Cracking a skill-specific interview, like one for Neon Sign Design, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Neon Sign Design Interview

Q 1. Explain the difference between traditional glass neon and LED neon signs.

The core difference between traditional glass neon and LED neon signs lies in their light source. Traditional neon signs use glass tubes filled with neon or other gases, which are energized by high-voltage electricity to produce light. The gas inside glows a specific color depending on its composition. LED neon signs, on the other hand, use LED lights encased in flexible tubes that mimic the appearance of traditional neon. They’re powered by low-voltage electricity.

- Traditional Neon: Brighter, more vibrant glow, unique handcrafted aesthetic, higher energy consumption, more fragile, requires specialized expertise for repair and maintenance. Think of the classic, iconic look of a vintage diner sign.

- LED Neon: Lower energy consumption, more durable and flexible, easier to install and repair, wider variety of colors, can be shaped more intricately, sometimes perceived as less ‘authentic’ by purists.

Imagine it like comparing a hand-blown glass vase to a mass-produced plastic one – both can be beautiful, but they possess different qualities and appeal to different tastes.

Q 2. Describe your experience with various neon bending techniques.

My experience encompasses a wide range of neon bending techniques, from the classic hand-bending method using a torch and a jig to more advanced techniques involving specialized bending machines. Hand-bending allows for precise control and artistic expression, particularly useful for intricate designs. It involves heating sections of the glass tubing until pliable, then shaping it carefully around molds or by hand. Machines, while faster for simpler shapes, sometimes lack the fine control needed for complex curves. I’m proficient in both.

I’ve worked with various tube diameters and glass types, each requiring nuanced adjustments to the heating and bending process. For example, smaller diameter tubes require more precision and faster heating to avoid collapse, while larger tubes need more controlled heating to prevent uneven bending and cracking. I’ve also worked extensively on shaping neon into three-dimensional forms which can demand a significant level of skill and planning.

Beyond the actual bending, I also master the art of ‘filling’ the bent glass tubes with inert gases and then sealing them for a perfect and long lasting finish.

Q 3. How do you ensure the longevity and durability of a neon sign?

Ensuring longevity and durability requires attention to detail at every stage. It begins with the quality of materials—using high-quality glass tubes and electrodes is crucial. Proper bending techniques, as discussed earlier, prevent stress points that can lead to breakage. The internal gas pressure should be carefully regulated during filling to prevent leaks or over-pressure. A crucial step is the application of a robust protective coating to shield the neon tubing from environmental factors like moisture, temperature fluctuations, and UV exposure. This coating acts as a significant shield against damage, especially in outdoor environments. Finally, proper installation—secure mounting and protection from physical impact—is paramount. Regular inspections and maintenance can also increase lifespan. We always advise clients on proper cleaning and maintenance routines for their specific signs.

Q 4. What safety precautions do you take when working with high-voltage electricity in neon sign fabrication?

Safety is paramount when working with high-voltage electricity. We always adhere to strict safety protocols. This includes working in a well-ventilated area, wearing appropriate personal protective equipment (PPE) such as insulated gloves, safety glasses, and closed-toe shoes. We never work alone; at least two trained technicians are always present. Before starting any work, we thoroughly check our equipment for any signs of damage and ensure that all electrical connections are secure. The work area is clearly marked as a high-voltage zone, with clear warnings in place. After completion, we meticulously double-check all connections and ensure the power is safely disconnected. We also perform regular safety inspections and keep detailed records of all safety procedures.

Q 5. Explain your process for designing a neon sign from concept to completion.

My process for designing a neon sign is meticulous and iterative, starting with an initial client consultation to understand their vision, budget, and desired location. We then develop a design concept incorporating their ideas, using computer-aided design (CAD) software to create detailed drawings and renderings. The next step is creating a template from the design which is then used to carefully bend the neon tubing. Once the tubes are bent, they’re filled with the chosen gas and the electrodes are inserted and soldered. Then comes the rigorous testing and quality control stage to ensure the sign’s functionality and longevity. After that, we carefully assemble the completed sign onto its backing and perform a final test to confirm everything is as it should be.

Q 6. How do you handle client revisions and feedback during the design process?

