Cracking a skill-specific interview, like one for Nutrient Removal Technologies, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Nutrient Removal Technologies Interview

Q 1. Explain the different types of nutrient removal processes.

Nutrient removal processes aim to eliminate excess nitrogen and phosphorus from wastewater, preventing water pollution. These processes can be broadly categorized into physical, chemical, and biological methods.

- Physical methods primarily involve filtration and sedimentation to remove solids containing nutrients. Think of it like using a sieve to separate larger particles from the water. This is often a preliminary step.

- Chemical methods utilize chemical precipitation or adsorption to remove nutrients. For example, adding chemicals like ferric chloride can precipitate phosphorus out of solution, allowing it to be easily removed. This is a direct approach, effective but often more costly.

- Biological methods leverage microorganisms to break down and remove nutrients. This is the most common and often the most cost-effective approach, relying on the natural processes of bacteria consuming nutrients. These methods are further categorized into various processes like activated sludge, membrane bioreactors, and constructed wetlands.

The choice of method depends on factors like the characteristics of the wastewater, the desired level of nutrient removal, and the available budget.

Q 2. Describe the principles of biological nutrient removal.

Biological nutrient removal (BNR) relies on the synergistic action of different types of microorganisms to remove both nitrogen and phosphorus from wastewater. It’s a complex, multi-step process.

Phosphorus removal typically occurs during the anaerobic (oxygen-free) phase. Bacteria release polyphosphate to obtain energy, making phosphorus available for removal. Then, in the aerobic (oxygen-rich) phase, phosphorus is taken up by other organisms. Think of it like a two-step dance where bacteria release and then others store the phosphorus.

Nitrogen removal is achieved through a process called nitrification-denitrification. Nitrification involves aerobic bacteria converting ammonia to nitrite and then to nitrate. Denitrification occurs in anoxic (low-oxygen) conditions, where bacteria use nitrate as an electron acceptor, converting it to nitrogen gas, which is released into the atmosphere. It’s a clever process of converting a harmful pollutant into harmless gas.

The success of BNR depends on carefully controlling the environment (oxygen levels, pH, temperature) to favor the growth and activity of these specific bacteria.

Q 3. What are the key differences between activated sludge and membrane bioreactor systems?

Both activated sludge and membrane bioreactor (MBR) systems are biological wastewater treatment processes, but they differ significantly in their solids separation mechanism.

- Activated sludge relies on gravity settling in a clarifier to separate the activated sludge (microorganisms) from the treated effluent. This process is relatively simple and less expensive but has limitations in terms of effluent quality, especially when dealing with high solids concentrations or small particle sizes.

- Membrane bioreactors (MBRs) integrate a membrane filtration unit within the activated sludge process. This membrane acts as a physical barrier, removing solids and microorganisms much more effectively. MBRs deliver a higher quality effluent with lower suspended solids and better nutrient removal, but are more expensive to operate and maintain, requiring membrane cleaning and replacement.

In essence, activated sludge is like a simple filter, while MBR is a sophisticated one with a much finer mesh.

Q 4. How do you optimize nutrient removal in a wastewater treatment plant?

Optimizing nutrient removal in a wastewater treatment plant requires a multi-faceted approach involving monitoring, control, and process adjustments.

- Process control: Precisely controlling parameters such as dissolved oxygen levels, pH, and sludge retention time (SRT) is crucial. These parameters dictate the microbial activity and nutrient removal efficiency.

- Monitoring: Continuous monitoring of influent and effluent nutrient concentrations (ammonia, nitrate, nitrite, phosphorus) is critical for real-time process adjustments and performance evaluation. Regular testing is like taking the pulse of the system.

- Operational adjustments: Based on monitoring data, adjustments like aeration rates, return sludge flows, and chemical additions can be made to optimize the process. This is a dynamic approach requiring skilled operators.

- Process upgrades: Consider adding advanced treatment technologies like enhanced biological phosphorus removal (EBPR) or anaerobic/anoxic/oxic (A2O) systems to enhance nutrient removal capabilities when the existing system is insufficient.

Regular maintenance and staff training are also important aspects of optimization. A well-trained team is the backbone of a well-functioning plant.

Q 5. What are the limitations of various nutrient removal technologies?

Various nutrient removal technologies have limitations, including:

- Biological methods: Sensitivity to temperature fluctuations, toxic substances, and variations in wastewater composition can impact their effectiveness. For example, sudden influxes of industrial waste can disrupt the microbial balance.

- Chemical methods: Can generate sludge requiring disposal, adding to the operational costs and environmental concerns. Chemical use can also increase the total dissolved solids (TDS) in the treated water.

- Membrane filtration (MBRs): Membrane fouling and high energy consumption can be significant drawbacks. Membrane replacement is a considerable cost and also creates disposal issues.

