The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Monitoring Fruit Ripening interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Monitoring Fruit Ripening Interview

Q 1. Explain the role of ethylene in fruit ripening.

Ethylene is a naturally occurring plant hormone, a gaseous phytohormone, that plays a crucial role in fruit ripening. Think of it as the ‘ripening signal’ sent out by the fruit itself. As fruits mature, they begin producing ethylene, which triggers a cascade of biochemical changes. These changes lead to the characteristic softening, color changes, aroma development, and sugar accumulation associated with ripe fruit.

For example, a single ripe apple placed amongst unripe apples will accelerate the ripening of the others because of the ethylene it releases. This is why it’s recommended to separate unripe from ripe fruits during storage.

The process isn’t simply on/off; the amount of ethylene produced influences the rate and extent of ripening. Higher ethylene concentrations generally lead to faster and more complete ripening, but this can also increase the risk of over-ripening and spoilage.

Q 2. Describe different methods for monitoring fruit ripening.

Monitoring fruit ripening involves a range of techniques, broadly categorized as destructive and non-destructive. Destructive methods require damaging the fruit to obtain samples for analysis (e.g., measuring sugar content or firmness), providing precise data but sacrificing the fruit. Non-destructive methods analyze the fruit without harming it, which is usually preferred in commercial settings.

- Destructive Methods: These include measuring soluble solids content (using a refractometer), assessing firmness (using a penetrometer), and analyzing acidity levels (titration).

- Non-Destructive Methods: These encompass techniques such as colorimetry (measuring color changes), near-infrared spectroscopy (NIR), and imaging systems (analyzing surface texture and color). We also observe external changes like visual appearance, aroma, and feel.

The choice of method depends on factors like the type of fruit, the stage of ripening being monitored, the resources available, and the intended application (e.g., research vs. commercial production).

Q 3. What are the key indicators of fruit ripeness?

Key indicators of fruit ripeness vary depending on the fruit type, but common indicators include:

- Color changes: Green to red for apples, yellowing for bananas, etc.

- Softening: A decrease in firmness, often assessed by touch.

- Aroma development: The release of volatile compounds contributes to the characteristic scent of ripe fruit.

- Sugar accumulation: An increase in soluble solids content, which contributes to sweetness.

- Acidity reduction: A decrease in acidity often accompanies ripening.

For example, a ripe mango will transition from a green or greenish-yellow color to a bright yellow or orange, accompanied by a fragrant aroma and softer texture. These visual and sensory cues indicate that the mango is at its optimal ripeness.

Q 4. How do you assess the quality of ripened fruit?

Assessing the quality of ripened fruit involves a multifaceted approach. It’s not just about ripeness but also involves factors related to its overall condition. We consider:

- Sensory attributes: This includes evaluating color, aroma, taste, and texture. A panel of trained sensory experts can provide objective assessments.

- Physical attributes: We look at size, shape, firmness, and the absence of defects (bruises, blemishes, etc.).

- Chemical composition: This includes measuring sugar content, acidity, and the concentration of volatile compounds.

- Microbiological quality: Assessing the presence of spoilage microorganisms helps determine shelf life and safety.

A high-quality ripe fruit will exhibit desirable sensory attributes, be free from defects, have an optimal chemical composition, and be microbiologically safe. Imagine a perfectly ripe strawberry: vibrant red color, sweet taste, pleasant aroma, firm but not hard texture, and free from any blemishes.

Q 5. What are the challenges in maintaining fruit quality during storage and transportation?

Maintaining fruit quality during storage and transportation poses significant challenges. Key issues include:

- Physiological changes: Ripening continues even after harvest, potentially leading to over-ripening, spoilage, and loss of quality.

- Mechanical damage: Bruises and other physical damage can accelerate deterioration and reduce shelf life.

- Pathogen growth: Microbial contamination can lead to spoilage and safety concerns.

- Temperature fluctuations: Temperature changes during transport can negatively impact fruit quality and increase the risk of chilling injury (damage from low temperatures).

Imagine a shipment of mangoes: temperature fluctuations during transportation can cause chilling injury, and any slight damage incurred during handling can accelerate spoilage.

Q 6. Explain the concept of controlled atmosphere storage (CAS).

Controlled Atmosphere Storage (CAS) is a technique used to extend the shelf life of fruits and vegetables by modifying the gaseous composition within the storage environment. This carefully controlled atmosphere slows down respiration and other metabolic processes that cause ripening and deterioration.

