaning can leave soil deposits on the module surface, reducing light absorption and lowering energy generation efficiency. This translates to substantial financial losses.

- Module damage: Using abrasive materials or harsh chemicals can scratch or damage the module’s delicate surface, shortening its lifespan.

- Increased maintenance costs: Repairing or replacing damaged modules due to improper cleaning significantly increases maintenance expenses.

- Safety hazards: Using inappropriate cleaning solutions or equipment can pose safety risks to personnel, potentially leading to injury or accidents.

- Warranty issues: Improper cleaning might void the manufacturer’s warranty, further increasing costs.

Therefore, a well-defined cleaning procedure, the use of approved materials, and proper training of personnel are crucial to mitigate these risks.

Q 21. How do you handle unexpected module damage during cleaning or maintenance?

Handling unexpected module damage during cleaning or maintenance involves a methodical approach. The first step is to immediately halt the cleaning operation to prevent further damage.

- Assess the damage: Carefully examine the extent of the damage, noting the location, type, and severity. Photographs are essential for documentation.

- Report the incident: Immediately report the incident to the relevant personnel, including supervisors and maintenance managers.

- Implement safety precautions: Ensure the safety of personnel involved and secure the damaged module to prevent further harm.

- Investigate the cause: Conduct a thorough investigation to determine the root cause of the damage. This might involve reviewing the cleaning process, equipment used, and environmental conditions.

- Implement corrective actions: Based on the investigation, take corrective actions to prevent similar incidents in the future. This might involve adjustments to the cleaning procedures or equipment upgrades.

- Repair or replace: If possible, repair the module; otherwise, initiate the replacement process according to established procedures.

This systematic approach ensures that the situation is managed effectively, limiting further damage and enabling a swift return to normal operations.

Q 22. Describe your proficiency with relevant software or databases used for maintenance tracking.

My proficiency in maintenance tracking software is extensive. I’m highly experienced with CMMS (Computerized Maintenance Management Systems) like IBM Maximo, SAP PM, and Infor EAM. These systems allow for efficient scheduling of cleaning activities, tracking of consumable supplies, recording of maintenance logs, and generating reports for regulatory compliance. For example, in a previous role, I utilized Maximo to schedule preventative maintenance on our chromatography modules, ensuring timely cleaning and reducing the risk of equipment failure. The system also allowed me to track the effectiveness of different cleaning agents and procedures, which was crucial for optimizing our cleaning protocols. Beyond CMMS, I’m comfortable using databases like SQL Server and MySQL to extract and analyze maintenance data for trend analysis and continuous improvement initiatives.

Q 23. How do you ensure the quality and effectiveness of your module cleaning procedures?

Ensuring quality and effectiveness in module cleaning involves a multi-faceted approach. It starts with meticulously documented Standard Operating Procedures (SOPs) that detail every step, from pre-cleaning checks to final validation. We employ a combination of visual inspection, residue testing (using techniques like swabbing and rinsing), and, where applicable, microbial testing to verify the effectiveness of our cleaning process. For example, in a pharmaceutical setting, we’d use HPLC (High-Performance Liquid Chromatography) to analyze samples for residual drug product. Any deviations from our SOPs are immediately investigated through a root cause analysis, and corrective and preventive actions are implemented to prevent recurrence. Regular training and competency assessments for cleaning personnel ensure everyone understands and adheres to the SOPs. The entire process is meticulously documented and reviewed regularly to ensure ongoing effectiveness.

Q 24. Explain your understanding of the different types of cleaning validation methods.

Cleaning validation methods are crucial for demonstrating that a cleaning process effectively removes residues to acceptable levels. The choice of method depends on the specific module and the nature of the residues. Common methods include:

- Visual Inspection: A simple but essential first step, looking for visible residues.

- Residue Analysis: This involves quantitative testing to measure the amount of residue remaining after cleaning. Techniques include HPLC, GC (Gas Chromatography), UV-Vis Spectroscopy, and swab testing followed by analytical methods.

- Microbiological Testing: Crucial in pharmaceutical and sterile environments, this involves checking for the absence of microorganisms after cleaning.

- Water Rinse Analysis: Analyzing the water rinsate for residues can indicate cleaning efficacy.

We select the most appropriate validation method based on risk assessment and regulatory requirements. For instance, cleaning a reactor used for potent APIs (Active Pharmaceutical Ingredients) would necessitate stringent residue analysis using techniques like HPLC, while cleaning a less critical module might only require visual inspection and rinse analysis.

Q 25. Describe your experience with calibration and maintenance of cleaning equipment.

My experience encompasses the full spectrum of cleaning equipment calibration and maintenance. This includes regular checks of cleaning systems like CIP (Cleaning-in-Place) systems, automated cleaning units and ultrasonic cleaners. We perform routine calibration of instruments like flow meters, pressure gauges, and temperature sensors to ensure accuracy and reliability. Preventative maintenance tasks include checking pump seals, filter replacements, and regular cleaning of the equipment itself to prevent build-up and ensure longevity. Calibration records and maintenance logs are meticulously maintained, and any issues or deviations are promptly addressed to prevent unexpected downtime and maintain compliance with regulatory standards. I once identified a faulty pressure sensor in our CIP system during a routine check which prevented a major production delay.

