The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Mooring and Anchoring Techniques interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Mooring and Anchoring Techniques Interview

Q 1. Explain the different types of anchors and their suitability for various seabed conditions.

Anchors are classified based on their design and how they dig into the seabed. The choice of anchor depends heavily on the seabed composition – mud, sand, rock, or a combination – and the environmental conditions like currents and weather.

- Fluke Anchors (e.g., Danforth, Bruce): These anchors have two or more flukes that dig into the seabed. Danforths are excellent in mud and sand, while Bruce anchors perform well in various conditions, including rocky bottoms. Think of them as digging claws.

- Plow Anchors (e.g., CQR, Manson Supreme): These have a plow-like shape that bites into the seabed. They’re particularly effective in sand, clay, and mixed bottoms. They’re known for their holding power and ability to resettle if disturbed.

- Mushroom Anchors: These anchors are designed for softer substrates like mud and sand. Their large surface area provides good holding power in these conditions, but they are less effective in harder grounds.

- Grappling Anchors: These anchors feature multiple points or hooks designed to grab onto rocks or other irregular surfaces. They are best suited for rocky or coral-covered seabeds but offer poor holding power in softer substrates. Think of them as hooks grabbing onto anything.

- Delta Anchors: Often found in applications where ease of deployment is crucial, these provide decent holding in many seabed types.

For instance, a boat frequently anchoring in a muddy estuary might use a Danforth anchor, whereas a vessel operating near rocky shorelines might opt for a grappling or a Bruce anchor. The selection process always considers the prevailing seabed conditions and the vessel’s weight and size.

Q 2. Describe the process of calculating the required scope of chain for a given anchoring situation.

The scope of chain refers to the ratio of chain length to the depth of water. It’s crucial for maintaining adequate holding power and absorbing shock loads. The calculation isn’t a simple formula but rather a judgment call based on several factors:

- Water Depth: The fundamental factor influencing the necessary chain length.

- Seabed Conditions: A soft seabed requires a longer scope than a firm one. A longer scope provides additional bite for the anchor.

- Environmental Conditions: High winds, strong currents, and rough seas demand a larger scope to counteract the forces acting on the vessel.

- Vessel Size and Weight: Heavier vessels naturally need more scope to maintain stability.

- Type of Anchor: Some anchors need longer scopes than others to function optimally.

While there’s no universally accepted formula, a common guideline is to use a minimum scope of 5:1 to 7:1 (five to seven times the water depth in chain length). However, this is a starting point. In rough conditions, or on a less-than-ideal bottom, I would readily increase the scope to 10:1. For example, if the water depth is 10 meters, a scope of 5:1 would necessitate 50 meters of chain. For a safer margin, increasing this to 70 meters is not an unreasonable option in many scenarios.

Q 3. What are the safety precautions to be taken during anchoring and mooring operations?

Anchoring and mooring are inherently risky operations. Safety should be the paramount concern. Key precautions include:

- Thorough Planning: Chart the area carefully; identify potential hazards such as rocks, wrecks, and shallow areas. Weather forecasts are essential.

- Proper Equipment: Ensure all equipment, including anchors, chains, ropes, and winches, is in excellent working condition and appropriately sized for the vessel and conditions.

- Communication: Maintain clear communication with other vessels in the vicinity. Radio communication is critical in crowded anchorages.

- Personnel Safety: Wear appropriate personal protective equipment (PPE) such as life jackets and gloves. Never work alone; at least two individuals are advisable for more significant mooring operations.

- Emergency Procedures: Establish clear emergency procedures, including procedures for dragging anchors or equipment failure. Always have a backup anchoring plan.

- Regular Checks: Regularly check the anchor’s position and the chain’s tension. Listen for changes in sound (clattering, dragging).

- Environmental Awareness: Avoid anchoring on sensitive marine environments like seagrass beds or coral reefs.

A story from my own experience highlights the importance of pre-planning: once, a colleague almost lost his boat because he underestimated the strength of an unexpected squall. Adequate planning, a larger chain scope, and appropriate communication could have easily mitigated the risk.

Q 4. How do you determine the holding power of an anchor?

Determining an anchor’s holding power involves a combination of theoretical calculations and practical testing. Theoretical calculations utilize design parameters and empirical formulas to estimate holding power, but these estimates must be verified using practical methods. The most common method is a pull test, using a dynamometer (a force measuring device) to measure the force required to break the anchor’s hold. However, these tests are typically costly and impractical for most boat owners.

Manufacturers often provide holding power ratings in their documentation. These ratings are based on tests conducted under controlled conditions in various seabed types. It is important to understand that these ratings are often idealized, and actual holding power can vary based on environmental conditions, seabed composition, and anchor set quality.

Ultimately, understanding the interplay between anchor design, seabed conditions, and environmental forces is paramount for choosing an anchor that will hold safely in the intended waters. An experienced mariner or marine surveyor can assist in selecting the appropriate anchor and determining its effectiveness in a particular location.

Q 5. Explain the different types of mooring lines and their applications.

Mooring lines are essential for securing a vessel in a specific location. Various types exist, each suited to a particular application:

- Nylon: A popular choice due to its elasticity, absorbing shock loads. However, it stretches under load, requiring longer lengths to compensate.

- Polyester: Stronger and less elastic than nylon, providing better holding power with less stretch. Good for applications needing less give and increased strength.

- Polypropylene: Floats, useful for fenders or surface buoys. Less durable and has lower breaking strength than nylon or polyester.

- Dyneema/Spectra: High-strength, low-stretch fibers, ideal for critical mooring applications where minimal stretch is needed. They are often quite expensive.