Handling client revisions and feedback is a crucial part of the process. We encourage open communication throughout the design phase. We provide regular updates and solicit feedback at key milestones, such as after the initial concept design and before manufacturing begins. Revisions are incorporated thoughtfully, with clear explanations of any technical limitations or cost implications. We use collaborative tools to share designs and revisions, ensuring transparency and efficiency in the process. Ultimately, our goal is to create a sign that not only meets but exceeds the client’s expectations.

Q 7. Describe your experience with different types of neon gas and their effects on color.

Different neon gases produce different colors. Neon itself produces a characteristic orange-red glow. Other gases, such as argon (blue-violet), helium (pinkish-white), krypton (white-yellow), and xenon (bluish-white) offer a range of colors. By combining different gases in the tube, and applying phosphor coatings to the inside of the glass tube, we can create a wide spectrum of colors and hues. For example, a combination of neon and argon can create a brighter, richer orange-red than using neon alone. A coating of phosphor allows us to create a whole variety of neon colours.

The specific gas mixture and phosphor coating selection are critical for achieving the desired color accuracy and intensity. I have extensive experience in understanding the properties of these gases and how to use this knowledge to best deliver on client requirements.

Q 8. How do you determine the appropriate transformer size for a neon sign?

Determining the correct transformer size for a neon sign is crucial for its proper function and longevity. It’s all about matching the transformer’s output voltage and amperage to the sign’s requirements. Think of it like choosing the right power supply for your computer – too little, and it won’t work; too much, and you risk damage.

First, you need to know the total length of the neon tubing in the sign. Each foot of tubing requires a specific voltage (typically 150-200 volts per foot, depending on the tube’s diameter and gas fill). Then, calculate the total voltage needed: Total Voltage = Voltage per Foot * Total Feet of Tubing.

Next, you need the amperage. This depends on the gas used in the neon tube; different gases have different current requirements. This information is usually provided by the neon tubing manufacturer. Let’s say your calculation reveals a need for 1500 volts and 15 milliamps. You’d then need a transformer capable of supplying at least 1500 volts and 15 milliamps, preferably slightly higher to account for voltage drop and safety margin. Always round up to the nearest available transformer size.

For example, if a sign requires 1600 volts and 20 milliamps, you’d select a transformer with a rating of at least 1600 volts and 20 milliamps or higher. You should also consider the type of transformer: constant current or constant voltage. Constant current transformers are generally preferred for neon signs because they maintain a stable current, which is critical for consistent brightness and prevents damage from voltage fluctuations.

Q 9. What are the common issues encountered during neon sign installation, and how do you address them?

Neon sign installation presents unique challenges. Common issues include improper grounding, which can lead to electrical shock hazards; difficulty navigating tight spaces, especially with large or complex signs; and potential damage to the sign during handling and mounting. Accurate measurements and planning are crucial to avoid these issues.

Addressing these issues requires careful preparation. Before installation, a thorough site survey must be done, which includes checking for structural integrity and identifying potential obstructions. Secure mounting points are crucial. We use specialized brackets and supports designed to handle the weight and stress of the neon tubes. Grounding is paramount for safety, following all relevant electrical codes to prevent shocks and shorts.

Dealing with tight spaces often requires using flexible tubing and custom-designed brackets to maneuver the sign into position. During installation, meticulous care is essential to prevent damage. We use padded surfaces and protective coverings to avoid scratching or breaking the delicate glass tubing. Post-installation, a final inspection is conducted to ensure secure mounting and correct electrical connections.

Q 10. How do you troubleshoot and repair a malfunctioning neon sign?

Troubleshooting a malfunctioning neon sign often involves systematically checking various components. A non-functioning sign could be due to issues with the transformer, power supply, electrodes, or even a broken section of the neon tubing itself. Always prioritize safety – disconnect the power before any inspection or repair.

My process begins with a visual inspection. I look for broken or damaged tubing, loose connections, or any signs of overheating. I use a neon sign tester to check the voltage and current at different points along the circuit. A multimeter is invaluable here for precise voltage and resistance measurements. If a problem is located in the transformer, it can sometimes be repaired by replacing internal components; otherwise, it would need to be replaced.

Identifying a break in the tubing involves using a high-voltage tester to pinpoint the exact location. Repairing broken tubing requires specialized skills and tools. We carefully seal the break using a glass-blowing torch and refilling the tube with the appropriate neon gas. After the repair, the tube is tested again to ensure proper function before reinstalling it in the sign.