- Constructed wetlands: Land requirement is substantial and their effectiveness is influenced by climate, particularly temperature and precipitation.

The optimal technology choice involves weighing the advantages and disadvantages based on specific site conditions and project constraints.

Q 6. Explain the role of phosphorus removal in eutrophication control.

Phosphorus is a crucial nutrient for plant growth, but its excessive presence in water bodies leads to eutrophication. Eutrophication is a process where excessive nutrients stimulate algal blooms, depleting oxygen levels and harming aquatic life. This creates ‘dead zones’ – areas with insufficient oxygen to support life. Therefore, effective phosphorus removal is vital for eutrophication control.

By removing phosphorus from wastewater before it reaches receiving waters, we can significantly reduce the risk of eutrophication, thereby protecting water quality and preserving aquatic ecosystems. This is a crucial step in safeguarding our water resources. Think of it as preventing a wildfire by controlling the fuel source (phosphorus) in advance.

Q 7. Discuss the impact of nitrogen removal on water quality.

Nitrogen removal is essential for maintaining healthy aquatic ecosystems and protecting human health. Excessive nitrogen can cause:

- Eutrophication: Similar to phosphorus, excess nitrogen fuels algal blooms and oxygen depletion, harming aquatic life.

- Formation of harmful algal blooms (HABs): Certain types of algae produce toxins that are harmful to humans and animals.

- Ground and drinking water contamination: Nitrate contamination in drinking water is a serious health concern, especially for infants (blue baby syndrome).

By removing nitrogen from wastewater, we can protect water quality, prevent eutrophication, reduce the risk of HABs, and safeguard human health. The impact is significant and multifaceted, impacting both the environment and human well-being.

Q 8. What are the common methods for nitrogen removal?

Nitrogen removal is crucial in wastewater treatment to prevent eutrophication of receiving water bodies. Common methods broadly fall into two categories: biological and chemical.

- Biological Nitrogen Removal (BNR): This is the most common approach, relying on microbial processes. It involves two key steps: nitrification and denitrification (explained in more detail in the next question). This is typically implemented in activated sludge processes or membrane bioreactors.

- Chemical Nitrogen Removal: This involves using chemicals to precipitate or otherwise remove nitrogen. Common methods include:

- Breakthrough technology: The use of advanced oxidation processes (AOPs) such as ozonation or UV/H2O2, which can oxidize ammonia to nitrate and then further to nitrogen gas, eliminating nitrogen.

- Chemical precipitation: Adding chemicals like alum or ferric chloride to precipitate ammonia as a solid, which can then be removed by sedimentation.

- Ion exchange: Using ion exchange resins to selectively remove ammonium ions from the wastewater.

The choice of method depends on factors such as the type and concentration of nitrogen in the wastewater, the required level of treatment, and the cost-effectiveness of each option. For example, a municipal wastewater treatment plant might use BNR due to its cost-effectiveness for large volumes, whereas an industrial facility with a high ammonia concentration might opt for chemical precipitation.

Q 9. Describe the process of nitrification and denitrification.

Nitrification and denitrification are two crucial biological processes involved in nitrogen removal. Think of them as two parts of a bacterial relay race aimed at converting harmful ammonia into harmless nitrogen gas.

- Nitrification: This is an aerobic (oxygen-requiring) process where ammonia (NH3) is oxidized to nitrite (NO2–) by ammonia-oxidizing bacteria (AOB), and then nitrite is further oxidized to nitrate (NO3–) by nitrite-oxidizing bacteria (NOB). This can be represented as:

NH3 + O2 → NO2- → NO3-- Denitrification: This is an anaerobic (oxygen-free) process where nitrate (NO3–) is reduced to nitrogen gas (N2) by denitrifying bacteria. This requires an electron donor, often organic carbon, and the absence of oxygen. The reaction can be simplified as:

NO3- → NO2- → NO → N2O → N2These two stages are often performed in separate zones within a wastewater treatment system to optimize conditions for each process. For instance, a typical activated sludge system might have an aeration tank (high DO for nitrification) followed by an anoxic tank (low DO for denitrification).

Imagine a factory where ammonia is a dangerous waste product. Nitrification is like the first assembly line that transforms ammonia into a less harmful intermediate (nitrate). Denitrification is the second line that then converts that intermediate into completely harmless nitrogen gas, which is then released into the atmosphere.

Q 10. How do you monitor and control the nutrient removal process?

Monitoring and controlling nutrient removal is critical for maintaining treatment plant efficiency and effluent quality. This involves a combination of online monitoring, regular laboratory analysis, and process adjustments.

- Online Monitoring: Sensors continuously measure key parameters like dissolved oxygen (DO), pH, and nitrate concentration. This provides real-time data that allows operators to quickly respond to process changes.

