The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Oil Tanker and Storage Operations interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Oil Tanker and Storage Operations Interview

Q 1. Explain the different types of oil tankers and their applications.

Oil tankers are classified primarily by size and the type of cargo they carry. Think of them as specialized trucks for transporting oil across vast distances.

- Very Large Crude Carriers (VLCCs): These are the giants, carrying upwards of 2 million barrels of crude oil. They’re mainly used for long-haul transport between oil-producing regions and refineries.

- Ultra Large Crude Carriers (ULCCs): Even larger than VLCCs, exceeding 2 million barrels capacity. Their sheer size necessitates careful planning for port access and docking.

- Suezmax Tankers: Named for their ability to transit the Suez Canal, they carry around 1 million barrels. They represent a good balance between capacity and maneuverability.

- Aframax Tankers: Slightly smaller than Suezmax, these are frequently used for shorter-haul transport and are more adaptable to different port sizes.

- Panamax Tankers: Sized to transit the Panama Canal, they are useful for inter-oceanic transport and have a more versatile application.

- Product Tankers: Unlike crude carriers, these transport refined petroleum products like gasoline, diesel, and jet fuel. They often have numerous smaller tanks to segregate different products.

The choice of tanker type depends on the volume, type of oil, and the distance between the origin and destination. For instance, transporting large quantities of crude oil across the Atlantic would utilize a VLCC or ULCC, whereas smaller quantities of refined products between regional ports might utilize an Aframax or a product tanker.

Q 2. Describe the process of loading and discharging oil from a tanker.

Loading and discharging oil involves several key steps and stringent safety protocols. Imagine it like a highly choreographed dance requiring perfect coordination.

- Pre-loading Checks: Before commencing, the tanker undergoes inspections of its tanks, pipelines, and pumps. This ensures no leaks or obstructions exist.

- Connecting Hoses and Lines: Heavy-duty hoses connect the tanker’s manifold (a series of valves and connections) to the shore pipeline or another vessel.

- Stripping (Discharge): For discharging, the process involves pumping oil from the tanker’s tanks to the shore’s storage facilities or another vessel. Inert gas is often used to prevent explosion hazards.

- Loading: Loading crude oil involves reverse process from stripping. The oil is carefully pumped into the tanker’s tanks while continuously monitoring its level, temperature, and pressure. This process includes using different pipelines for different grades of oil to prevent mixing and contamination.

- Monitoring and Control: Throughout the process, experienced personnel monitor flow rates, pressures, and temperatures, to ensure the process stays within safe parameters.

- Closing Hoses and Lines: Once complete, hoses and lines are disconnected and secured. Final inspections for leaks are performed.

- Documentation: Detailed records are maintained and documented to track the entire process. This paperwork may include weight calculations, cargo quality, and other details, for billing purposes and regulatory compliance.

Throughout this entire process, meticulous attention is paid to prevent spills, explosions, and other safety risks.

Q 3. What are the key safety regulations governing oil tanker operations?

Oil tanker operations are governed by a complex web of international and national regulations aimed at minimizing environmental damage and ensuring the safety of personnel and equipment. Think of these regulations as a global safety net for oil transport.

- International Maritime Organization (IMO) regulations: These cover numerous aspects, including the International Convention for the Prevention of Pollution from Ships (MARPOL), which regulates ballast water management and oil discharge. The Safety of Life at Sea (SOLAS) convention deals with ship construction and safety standards.

- Port State Control: Authorities in ports worldwide have the right to inspect tankers to ensure compliance with international regulations. Non-compliance can lead to detention of the vessel.

- National regulations: Countries often have their own regulations that supplement international rules, often addressing specific local concerns.

- Oil spill response plans: Tankers must have comprehensive plans in place to deal with oil spills, including containment, cleanup, and reporting procedures. These plans are regularly tested and updated.

- Crew training and certification: Oil tanker crews must undergo rigorous training and certification to operate safely and manage emergencies effectively.

Compliance with these regulations is crucial not only for legal reasons but also to minimize risks, prevent accidents, and protect the marine environment.

Q 4. How do you manage cargo segregation and compatibility in oil storage?

Cargo segregation and compatibility are crucial in oil storage to prevent dangerous reactions, contamination, and quality degradation. It’s like organizing a meticulously arranged pantry, keeping incompatible items separate.

Proper segregation depends on the types of oil stored. For example, you wouldn’t want to store highly reactive chemicals near crude oil. The process involves:

- Dedicated Tanks: Different types of crude oil and refined products are stored in separate tanks, preventing cross-contamination.

- Tank Cleaning: Before storing a new type of oil, tanks are thoroughly cleaned and purged to remove any residue from previous contents.

- Incompatible Substances: A critical aspect is preventing the mixing of incompatible products, such as acids and alkalis. These substances could react violently if mixed.

- Monitoring and Inspection: Regular monitoring and inspections of storage tanks help identify potential problems like leaks or contamination early on.

- Data Management: Detailed records are kept on the types and quantities of oil stored in each tank to help manage cargo flow and quality.

Failure to manage cargo segregation can have disastrous consequences, including explosions, environmental damage, and significant financial losses.

Q 5. What are the common causes of oil spills and how can they be prevented?

Oil spills are a significant environmental hazard and can have devastating consequences for marine life and coastal communities. Preventing them requires a multi-layered approach.

- Collisions and Groundings: These are among the most frequent causes. Improved navigation technology, stricter crew training, and traffic management systems help mitigate these risks.

- Equipment Failure: Malfunctioning pumps, valves, and pipelines can lead to leaks. Regular maintenance, inspections, and the use of redundant systems greatly reduce such occurrences.

- Human Error: Negligence, improper handling procedures, and lack of training contribute significantly to spills. Comprehensive training programs and robust safety procedures are critical.

- Hull Defects: Structural damage to the tanker’s hull can result in leaks. Thorough inspections and regular maintenance help detect and rectify such problems.

- Severe Weather: Storms and extreme weather can damage tankers and lead to spills. Improved weather forecasting and proactive measures such as seeking shelter in calmer waters are necessary.

Prevention strategies include rigorous inspections, thorough maintenance, advanced training for personnel, emergency response planning, and robust regulatory frameworks.

Q 6. Explain the role of ballast water management in oil tanker operations.