Q 11. Describe your experience with different types of neon sign enclosures and their applications.

Neon sign enclosures play a vital role in protecting the delicate glass tubing and enhancing the sign’s overall aesthetic. Several types are available, each suited for different applications. Think of enclosures like a protective jacket for the neon heart of the sign.

- Metal Enclosures: These offer robust protection against impacts and weather damage, making them ideal for outdoor signs or high-traffic areas. Aluminum and stainless steel are common choices due to their durability and corrosion resistance.

- Acrylic Enclosures: Acrylic provides excellent clarity, allowing the neon glow to shine through brilliantly. It’s lighter than metal but may be more susceptible to cracking. Acrylic enclosures are often preferred for indoor signs where impact risk is lower.

- Custom Enclosures: For truly unique designs, we may work with wood, stone, or other materials, shaping them to complement the sign’s aesthetic and integrate seamlessly into the surroundings.

The choice of enclosure depends on the sign’s location, its intended use, and the desired aesthetic. For instance, a neon sign for a bar in a busy city street would benefit from a rugged metal enclosure, while a more delicate sign in a boutique might use a sleek acrylic enclosure.

Q 12. What software programs are you proficient in for neon sign design and fabrication?

Proficiency in design software is key to creating effective and visually appealing neon signs. I’m well-versed in several programs, each serving a different purpose in the design and fabrication process.

- Adobe Illustrator: This is my primary tool for vector-based design. I use it to create the initial sketches, refine the lettering and imagery, and ensure the design is scalable for various sizes.

- AutoCAD: This is essential for precise technical drawings and creating accurate templates for the sign’s construction. I use AutoCAD to design the overall structure, including the placement of the tubing and electrical components.

- SolidWorks (or similar 3D modeling software): When designing complex or three-dimensional signs, I use 3D modeling software to visualize the final product and ensure all components fit together properly. This is especially helpful when working with custom enclosures.

Beyond these, I’m also familiar with various image editing and rendering programs for creating visual presentations for clients.

Q 13. Explain your understanding of electrical codes and safety regulations related to neon signs.

Understanding and adhering to electrical codes and safety regulations are paramount in neon sign design and installation. Failure to comply can lead to serious accidents, fires, and legal repercussions. My knowledge spans local, state, and national codes.

Key aspects include proper grounding, use of appropriate insulation, correct wiring techniques, and the implementation of safety devices like fuses and circuit breakers. I always ensure that all electrical work complies with the National Electrical Code (NEC) and any relevant local ordinances. This includes using certified components, maintaining accurate documentation of all wiring and connections, and conducting thorough safety inspections before and after installation.

For instance, I am well-versed in the requirements for outdoor signs concerning weatherproofing and preventing electrical shock hazards. I utilize techniques like conduit protection and sealed connections to ensure that the sign is safe and protected from the elements. I also stay updated on the latest code changes and technological advancements in neon sign safety.

Q 14. How do you estimate the cost of materials and labor for a neon sign project?

Estimating costs accurately is crucial for both the client and myself. It involves carefully considering the various factors that contribute to the overall expense. There’s no simple formula; each sign is unique.

My cost estimation includes several key components:

- Materials: This is the cost of the neon tubing itself, the transformer, the enclosure, the gas, and any additional components like brackets or wiring.

- Labor: This accounts for design time, fabrication, installation, and any potential troubleshooting or repairs. Complex designs naturally require more labor.

- Overhead: This accounts for expenses such as shop rent, utilities, and insurance.

- Profit Margin: A reasonable profit margin is factored in to account for my expertise and to ensure business viability.

I provide detailed breakdown sheets, and I often use historical data from similar projects to refine my estimates. I work closely with clients to understand their budget constraints and find creative ways to balance quality with affordability. A transparent cost estimation process builds trust and helps avoid unforeseen expenses during the project.

Q 15. How do you manage multiple projects simultaneously while meeting deadlines?

Managing multiple neon sign projects simultaneously requires a structured approach. I utilize project management software to track deadlines, resources, and client communication for each project. This allows me to visualize the entire workflow and prioritize tasks based on urgency and deadlines. For example, I might dedicate Monday mornings to design work for one client, then spend the afternoon working on the fabrication process for another. This staggered approach prevents bottlenecks and ensures timely completion of all projects. Regular client communication is key – keeping them informed of progress updates and potential issues keeps projects on track and prevents misunderstandings.