- Laboratory Analysis: Regular laboratory tests verify online sensor readings and provide a more detailed assessment of effluent quality, including total nitrogen, total phosphorus, and other parameters.

- Process Control: Based on monitoring data, operators adjust process parameters such as aeration rate (affecting DO), return activated sludge (RAS) rate, and the addition of chemicals (e.g., carbon source for denitrification). Advanced control systems, like Supervisory Control and Data Acquisition (SCADA) systems, can automate many aspects of the process control.

For instance, if online DO sensors show a drop in oxygen levels, the aeration rate can be increased to stimulate nitrification. Similarly, if nitrate levels are consistently high, the addition of a carbon source could be increased to enhance denitrification.

Q 11. What are the key parameters to monitor in nutrient removal?

Key parameters to monitor in nutrient removal processes include:

- Dissolved Oxygen (DO): Crucial for nitrification.

- Nitrate (NO3–) and Nitrite (NO2–): Indicate the efficiency of nitrification.

- Ammonia (NH3): Indicates the effectiveness of nitrification and the amount of nitrogen remaining to be treated.

- Total Kjeldahl Nitrogen (TKN): Measures the total nitrogen content in the wastewater.

- Total Nitrogen (TN): Measures all forms of nitrogen, including organic and inorganic forms.

- Orthophosphate (PO43-): Key indicator for phosphorus removal, often monitored alongside nitrogen.

- pH: Impacts microbial activity and chemical processes.

- Alkalinity: Important for maintaining the pH during nitrification.

- Mixed Liquor Suspended Solids (MLSS): Represents the concentration of biomass in the activated sludge system.

- Solids Retention Time (SRT): Impacts the microbial community and influences nutrient removal efficiency.

Monitoring these parameters allows for timely identification of any problems and enables the operators to make necessary adjustments to optimize the process.

Q 12. How do you troubleshoot problems in nutrient removal processes?

Troubleshooting nutrient removal problems requires a systematic approach. It starts with analyzing the monitoring data to identify the specific issue.

- Low Nitrification: Check DO levels, pH, temperature, and ammonia concentration. Low DO points to insufficient aeration, while low pH might indicate a need for alkalinity adjustment. Low temperature can slow down microbial activity.

- Low Denitrification: Ensure sufficient organic carbon source, check for oxygen intrusion into the anoxic zone, and verify suitable pH and temperature conditions.

- High Effluent Nitrogen: Investigate nitrification and denitrification efficiencies. Check for bypasses or short-circuiting in the reactor.

- Poor Phosphorus Removal: Examine chemical dosing strategies if chemical phosphorus removal is implemented, or look at the SRT and MLSS in biological phosphorus removal systems.

Once the problem is identified, corrective actions can be taken. This might involve adjusting process parameters, adding chemicals, or even investigating mechanical issues within the treatment plant. A detailed history of the plant’s operation is always valuable for tracking down the root cause. For example, a sudden increase in effluent ammonia may be due to a malfunction in the aeration system. A slow decline in denitrification could signal a depletion of the carbon source.

Q 13. Explain the significance of solids retention time (SRT) in nutrient removal.

Solids Retention Time (SRT) is the average time that activated sludge biomass remains in the system. It’s a crucial parameter in nutrient removal because it directly impacts the growth and activity of the microorganisms responsible for nitrification and denitrification.

A longer SRT allows the development of a more robust microbial population capable of efficient nutrient removal. This is because longer SRT promotes the growth of slow-growing nitrifying bacteria, which are essential for complete nitrogen removal. However, excessively long SRTs can lead to sludge bulking and other operational issues.

Conversely, a shorter SRT might lead to a less diverse microbial community and reduced nutrient removal efficiency, as the system might not be able to sustain sufficient biomass for optimal nitrification and denitrification. Finding the optimal SRT is critical for efficient and stable operation; it’s often determined experimentally for each specific wastewater and treatment system.

Think of SRT like the amount of time employees spend at a company. A longer SRT is like having experienced, highly skilled workers who are experts at their tasks. A shorter SRT might mean many new employees, lacking in experience, resulting in a less productive team.

Q 14. What is the role of dissolved oxygen (DO) in nutrient removal?

Dissolved oxygen (DO) plays a critical role in nutrient removal, primarily in nitrification. Nitrifying bacteria require oxygen to oxidize ammonia to nitrate. Therefore, maintaining sufficient DO levels in the aeration tank is crucial for efficient nitrification.

The required DO concentration is typically between 2-4 mg/L; however, this can vary depending on several factors including temperature, influent ammonia concentration, and the microbial community. Insufficient DO will significantly reduce nitrification efficiency, resulting in higher ammonia concentrations in the effluent.