Ballast water management is crucial in minimizing the spread of invasive species between different aquatic ecosystems. Think of ballast water as the counterweight used to stabilize a ship during transit.

When a tanker discharges cargo at its destination, it takes on ballast water to maintain stability. This ballast water can contain a variety of marine organisms. When the tanker then takes on cargo in a different location, the ballast water is discharged, potentially introducing these foreign species into a new environment.

Effective ballast water management involves:

- Ballast Water Exchange: Replacing ballast water at sea helps reduce the concentration of organisms. This is a commonly used technique.

- Treatment Systems: Advanced treatment systems use filtration, UV radiation, or other methods to kill or remove organisms from ballast water.

- Regulations and Standards: The IMO has set standards for ballast water management to minimize the spread of invasive species.

- Record Keeping: Tankers are required to keep records of their ballast water management activities.

Proper ballast water management is vital to protect the health of the world’s oceans and prevent ecological damage.

Q 7. Describe your experience with cargo handling equipment.

Throughout my career, I’ve worked extensively with various cargo handling equipment, including:

- Cargo Pumps: I’m proficient in operating and maintaining centrifugal pumps, positive displacement pumps, and other types used for loading and discharging oil. Troubleshooting pump malfunctions is a routine part of my work.

- Pipelines and Valves: I possess a deep understanding of pipeline systems, including their layout, pressure and flow control, and emergency shutdown procedures. I have experience working with various valve types, ensuring efficient and safe oil transfer.

- Inert Gas Systems: I’m well-versed in the operation and maintenance of inert gas systems used to prevent explosions by displacing oxygen in tanks. This requires a good grasp of gas handling safety procedures.

- Gauging Systems: I’m familiar with different methods for gauging oil levels and quality in tanks, including electronic sensors and manual methods. Accurate gauging is essential for inventory management and efficient cargo handling.

- Loading Arms and Manifolds: I have experience working with loading arms and manifolds, ensuring safe and efficient connection to shore pipelines or other vessels. This requires awareness of pressure, flow rate, and safety procedures.

My expertise extends beyond mere operation; I also understand preventative maintenance procedures and troubleshooting techniques for these systems, contributing to a safe and efficient workflow.

Q 8. How do you ensure the accuracy of oil inventory measurements?

Accurate oil inventory measurement is crucial for commercial and operational reasons. We use a multi-pronged approach combining sophisticated technology with rigorous procedures. Think of it like a high-stakes accounting system for a very valuable commodity.

Tank gauging: We utilize various methods, including manual gauging (dipsticking), automated tank gauging systems (ATG) that use radar, ultrasonic, or hydrostatic technologies to measure the level of oil in the tanks. These systems provide real-time data, minimizing manual error. ATG data is then processed using software that calculates the volume based on tank geometry.

Calibration and verification: Regular calibration of all gauging equipment is paramount. This involves comparing the readings against known standards, ensuring accuracy. We also perform periodic independent verification of the ATG systems to confirm their reliability.

Temperature correction: Oil expands and contracts with temperature fluctuations. Our systems incorporate temperature compensation to account for these changes and calculate accurate volumes at standard temperatures.

Data reconciliation: We compare the measured inventory with the recorded inflows and outflows (from loading/discharging operations, and any losses) to identify any discrepancies. These discrepancies require investigation to identify sources of error.

Quality Control Procedures: The use of certified labs for sampling and independent analysis further ensures the quality and quantity of the oil reported. This acts as an independent check on the data.

For example, on a recent VLCC (Very Large Crude Carrier) cargo, we identified a small discrepancy between ATG readings and the declared cargo quantity. By analyzing the temperature corrections and recalibrating the ATG system, we resolved the difference, avoiding costly disputes.

Q 9. What are the procedures for handling oil leaks or spills?

Oil leaks and spills are serious environmental and safety hazards, demanding immediate and decisive action. Our procedures follow a strict protocol emphasizing containment, cleanup, and reporting.

Immediate Response: The first step is to isolate the source of the leak, if possible, to prevent further spillage. This might involve closing valves, plugging leaks, or deploying containment booms.

Containment and cleanup: We deploy absorbent materials (booms, pads, etc.) to contain the spill and prevent it from spreading. Specialized cleanup crews are mobilized to remove the spilled oil, using appropriate techniques depending on the environment (land, sea).

Emergency Services: We immediately notify relevant authorities (Coast Guard, environmental agencies) according to the established emergency response plans and relevant regulations. This is critical for compliance and effective large-scale response.

Environmental Impact Assessment: Once the immediate threat is controlled, a thorough environmental impact assessment is conducted to determine the extent of the damage and to plan remediation efforts.

Investigation and Prevention: A thorough investigation is launched to determine the root cause of the spill and implement corrective measures to prevent future occurrences. This could involve inspections of equipment, training of personnel, or upgrading safety systems.

We regularly conduct drills to ensure personnel are familiar with these procedures. For example, during a recent training exercise, we simulated a spill from a storage tank, practicing the deployment of booms and absorbent materials and communicating effectively with emergency services.

Q 10. Explain the importance of maintaining accurate oil tanker logs.

Accurate oil tanker logs are essential for several reasons: legal compliance, operational efficiency, and safety. Think of them as the detailed record of a ship’s journey and its cargo.

Legal Compliance: International maritime regulations (SOLAS, MARPOL, etc.) mandate the maintenance of detailed logs, including cargo details, operations, maintenance, and any incidents. Failure to comply can result in heavy penalties.

Operational Efficiency: Accurate logs allow us to track fuel consumption, cargo movements, and maintenance activities, optimizing operations and reducing costs. This data is used for analysis and improvement.

Safety: Logs provide a crucial record for investigating accidents or incidents, identifying patterns, and implementing preventive measures. They serve as evidence in case of disputes.

Auditing and Accountability: Detailed logs are essential for audits, providing transparency and accountability for all operations. They form a record for any investigations required by insurance companies.

For instance, during a recent port state control inspection, the accurate and meticulously maintained logs allowed us to demonstrate compliance with all regulations, preventing any delays or penalties.

Q 11. Describe your experience with marine communication systems.

Proficient communication is vital for safe and efficient oil tanker operations. We utilize a range of marine communication systems, both for internal coordination and external communication.