The choice of mooring line material depends on several factors including the required strength, the desired elasticity, the environmental conditions, and the budget. For instance, a racing yacht would likely use high-strength, low-stretch lines for optimal control, whereas a recreational boat might utilize more economical nylon lines.

Q 6. Describe the procedure for setting up a three-point mooring system.

A three-point mooring system offers greater stability than a single anchor. It involves three mooring lines attached to different points on the vessel and secured to three distinct points on the seabed or to shore-based structures. The process involves:

- Site Selection: Carefully select three suitable mooring points on the seabed that form a triangle around the intended position of the vessel. The seabed should provide good holding power for each mooring.

- Mooring Line Deployment: Deploy three mooring lines of appropriate length and strength to each of the chosen points. Consider using appropriate anchors at the mooring locations, depending on the seabed type.

- Vessel Positioning: Maneuver the vessel into the center of the triangle formed by the three mooring lines. Make sure to maintain adequate distance to ensure appropriate tension on all mooring lines.

- Line Adjustment: Adjust the length of each mooring line to achieve the desired tension. The lines should be taut but not overly so; this can cause damage or undue stress on the vessel or the mooring points.

- Securing Lines: Secure the lines to the appropriate cleat or point on the vessel, ensuring they are properly fastened and protected from chafing.

Properly configured, a three-point mooring system significantly enhances the vessel’s stability, reducing the risk of swinging or dragging. It’s particularly useful in areas with strong currents or prevailing winds.

Q 7. How do you handle a dragging anchor?

A dragging anchor is a serious situation requiring immediate action. The response depends on the circumstances:

- Assess the Situation: Determine the severity of the drag. Is the boat drifting slowly, or rapidly? What is the wind and current conditions? Are there any hazards nearby?

- Increase Scope: If the drag is slight, try increasing the chain scope to give the anchor more bite in the seabed.

- Engine Assistance: Use the vessel’s engines to steer against the drag, counteracting the wind and current’s influence. Try to reposition the boat into the wind or current, increasing the angle of pull on the anchor.

- Heave In Chain: Attempt to heave in some chain to take up slack and potentially reset the anchor in a better position.

- Deploy Second Anchor: If the anchor continues to drag, deploy a second anchor at an appropriate angle from the first one to create a greater holding force. This can create a temporary ‘two-point’ mooring until the situation is resolved.

- Seek Assistance: If the situation remains critical despite all efforts, notify the Coast Guard or other marine authorities for assistance. This is particularly important in hazardous conditions or during nighttime hours.

Remember, prevention is always better than cure. Proper planning and attention to detail during anchoring operations are crucial to avoiding the need for a dragging-anchor emergency procedure.

Q 8. What are the factors to consider when selecting a mooring location?

Selecting a mooring location is crucial for safety and operational efficiency. It’s like choosing the perfect spot to anchor your tent – you need stability and protection from the elements. Several factors must be considered:

- Water Depth and Bottom Conditions: Sufficient depth is essential to prevent grounding. The seabed should be firm and free of obstructions (rocks, wrecks, etc.) to ensure secure anchoring. Imagine trying to anchor in quicksand – not a good idea!

- Environmental Conditions: Predominant wind, currents, and wave patterns significantly impact mooring forces. A sheltered location reduces stress on the mooring system. Think about a storm – you want your mooring to be able to withstand it.

- Proximity to Hazards: Maintain safe distances from shipping lanes, navigation markers, and other potential hazards. This ensures both the safety of your vessel and other users of the waterway.

- Accessibility: Consider the ease of deploying and retrieving mooring equipment. A location that’s difficult to access can create unnecessary challenges during operations.

- Legal and Regulatory Requirements: Adhere to all applicable regulations regarding mooring locations within specific areas. This might involve permits or designated mooring zones.

For example, a large vessel in a busy port will need a mooring location with ample space, strong seabed conditions, and proximity to support services. In contrast, a smaller recreational boat might find a sheltered bay with suitable depth sufficient.

Q 9. Explain the concept of dynamic positioning and its role in mooring.

Dynamic positioning (DP) is a computer-controlled system that uses thrusters to maintain a vessel’s position and heading without the need for anchors or moorings. Think of it as a sophisticated, automated GPS for ships. It’s particularly useful in challenging environments where traditional mooring is difficult or impractical.

In mooring, DP complements or replaces traditional systems. It can be used:

- During mooring operations: DP assists in precise maneuvering into a mooring position, reducing the risk of collision and improving efficiency.

- In areas with unsuitable seabed conditions: DP allows vessels to maintain position in areas where anchoring is impossible due to soft seabed, extreme water depth, or the presence of obstructions.

- For temporary station-keeping: DP enables vessels to remain stationary for prolonged periods, such as during offshore operations, without relying on anchors or moorings.

The system uses GPS, sensors, and a sophisticated control system to calculate necessary thrust adjustments. It continuously monitors the vessel’s position and heading and corrects any deviations in real-time. This is essential in dynamic environments with strong currents and winds where a traditional mooring system might struggle.

Q 10. Describe the different types of mooring buoys and their uses.

Mooring buoys come in various types, each designed for specific applications:

- Danforth Buoy: A common type featuring a mushroom-shaped float, it’s suitable for lighter vessels and sheltered areas.

- Mushroom Buoy: A larger, more stable buoy offering excellent holding power, commonly used for larger vessels.

- Boat Buoy: Specifically designed for securing boats, these often have rings or lines for attachment.

- T-Buoy: A robust buoy that is ideal for extreme conditions; it provides good resistance to high currents and waves.

- Swinging Buoy: Allows the vessel to swing freely around the buoy, commonly used in areas with significant currents.