Typically, CAS reduces the oxygen (O2) levels and increases the carbon dioxide (CO2) levels while maintaining appropriate temperature and humidity. The precise composition of the atmosphere varies depending on the type of fruit and the desired storage duration. The lower oxygen level slows down respiration and reduces ethylene production, while the higher CO2 level inhibits enzymatic activity that contributes to deterioration.

For example, apples might be stored in an atmosphere with 1-3% O2 and 1-5% CO2 to significantly extend their shelf life compared to storage in normal air.

Q 7. Describe different non-destructive methods for evaluating fruit ripeness.

Several non-destructive methods exist for evaluating fruit ripeness, offering rapid and efficient assessment without damaging the produce.

- Near-infrared (NIR) spectroscopy: This technique uses light in the near-infrared region to analyze the chemical composition of the fruit, providing information on sugar content, acidity, and other quality parameters. NIR is rapid, accurate, and requires minimal sample preparation.

- Colorimetry: This involves measuring the color of the fruit using a colorimeter or image analysis software. Color changes are often a reliable indicator of ripening stage.

- Acoustic methods: Sound waves are used to assess the firmness and internal structure of the fruit. Changes in acoustic properties can reflect changes in texture and ripeness.

- Imaging techniques: Hyperspectral imaging combines image processing with spectral data to obtain detailed information on fruit quality.

These methods are increasingly used in commercial settings for rapid and objective quality control, enabling efficient sorting and grading of fruit based on ripeness.

Q 8. How do you manage ethylene levels to optimize fruit ripening?

Ethylene is a plant hormone crucial for fruit ripening. Managing its levels is key to optimizing the process. We can either reduce ethylene production to slow ripening or enhance it to accelerate it, depending on our goals.

- Reducing Ethylene: This is often done during storage and transport. Methods include controlled atmosphere storage (CAS), which lowers oxygen and increases carbon dioxide levels, thus inhibiting ethylene production. Another technique involves using ethylene absorption materials like potassium permanganate, which chemically binds to ethylene molecules.

- Enhancing Ethylene: For fruits that ripen slowly post-harvest, we might introduce controlled amounts of ethylene gas to accelerate ripening uniformly. This is often done in commercial settings using specialized chambers or generators.

For example, consider bananas. If you want to slow their ripening, keeping them in a cool, well-ventilated place will reduce ethylene production. Conversely, placing a ripe banana with unripe ones will speed up ripening due to ethylene release from the ripe banana.

Q 9. What are the effects of temperature on fruit ripening?

Temperature plays a pivotal role in fruit ripening. It significantly influences the rate of enzymatic activity responsible for ripening processes. Generally, higher temperatures accelerate ripening, while lower temperatures slow it down.

- High Temperatures: Can lead to rapid ripening, sometimes resulting in undesirable texture and flavor changes. Think of a perfectly ripe mango quickly turning overripe in warm weather.

- Low Temperatures: Slow down ripening, extending shelf life. However, extremely low temperatures can damage fruit cells, causing chilling injury which manifests as discoloration and texture problems.

The optimal temperature range varies greatly depending on the type of fruit. For example, apples generally require cool storage, whereas bananas need warmer conditions to ripen properly.

Q 10. What are the effects of humidity on fruit ripening?

Humidity also impacts fruit ripening, mainly affecting water loss (transpiration) and susceptibility to diseases.

- High Humidity: Can promote fungal growth and decay, leading to spoilage. It also slows down transpiration, potentially affecting the fruit’s texture and flavor development. Think of storing berries – high humidity can encourage mold formation.

- Low Humidity: Can cause excessive water loss through transpiration, leading to shriveling and reduced quality. This is common in fruits stored in dry environments.

Finding the optimal humidity level is crucial. It needs to be balanced to prevent both spoilage and excessive water loss. The ideal range varies greatly based on the fruit type and storage conditions.

Q 11. How do you identify and manage physiological disorders related to fruit ripening?

Physiological disorders related to ripening often manifest as abnormalities in color, texture, or flavor. Early detection is essential for minimizing losses.

- Identifying Disorders: Visual inspection is the first step. We look for signs like uneven ripening, discoloration, blemishes, or unusual textures. Advanced techniques such as near-infrared spectroscopy (NIRS) can help detect internal defects non-destructively.