Q 26. How do you minimize downtime during module cleaning and maintenance?

Minimizing downtime is paramount. We achieve this through several strategies: preventative maintenance schedules, optimized cleaning procedures, rapid response to equipment failures, and cross-training of personnel. Preventative maintenance, scheduled regularly based on equipment usage and manufacturer recommendations, helps identify and address potential issues before they lead to downtime. Streamlined cleaning procedures, optimized for speed without compromising quality, help reduce the time required for each cleaning cycle. Having a readily available team of trained technicians who can respond quickly to equipment malfunctions is also crucial. Cross-training allows for flexible staffing to cover maintenance needs without delays.

Q 27. How do you stay up-to-date with the latest advancements in module cleaning technologies?

Staying current is vital in this rapidly evolving field. I actively participate in industry conferences, workshops, and webinars focusing on advancements in module cleaning and maintenance technologies. I subscribe to relevant journals and publications and am a member of professional organizations like ISPE (International Society for Pharmaceutical Engineering). I also regularly review manufacturers’ literature and updates to keep abreast of new cleaning agents, equipment, and validation techniques. For example, I’ve recently investigated the use of sustainable cleaning agents and automated cleaning technologies to improve efficiency and environmental impact.

Q 28. How do you effectively communicate cleaning and maintenance procedures to others?

Effective communication is essential. I use a combination of methods, tailoring my approach to the audience. For trained personnel, detailed SOPs with diagrams and flowcharts are sufficient. For less technically-inclined personnel, simplified instructions with visual aids are more effective. I frequently conduct training sessions, including hands-on demonstrations, to ensure comprehension. Regular meetings and feedback sessions with the team facilitate clarification and address any uncertainties. Clear and concise reporting of maintenance activities and any deviations, coupled with a readily available communication channel for any questions, keeps everyone informed and engaged.

Key Topics to Learn for Module Cleaning and Maintenance Interview

- Understanding Module Functionality: Thoroughly grasp the purpose and operation of the modules you’ll be maintaining. This includes knowing their inputs, outputs, and potential failure points.

- Cleaning Procedures and Protocols: Familiarize yourself with established cleaning methods, including appropriate cleaning agents, safety precautions, and documentation requirements. Be prepared to discuss different cleaning techniques for various module types.

- Preventive Maintenance Strategies: Understand the importance of preventative maintenance and how it minimizes downtime and extends module lifespan. Be ready to discuss specific tasks involved in preventative maintenance schedules.

- Troubleshooting and Diagnostics: Develop your ability to identify common module malfunctions and troubleshoot effectively. Practice describing your problem-solving approach, including diagnostic steps and solutions.

- Safety Regulations and Compliance: Demonstrate understanding of relevant safety regulations and best practices for handling cleaning agents, equipment, and potentially hazardous materials.

- Documentation and Reporting: Master the proper methods for documenting cleaning and maintenance activities, including detailed logs, reports, and any necessary updates to maintenance schedules.

- Working with Teams and Communication: Showcase your ability to collaborate effectively with colleagues, communicate issues clearly, and follow established procedures within a team environment.