In contrast, denitrification, the second part of the nitrogen removal process, requires anaerobic conditions (low or no DO). The absence of oxygen allows denitrifying bacteria to use nitrate as an electron acceptor, reducing it to nitrogen gas. The presence of oxygen in the anoxic zone can inhibit denitrification.

Precise control of DO is essential for optimizing both nitrification and denitrification within a biological nutrient removal system. It’s a delicate balancing act: sufficient DO in the aerobic zone, and a lack of DO in the anoxic zone. This control often involves careful monitoring and adjustments to the aeration system and process flow.

Q 15. How do you manage sludge production in nutrient removal processes?

Sludge management is a critical aspect of nutrient removal, as these processes inevitably generate significant amounts of solids. Effective management minimizes environmental impact and operational costs. Think of it like cleaning your house – you generate waste (sludge), and you need a plan to dispose of it properly.

- Thickening: Before further treatment, sludge is thickened to reduce its volume and improve handling. This often involves gravity thickening or mechanical methods like centrifugation.

- Anaerobic Digestion: This biological process breaks down organic matter in the sludge, reducing its volume and producing biogas, a renewable energy source. It’s like composting on a large scale, turning waste into usable energy.

- Dehydration: Further volume reduction is achieved through dewatering, using methods like belt presses or centrifuges to remove excess water. This makes sludge easier and cheaper to transport and dispose of.

- Disposal: Final disposal options include land application (as fertilizer, after stringent testing), incineration, or landfilling. The choice depends on local regulations and environmental considerations.

For example, a wastewater treatment plant might use anaerobic digestion to reduce sludge volume by 50%, generating biogas to power part of the plant’s operations. The remaining dewatered sludge could then be land-applied as a soil amendment after meeting stringent regulatory requirements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Discuss the energy consumption aspects of various nutrient removal technologies.

Energy consumption is a major factor in the cost-effectiveness and environmental footprint of nutrient removal. Different technologies have varying energy demands. Imagine comparing the energy needed to wash dishes by hand versus using a dishwasher – both achieve the same goal, but with different energy footprints.

- Activated Sludge: This traditional method requires energy for aeration (adding oxygen) to support microbial activity. Energy consumption is significant and depends on the aeration system’s efficiency and the plant’s oxygen demand.

- Membrane Bioreactors (MBRs): MBRs combine biological treatment with membrane filtration. While efficient for nutrient removal, they demand substantial energy for membrane operation, including pumping and cleaning.

- Anaerobic Digestion: While producing biogas that can offset energy needs, anaerobic digestion still requires energy for mixing and heating the digester, and potentially for biogas upgrading.

- Chemical Precipitation: This method uses chemicals to remove nutrients. Although it can be energy-efficient in terms of aeration, it necessitates energy for chemical production, transportation, and handling.

Optimizing energy use involves selecting appropriate technologies, implementing energy-efficient equipment, and recovering energy from byproducts like biogas. For example, a plant might choose low-energy aeration systems and optimize the aeration process using advanced control strategies.

Q 17. What are the costs associated with different nutrient removal methods?

Costs vary widely depending on the chosen technology, plant size, and local conditions. Think of building a house – materials, labor, and location significantly impact the overall price.

- Capital Costs: These include the initial investment in infrastructure, equipment (reactors, pumps, membranes), and land. MBRs, for example, typically have higher capital costs than activated sludge systems due to the membrane modules.

- Operational Costs: These cover energy, chemicals, labor, maintenance, and sludge disposal. Energy-intensive processes like MBRs have higher operational costs, but they may be offset by reduced sludge production.

- Chemical Costs: Methods using chemical precipitation, like struvite recovery, incur costs for purchasing and handling chemicals. The cost fluctuates based on market prices.

A life-cycle cost analysis, which considers both capital and operational costs over the system’s lifespan, is essential for informed decision-making. For instance, a smaller plant might opt for a simpler, less expensive activated sludge system, whereas a larger facility with stricter discharge limits might invest in a more advanced, but potentially more costly, MBR system.

Q 18. Describe the environmental impacts of nutrient removal technologies.

Environmental impacts are multifaceted and need careful consideration. The goal is to minimize negative effects while achieving effective nutrient removal. Just like any construction project, there are potential environmental consequences that must be mitigated.

- Greenhouse Gas Emissions: Energy consumption contributes to greenhouse gas emissions. Anaerobic digestion can reduce this impact by producing biogas, but it’s still crucial to optimize energy efficiency.

- Chemical Use: Chemical precipitation methods release chemicals into the environment, requiring careful management to minimize their impact on aquatic life and soil quality.

- Sludge Disposal: Improper sludge management can lead to soil and water contamination. Sustainable disposal methods, such as anaerobic digestion and responsible land application, are crucial.