- Managing Disorders: Strategies depend on the specific disorder. They may include adjusting temperature and humidity controls, implementing proper harvesting techniques to minimize physical damage, and applying post-harvest treatments to inhibit fungal growth.

For example, ‘bitter pit’ in apples is a physiological disorder characterized by small, bitter spots inside the fruit. Proper calcium management during growth and storage can help prevent it.

Q 12. Describe the importance of proper harvesting techniques in fruit quality.

Proper harvesting techniques are paramount in ensuring high-quality fruit. Damage inflicted during harvest can significantly impact shelf life and marketability.

- Minimizing Physical Damage: Using appropriate tools, avoiding excessive force, and careful handling prevent bruising and cuts, which are entry points for pathogens.

- Harvesting at Optimal Maturity: Harvesting at the correct stage of maturity (based on factors like color, firmness, and soluble solids content) ensures optimal flavor, aroma, and texture. Premature harvesting results in poor quality, whereas overripe fruits are highly susceptible to damage and rapid spoilage.

- Rapid Cooling: Immediately after harvesting, rapid cooling slows down metabolic processes, delaying ripening and extending shelf life. This is often done using hydrocooling or forced-air cooling.

Imagine harvesting delicate berries. Gently picking them and using soft containers minimizes damage, thus ensuring their marketability and freshness.

Q 13. Explain your understanding of different fruit ripening stages.

Fruit ripening is a complex process typically divided into several stages. The exact stages and their descriptions vary depending on the type of fruit. However, generally we can identify:

- Stage 1: Immature Stage: The fruit is hard, green (or its characteristic unripe color), and lacks flavor and aroma.

- Stage 2: Pre-climacteric Stage: The fruit begins to soften slightly, and color changes may be noticeable. Ethylene production is relatively low.

- Stage 3: Climacteric Stage: This is characterized by a rapid increase in respiration and ethylene production. The fruit softens significantly, developing its characteristic aroma and flavor. This stage is crucial for many fruits and often determines harvest time.

- Stage 4: Mature Stage (ripe): The fruit is at its peak flavor, aroma, and texture. This stage is short-lived.

- Stage 5: Senescence Stage (overripe): The fruit begins to deteriorate. Texture becomes mushy, and flavor can turn unpleasant. Spoilage becomes likely.

Understanding these stages is critical for determining the optimal harvest time and subsequent handling and storage.

Q 14. How do you interpret data from fruit ripening sensors?

Fruit ripening sensors provide valuable data on various parameters relevant to ripening, such as firmness, color, and volatile organic compound (VOC) levels. Interpreting this data requires understanding the specific sensor and its output.

- Firmness Sensors: Measure the firmness of the fruit, reflecting its maturity. A decrease in firmness typically indicates ripening.

- Color Sensors: Assess the color changes during ripening using parameters like hue, chroma, and brightness. These data help determine ripeness and uniformity.

- VOC Sensors: Detect specific volatile compounds released during ripening, indicating maturity and potential spoilage. Ethylene levels are often a key indicator monitored by these sensors.

The data is typically analyzed using software that converts sensor readings into meaningful indicators of ripeness. This information is crucial for optimizing harvest timing, storage conditions, and ultimately, product quality and shelf life. For instance, if VOC sensors detect elevated levels of specific spoilage compounds, immediate action might be required to prevent wider spoilage.

Q 15. What are the common post-harvest losses associated with fruit?

Post-harvest losses in fruit are significant and encompass a range of factors impacting quality and quantity. These losses can occur from the moment the fruit is harvested until it reaches the consumer. They’re broadly categorized into:

- Physiological losses: These are due to natural processes like respiration, transpiration (water loss), and enzymatic activity, leading to ripening, senescence (aging), and ultimately decay. For example, rapid respiration in mangoes after harvest can cause significant softening and browning before they reach the market.

- Physical losses: These include damage during handling, transportation, and storage. Bruising, cuts, and pressure injuries increase susceptibility to decay. Imagine the impact of improperly stacked crates of strawberries, resulting in significant losses due to crushing.

- Pathological losses: These result from fungal, bacterial, or viral infections. These pathogens can cause rotting, discoloration, and other quality defects, reducing marketability. A common example is the gray mold (Botrytis cinerea) affecting berries during storage.