Next Steps

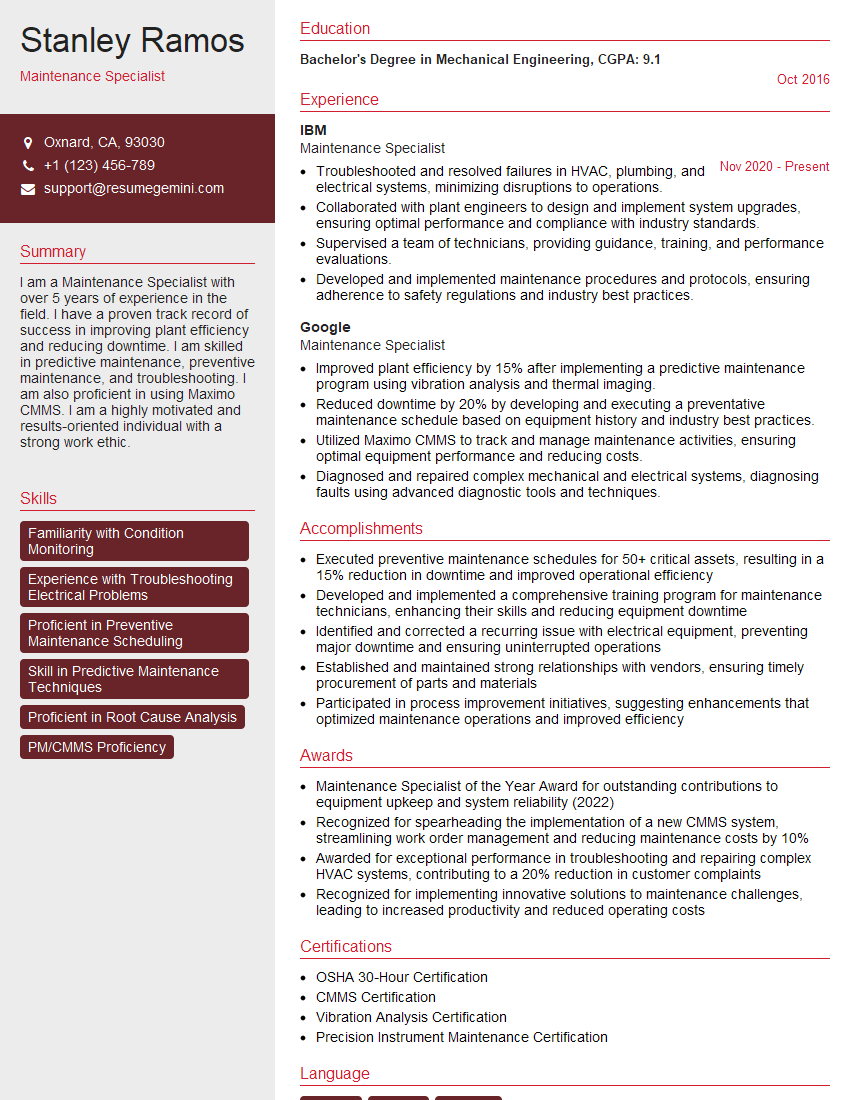

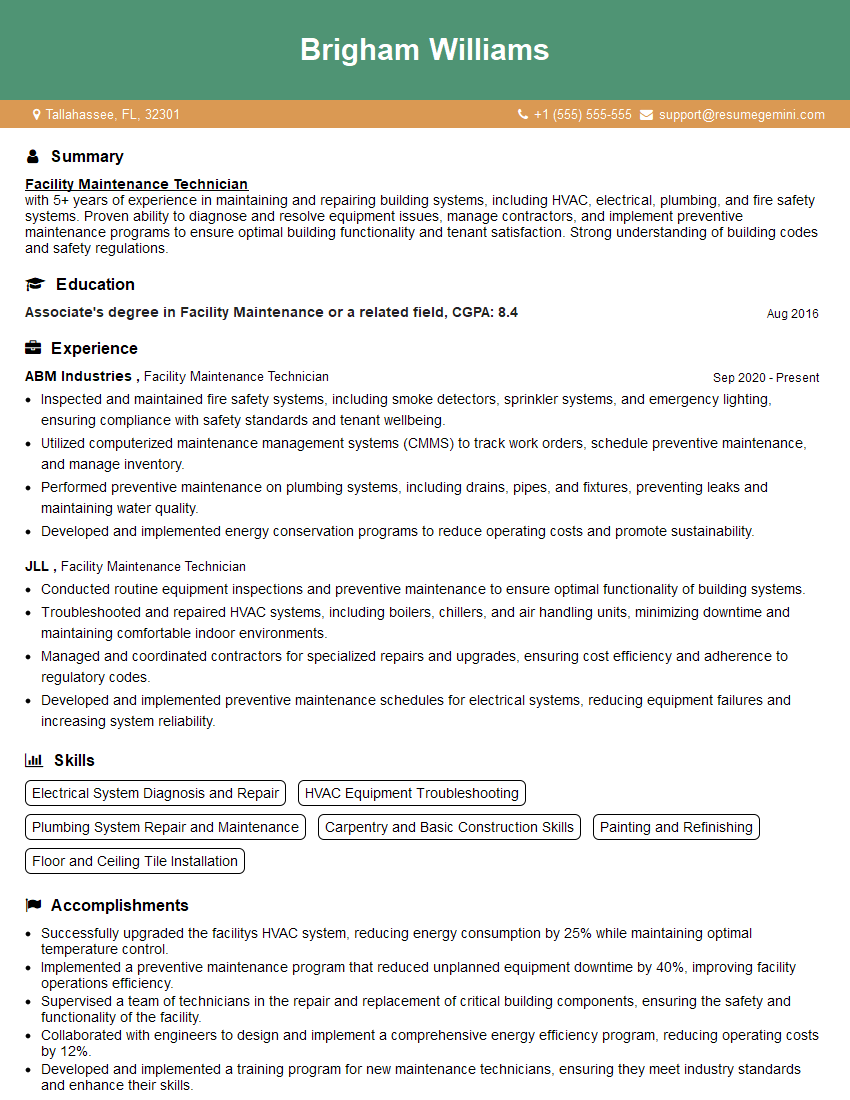

Mastering Module Cleaning and Maintenance is crucial for career advancement in many technical fields. A strong understanding of these concepts directly translates to increased efficiency, reduced downtime, and improved safety. To enhance your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. We provide examples of resumes tailored specifically to Module Cleaning and Maintenance to help you get started. Take the next step towards your dream career – build a standout resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.