- Prioritization Matrix: I use a prioritization matrix to rank tasks based on urgency and importance, ensuring that critical tasks are addressed first.

- Time Blocking: I allocate specific time blocks for each project, ensuring dedicated time slots for design, fabrication, and client interaction.

- Regular Check-ins: I schedule regular check-ins with my team and clients to discuss progress, address roadblocks, and ensure alignment on project goals.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of neon sign finishes and their effects on the final product.

Neon sign finishes significantly impact the final aesthetic and longevity of the sign. Common finishes include:

- Clear Coat: A clear protective layer that enhances color vibrancy and protects against UV damage and environmental wear. This is especially important for outdoor signs.

- Powder Coating: Adds a durable and textured finish, available in various colors. This is a more robust option for outdoor signs, offering superior protection against corrosion.

- Hand-Painted Finishes: For a truly unique look, hand-painted finishes allow for intricate designs and custom color blends. This adds an artisan touch but requires more time and skill.

- Metallic Finishes: These add a luxurious, shimmering effect. They can enhance the overall design and make the sign stand out, particularly in low-light settings.

For instance, a clear coat is ideal for a delicate, vintage-style sign, while powder coating might be best for a brightly colored, outdoor storefront sign that needs to withstand harsh weather. The choice depends greatly on the design’s intended location and aesthetic.

Q 17. How do you ensure accurate color matching in your neon sign designs?

Accurate color matching is crucial for neon signs. I use a combination of digital tools and physical samples to achieve this. We start with a client’s preferred color palette, often represented as Pantone numbers or RGB values. These are then input into our design software to create a visual representation. We utilize specialized color charts and software that accurately translate digital color to neon gas color. Before fabrication, we create small test pieces with the chosen neon gas to verify the color matches expectations under various lighting conditions. This ensures a seamless transition from digital design to the final neon product, minimizing discrepancies and keeping the client satisfied.

Q 18. What is your experience with creating custom lettering and designs for neon signs?

Creating custom lettering and designs is a cornerstone of my work. I’m proficient in various design software such as Adobe Illustrator and CorelDRAW, which allow for precise vector-based design. I collaborate closely with clients to understand their vision, incorporating their ideas and brand identity into the design. From classic serif fonts to modern, geometric styles, I can adapt to any design request. My expertise extends beyond simple text; I often create intricate custom designs incorporating logos, graphics, and illustrative elements to craft unique and memorable neon signs. For example, I recently completed a project creating a custom neon sign for a brewery, integrating their logo with a stylized hop plant design.

Q 19. Explain your understanding of the different types of glass used in neon sign fabrication.

The type of glass used in neon sign fabrication significantly influences the sign’s appearance, durability, and light transmission. Common types include:

- Borosilicate Glass: This is the most common type due to its high heat resistance and ability to withstand the high temperatures of the neon gas. It’s also robust, making it ideal for outdoor applications.

- Soda-Lime Glass: A more affordable option, it’s generally used for indoor signs or in cases where high heat resistance isn’t critical. It’s less resistant to thermal shock.

- Colored Glass: Colored glass tubes are available in a wide range of colors, allowing for creative design options. These tubes are often made of borosilicate glass and colored during the manufacturing process.

The choice of glass depends on the project’s specific requirements. For outdoor applications, where the sign will face extreme temperature variations, borosilicate glass is essential to prevent cracking. For less demanding applications, soda-lime glass might suffice, offering a cost-effective solution.

Q 20. Describe your experience with maintaining and repairing neon signs in various environments (indoor/outdoor).

Maintaining and repairing neon signs requires specialized knowledge and equipment. Outdoor signs face more aggressive environmental factors—extreme temperatures, humidity, and potential damage from weather events. Regular inspections are crucial, checking for gas leaks, cracked glass, and faulty transformers. Repairs often involve replacing damaged sections of glass tubing, refilling gas, or replacing electrical components. Indoor signs generally require less maintenance, but regular checks for gas leaks and potential electrical issues are still important. Proper ventilation is key in both environments to prevent overheating and to ensure longevity. I am experienced in troubleshooting both common and complex issues, utilizing specialized tools and diagnostic techniques to efficiently restore neon signs to their optimal functionality.

Q 21. How do you address potential challenges with neon sign installation in difficult locations?