VHF Radio: This is our primary means of communication for short-range contact with other vessels, harbor authorities, and pilot boats. We use it for reporting positions, requesting assistance, and coordinating maneuvers.

GMDSS (Global Maritime Distress and Safety System): This system ensures global communication, especially in emergencies. It includes satellite communication, enabling communication even in remote areas.

Inmarsat: This satellite-based communication system allows for data transmission, email, and voice communication, vital for coordinating operations across long distances.

AIS (Automatic Identification System): AIS transmits our vessel’s position, course, speed, and other information to other vessels and coastal authorities, enhancing collision avoidance and safety.

Internal Communication Systems: Onboard, we use public address systems, internal telephone networks, and crew communication apps to coordinate tasks and maintain efficient crew communication.

I have extensive experience using all these systems, including troubleshooting and maintenance. For example, during a recent storm, we used Inmarsat to update our shore office about the situation and maintain contact with relevant authorities despite high seas and challenging weather conditions.

Q 12. What are the key aspects of oil tanker stability and trim?

Maintaining the stability and trim of an oil tanker is crucial for safety and operational efficiency. It involves careful management of the cargo and ballast water distribution.

Stability: This refers to the tanker’s ability to remain upright and resist capsizing. Factors affecting stability include the cargo’s weight and distribution, the vessel’s structural characteristics, and environmental conditions (wind, waves).

Trim: This refers to the difference in draft (the depth of the hull below the waterline) between the bow (front) and stern (rear). Proper trim ensures efficient sailing and avoids stress on the hull.

Ballast Water Management: Ballast water is used to maintain stability when the cargo tanks are empty or partially full. Proper management of ballast ensures optimal trim and stability. This also involves managing the environmental impacts of ballast water discharge.

Load Calculations: Prior to loading, detailed load calculations are performed to determine the safe and stable cargo distribution that optimizes trim and avoids exceeding structural limits. These calculations are crucial for safety.

Monitoring Systems: Modern tankers are equipped with sophisticated monitoring systems that provide real-time information on stability and trim, allowing for proactive adjustments.

During a recent voyage, we encountered strong headwinds. Using load calculations and adjusting ballast water distribution, we successfully maintained the stability and optimal trim, ensuring a safe and efficient journey.

Q 13. How do you handle emergencies during oil tanker operations?

Handling emergencies during oil tanker operations requires a well-defined response plan and effective teamwork. Our procedures emphasize swift action, clear communication, and strict adherence to safety protocols.

Emergency Response Plan: We have a comprehensive emergency response plan detailing procedures for various scenarios, including fire, flooding, collisions, and medical emergencies.

Communication: Immediate and clear communication is vital, both internally among the crew and externally with authorities and other vessels.

Emergency Drills: Regular drills and training are crucial to ensure the crew is proficient in emergency procedures. This involves practical exercises and simulations.

Damage Control: Effective damage control measures are crucial to minimize the extent of damage and prevent further escalation. This includes procedures for fire fighting, flooding control, and leak repair.

Post-Incident Investigation: Following an emergency, a thorough investigation is conducted to determine the root cause, identify areas for improvement, and prevent future incidents.

For example, during a simulated fire drill, the crew successfully contained the fire within minutes, demonstrating their training and preparedness.

Q 14. Explain the process of bunkering operations.

Bunkering is the process of transferring fuel oil from a bunker barge or another vessel to an oil tanker. It’s a complex operation requiring precision and adherence to safety regulations.

Pre-bunkering checks: Before bunkering commences, we perform checks on the bunker barge’s documentation, ensuring compliance with quality standards and regulations. We also verify the barge’s stability and the condition of its hoses and connections.

Connection and hoses: Secure connections between the bunker barge and the tanker are crucial. We use high-quality hoses that are thoroughly checked before and after each use.

Fuel quality testing: Samples of the fuel are taken during bunkering for quality testing, ensuring compliance with the specified standards. This prevents contamination and ensures fuel quality.

Flow measurement and quantity reconciliation: The quantity of fuel transferred is meticulously measured using flow meters. The measured quantity is reconciled with the quantity received to ensure accurate accounting.

Post-bunkering checks: After bunkering, we conduct checks on the tanker’s fuel tanks and surrounding areas to ensure there are no leaks or spills.

Documentation: All procedures, measurements, and test results are carefully documented to comply with international standards.

During a recent bunkering operation, we carefully monitored the fuel transfer rates and identified a slight discrepancy in the initial measurements. After re-checking, we resolved the discrepancy, ensuring the accurate quantity transfer and avoiding disputes.

Q 15. What are the different types of oil storage tanks and their characteristics?

Oil storage tanks are categorized based on several factors, including construction material, shape, and capacity. Common types include:

- Aboveground Storage Tanks (ASTs): These are typically cylindrical, constructed from steel, and range from small capacity tanks used for farm fuel storage to massive tanks holding millions of barrels at refinery sites. Their design needs to account for wind loads, thermal expansion, and potential seismic activity. We often see these in various configurations, including single-walled and double-walled tanks for enhanced leak prevention.

- Underground Storage Tanks (USTs): These are commonly used for smaller-scale storage, such as at gas stations or smaller businesses. They are often made of steel or fiberglass and are subject to stricter regulations due to the environmental risks associated with leaks. Regular leak detection monitoring is crucial for these tanks.

- Floating Roof Tanks: Designed for large-scale storage of volatile liquids, a floating roof reduces vapor space, minimizing evaporative losses and fire hazards. The roof floats on the surface of the oil, sealing off the vapor space. These are common in refineries and bulk terminals.

- Horzontal Tanks: These cylindrical tanks, laid on their side, are frequently used for smaller storage volumes and are often seen in industrial settings.

The choice of tank type depends on factors like storage capacity, product type, environmental regulations, and site-specific constraints. For example, a refinery might use a combination of large-capacity floating roof tanks and smaller, horizontal tanks for different intermediate products during the refining process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the structural integrity of oil storage tanks?

Ensuring structural integrity of oil storage tanks is paramount for safety and environmental protection. This involves a multi-faceted approach:

- Regular Inspections: Thorough inspections, both internal and external, are crucial. These include visual checks for corrosion, leaks, and damage, as well as more advanced techniques like ultrasonic testing to detect flaws in the tank walls.