The selection of a mooring buoy depends on factors such as vessel size, water depth, environmental conditions, and the required level of holding power. A small sailing boat might use a simple Danforth buoy, while a large tanker would require a much more robust system like a multiple-buoy arrangement.

Q 11. How do you inspect mooring lines for wear and tear?

Regular inspection of mooring lines is critical to preventing failures. Think of it as a regular car checkup – you wouldn’t drive without one! Inspections should involve:

- Visual Examination: Check for cuts, abrasions, chafing, fraying, and any signs of weakening. Pay close attention to areas where the line is subjected to high stress, such as near shackles and cleats.

- Feel Test: Carefully feel the line for any unusual stiffness, softness, or swelling. This can indicate internal damage or degradation.

- Load Test (if applicable): For high-strength lines, load testing can be performed to determine the remaining strength. This should be carried out by a qualified professional.

- Documentation: Maintain a detailed log of inspection findings, including dates, observations, and any corrective actions taken.

For example, you might find a small chafe mark on a mooring line. While seemingly minor, this could develop into a larger problem if left unattended. Prompt repair or replacement is key to safety.

Q 12. What are the common causes of mooring line failure?

Mooring line failures can have devastating consequences. Common causes include:

- Excessive Load: Unexpectedly high forces from storms or strong currents can exceed the line’s breaking strength. Think of a rope trying to hold a much heavier weight than its designed capacity.

- Abrasion and Chafing: Continuous rubbing against hard surfaces can weaken the line over time. This often occurs near sharp objects or when the line is poorly routed.

- UV Degradation: Prolonged exposure to sunlight degrades the line’s material strength, making it brittle and prone to failure. Similar to how prolonged sun exposure can fade and damage a shirt.

- Improper Handling and Storage: Improper coiling, kinking, or damage during handling can create weak points in the line.

- Manufacturing Defects: Occasionally, defects in the manufacturing process can result in a weaker line than specified.

Addressing these potential failure points through regular inspection and maintenance is crucial to ensure the continued safety and reliability of mooring systems.

Q 13. Explain the importance of proper communication during mooring operations.

Clear and effective communication is paramount during mooring operations. It’s like a well-orchestrated dance – everyone needs to know their steps and work together. Miscommunication can lead to accidents and delays. Key aspects include:

- Pre-Mooring Briefing: A thorough briefing outlining the plan, roles and responsibilities, and potential hazards.

- Use of Standardized Terminology: Employ clear, concise language to avoid confusion. Ensure everyone understands the commands and signals used.

- Visual Signals: Hand signals and lighting should be used in conjunction with verbal communication, especially in noisy environments.

- Communication Channels: Utilize appropriate communication channels (radio, hand signals) depending on the situation. Multiple channels can provide redundancy.

- Post-Mooring Debrief: A post-operation debrief to review the process, identify areas for improvement, and address any issues encountered.

For instance, if a line is about to go under tension, clear communication is needed to ensure everyone moves clear of the line and the winch operator is ready to take the load.

Q 14. How do you handle an emergency situation during mooring operations?

Handling emergency situations during mooring requires quick thinking and decisive action. A well-defined emergency response plan is crucial. It should include:

- Assessment of the Situation: Identify the nature of the emergency (e.g., line failure, vessel dragging, collision).

- Initiate Emergency Procedures: Implement the pre-established emergency response plan, including communication protocols and safety measures.

- Secure the Vessel: Take immediate action to secure the vessel and prevent further damage or injury.

- Alert Relevant Authorities: Notify relevant authorities (coast guard, port authorities) as appropriate.

- Damage Control: Assess the damage and initiate repair or replacement of equipment.

- Post-Incident Investigation: Conduct a thorough investigation to identify the cause of the emergency and implement corrective actions to prevent recurrence.

For example, if a mooring line snaps during a storm, the immediate priority is to secure the vessel using the remaining lines and deploy emergency anchors. Simultaneously, alerting the relevant authorities is vital to receive assistance.

Q 15. Describe the process of securing a vessel alongside a quay.

Securing a vessel alongside a quay involves a coordinated effort to safely and efficiently berth the vessel. It’s a delicate dance between vessel control, line handling, and communication. The process typically starts with a pre-berthing plan, considering factors like wind, current, tide, and the vessel’s maneuverability.

- Approach: The vessel approaches the quay at a slow, controlled speed, typically with the assistance of tugboats if required. The captain maintains a constant assessment of the situation.

- Line Handling: As the vessel nears the quay, mooring lines (typically ropes or wire) are passed ashore to the dockworkers. This involves skilled teamwork, ensuring lines are handled properly to prevent damage. Heavier lines are typically used at the bow and stern, providing the main holding power, while lighter lines, called breast lines, control the vessel’s side-to-side movement.

- Fendering: Fenders (large, rubber or other material bumpers) are placed strategically to protect the hull from damage during contact with the quay. Their placement is crucial to minimizing impact forces.

- Securing: Once lines are ashore, they’re secured to bollards (fixed posts) or cleats on the quay. The lines are progressively tightened to hold the vessel securely, ensuring even pressure distribution. The lines are often worked to take up slack as the tide changes or conditions shift.

- Final Check: After all lines are secured, a final check is performed to verify proper tension, fender positioning, and overall security of the vessel. The vessel’s location and stability are constantly monitored.

Imagine it like carefully parking a large car next to a wall – you need to approach slowly, use your brakes (mooring lines) and bumpers (fenders) to prevent damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the use of fenders in mooring operations.