Minimizing these losses requires careful management throughout the supply chain, from harvesting practices to proper storage and transport conditions.

Career Expert Tips:

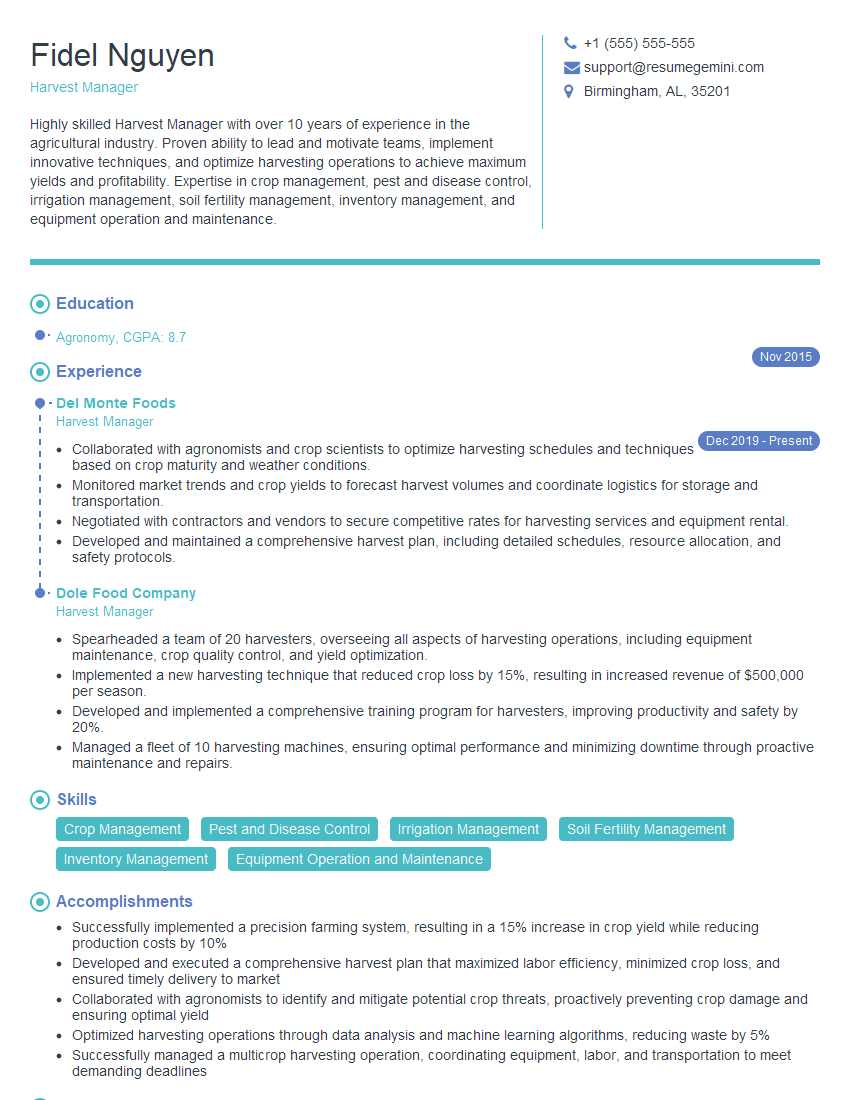

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How can technology improve the monitoring of fruit ripening?

Technology plays a vital role in enhancing fruit ripening monitoring. Precision agriculture techniques and advanced sensors allow for real-time data acquisition and analysis, improving decision-making and reducing losses.

- Non-destructive sensing: Techniques like hyperspectral imaging and near-infrared spectroscopy can assess internal fruit quality parameters (e.g., sugar content, firmness) without damaging the fruit. This allows for precise ripeness assessment at different stages of the supply chain.

- Smart packaging: Packaging incorporating sensors that monitor temperature, humidity, and ethylene levels provides real-time data on the fruit’s environment. This helps in optimizing storage and transport conditions.

- Artificial intelligence (AI) and machine learning (ML): AI algorithms can analyze data from various sensors to predict ripening rates, optimize harvesting time, and detect potential quality issues early on. For example, an AI system could predict the optimal harvest date for a specific orchard based on weather patterns, fruit growth data, and historical records.

- Blockchain technology: This technology enhances traceability, allowing for better monitoring of fruit from farm to consumer. It can track quality parameters and handling practices, improving accountability and reducing the risk of spoilage.