Installing neon signs in difficult locations requires careful planning and execution. Factors such as high ceilings, limited access, or complex structural features need to be addressed proactively. I typically conduct a thorough site survey before installation to identify potential obstacles. This includes assessing structural integrity, available access points, and electrical requirements. For high-ceiling installations, specialized equipment like lifts or scaffolding is used. When access is limited, I develop a detailed plan outlining installation steps, ensuring minimal disruption to the surroundings. Safety is paramount. My team follows strict safety protocols, using appropriate personal protective equipment (PPE) and ensuring all electrical work is carried out safely and according to code. A well-defined plan, along with the use of proper equipment and safety measures, ensures a successful installation even in the most challenging environments.

Q 22. Explain your experience with different types of neon sign transformers and their functions.

Neon sign transformers are crucial for stepping down high-voltage AC power to the lower voltage required by the neon gas within the tubing. I’ve worked extensively with several types, each with unique characteristics.

- Step-Down Transformers: These are the most common, reducing the high voltage from the mains supply (typically 120V or 240V) to the operating voltage of the neon tubing (usually between 2kV and 15kV, depending on the length and gas used). I’ve used various models with different power ratings to accommodate different sign sizes and configurations. A larger sign naturally requires a higher power transformer.

- Constant Current Transformers: These are particularly important for maintaining consistent brightness across the neon tubing. Unlike simple step-down transformers, constant current transformers regulate the current, even if the voltage fluctuates. This ensures a stable glow and extends the lifespan of the tubing. I prefer these for larger or more complex installations where brightness consistency is paramount.

- Autotransformers: Less common in neon sign applications, these transformers use a single winding to step up or step down voltage. Their main benefit is size; however, they lack the isolation provided by a step-down transformer, posing potential safety risks if not handled carefully. I generally avoid these unless specific project requirements demand compact dimensions.

Understanding the voltage and current ratings of these transformers is critical for safety and optimal performance. Incorrect transformer selection can lead to dim signs, premature tube failure, or even electrical hazards.

Q 23. How do you ensure the proper grounding and wiring of a neon sign?

Proper grounding and wiring are paramount for safety and preventing electrical shocks. My approach follows stringent safety protocols.

- Grounding: The metal chassis of the transformer and any metal parts of the sign must be securely grounded to earth. This is typically done using a dedicated ground wire connected to a proper earth ground. Failure to do so could lead to dangerous electrical shock hazards. I always visually inspect the ground connection after installation and regularly test its continuity.

- Wiring: I use high-voltage, high-temperature rated wires specifically designed for neon signs. These wires must be properly insulated and securely connected to both the transformer and the electrodes within the neon tubes. Connections are meticulously crimped and soldered to ensure reliable contact and prevent arcing or short circuits. I always use heat-shrink tubing over all connections for added insulation and protection.

- Overcurrent Protection: A fuse or circuit breaker is always included in the wiring to protect the circuit from overloads and short circuits, preventing damage to the transformer and sign, and most importantly, preventing fires.

Using color-coded wires and clearly labeling all connections is crucial for troubleshooting and maintenance. I always document wiring diagrams for each sign for future reference.

Q 24. Describe your experience with using different types of electrodes in neon sign fabrication.

Electrode selection significantly impacts the lifespan and performance of a neon sign. I have experience with various types:

- Nickel Electrodes: These are the most common electrodes used in neon sign fabrication. They are relatively inexpensive, easy to work with, and have good longevity. I often utilize these for standard neon signs due to their reliability.

- Platinum Electrodes: While more expensive, platinum electrodes offer superior performance, especially in applications requiring high brightness or long operating hours. They resist corrosion better and have a longer lifespan than nickel electrodes. I use these for projects requiring exceptionally high quality and extended performance.

- Other Alloys: Occasionally, specialty alloys might be employed for specific gas mixtures or operating conditions. The choice often depends on the application and the desired color of the neon glow.

Proper electrode preparation and installation are critical. I carefully clean and shape the electrodes to ensure optimal gas ionization and minimize sputtering, which can reduce the sign’s brightness and lifespan.

Q 25. What is your experience with different types of neon sign power supplies and their requirements?