- Water Consumption: Some processes, especially those involving membrane filtration, require significant water for cleaning and backwashing.

Life cycle assessments (LCAs) evaluate the overall environmental impacts of different nutrient removal technologies throughout their entire life cycle, from raw material extraction to final disposal. This helps identify hotspots and guide the selection of the most environmentally sound option.

Q 19. Explain the regulations related to nutrient discharge limits.

Regulations concerning nutrient discharge limits vary significantly depending on location and receiving water body quality. These regulations are designed to protect water bodies from eutrophication (excessive nutrient enrichment) which can lead to algal blooms and oxygen depletion.

Many countries and regions have established stringent limits for nitrogen and phosphorus discharge from wastewater treatment plants. These limits are often expressed in milligrams per liter (mg/L) or kilograms per day (kg/day). For example, a specific regulation might set a limit of 10 mg/L for total nitrogen and 1 mg/L for total phosphorus. Non-compliance can lead to penalties and legal actions.

Agencies like the Environmental Protection Agency (EPA) in the United States or equivalent bodies in other countries set and enforce these discharge permits. Regular monitoring and reporting are required to ensure compliance. The specific limits depend on factors such as the receiving water body’s sensitivity, its current water quality, and the overall goals of water quality management in the area.

Q 20. How do you design a nutrient removal system for a specific application?

Designing a nutrient removal system requires a systematic approach tailored to the specific application. Imagine designing a custom-built wardrobe – you wouldn’t use the same design for a small closet as you would for a large walk-in wardrobe.

- Characterize the Wastewater: Analyze wastewater characteristics, including flow rate, nutrient concentrations (nitrogen and phosphorus), and other pollutants.

- Define Objectives: Specify the required nutrient removal efficiency, taking into account discharge limits and receiving water quality standards.

- Select Technology: Choose appropriate technologies based on the wastewater characteristics, desired efficiency, budget, energy availability, and space constraints. Consider factors like activated sludge, MBRs, or combinations of processes.

- Design the System: Develop a detailed design, including reactor sizing, aeration system selection, sludge management strategies, and instrumentation.

- Pilot Testing: Conduct pilot-scale testing to validate the design and optimize performance before full-scale implementation.

- Commissioning and Operation: Implement the system, train operators, and establish monitoring procedures to ensure efficient and reliable operation.

For example, a system for a small community might utilize a simplified activated sludge process, whereas a large industrial facility with high nutrient loads and stringent discharge requirements might require a multi-stage process incorporating advanced technologies like membrane filtration or chemical precipitation.

Q 21. What are the advanced nutrient removal techniques?

Advanced nutrient removal techniques aim to achieve higher removal efficiencies and recover valuable resources. Think of these as advanced cleaning solutions beyond basic washing – they focus on specific tasks and enhance overall results.

- Enhanced Biological Phosphorus Removal (EBPR): Uses specific microorganisms to achieve high phosphorus removal efficiencies.

- Anaerobic Ammonium Oxidation (ANAMMOX): A biological process that converts ammonium to nitrogen gas without the need for external oxygen, saving energy and reducing emissions.

- Struvite Recovery: Precipitates phosphorus as struvite, a valuable fertilizer, reducing sludge production and recovering resources. This is like recycling valuable components instead of disposing of them as waste.

- Membrane Bioreactors (MBRs): Combine biological treatment with membrane filtration, achieving high nutrient removal and effluent quality.

- Electrochemical Treatment: Uses electrochemical methods to remove nutrients, offering high removal efficiency but potentially requiring higher energy input.

The choice of advanced techniques depends on several factors, including the specific nutrient removal goals, wastewater characteristics, cost considerations, and environmental impact. For instance, ANAMMOX can be a highly energy-efficient solution for nitrogen removal in wastewater with high ammonium concentrations.

Q 22. Describe your experience with different types of filtration systems.

My experience spans a wide range of filtration systems used in nutrient removal, from conventional methods to advanced technologies. I’ve worked extensively with:

- Sand filtration: A fundamental process, effective for removing suspended solids, but requiring careful management for optimal nutrient removal. I’ve optimized sand filter backwashing schedules in municipal wastewater treatment plants to enhance nutrient removal efficiency. For instance, adjusting the backwash intensity and frequency to effectively remove accumulated phosphorus and nitrogen-laden biomass.

- Membrane filtration (microfiltration, ultrafiltration, nanofiltration): These systems offer superior removal of suspended solids and dissolved organic matter, influencing nutrient removal indirectly by improving the performance of downstream biological processes. In one project, we used ultrafiltration to pre-treat wastewater before tertiary biological treatment, significantly improving the removal of dissolved phosphorus.

