Are you ready to stand out in your next interview? Understanding and preparing for Operate and calibrate plant instrumentation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Operate and calibrate plant instrumentation Interview

Q 1. Explain the importance of instrument calibration in a process plant.

Accurate instrumentation is the backbone of safe and efficient plant operation. Calibration ensures that the instruments used to measure process variables (temperature, pressure, flow, level, etc.) provide readings that are consistently accurate and reliable. Inaccurate readings can lead to incorrect process control, potential safety hazards, off-spec product, increased production costs, and even equipment damage. Think of it like this: if your car’s speedometer is consistently off by 10 mph, you might underestimate your speed, leading to dangerous situations. Similarly, inaccurate instruments in a plant can lead to serious consequences.

Regular calibration minimizes measurement errors, allowing for precise process control, improved product quality, reduced waste, enhanced safety, and ultimately, optimized plant performance. It’s a crucial part of maintaining compliance with industry standards and regulations.

Q 2. Describe the different types of calibration techniques you are familiar with.

Calibration techniques vary depending on the instrument type, but generally fall into these categories:

- Direct Comparison: This involves comparing the instrument’s reading against a known standard (e.g., comparing a pressure gauge to a calibrated deadweight tester). This is often the most accurate method.

- Indirect Comparison (Calibration via secondary standard): This involves using a secondary standard (already calibrated against a primary standard) to calibrate the instrument. This is suitable when direct comparison is impractical.

- Multi-point Calibration: This is where multiple points across the instrument’s range are calibrated. This method helps to identify non-linearity or drift in the instrument’s response.

- In-situ Calibration: Calibration is performed without removing the instrument from its process connection. This saves time and minimizes process disruption.

- Loop Calibration: This involves verifying the entire instrument loop, including the transmitter, wiring, and control system, to ensure the signal is accurately transmitted and processed.

The choice of technique depends on factors such as the instrument’s accuracy requirements, available resources, and process constraints.

Q 3. How do you identify faulty instrumentation in a process plant?

Identifying faulty instrumentation requires a systematic approach. I typically start with a visual inspection, checking for obvious signs of damage, corrosion, or loose connections. Then, I move on to functional checks:

- Review historical data: Look for unusual trends or anomalies in the instrument’s readings. A sudden jump or consistent drift away from the expected values can signal a problem.

- Compare readings to other instruments: If multiple instruments measure the same process variable, comparing their readings can reveal inconsistencies.

- Check calibration history: Review the calibration records to see if the instrument was recently calibrated and if any issues were noted.

- Perform functional tests: Depending on the instrument type, this may involve applying known inputs and observing the output. For example, for a temperature sensor, I might immerse it in a bath of known temperature and compare the readings.

- Use diagnostic tools: Many modern instruments have built-in diagnostics that can identify potential issues.

Once a fault is identified, I then proceed with troubleshooting and repair or replacement as needed.

Q 4. What are the common causes of instrument drift?

Instrument drift, the gradual change in an instrument’s output over time, can stem from several factors:

- Environmental conditions: Temperature fluctuations, humidity, and vibration can all affect instrument accuracy.

- Aging components: Over time, components within the instrument may wear out or degrade, leading to drift.

- Power supply variations: Inconsistent power supply can affect the performance of electronic instruments.

- Mechanical wear: Moving parts in mechanical instruments are subject to wear and tear.

- Corrosion: Exposure to corrosive substances can degrade internal components.

For example, a temperature sensor might drift due to long-term exposure to high temperatures, leading to inaccurate readings. Addressing these underlying causes is key to minimizing drift and maintaining instrument accuracy.

Q 5. Explain the procedure for calibrating a pressure transmitter.

Calibrating a pressure transmitter involves a series of steps:

- Safety First: Lockout/Tagout procedures must be followed to ensure safety before accessing the instrument and associated equipment.

- Gather equipment: This includes a calibrated pressure source (e.g., a deadweight tester or a calibrated pressure gauge), appropriate fittings, and calibration documentation.

- Prepare the transmitter: Isolate the transmitter from the process line and ensure the power is off if necessary.

- Apply known pressures: Apply a series of known pressures to the transmitter, typically at low, mid-range and high-range points, ensuring that the applied pressure is stable at each step. Note the transmitter’s readings.

- Compare readings: Compare the transmitter’s readings to the known pressures. Calculate the deviation.

- Adjust (if necessary): Many transmitters have adjustments to correct deviations. Adjust the transmitter according to the manufacturer’s instructions to minimize the deviation.

- Verify: Once adjustments are done, repeat steps 4 and 5 to verify calibration.

- Document: Record all calibration data, including date, time, applied pressures, transmitter readings, deviations, and any corrective actions taken.

Calibration of any field instrument should follow the manufacturer’s instructions.

Q 6. How do you troubleshoot a malfunctioning level transmitter?

Troubleshooting a malfunctioning level transmitter is a methodical process. I’d start with:

- Visual inspection: Check for physical damage, loose connections, or signs of corrosion.