The integration of these technologies allows for more precise and efficient management of fruit ripening, leading to improved quality and reduced waste.

Q 17. What are the benefits of using color charts or spectral analysis in assessing fruit ripeness?

Color charts and spectral analysis are valuable tools for assessing fruit ripeness, offering both objective and subjective measurements.

- Color charts: These provide a visual guide for comparing fruit color to standardized scales. While subjective, they offer a simple and readily accessible method for assessing ripeness. For example, a color chart might categorize tomatoes into green, breaker, turning, pink, and red stages.

- Spectral analysis: Techniques like hyperspectral imaging or near-infrared spectroscopy measure the reflectance or absorbance of light across a wide range of wavelengths. This data can then be used to predict internal fruit quality attributes, such as sugar content, firmness, and acidity, which are strong indicators of ripeness. This method offers a more objective and quantitative assessment than color charts alone.

Combining color charts with spectral analysis provides a comprehensive approach. Color charts offer a quick, preliminary assessment, while spectral analysis provides a more detailed, quantitative analysis for quality control and prediction.

Q 18. How do you handle variations in fruit ripening rates within a batch?

Variations in ripening rates within a batch are common due to factors like fruit size, position on the tree, environmental conditions during growth, and genetic differences. Handling these variations requires a multi-pronged approach:

- Selective harvesting: Harvesting in multiple passes allows for the selection of fruits at optimal ripeness levels. This minimizes losses associated with premature or overripe fruit.

- Modified atmosphere packaging (MAP): MAP uses controlled atmospheres (reduced oxygen, increased carbon dioxide) to slow down respiration rates and extend shelf life. This helps maintain consistency by slowing ripening in the faster-maturing fruits.

- Temperature control: Maintaining appropriate temperatures during storage and transport slows down ripening. However, the optimal temperature depends on the type of fruit.

- Sorting and grading: Sorting fruit by size, color, and other quality parameters helps to group fruits with similar ripening rates. This facilitates more effective management and ensures more uniform ripeness across different batches.

By combining these strategies, we can minimize the impact of variations in ripening rates and improve overall product quality and shelf life.

Q 19. Describe your experience with different fruit ripening models.

My experience encompasses various fruit ripening models, both empirical and mechanistic. Empirical models, often based on statistical relationships between environmental factors and ripening parameters, are valuable for prediction in specific situations. Mechanistic models, on the other hand, are based on the underlying physiological processes of ripening and are more complex but offer a deeper understanding of the phenomenon.

Examples include the modified Gompertz model, widely used to describe the growth and ripening curves of fruits, and models based on respiration rate and ethylene production. The choice of model depends on the specific fruit type, available data, and desired level of detail.

I’ve also worked extensively with models that integrate data from various sensors and incorporate climate data to predict ripening kinetics, leading to improved harvest timing and quality control.

Q 20. Explain your experience with quality control procedures related to fruit ripening.

Quality control procedures for fruit ripening are critical to minimizing post-harvest losses and ensuring consumer satisfaction. My experience includes the implementation and monitoring of several key procedures:

- Pre-harvest assessments: Regularly monitoring fruit development through visual inspections, sampling, and non-destructive testing methods to estimate maturity and predict ripening time.

- Harvesting practices: Employing appropriate harvesting techniques (e.g., hand-picking to reduce damage) and promptly cooling the harvested fruit to slow down respiration and enzymatic activity.

- Post-harvest handling: Implementing rigorous quality control checks during sorting, grading, washing, and packaging to identify and remove damaged or substandard fruits.

- Storage and transportation: Maintaining appropriate temperature, humidity, and atmosphere during storage and transportation to minimize ripening rate and extend shelf life. Regular monitoring of temperature and humidity is key here.

- Sensory evaluation: Employing trained sensory panels to assess the quality attributes (e.g., color, aroma, taste, texture) of the fruit at various stages to ensure consistency.

Data analysis and record-keeping are vital components of effective quality control. This enables identification of trends, optimization of processes, and continuous improvement.

Q 21. How do you ensure consistency in fruit ripeness throughout the supply chain?

Ensuring consistency in fruit ripeness throughout the supply chain demands a holistic approach encompassing all stages, from farm to table. Key strategies include:

- Standardized protocols: Implementing standardized protocols for harvesting, handling, storage, and transportation across the supply chain. This ensures uniformity in practices and minimizes variations.