- Biological filtration (activated sludge, trickling filters, rotating biological contactors): These are crucial for biological nutrient removal, relying on microbial communities to break down nitrogen and phosphorus. I have experience designing and optimizing these systems, including adjusting aeration rates and sludge retention times to optimize nutrient removal. For example, I optimized the dissolved oxygen levels in an activated sludge system to maximize nitrification and denitrification rates, resulting in a significant reduction in nitrogen discharge.

My expertise also extends to advanced oxidation processes (AOPs) which can be integrated with these systems to enhance nutrient removal.

Q 23. How do you ensure the efficiency and reliability of nutrient removal systems?

Ensuring efficiency and reliability in nutrient removal systems requires a multi-faceted approach focusing on both operational and design aspects.

- Regular monitoring and maintenance: This includes frequent analysis of influent and effluent water quality, regular cleaning or replacement of filter media, and timely inspection of equipment to prevent malfunctions. This is akin to regular check-ups on a car – preventing small issues from becoming major problems.

- Process optimization: Fine-tuning operational parameters like aeration rates, sludge retention time (SRT), and chemical dosages is critical. Using data analytics to identify trends and optimize these parameters is crucial. For example, I’ve used statistical process control (SPC) charts to track key performance indicators (KPIs) and proactively address potential issues.

- Redundancy and backup systems: Incorporating backup systems can mitigate the risk of system failures. For example, having a standby pump or generator ensures continuous operation, preventing major disruptions in nutrient removal.

- Proper design and sizing: The system must be appropriately sized to handle the expected wastewater flow and nutrient load. An undersized system is doomed to fail. I’ve leveraged hydraulic and biological modeling software to ensure optimal design.

Finally, having a well-trained operational team is paramount. Regular training and effective troubleshooting procedures are essential to ensure optimal performance.

Q 24. Discuss your experience with process control and automation in water treatment.

My experience with process control and automation in water treatment is extensive. I’ve worked with Supervisory Control and Data Acquisition (SCADA) systems and programmable logic controllers (PLCs) to automate various aspects of nutrient removal processes.

For instance, I’ve designed automated systems to control chemical dosing based on real-time monitoring of nutrient concentrations. This not only optimizes nutrient removal but also reduces chemical consumption and operating costs. Imagine a thermostat controlling your house’s temperature; similarly, automated systems control the water treatment process to maintain optimal conditions.

I’ve also utilized advanced process control strategies such as model predictive control (MPC) to optimize the overall performance of treatment plants, predicting future conditions and proactively adjusting operational parameters to prevent upsets.

Furthermore, I have experience implementing data historian systems to collect and store process data, enabling detailed analysis and historical trend identification. This data is invaluable for optimization, troubleshooting, and regulatory compliance.

Q 25. What software and tools are you familiar with for modeling and simulating nutrient removal processes?

I am proficient in several software packages for modeling and simulating nutrient removal processes. My experience includes:

- Biowin: A widely used software for modeling activated sludge processes and optimizing nutrient removal strategies.

- GPS-X: A powerful tool for simulating various water treatment processes, including advanced oxidation processes and membrane filtration.

- MATLAB/Simulink: I use these platforms for developing custom models and simulations, often tailoring them to specific site conditions and operational scenarios. For example, I’ve developed a Simulink model to optimize the control strategy of an AOP system for enhanced phosphorus removal.

These tools are crucial for design optimization, troubleshooting, and process improvement, allowing for virtual testing before implementation.

Q 26. Explain your experience with data analysis and interpretation in the context of nutrient removal.

Data analysis is the cornerstone of effective nutrient removal management. I use various statistical methods and data visualization techniques to interpret data from water quality monitoring, process sensors, and laboratory analyses.

My work often involves:

- Statistical process control (SPC): Tracking key performance indicators (KPIs) like effluent nutrient concentrations and identifying trends to proactively address potential issues.

- Regression analysis: Establishing relationships between operational parameters (e.g., aeration rate, SRT) and nutrient removal efficiency. This helps to optimize these parameters for better performance.

- Multivariate analysis: Analyzing complex datasets to identify underlying patterns and correlations between various factors affecting nutrient removal.

Data visualization tools like Tableau and Power BI are regularly used to present findings in a clear and understandable manner, enabling effective communication with stakeholders and facilitating informed decision-making. For instance, I’ve used these tools to demonstrate the impact of process changes on nutrient removal efficiency to plant management.

Q 27. How do you stay up-to-date with the latest advancements in nutrient removal technologies?

Staying abreast of the latest advancements is crucial in this rapidly evolving field. I achieve this through several avenues:

- Professional organizations: Active participation in organizations like the Water Environment Federation (WEF) and attending conferences and workshops.

- Peer-reviewed publications: Regularly reading scientific journals and technical publications to keep updated on new research and technologies.

- Industry events and webinars: Attending industry conferences and webinars to learn about new products and technologies.