Fenders are essential safety equipment in mooring operations; they act as shock absorbers, preventing damage to both the vessel and the quay or another vessel during contact. They’re strategically placed between the vessel and the structure, distributing the impact force over a larger area and minimizing stress on the hull. Different types of fenders exist, each suited for particular applications. For example, cylindrical fenders are common for general-purpose use, while more specialized fenders are designed for high-impact situations or to protect specific hull sections. The size and material of the fender are critical, dependent on the size and type of the vessel and the expected impact forces. Incorrect fender selection can cause damage or inadequate protection. During docking, the right placement and number of fenders are crucial to distribute the pressure effectively and ensure a safe berthing.

Think of fenders as giant cushions: they absorb the energy from the impact, thus protecting both the boat and its surroundings. Without them, even minor contact can cause costly damage.

Q 17. What are the environmental considerations related to anchoring and mooring?

Environmental considerations in anchoring and mooring are paramount to minimize any negative impact on the marine ecosystem. These considerations include:

- Seabed Protection: Anchors and mooring systems can cause damage to sensitive seabed habitats such as coral reefs and seagrass beds. Choosing suitable anchor types and mooring systems, conducting proper environmental impact assessments, and selecting locations that minimize damage are vital.

- Water Quality: Certain mooring systems or anchor materials may leach pollutants into the water. Selecting environmentally friendly materials and minimizing the use of chemicals or coatings are important.

- Noise Pollution: Anchoring and mooring operations can create underwater noise that disrupts marine life, especially sensitive species like whales and dolphins. Implementing noise reduction techniques and selecting quieter procedures can help mitigate this impact.

- Visual Impact: Moorings and anchors can be unsightly, affecting the aesthetic value of coastal areas. Careful planning and placement can lessen this impact. The use of subsurface moorings can minimize visibility.

Responsible anchoring and mooring practices are crucial for preserving the health and integrity of our oceans and maintaining a sustainable marine environment. Environmental regulations and best practices should always be followed.

Q 18. How do you calculate the tension in a mooring line?

Calculating the tension in a mooring line is crucial for ensuring vessel safety and mooring system integrity. The exact calculation depends on various factors and can be complex, often requiring specialized software or engineering analysis. However, a simplified approach involves considering the following:

- Vessel characteristics: Size, weight, and shape of the vessel influence the forces acting on the mooring lines.

- Environmental conditions: Wind speed and direction, current strength and direction, and wave height significantly impact line tension.

- Mooring configuration: The arrangement of mooring lines and their angles affect the tension distribution.

- Line properties: Material, diameter, and length of the mooring lines influence their strength and elasticity.

Often, a static analysis is initially performed, assuming equilibrium. However, dynamic analysis, considering factors like wave action, is necessary for a more accurate assessment. In reality, sophisticated software and engineering expertise are often employed for precise calculations, particularly for large vessels or challenging environments. Simplified formulas can be used for quick estimations in certain scenarios, but careful consideration must always be made regarding factors that might affect those estimates.

Q 19. Explain the role of a mooring winch in mooring operations.

A mooring winch is a powered drum used to control the tension and payout of mooring lines. It’s a vital component in mooring operations, providing the mechanical advantage needed for handling heavy lines and managing tension effectively. The winch allows for safe and controlled deployment, retrieval, and adjustment of mooring lines. Key functions of a mooring winch include:

- Line control: Precise control over line tension, allowing for careful adjustment and maintaining optimal tension levels.

- Heaving in and veering out: The winch allows the controlled retrieval (heaving in) and payout (veering out) of lines, critical during docking, undocking, and adjusting the vessel’s position.

- Tension maintenance: The winch aids in maintaining consistent tension on the lines, counteracting changes in environmental conditions.

- Safety: The controlled operation of the winch reduces the risk of manual handling injuries and improves overall safety during mooring operations.

Without a mooring winch, managing heavy lines manually would be dangerous, inefficient, and impractical, especially for larger vessels.

Q 20. Describe the different types of mooring knots and their applications.

Various mooring knots are used in different applications depending on their specific properties, such as strength, ease of tying, and the ability to hold under load. Some common mooring knots include:

- Bowline: Forms a strong, closed loop that won’t slip, excellent for mooring lines that need to be secured to a cleat or bollard.

- Clove Hitch: A quick and easy knot, commonly used as a temporary attachment or as a base for other knots. It is often used to secure lines to a bitt or ring.

- Figure Eight: Used to create a secure loop in a line and secure a running end to the standing part, commonly used in securing lines to a ring or hook.

- Cleat Hitch: Used specifically for securing a line to a cleat, offering a secure and easily adjustable fastening. This knot is widely used in docking maneuvers.

- Rolling Hitch: A useful knot for attaching a line to another rope or to a post, allowing easy adjustment. It provides excellent holding power.

The choice of knot depends on the specific situation and requires knowledge of knot strengths and limitations. Incorrect knot selection can result in failure and unsafe conditions. Training and experience are essential for selecting and tying appropriate knots.

Q 21. How do you respond to a sudden change in wind or current during mooring?

Responding to sudden changes in wind or current during mooring requires quick thinking and decisive action. The priority is to prevent the vessel from breaking free from its moorings or colliding with other vessels or structures. Actions to take include:

- Assess the Situation: Quickly determine the magnitude and direction of the wind or current change and its impact on the vessel’s position.

- Adjust Mooring Lines: Heave in or veer out mooring lines as needed to compensate for the change. This might involve using the mooring winches to adjust tension.

- Use Fenders: If necessary, reposition fenders to protect the hull against impact.

- Communicate: Maintain clear communication with the dock crew, tugboats (if present), and other vessels in the vicinity.

- Prepare for Additional Assistance: If the situation worsens, request additional assistance from tugboats or other support vessels.

- Monitor Continuously: Continuously monitor the vessel’s position, line tensions, and environmental conditions.