- Traceability systems: Implementing robust traceability systems (e.g., blockchain) that track fruit movement and quality parameters. This allows for rapid identification and isolation of issues that compromise quality.

- Collaboration and communication: Fostering strong collaboration and communication between all stakeholders (farmers, packers, transporters, retailers) to ensure everyone understands and adheres to quality standards. Regular meetings and information sharing are crucial for success.

- Technology integration: Leveraging technologies like sensors, data analytics, and predictive modeling to monitor fruit condition and predict quality changes during the supply chain. This allows for proactive intervention and adjustment of conditions as necessary.

- Continuous improvement: Regularly reviewing and improving processes based on data analysis and feedback from stakeholders. Regular audits and assessments are critical for maintaining quality standards.

A consistent focus on quality control at every stage of the supply chain is paramount for achieving consistent ripeness and minimizing losses.

Q 22. Describe your experience with different fruit varieties and their specific ripening characteristics.

My experience spans a wide range of fruit varieties, each with unique ripening characteristics. For example, climacteric fruits like bananas and apples continue to ripen after harvest, exhibiting a significant rise in respiration and ethylene production. This contrasts sharply with non-climacteric fruits such as strawberries and blueberries, which ripen primarily on the plant and show little further change after harvest. I’ve worked extensively with stone fruits (peaches, plums), berries (strawberries, raspberries, blueberries), pome fruits (apples, pears), and tropical fruits (mangoes, pineapples), understanding their specific needs for optimal ripening, including temperature, humidity, and ethylene control. For instance, maintaining a slightly higher humidity for berries helps prevent shriveling, while carefully managing ethylene levels in a storage facility for climacteric fruits is crucial to avoid over-ripening and spoilage.

- Apples: Require controlled atmosphere storage to slow down ripening and extend shelf life.

- Bananas: Ripen best at room temperature with exposure to ethylene.

- Strawberries: Highly perishable and need rapid cooling after harvest to maintain quality.

Understanding these nuances allows me to tailor ripening protocols to individual fruit types, ensuring optimal quality and minimizing losses.

Q 23. How do you handle unexpected problems during the fruit ripening process?

Unexpected problems during fruit ripening are inevitable. My approach involves a systematic troubleshooting process. First, I identify the problem – is it physiological (e.g., uneven ripening), pathological (e.g., fungal infection), or related to storage conditions (e.g., temperature fluctuations)? I then gather data: temperature and humidity readings, ethylene levels, visual inspections for disease, and analyze the fruit’s physical characteristics. For instance, if I observe rapid browning in apples, I might suspect a problem with oxygen levels or a fungal infection. Based on this analysis, I implement corrective actions. This might involve adjusting temperature and humidity settings, applying appropriate fungicides, or using ethylene absorbents. Finally, I document the problem, the corrective actions taken, and the results to improve future practices. For instance, if a batch of mangoes showed high spoilage due to uneven ripening, I’d adjust the pre-cooling and storage parameters in subsequent batches.

Q 24. What are the most important factors to consider when designing a fruit storage facility?

Designing an effective fruit storage facility requires careful consideration of several factors. Temperature and humidity control are paramount, as they directly influence the rate of respiration and ripening. The facility must maintain consistent, optimal conditions for the specific fruit being stored. Proper ventilation is essential to prevent the build-up of ethylene and other volatile compounds. Sanitation is crucial to minimize microbial growth and prevent spoilage. The design should also consider factors like accessibility for loading and unloading, efficient layout for handling and sorting, and appropriate infrastructure for monitoring and control. For example, a facility storing apples might use controlled atmosphere storage, whereas a berry storage facility might prioritize rapid cooling and high humidity. Regular maintenance and calibration of equipment is vital for ensuring optimal performance and consistency.

Q 25. Describe your understanding of the different types of packaging materials and their effect on fruit ripening.

Packaging materials significantly impact fruit ripening by affecting gas exchange, moisture loss, and physical protection. Permeable materials such as paper or netting allow for gas exchange, which can be beneficial for climacteric fruits that require some ethylene build-up for ripening, but can accelerate spoilage if not managed correctly. Impermeable materials like plastic films reduce gas exchange and moisture loss, extending shelf life but potentially hindering ripening in climacteric fruits. Modified atmosphere packaging (MAP) uses films with controlled permeability to create an optimal atmosphere for specific fruits. For example, MAP can extend the shelf life of berries by controlling oxygen and carbon dioxide levels. Sustainable packaging materials are increasingly important, balancing environmental concerns with preservation of fruit quality. The choice of packaging must be tailored to the specific fruit type, its intended shelf life, and environmental considerations.