- Proper Design and Construction: Tanks must be designed to meet stringent industry standards and local codes, accounting for factors like soil conditions, seismic activity, and the properties of the stored oil. Quality control during construction is vital.

- Corrosion Prevention: Steel tanks are susceptible to corrosion. Protective coatings and cathodic protection systems are employed to mitigate this. Regular monitoring of the protective systems is essential.

- Maintenance and Repairs: Timely repairs of any detected damage are crucial to prevent escalation. This includes addressing corrosion, fixing leaks, and reinforcing weakened areas.

- Overpressure Protection: Pressure relief valves and other safety devices are necessary to prevent tank rupture from over-pressurization due to thermal expansion or other factors. Regular testing of these safety devices is mandatory.

For example, in my previous role, we implemented a rigorous inspection program that included both scheduled inspections and inspections triggered by events like unusual temperature fluctuations or reported leaks. This proactive approach allowed us to address potential issues before they could escalate into major incidents.

Q 17. Describe your experience with oil pipeline operations.

My experience with oil pipeline operations encompasses various aspects, from pipeline integrity management to operational efficiency and safety protocols. I’ve been involved in:

- Pipeline Integrity Management (PIM): This involves overseeing regular inspections using tools such as in-line inspection (ILI) tools to identify and assess pipeline defects like corrosion or cracks. I’ve helped develop and implement risk-based inspection plans to prioritize maintenance based on the severity and likelihood of failure.

- Operational Control and Monitoring: I’ve worked with SCADA (Supervisory Control and Data Acquisition) systems to monitor pipeline pressure, flow rates, and other critical parameters in real-time, enabling proactive responses to potential issues. This includes managing emergency shutdown procedures in case of leaks or other emergencies.

- Pipeline Maintenance and Repair: I’ve overseen the planning and execution of pipeline maintenance and repair activities, ensuring compliance with safety regulations and minimizing downtime.

- Regulatory Compliance: Oil pipeline operations are heavily regulated. I possess extensive knowledge of relevant safety regulations and have experience in ensuring compliance with these regulations. For instance, I am familiar with the requirements of pipeline integrity management programs outlined by regulatory bodies.

One particular project involved optimizing a pipeline’s operational parameters to improve efficiency and reduce energy consumption while ensuring safety. This involved analyzing flow patterns, pressure profiles, and pump performance data using advanced analytics.

Q 18. How do you monitor and control the temperature of stored oil?

Controlling the temperature of stored oil is crucial to maintain its quality and prevent hazards. Methods include:

- Insulation: Tank insulation helps minimize heat transfer between the stored oil and the ambient environment. Different insulation materials, such as fiberglass or polyurethane foam, are chosen based on the operating temperature range and environmental conditions.

- Heat Tracing: Electrically heated cables wrapped around the tank or pipelines can be used to maintain the oil at a desired temperature, particularly important for preventing wax precipitation in colder climates.

- Cooling Systems: For highly volatile products or in hot climates, cooling systems, such as air or water cooling coils, may be necessary to prevent excessive temperature rise.

- Temperature Monitoring: Multiple temperature sensors inside and outside the tank provide real-time monitoring data. This data helps adjust heating or cooling systems as needed and assists with detecting potential issues such as leaks or equipment malfunctions.

- Tank Design: The tank’s shape and orientation can affect heat transfer. Consideration is given to the tank’s aspect ratio and the surrounding environment during the design stage.

For instance, we might use heat tracing to maintain the temperature of heavy crude oil above its pour point to ensure easy pumping during winter months. A sophisticated control system adjusts the heat tracing based on real-time temperature data from the tank.

Q 19. What are the procedures for conducting routine inspections of oil storage tanks?

Routine inspections of oil storage tanks are critical for preventing accidents and environmental damage. Procedures typically involve:

- External Inspection: Visual examination of the tank exterior for signs of corrosion, leaks, damage, or deterioration of the protective coatings. This may include checking for foundation stability and the condition of surrounding areas.

- Internal Inspection: This is usually more comprehensive and might involve entering the tank (with proper safety precautions) for a visual inspection, or using specialized tools such as robotic cameras or ultrasonic thickness gauges to assess the tank’s interior condition.

- Gauging and Level Measurement: Checking the oil level and ensuring accurate inventory measurements.

- Sampling: Collecting samples of the stored oil for quality control testing to detect contamination or deterioration.

- Testing of Safety Devices: Checking the functionality of pressure relief valves, flame arresters, and other safety devices.

- Documentation: Detailed records of all inspections, including findings, corrective actions, and dates, are meticulously maintained.

A common example is the use of a ‘bottom-scan’ technique during internal inspections, which provides a detailed image of the tank floor, enabling the early detection of corrosion or other defects.

Q 20. Explain the importance of maintaining accurate oil inventory records.

Accurate oil inventory records are vital for several reasons:

- Financial Accounting: Precise inventory tracking is essential for accurate financial reporting. It allows for proper valuation of assets and facilitates timely tax filings. Inaccurate records can lead to significant financial discrepancies.

- Operational Efficiency: Accurate inventory helps optimize storage capacity, scheduling of shipments, and procurement decisions, reducing operational costs.

- Loss Prevention: Regular reconciliation of physical inventory against records can detect discrepancies that may indicate leaks or theft, allowing prompt corrective action.

- Regulatory Compliance: Many regulatory bodies require detailed oil inventory records for environmental protection and security purposes. Non-compliance can result in penalties.

- Supply Chain Management: Accurate inventory allows effective planning and coordination within the supply chain. It helps ensure that there is enough product to meet demand while avoiding unnecessary overstocking.

In practice, we utilize automated tank gauging systems and sophisticated inventory management software to ensure accuracy and track every movement of oil in and out of storage.

Q 21. How do you ensure the environmental compliance of oil storage operations?

Environmental compliance in oil storage operations is paramount. Key strategies include:

- Spill Prevention, Control, and Countermeasure (SPCC) Plans: Developing and implementing detailed SPCC plans that outline procedures for preventing, containing, and cleaning up oil spills.

- Leak Detection and Prevention: Regular leak detection testing, secondary containment systems (e.g., double-walled tanks, sumps), and diligent maintenance of tanks and pipelines are crucial.

- Vapor Recovery Systems: Using vapor recovery systems to minimize the emission of volatile organic compounds (VOCs) into the atmosphere.