The power supply is the heart of a neon sign, providing the necessary high voltage to energize the gas within the tubing. My experience encompasses diverse types:

- High-Voltage AC Power Supplies: These are the most traditional power supplies for neon signs, directly converting line voltage to the high voltage needed for the neon gas. They are robust and reliable but can be bulky and less energy-efficient than modern alternatives. I primarily use these for traditional neon signs.

- Switching Power Supplies: These are becoming increasingly popular due to their smaller size, higher efficiency, and better regulation of the high voltage output. They offer more sophisticated control and potentially lower energy consumption. I am incorporating these more often in new designs for energy efficiency and space-saving applications.

- LED Power Supplies (for LED Neon Flex): In cases where LED neon flex is used (a more modern, energy-efficient alternative to traditional neon), standard LED driver power supplies are required. These provide the lower voltage (typically 12V or 24V) necessary to operate these LED strips. I select these based on the wattage and current requirements of the LED flex.

Selecting the appropriate power supply necessitates careful consideration of voltage, current, and power ratings to match the specific needs of the neon tubing or LED flex being used.

Q 26. How do you ensure the proper ventilation for a neon sign to prevent overheating?

Overheating is a significant concern with neon signs, especially larger ones. Proper ventilation is crucial to prevent premature failure and potential fire hazards. My strategies include:

- Adequate Spacing: Ensuring sufficient space around the neon tubing allows for better air circulation and heat dissipation. I avoid enclosing the sign in a way that restricts airflow.

- Open-Back Design: For larger signs, an open-back design allows for more effective heat dissipation. The heat can escape more readily from the back of the sign.

- Heat Sinks (for LED Neon Flex): With LED neon flex, I often utilize heat sinks or thermal management solutions to dissipate heat generated by the LED strips.

- External Fans: For very large or high-power signs, incorporating external fans can significantly improve cooling. This is especially relevant for enclosed signs or those located in areas with poor natural ventilation.

Proper ventilation significantly increases the lifespan of the sign components and reduces the risk of fire hazards.

Q 27. Describe your experience with designing and fabricating neon signs for different applications (e.g., commercial, residential, artistic).

My experience spans a wide range of neon sign applications, demanding diverse design and fabrication approaches.

- Commercial: I’ve designed and fabricated vibrant, eye-catching signs for businesses, ranging from small storefront signs to large-scale advertising displays. These require durability, high visibility, and often incorporate custom lettering and logos. I’ve integrated various techniques to achieve the desired aesthetic effects and ensure the longevity of the sign in demanding outdoor environments.

- Residential: For residential applications, the focus shifts towards custom designs tailored to individual preferences and architectural styles. I’ve created unique and personalized signs for homes, integrating delicate designs and softer lighting effects to complement the surrounding architecture.

- Artistic: Working on artistic projects allows for greater creative freedom. I’ve collaborated with artists to translate abstract concepts and designs into striking neon installations, often employing unconventional shapes, colors, and techniques. This involves careful consideration of aesthetics, lighting effects, and the overall artistic message.

Each application presents unique challenges and demands a tailored approach to design, materials, and construction techniques.

Q 28. How do you stay up-to-date with the latest advancements and trends in neon sign technology?

Staying current in the neon sign field involves continuous learning and engagement with industry developments.

- Industry Publications and Trade Shows: I regularly read industry magazines and attend trade shows to learn about new materials, techniques, and technologies. This includes exploring new LED technologies and their integration with traditional neon.

- Online Forums and Communities: Engaging with online forums and communities allows me to connect with other neon sign professionals, share knowledge, and stay updated on the latest trends and innovations. I find that the exchange of ideas and experiences is invaluable.

- Continuing Education: I actively pursue workshops and training courses to enhance my skills and knowledge of new technologies and techniques. Keeping my skills sharp ensures I can offer clients the latest and most efficient options.

The neon sign industry is constantly evolving, so continuous learning is essential to remain competitive and deliver high-quality work.

Key Topics to Learn for Your Neon Sign Design Interview

- Design Principles & Aesthetics: Understanding composition, color theory, typography, and visual hierarchy as applied to neon sign design. Consider how these principles impact readability and overall impact.

- Neon Fabrication Techniques: Familiarity with bending, shaping, and assembling neon tubes. Knowledge of different gas fills and their color effects is crucial. Discuss troubleshooting common fabrication challenges.

- Electrical Systems & Safety: Understanding transformers, power supplies, and wiring techniques specific to neon signs. Highlight your knowledge of safety regulations and best practices to prevent electrical hazards.