Q 26. How do you maintain accurate records and documentation related to fruit ripening?

Maintaining accurate records is crucial for traceability, quality control, and regulatory compliance. I utilize a combination of electronic and physical records. Electronic databases track parameters like temperature, humidity, ethylene levels, and treatment applications. This data is linked to batch numbers and harvest dates for traceability. Physical records include inspection reports, quality assessments, and treatment logs. This dual approach allows for real-time monitoring and historical analysis. Data integrity is ensured through regular backups, quality checks, and standard operating procedures. For instance, a temperature logger continuously records readings and produces a printable report, whilst a digital database houses the results, alongside relevant comments from inspectors. This combined system provides complete documentation of the ripening process.

Q 27. Describe your experience with data analysis and interpretation related to fruit ripening data.

My data analysis skills involve using statistical software to analyze large datasets of ripening parameters and quality assessments. I can identify trends and correlations that reveal the impact of various factors on fruit quality. For example, by analyzing temperature and humidity data alongside spoilage rates, I can optimize storage conditions. Regression analysis can help predict optimal harvest times and storage durations. I also use visual tools such as graphs and charts to communicate complex findings to stakeholders. This data-driven approach enables evidence-based decision-making, leading to improved efficiency and reduced losses. For example, I may use statistical process control charts to monitor ripening uniformity in a large batch of produce and identify early signs of deviation from the ideal process.

Q 28. Explain your understanding of food safety regulations related to fruit handling and storage.

I am thoroughly familiar with food safety regulations related to fruit handling and storage, including those set by bodies like the FDA and USDA. These regulations cover aspects such as Good Agricultural Practices (GAPs), Good Handling Practices (GHPs), and Hazard Analysis and Critical Control Points (HACCP) principles. GAPs address issues related to safe agricultural practices, while GHPs focus on safe handling during post-harvest operations. HACCP provides a systematic approach to identifying and controlling potential hazards that could compromise food safety. Compliance involves meticulous record-keeping, regular inspections, and adherence to sanitation protocols. Understanding and implementing these regulations ensures that the fruit is handled and stored safely, minimizing risks of contamination and spoilage, and protecting consumers.

Key Topics to Learn for Monitoring Fruit Ripening Interview

- Physiological Changes During Ripening: Understand the biochemical processes involved in fruit ripening, including respiration rate, ethylene production, and changes in texture and color. Explore the differences across various fruit types.

- Non-Destructive Measurement Techniques: Become familiar with technologies used to monitor fruit ripening without damaging the fruit, such as near-infrared spectroscopy (NIRS), hyperspectral imaging, and acoustic methods. Practice explaining their principles and applications.

- Data Analysis and Interpretation: Develop your skills in analyzing data collected from ripening monitoring systems. Learn to identify trends, predict ripening stages, and make informed decisions based on data insights. This includes understanding statistical methods relevant to the field.

- Quality Control and Assurance: Discuss the importance of monitoring fruit ripening in ensuring consistent quality and minimizing post-harvest losses. Explain how your knowledge can contribute to optimizing storage and transport conditions.

- Impact of Environmental Factors: Understand how temperature, humidity, and light affect the ripening process. Be prepared to discuss strategies for controlling these factors to optimize fruit quality and shelf life.

- Post-Harvest Handling and Storage: Demonstrate your knowledge of appropriate handling and storage techniques for different types of fruit, based on their specific ripening characteristics and requirements.

- Problem-Solving and Troubleshooting: Be ready to discuss scenarios involving unexpected ripening patterns or quality issues. Practice explaining how you would approach diagnosing the problem and implementing corrective actions.

Next Steps

Mastering the art of monitoring fruit ripening opens doors to exciting career opportunities in the agricultural technology and food processing sectors. It demonstrates a valuable skillset in quality control, data analysis, and technological application. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application gets noticed. Examples of resumes tailored to Monitoring Fruit Ripening are available within ResumeGemini to guide your creation process. Take the next step towards your dream career – build a resume that showcases your expertise!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.