- Wastewater Management: Implementing appropriate systems for handling and treating wastewater to ensure it meets environmental regulations before discharge.

- Air Quality Monitoring: Monitoring air quality around the storage facility to detect any leaks or emissions of harmful substances.

- Soil and Groundwater Monitoring: Regularly monitoring the soil and groundwater around the storage facility to detect any potential contamination.

- Regulatory Compliance: Maintaining up-to-date knowledge of and strict adherence to all applicable environmental regulations and permits.

For instance, we might use a combination of double-walled tanks, secondary containment berms, and automated leak detection systems to achieve the highest level of environmental protection. Regular soil and groundwater sampling is conducted to verify the effectiveness of these measures.

Q 22. What are the different types of oil tank coatings and their applications?

Oil tank coatings are crucial for protecting tanks from corrosion, chemical degradation, and environmental factors. The choice of coating depends heavily on the type of oil stored and the environmental conditions. Several types exist, each with specific applications:

- Epoxy Coatings: These are widely used due to their excellent chemical resistance, adhesion, and durability. They’re suitable for various oil types but may require specific formulations for high-temperature applications or aggressive chemicals. For example, a modified epoxy coating might be necessary for storing highly acidic crude oil.

- Polyurethane Coatings: Offering good abrasion resistance and flexibility, polyurethane coatings are often used in areas subject to impact or vibration. They are suitable for a wide range of oils but may not be as chemically resistant as epoxy in some cases.

- Vinyl Ester Coatings: Known for their superior chemical resistance and strength, vinyl ester coatings are ideal for storing highly corrosive oils or chemicals. They’re a more expensive option but offer long-term protection.

- Phenolic Coatings: These coatings provide excellent resistance to acids and solvents, making them suitable for specific applications involving highly corrosive oils. They are less commonly used due to their brittle nature compared to other options.

- Coal Tar Epoxy Coatings: This is a more cost-effective option frequently used for underground tanks due to their excellent barrier properties against water and moisture. However, their application is more limited due to their potential environmental concerns.

The selection process involves careful consideration of the oil’s properties (acidity, temperature, viscosity), environmental factors (temperature fluctuations, UV exposure, soil conditions), and cost-benefit analysis. Each project necessitates a detailed specification to ensure the chosen coating provides the required protection.

Q 23. Explain your experience with oil quality control procedures.

Oil quality control is paramount throughout the entire supply chain, from wellhead to refinery. My experience encompasses overseeing procedures including:

- Sampling and Testing: I’ve been involved in the meticulous collection of representative oil samples at various stages, ensuring adherence to strict protocols to avoid contamination. Subsequent lab analysis verifies parameters like density, viscosity, sulfur content, water content, and the presence of impurities using methods like chromatography and spectroscopy. Discrepancies trigger immediate investigation and remedial actions.

- Data Analysis and Reporting: I’m proficient in interpreting lab results and creating detailed reports that highlight any deviations from specifications. This informs decision-making regarding blending, treatment, or rejection of the oil. For instance, detecting high sulfur content necessitates refinery adjustments or potentially diverting the oil to a different processing plant.

- Calibration and Maintenance: I’ve managed the calibration of testing equipment and overseen regular maintenance to ensure accuracy and reliability of results. Regular checks prevent inaccurate measurements that could lead to significant financial losses or quality issues. For instance, a poorly calibrated viscometer could lead to incorrect blending ratios.

- Compliance and Regulations: Throughout my career, I’ve ensured adherence to international and local regulations concerning oil quality, proper documentation, and reporting. This aspect covers safety, environmental protection, and the overall integrity of the oil supply chain.

A real-world example involved a shipment of crude oil where unexpectedly high water content was detected. By thoroughly investigating the sampling and transportation procedures, we discovered a leak in a storage vessel, preventing further contamination and mitigating potential environmental damage.

Q 24. How do you manage risk associated with volatile oil products?

Managing the risks associated with volatile oil products requires a multi-faceted approach emphasizing safety and operational efficiency. Key strategies include:

- Proper Storage and Handling: Volatile oils necessitate specialized storage tanks equipped with pressure relief valves and inert gas blanketing to minimize the risk of explosions or fires. Strict adherence to safety procedures during loading, unloading, and handling is crucial. For example, using vapor recovery systems to capture and recycle hydrocarbon vapors during transfer operations minimizes environmental impact and reduces risk.

- Inventory Management: Real-time inventory monitoring minimizes storage times and reduces the potential for product degradation or loss due to evaporation. Precise inventory control is essential to preventing overfilling or underfilling of storage tanks.

- Temperature Control: Maintaining optimal temperatures is essential for volatile products, preventing excessive vapor pressure buildup. This often involves refrigeration or insulation of storage tanks and pipelines.

- Emergency Response Planning: Comprehensive emergency response plans, including spill control and fire suppression measures, are critical. Regular drills and training sessions equip personnel to respond effectively to potential incidents.

- Risk Assessment and Mitigation: Regular risk assessments identify potential hazards and help in implementing mitigation measures. This is critical to proactively addressing safety vulnerabilities and proactively preventing incidents.

For instance, during the transfer of highly volatile naphtha, implementing a robust vapor recovery system and meticulous monitoring of temperature and pressure significantly mitigated the risks of a vapor cloud explosion.

Q 25. Describe your experience with oil theft prevention measures.

Oil theft is a significant challenge in the industry, requiring a layered security approach. My experience includes:

- Physical Security Measures: This encompasses implementing robust perimeter fencing, access control systems (including biometric authentication), CCTV surveillance, and strategically placed lighting to deter and detect unauthorized access. Regular patrols by security personnel further enhance protection.

- Technological Advancements: Utilizing advanced technologies like GPS tracking of tankers, flow meters with tamper detection, and leak detection systems significantly aids in preventing and detecting theft. Data analytics can help identify suspicious patterns.

- Personnel Vetting and Training: A thorough background check of personnel and rigorous training on security protocols is crucial. This includes awareness of theft techniques and reporting procedures.

- Community Engagement: Collaborating with local communities to foster a culture of vigilance and reporting of suspicious activities helps deter theft.

- Data Analytics and Auditing: Regular reconciliation of inventory records with sales data can reveal discrepancies that may indicate theft. This requires sophisticated systems to track oil movement across the whole chain.