Think of it as a sailing boat caught in a squall: rapid and controlled adjustments are needed to maintain stability and prevent disaster. Preparation, situational awareness, and good communication are key to a successful response.

Q 22. What are the legal and regulatory requirements related to anchoring and mooring?

Legal and regulatory requirements for anchoring and mooring vary significantly depending on location (national and international waters), the type of vessel, and the specific activity. Generally, they aim to ensure safety of navigation, environmental protection, and responsible use of maritime resources.

- International Regulations: The International Maritime Organization (IMO) publishes regulations and guidelines, often adopted by individual countries. These cover aspects like anchor types, equipment standards, and mooring procedures for different vessel classes.

- National Regulations: Coastal states have their own laws and regulations governing anchoring and mooring within their territorial waters. These often include specific rules about designated anchorage areas, permitted anchoring practices (e.g., restrictions on seabed type), and environmental considerations (e.g., avoiding sensitive marine ecosystems).

- Port Regulations: Individual ports and harbors often have very detailed regulations regarding mooring procedures, fees, and permitted locations. These usually account for local conditions and infrastructure limitations.

- Environmental Regulations: Regulations exist to prevent damage to marine habitats from anchoring or mooring activities. This includes requirements for environmental impact assessments in sensitive areas and restrictions on anchoring in protected areas.

Failure to comply with these regulations can result in significant fines, port bans, and even criminal charges. It’s essential for anyone involved in anchoring and mooring operations to be fully aware of the relevant legal framework in their area of operation.

Q 23. Describe the maintenance procedures for anchors and mooring equipment.

Regular maintenance of anchors and mooring equipment is crucial for safety and operational reliability. Neglect can lead to equipment failure and potential damage to the vessel or surrounding environment. A comprehensive maintenance plan should include:

- Visual Inspections: Regularly inspect all components for signs of wear, corrosion, damage, or distortion. This includes chains, shackles, rings, ropes, and the anchor itself.

- Chain Testing: Regularly test the strength of anchor chains using non-destructive testing (NDT) methods to identify weaknesses. This is crucial for larger vessels.

- Anchor Fluke Inspection: Examine the anchor flukes for bending, cracks, or loss of sharpness. Blunt flukes significantly reduce holding power.

- Lubrication: Regularly lubricate moving parts to reduce friction and wear, extending the lifespan of the equipment.

- Corrosion Protection: Implement appropriate corrosion protection measures, such as painting or galvanizing, to prevent rust and extend the lifespan of metal components.

- Documentation: Maintain thorough records of all inspections, repairs, and maintenance activities. This documentation is critical for compliance and insurance purposes.

The frequency of maintenance will depend on factors like the environment (saltwater vs. freshwater), usage intensity, and the type of equipment. It’s best practice to follow manufacturer recommendations and adhere to a robust preventative maintenance schedule.

Q 24. Explain the use of mooring sensors and monitoring systems.

Mooring sensors and monitoring systems provide real-time data on various aspects of a mooring system, improving safety, efficiency, and optimizing operations. These systems typically include:

- Strain Sensors: Measure the tension on mooring lines, providing information on load distribution and potential points of failure.

- Position Sensors (GPS, Acoustic): Monitor the vessel’s position relative to its mooring point, allowing for precise adjustments and early detection of drift.

- Environmental Sensors (Wind, Current, Wave): Provide data on environmental conditions affecting the mooring system, allowing for proactive adjustments and mitigating risks associated with changes in weather.

- Anchor Monitoring Systems (Acoustic): In some cases, sophisticated underwater acoustic systems can be used to monitor anchor embedment and ensure the anchor maintains its hold.

The data collected by these sensors is often relayed to a central monitoring station, providing a comprehensive overview of the mooring system’s performance. This allows operators to identify potential problems early, make informed decisions, and optimize mooring operations for safety and efficiency. A sophisticated system might even integrate weather forecasting to offer predictions of mooring line loads and vessel displacement.

Q 25. How do you plan for and execute a complex mooring operation in challenging conditions?

Planning and executing a complex mooring operation in challenging conditions requires meticulous preparation, experienced personnel, and robust risk assessment. The process typically involves:

- Site Survey: Thoroughly investigate the location, including seabed conditions, water depth, currents, weather patterns, and potential obstructions.

- Mooring System Design: Select the appropriate mooring system based on the vessel’s characteristics, environmental conditions, and operational requirements. This might involve sophisticated modeling and simulation.

- Risk Assessment: Identify and evaluate potential hazards, such as extreme weather, equipment failure, or human error, developing mitigation strategies for each risk.

- Emergency Response Plan: Develop a comprehensive plan for handling emergencies, including equipment failures, unexpected weather, and other potential problems.

- Mooring Execution: Deploy the mooring system precisely according to the plan, carefully monitoring all aspects of the operation.

- Monitoring and Adjustment: Continuously monitor the mooring system’s performance, making adjustments as needed to maintain safety and stability.

- Post-Operation Assessment: After completion, review the entire operation, identifying areas for improvement and lessons learned.

For example, mooring a large FPSO (Floating Production, Storage, and Offloading) unit in a hurricane-prone region necessitates a very complex mooring system with substantial redundancy and real-time environmental monitoring, along with a detailed emergency response plan that includes potential evacuation procedures.

Q 26. Describe your experience with different types of mooring systems (e.g., single point, multi-point).

I have extensive experience with various mooring systems, including:

- Single-Point Mooring (SPM): These systems use a single mooring buoy or structure to connect to a vessel, typically suited for larger tankers and LNG carriers. The simplicity and efficiency of SPMs are balanced by their sensitivity to environmental conditions and potential for significant vessel movement.