- Software & Design Tools: Proficiency in relevant design software (e.g., Adobe Illustrator, Photoshop) for creating accurate blueprints and visual mockups. Discuss your workflow and ability to translate designs into practical fabrication plans.

- Client Communication & Project Management: Demonstrate your ability to understand client needs, manage expectations, and deliver projects on time and within budget. Discuss problem-solving skills related to design revisions and unexpected challenges.

- Material Selection & Cost Estimation: Knowledge of various materials used in neon sign construction (glass tubing, transformers, etc.) and ability to accurately estimate project costs. Discuss your approach to balancing design aesthetics with budgetary constraints.

- Installation & Maintenance: Understanding the process of installing and maintaining neon signs, including troubleshooting issues and performing repairs. Discuss your approach to ensuring long-term functionality and safety.

- Emerging Trends & Technologies: Demonstrate awareness of current trends in neon sign design, including LED technology and innovative design approaches. Show your commitment to professional development and staying current with industry advancements.

Next Steps

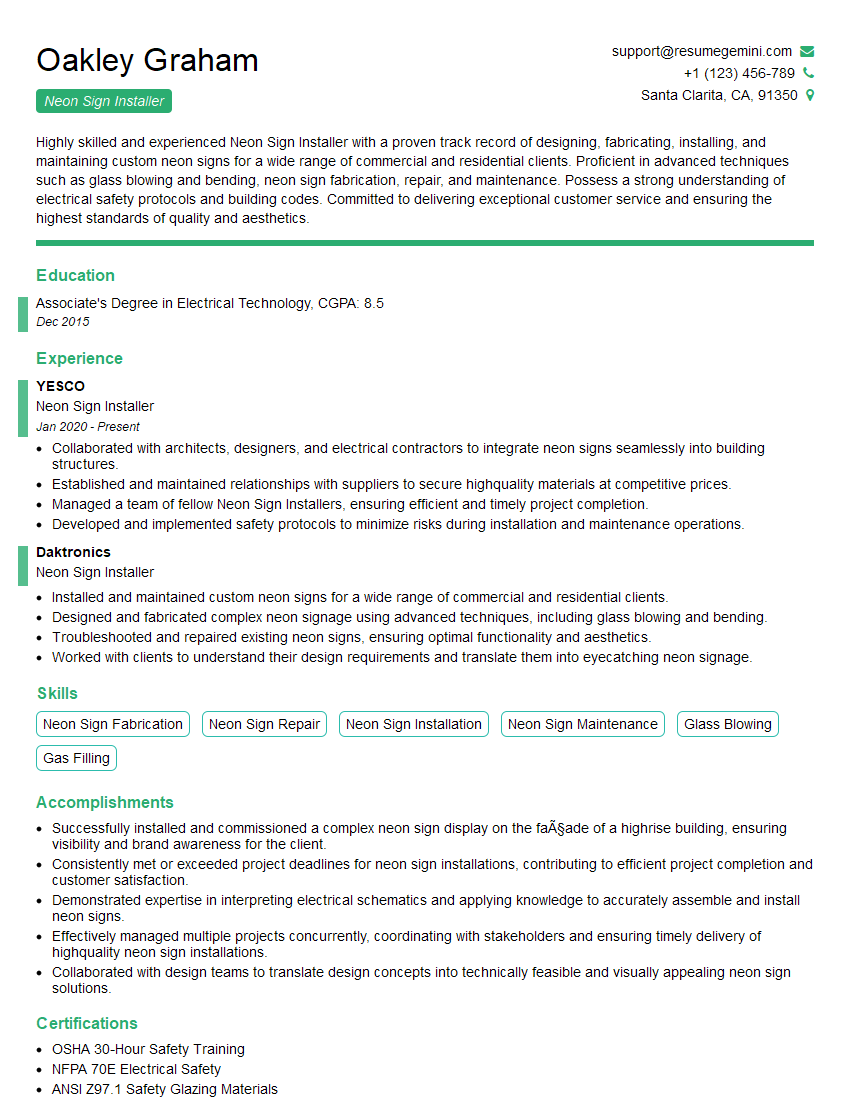

Mastering neon sign design opens doors to a rewarding career with diverse opportunities. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to the Neon Sign Design field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.