In one instance, the implementation of a GPS tracking system on our tanker fleet revealed a pattern of unusual detours, leading to the successful apprehension of individuals involved in oil theft. The use of data analytics played a key role in identifying this pattern and bringing the perpetrators to justice.

Q 26. What are the best practices for oil terminal security?

Best practices for oil terminal security encompass a comprehensive approach integrating physical, technological, and procedural elements:

- Perimeter Security: Robust fencing, access control gates with security personnel, and CCTV surveillance systems are essential. The use of intrusion detection systems helps promptly alert security personnel of any unauthorized entry attempts.

- Cybersecurity: Protecting the terminal’s control systems and data networks from cyberattacks is paramount. This includes firewalls, intrusion detection systems, and regular security audits to identify and address vulnerabilities. Protecting SCADA systems is critical.

- Personnel Security: Thorough background checks, regular security training, and strict access control procedures for employees and contractors are essential. Clearly defined roles and responsibilities enhance accountability and deter internal threats.

- Emergency Response Planning: Comprehensive plans for handling various security incidents, such as terrorism, sabotage, and theft, are necessary, including emergency drills and training.

- Collaboration and Information Sharing: Collaborating with law enforcement agencies and other terminals to share information on security threats enhances the overall security posture.

A layered security approach, where each layer supports and strengthens the others, provides the most robust protection. Regular security audits and reviews are crucial for identifying and addressing vulnerabilities. For instance, a combination of perimeter fencing, access control cards, and CCTV surveillance, integrated with a central monitoring station, forms an effective first line of defense.

Q 27. How do you handle discrepancies in oil inventory?

Discrepancies in oil inventory can stem from various sources, including measurement errors, theft, evaporation, and product degradation. Handling these discrepancies requires a systematic approach:

- Investigation: Thoroughly investigating the discrepancy is the first step. This includes reviewing tank gauging records, examining loading and unloading procedures, checking for leaks, and investigating potential theft. Data analysis is crucial in pinpointing the source.

- Calibration and Maintenance: Ensuring the accuracy of measurement equipment (level gauges, flow meters) through regular calibration and maintenance is essential. Faulty equipment can lead to significant errors.

- Reconciliation: Reconciling inventory records with sales data and transportation records helps identify discrepancies. This should be a continuous process, not only when a discrepancy is noted.

- Loss Control Measures: Implementing strategies to minimize potential losses, such as regular tank inspections, proper sealing of tanks, and vapor recovery systems, can help reduce future discrepancies.

- Reporting and Documentation: Detailed documentation of the investigation, findings, and corrective actions is crucial for future reference and to prevent recurrence.

For example, a recurring discrepancy in a particular tank might indicate a leak, prompting a thorough inspection and repair. Similarly, unexplained losses could signal potential theft, necessitating an investigation and enhanced security measures.

Q 28. Describe your experience with emergency response planning for oil spills.

Emergency response planning for oil spills is crucial for minimizing environmental damage and protecting human health. My experience includes:

- Spill Prevention: Implementing measures to prevent spills, such as regular inspections of pipelines and storage tanks, using leak detection systems, and adhering to strict operational procedures, is paramount. Regular training to prevent human error is vital.

- Containment and Cleanup: Developing detailed procedures for containing and cleaning up spills of varying sizes, including the use of booms, sorbents, and specialized equipment, is crucial. This includes having access to sufficient cleanup resources readily available.

- Emergency Response Team: Establishing a well-trained and equipped emergency response team is crucial for effective response. This team should include personnel trained in spill response, first aid, and communication.

- Notification and Communication: Having clear protocols for notifying relevant authorities (e.g., coast guard, environmental agencies), stakeholders, and the public in case of a spill is essential. This includes a plan for effective and timely communication.

- Post-Spill Assessment: Conducting a thorough post-spill assessment to identify the cause of the spill, evaluate the effectiveness of the response, and implement preventive measures to prevent future incidents is vital. This should include a root cause analysis.

A well-rehearsed emergency response plan, coupled with regular training, is vital. We conduct annual drills simulating various spill scenarios to ensure our team is ready to respond efficiently and effectively in the event of an emergency. For instance, we practice deploying booms and deploying sorbent materials to contain and remediate spills of different oil types.

Key Topics to Learn for Oil Tanker and Storage Operations Interview

- Cargo Handling and Management: Understanding procedures for loading, unloading, and transferring oil, including safety protocols and documentation requirements. Practical application: Describe your experience with different loading/unloading methods and their associated risks.

- Tanker Operations and Maintenance: Knowledge of vessel systems (ballasting, pumping, inert gas systems), their operation, and preventative maintenance schedules. Practical application: Explain how you would troubleshoot a malfunctioning pump or address a potential cargo contamination issue.

- Safety and Regulations: Familiarity with international maritime regulations (e.g., MARPOL, SOLAS), safety procedures (e.g., emergency response, fire prevention), and risk management strategies. Practical application: Detail your experience with implementing safety protocols and conducting safety audits.

- Storage Terminal Operations: Understanding the processes involved in receiving, storing, and dispatching oil from storage terminals, including inventory management, quality control, and pipeline operations. Practical application: Explain your understanding of different storage tank types and their suitability for various oil products.

- Environmental Protection and Sustainability: Knowledge of environmental regulations, spill prevention and response measures, and sustainable practices within the industry. Practical application: Describe your experience or knowledge of minimizing environmental impact during oil handling and storage.

- Inventory Management and Control: Understanding methods for tracking and managing oil inventories, including using inventory management systems and reconciliation procedures. Practical application: Explain how you would investigate and resolve discrepancies in inventory data.

- Documentation and Reporting: Knowledge of the documentation required for oil tanker and storage operations, including cargo manifests, tank surveys, and incident reports. Practical application: Describe your experience with accurate and timely reporting of operational data.