- Multi-Point Mooring: These systems utilize multiple mooring lines to provide greater stability and control, particularly beneficial in areas with strong currents or winds. This could involve spread mooring (multiple lines in a spread pattern) or turret mooring (a rotating structure allowing vessel weathervaning).

- Anchored Mooring: This involves using anchors embedded in the seabed for mooring. The suitability depends on seabed conditions and requires careful selection of anchor type and deployment techniques.

- Dynamic Positioning (DP): While not strictly a mooring system, DP uses thrusters and GPS to maintain a vessel’s position without anchors or moorings, usually used in conjunction with temporary moorings for operations that require high precision.

The choice of system depends on factors like vessel size and type, water depth, seabed conditions, environmental factors, and operational needs. Each system presents unique challenges and requires specialized knowledge for its design, installation, and operation.

Q 27. Explain the differences between swinging and fixed moorings.

The primary difference between swinging and fixed moorings lies in the vessel’s permitted movement.

- Swinging Mooring: In a swinging mooring, the vessel is allowed to swing freely around its anchor or mooring point, usually in response to changes in wind and current. This approach is simpler and less expensive but necessitates sufficient space to accommodate the vessel’s swing radius.

- Fixed Mooring: In a fixed mooring, the vessel’s position is tightly constrained, limiting its movement to a minimal area. This often requires multiple mooring lines, reducing the risk of collision with other vessels but increasing complexity and costs.

The choice depends on the specific requirements of the operation. Swinging moorings are suitable for locations with ample space and where minor vessel movement is acceptable. Fixed moorings are preferred when precise positioning is crucial, such as for offshore operations or in congested areas.

Q 28. Discuss the impact of vessel size and type on mooring techniques.

Vessel size and type significantly impact mooring techniques. Several factors are considered:

- Size: Larger vessels require more robust mooring systems with greater holding power, stronger lines, and more numerous mooring points. This often necessitates specialized equipment and more complex deployment procedures.

- Type: The type of vessel (e.g., tanker, container ship, FPSO) influences the choice of mooring system. Tankers, for instance, may require single-point or turret mooring for efficient loading and unloading. A dynamically positioned drillship requires a completely different setup than a smaller fishing vessel.

- Draft: The vessel’s draft (depth below the waterline) determines the required water depth and the potential for seabed interaction. Shallow-draft vessels may use simpler systems compared to deep-draft vessels.

- Stability: The vessel’s inherent stability influences the mooring system requirements. A less stable vessel may need a more redundant and robust mooring system to ensure adequate safety margins.

For example, a small sailboat might use a single anchor, while a supertanker needs multiple anchors, chains, and potentially a dynamic positioning system for safe mooring. Accurate assessment of these parameters is critical for selecting the appropriate mooring technique and ensuring the safety and stability of the vessel.

Key Topics to Learn for Mooring and Anchoring Techniques Interview

- Types of Anchors and Mooring Systems: Understand the characteristics, strengths, and weaknesses of various anchor types (e.g., Danforth, Bruce, Plow) and mooring configurations (e.g., single anchor, multiple anchor systems, stern moorings). Consider the impact of environmental factors (wind, currents, tides).

- Anchor Handling Procedures: Master the practical steps involved in deploying, setting, and recovering anchors. This includes understanding scope, rode management, and the use of appropriate equipment.

- Mooring Calculations and Planning: Learn how to calculate holding power, scope requirements, and the effects of different environmental conditions on mooring stability. Practice planning mooring operations for various vessel types and situations.

- Emergency Procedures: Develop a strong understanding of emergency procedures related to anchor dragging, equipment failure, and adverse weather conditions. Be prepared to discuss safe practices and contingency planning.

- Vessel Dynamics and Mooring Loads: Understand how vessel movement and environmental forces affect mooring loads and the stress on anchor systems. Be prepared to discuss techniques for minimizing stress and maintaining stability.

- Regulations and Best Practices: Familiarize yourself with relevant regulations and industry best practices related to mooring and anchoring. Be prepared to discuss safety protocols and environmental considerations.

- Problem-solving and Decision-making: Practice analyzing scenarios involving mooring challenges, such as anchor dragging or equipment malfunctions. Develop strategies for effective problem-solving and decision-making in diverse situations.