- Collaboration and networking: Networking with colleagues and experts in the field and participating in collaborative research projects.

Continuous learning is a vital aspect of my role, ensuring I apply the most efficient and effective nutrient removal strategies.

Q 28. Describe a situation where you had to troubleshoot a problem related to nutrient removal.

During a project involving an activated sludge plant, we experienced a sudden increase in effluent ammonia levels. Initial investigations revealed no major equipment malfunctions.

Our troubleshooting approach followed a systematic procedure:

- Data review: We meticulously analyzed operational data, including influent characteristics, aeration rates, sludge age, and dissolved oxygen levels, to identify any unusual patterns.

- Laboratory analysis: We conducted extensive laboratory tests on the activated sludge to assess microbial community composition and activity.

- Process simulations: Using Biowin, we simulated different operational scenarios to identify the most likely cause of the ammonia rise.

The root cause was eventually identified as a shift in the microbial community composition due to a change in influent characteristics, leading to inhibited nitrification. By adjusting the SRT and optimizing aeration strategies, we were able to restore normal ammonia removal levels, demonstrating the importance of data-driven decision-making and a thorough understanding of biological processes.

Key Topics to Learn for Nutrient Removal Technologies Interview

- Biological Nutrient Removal (BNR): Understand the underlying microbial processes (nitrification, denitrification, phosphorus uptake) and their operational parameters. Explore different BNR configurations (e.g., A2O, UCT).

- Chemical Precipitation: Learn about the chemical principles involved in phosphate removal using chemicals like ferric chloride or alum. Consider the impact on sludge production and the overall treatment process.

- Membrane Bioreactors (MBR): Familiarize yourself with the integration of membrane filtration in wastewater treatment for enhanced nutrient removal and effluent quality. Understand the advantages and disadvantages compared to conventional activated sludge systems.

- Advanced Oxidation Processes (AOPs): Explore various AOP techniques like UV/H2O2 and ozone for removing recalcitrant pollutants and improving overall effluent quality. Understand their application in nutrient removal processes.

- Nutrient Removal Modeling and Design: Grasp the fundamental principles of designing and modeling nutrient removal processes. Be prepared to discuss different process simulation tools and their applications.

- Sludge Management: Understand the implications of nutrient removal processes on sludge characteristics and the subsequent management strategies (e.g., anaerobic digestion, dewatering).

- Regulations and Compliance: Be familiar with relevant environmental regulations and effluent discharge limits related to nitrogen and phosphorus. Understand how nutrient removal technologies contribute to compliance.

- Case Studies and Practical Applications: Review successful implementations of nutrient removal technologies in various settings (municipal, industrial). Analyze the challenges and successes in real-world applications.

- Troubleshooting and Optimization: Understand common operational problems associated with nutrient removal systems (e.g., poor nitrification, bulking sludge) and strategies for optimization and troubleshooting.