Next Steps

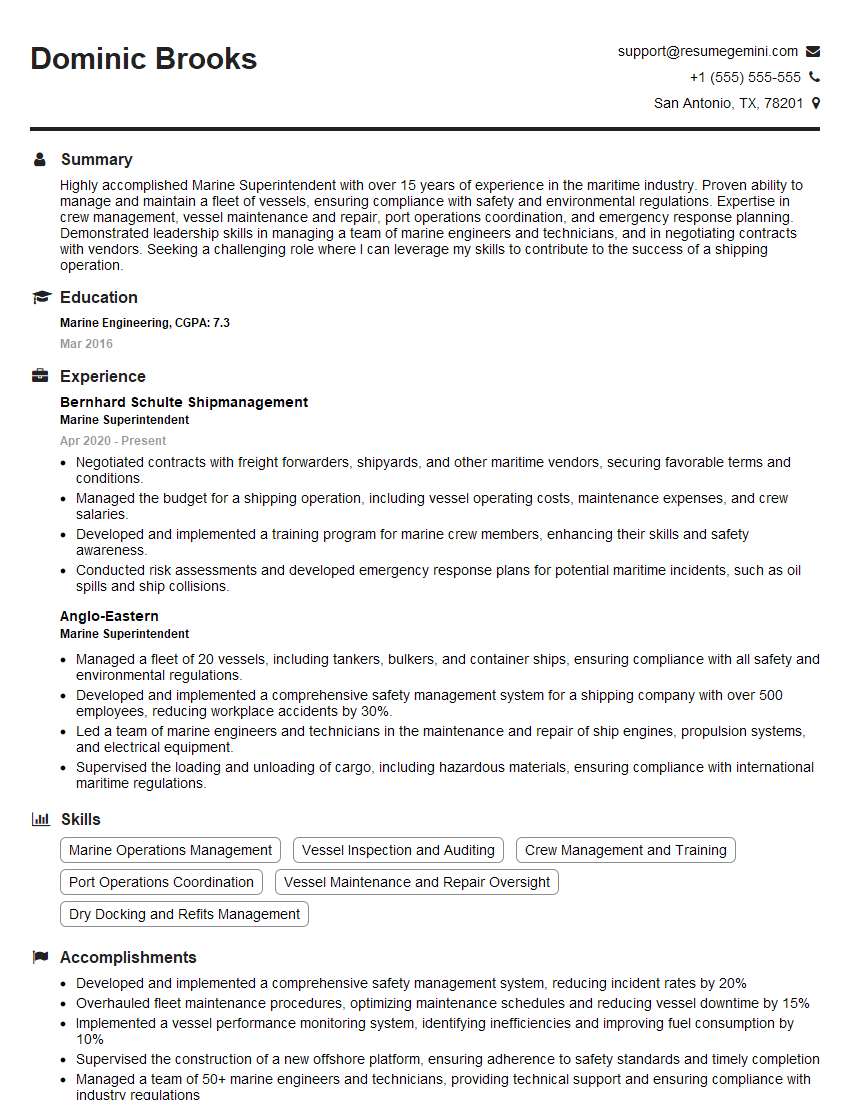

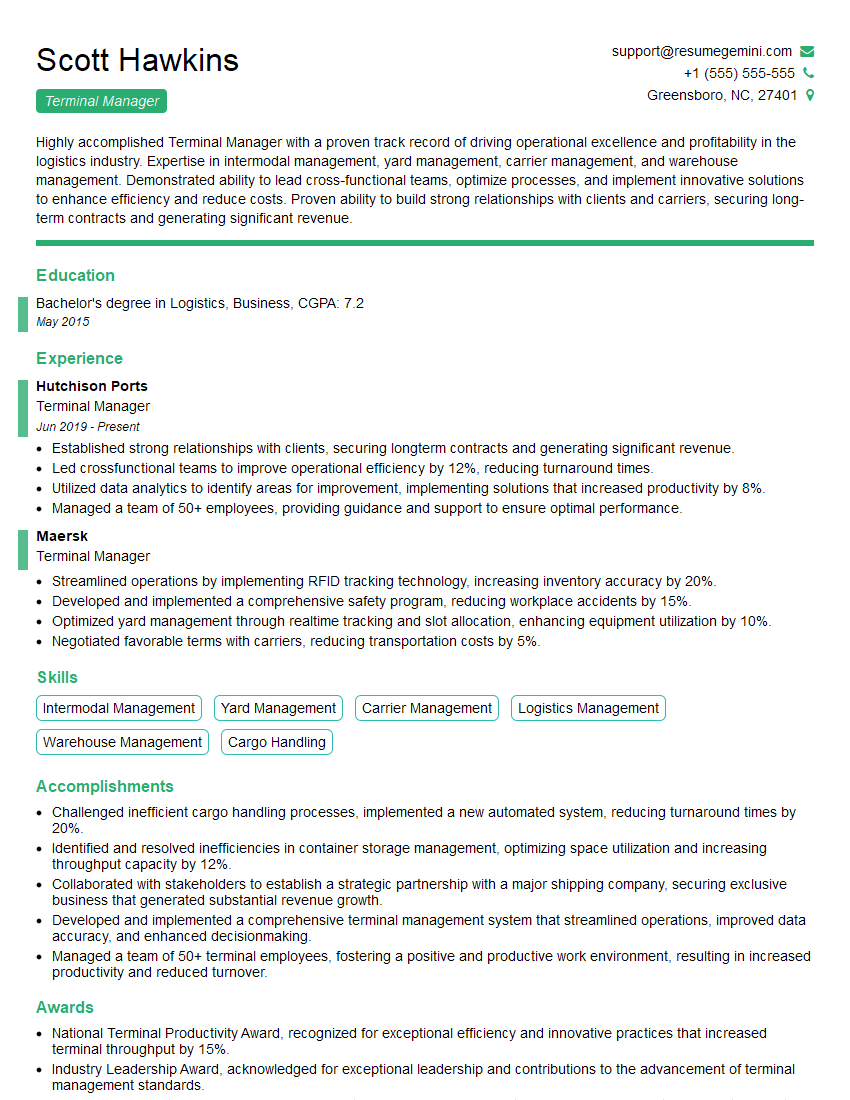

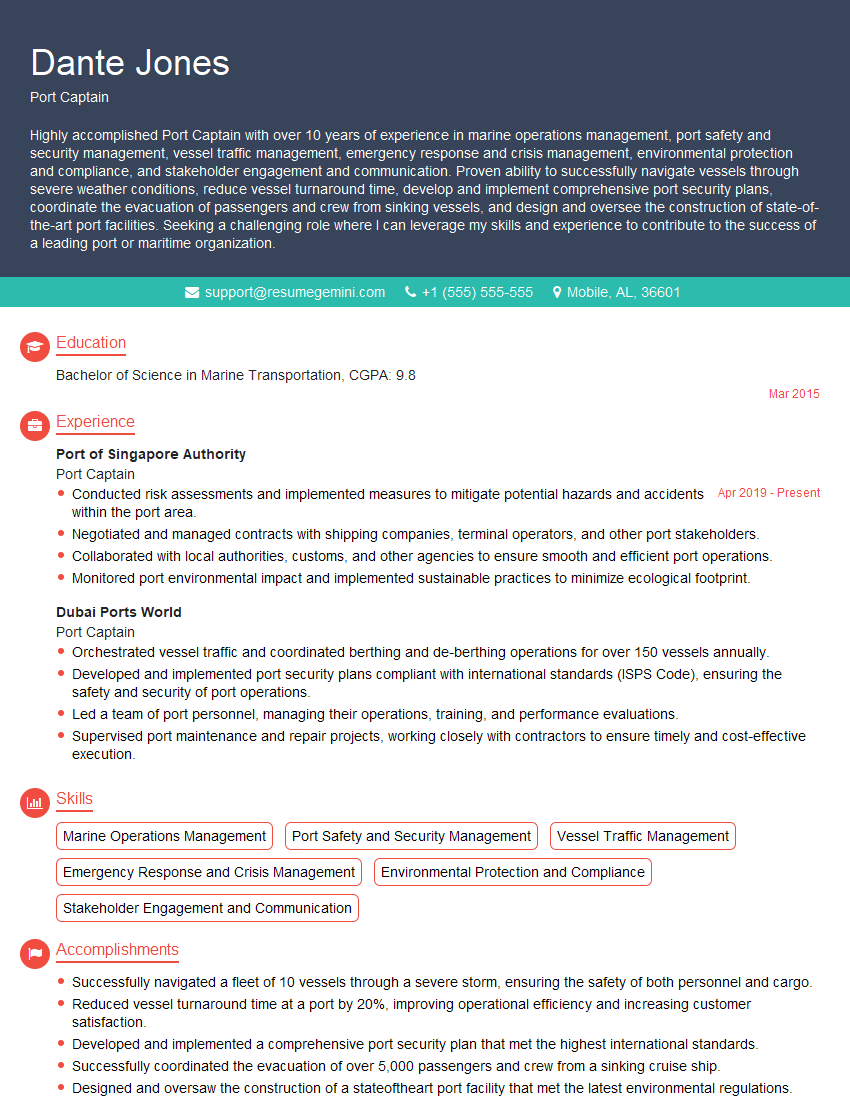

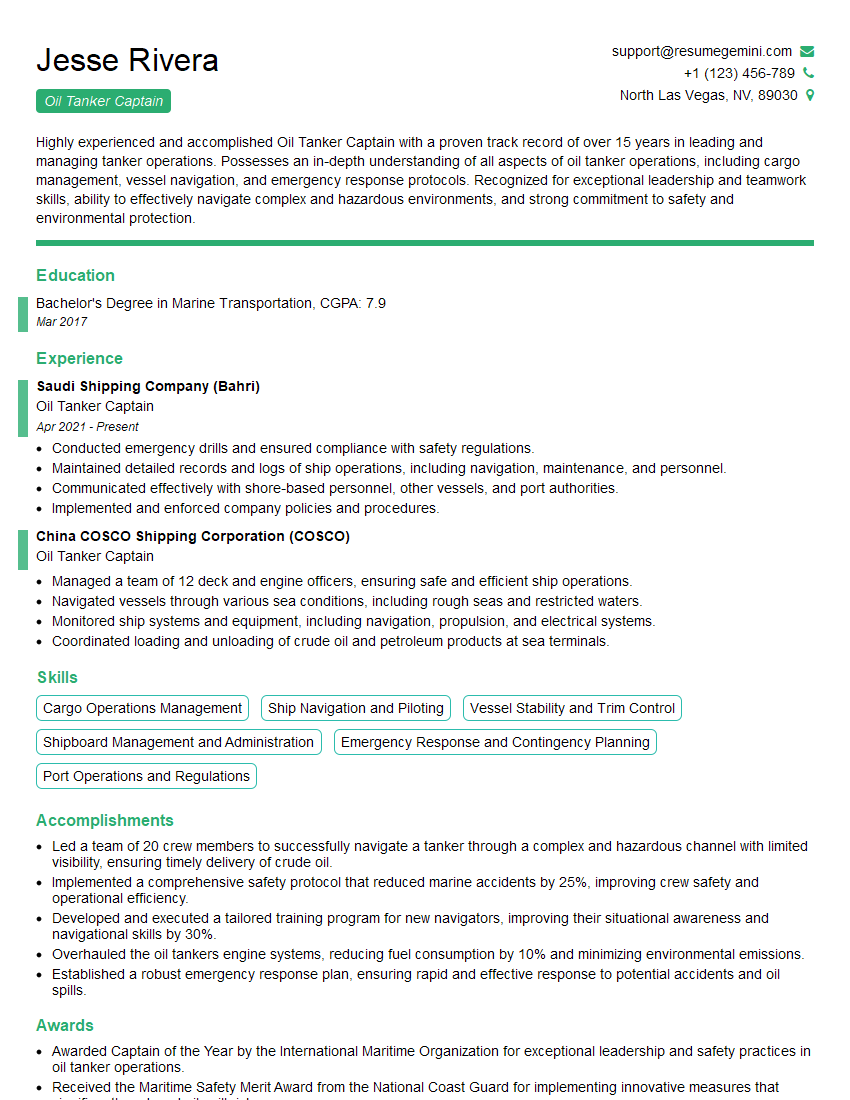

Mastering Oil Tanker and Storage Operations opens doors to rewarding and impactful careers in the energy sector. Demonstrating a strong understanding of these concepts is crucial for securing your dream role. To significantly improve your job prospects, creating an ATS-friendly resume is essential. This ensures your qualifications are effectively highlighted to recruiters and applicant tracking systems. We strongly recommend leveraging ResumeGemini, a trusted resource for crafting professional and impactful resumes. ResumeGemini provides examples of resumes tailored to Oil Tanker and Storage Operations, offering valuable guidance and inspiration to help you present your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.