Next Steps

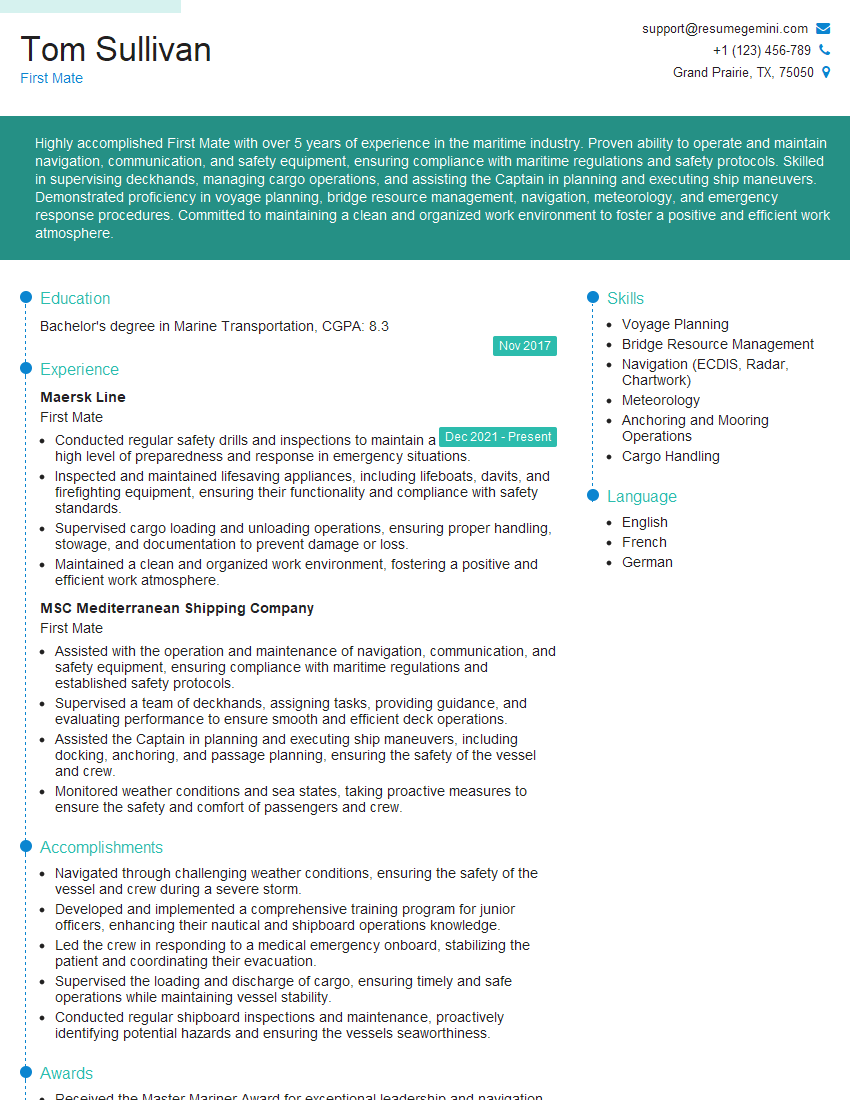

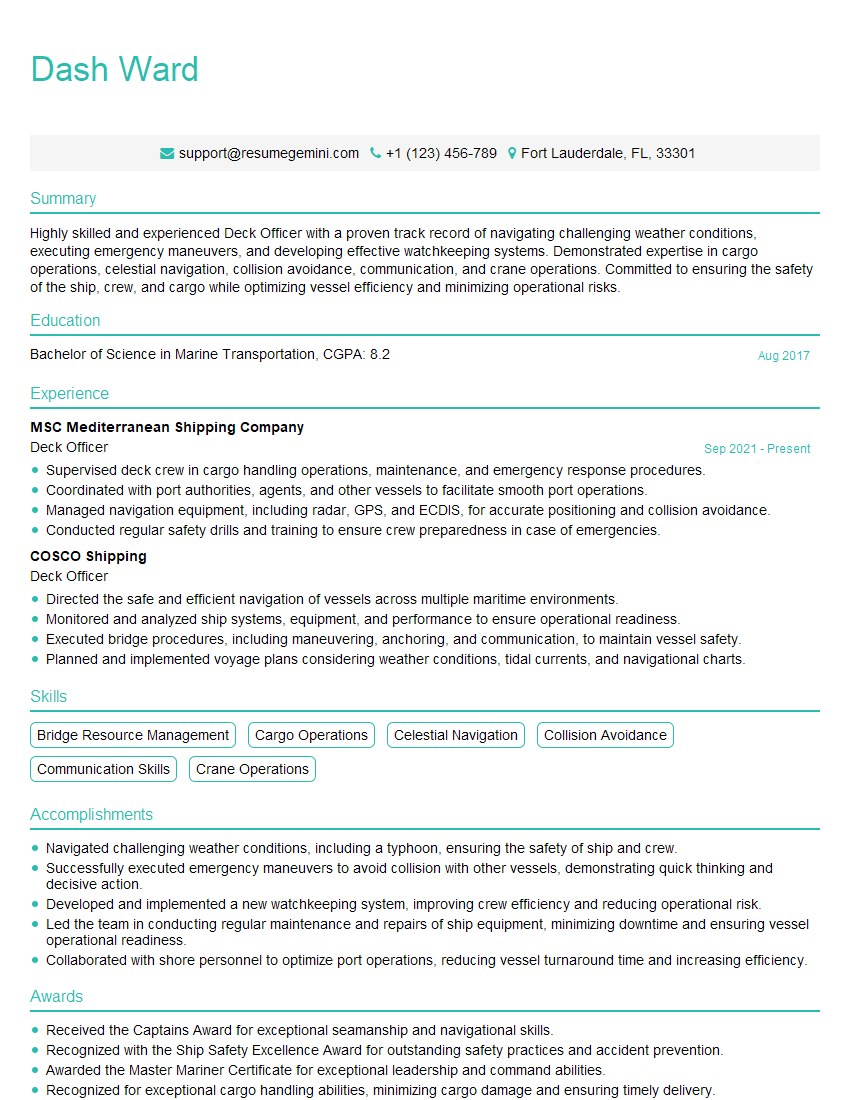

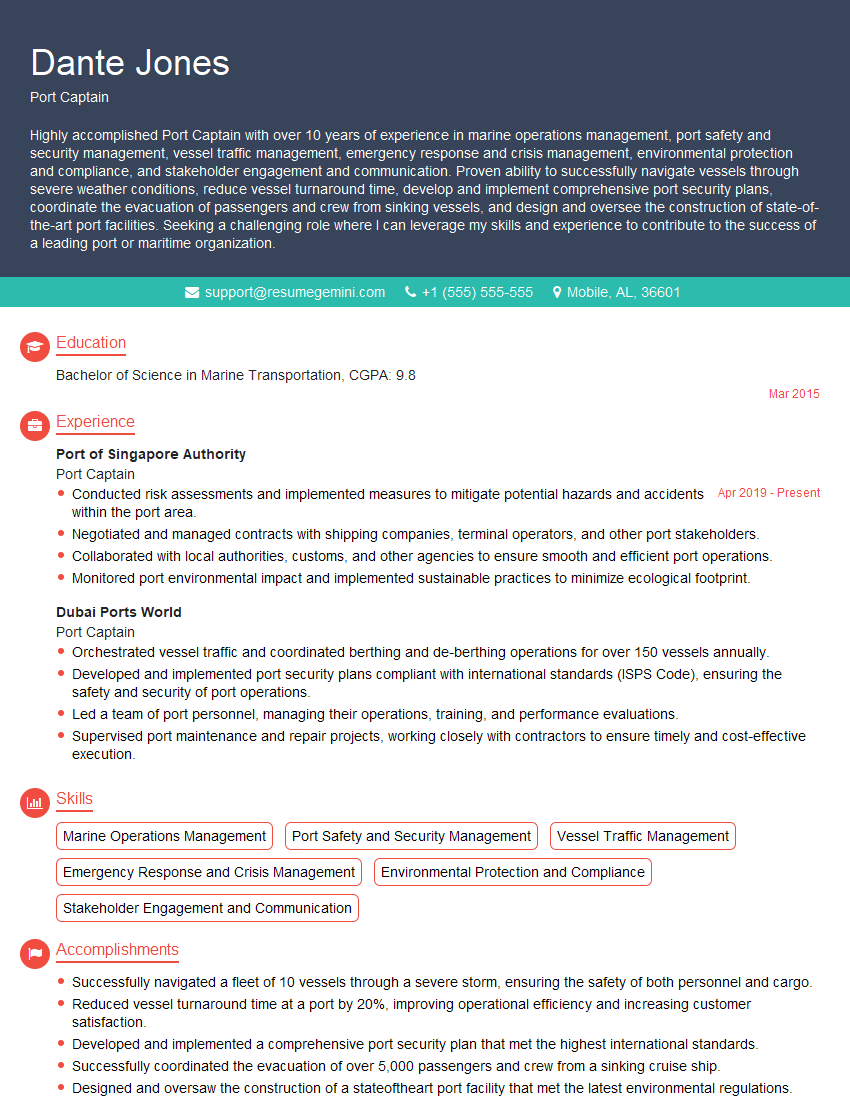

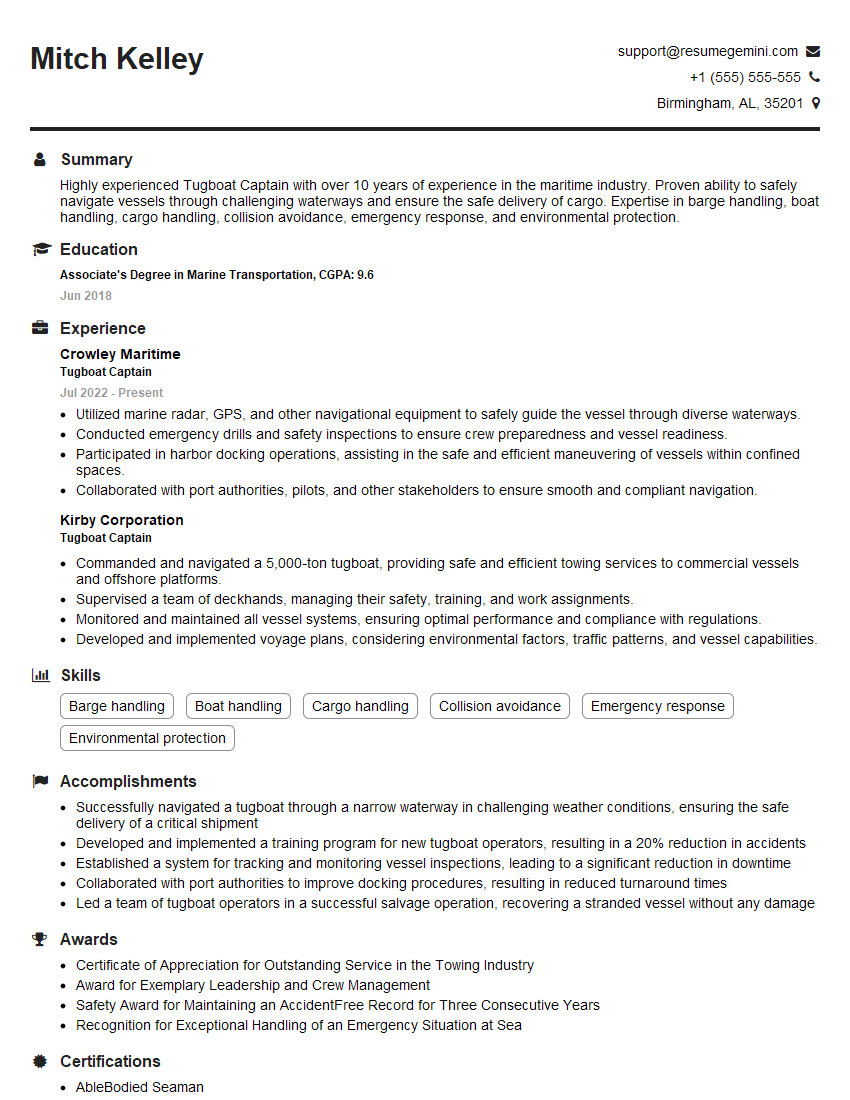

Mastering Mooring and Anchoring Techniques is crucial for career advancement in the maritime industry, opening doors to higher-responsibility roles and increased earning potential. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your expertise effectively. Examples of resumes tailored to Mooring and Anchoring Techniques are available to guide you in crafting the perfect application. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.