Next Steps

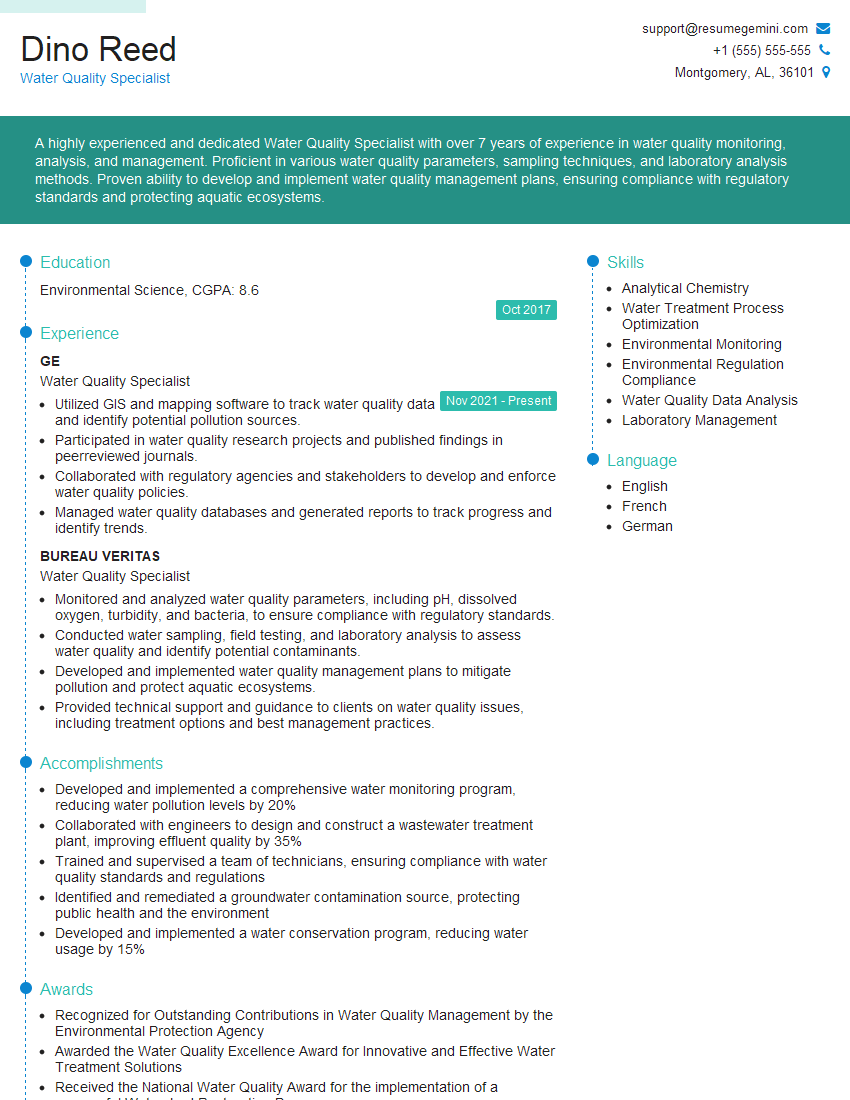

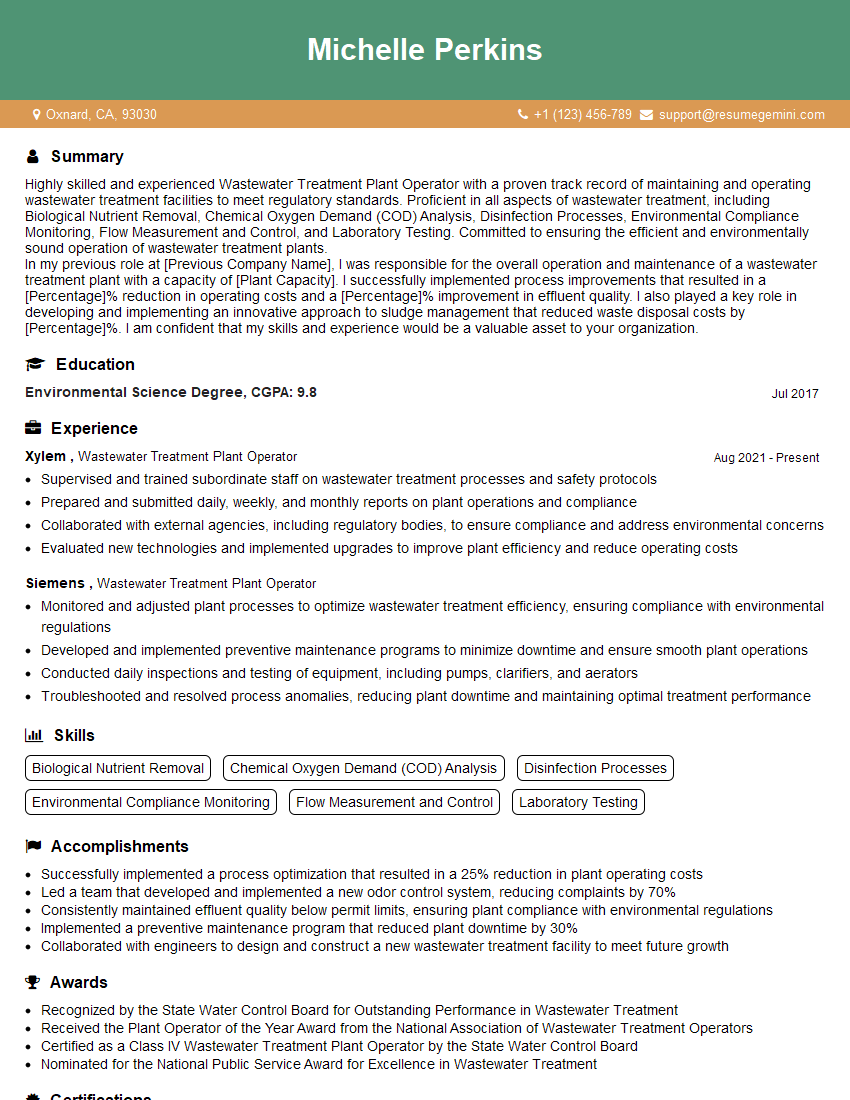

Mastering Nutrient Removal Technologies significantly enhances your career prospects in the environmental engineering and water treatment sectors. A strong understanding of these technologies opens doors to exciting roles with increasing responsibility and higher compensation. To maximize your job search success, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the specific requirements of Nutrient Removal Technologies roles. Examples of resumes specifically designed for this field are available to guide you. Invest the time in crafting a professional resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.