- Check power and signal: Verify that the transmitter is receiving power and that the signal is being transmitted correctly to the control system.

- Review historical data: Look for any patterns or anomalies in the level readings.

- Check for obstructions: Ensure that nothing is obstructing the sensor (e.g., build-up, debris).

- Verify calibration: Check the calibration history to see if it’s due for recalibration.

- Check the process: Sometimes, the problem is not with the transmitter itself, but with the process it’s measuring (e.g., unexpected changes in fluid density).

- Loop check: If the problem is in the signal transmission, check the connections and wiring in the loop.

- Use diagnostic tools: Many level transmitters have self-diagnostic capabilities that provide valuable clues about the problem.

Depending on the findings, further investigation might involve replacing components, recalibrating, or even replacing the entire transmitter.

Q 7. Describe your experience with different types of flow meters.

My experience encompasses a range of flow meters, including:

- Differential Pressure Flow Meters (e.g., orifice plates, venturi tubes, flow nozzles): These meters measure the pressure drop across a restriction in the pipe to determine flow rate. They are relatively inexpensive but can have high pressure drops.

- Positive Displacement Flow Meters (e.g., rotary, oval gear, piston): These meters measure flow by trapping a known volume of fluid and counting the number of volumes that pass through. They are highly accurate but can be more expensive and are generally suitable for lower flow rates.

- Turbine Flow Meters: These meters use a rotating turbine to measure the flow rate. They are accurate and have a wide flow range but can be susceptible to wear and tear.

- Ultrasonic Flow Meters (e.g., Doppler, transit-time): These meters use sound waves to measure flow without contacting the fluid. They are non-invasive and are suitable for a variety of fluids but can be sensitive to noise and turbulence.

- Electromagnetic Flow Meters (mag flow): These meters use Faraday’s law of induction to measure the flow rate of conductive fluids. They have no moving parts and are accurate but require the fluid to be conductive.

The selection of the most suitable flow meter depends on the specific application requirements, including fluid properties, flow rate, accuracy requirements, and budget.

Q 8. How do you ensure the accuracy of temperature measurements?

Ensuring accurate temperature measurements involves a multi-faceted approach. It starts with selecting the right sensor for the application – a thermocouple might be ideal for high temperatures, while an RTD (Resistance Temperature Detector) is better suited for precise measurements in a narrower range. Then, proper installation is critical. The sensor needs to be positioned to accurately reflect the temperature of the process, avoiding hot spots or drafts. For example, a temperature sensor measuring the temperature of a liquid stream should be immersed correctly, away from walls and other heat sources or sinks.

Regular calibration is paramount. This involves comparing the sensor’s readings against a known standard, such as a calibrated thermometer or a traceable reference source. We use documented procedures and keep detailed records of these calibrations. Finally, regular maintenance, including cleaning and checking for damage to the sensor or its wiring, helps ensure long-term accuracy. A faulty connection could lead to inaccurate readings. Imagine a loose wire on a thermocouple – the measured temperature would be wildly inaccurate, potentially causing process upsets or safety issues. We often use specialized calibration equipment to verify and fine-tune the instruments.

Q 9. Explain the concept of instrument loop checking.

Instrument loop checking is a systematic procedure to verify the integrity and accuracy of an entire measurement loop. This loop includes the sensor, the transmitter, the wiring, the control system, and the final control element (like a valve). It’s like checking each link in a chain to make sure it’s strong. Think of it as a detective story, where we’re trying to solve the mystery of why an instrument might be giving incorrect readings.

The process typically involves checking each component individually. We’ll start with a visual inspection to check for physical damage or loose connections. Then, we’ll use test equipment to check signals at various points in the loop. For example, we might use a multimeter to verify voltage levels at the transmitter output or use a signal simulator to send known signals through the loop to see how the system responds. We document all the steps and readings. If discrepancies are found, we identify and rectify the faulty component. This ensures that the measurement is reliable and that the control system is operating correctly.

Q 10. What safety precautions do you take when working with plant instrumentation?

Safety is our utmost priority when working with plant instrumentation. Before we start any work, we perform a thorough risk assessment, considering potential hazards like electrical shocks, high-pressure systems, hazardous chemicals, and confined spaces. We always follow the plant’s safety procedures and use appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hard hats. Lockout/Tagout (LOTO) procedures are strictly followed when working on live equipment to prevent accidental energization. We never work alone; a buddy system ensures another person is available for assistance or to call for help in an emergency. We’re also trained to recognize and respond to various emergency situations. For example, we know the location and use of emergency shut-off valves and fire extinguishers. Regular safety training keeps us up-to-date on the latest safety protocols and best practices.

Q 11. How do you document calibration procedures and results?

Calibration procedures and results are meticulously documented using standardized forms and software. This documentation ensures traceability and helps us maintain compliance with regulations. The documentation includes:

- Instrument identification number

- Date and time of calibration

- Calibration procedure used

- Calibration equipment used (including its calibration certificate)

- Calibration points and readings

- Calibration adjustments made

- Calibration technician’s signature and approval

- Any non-conformances and corrective actions taken

This documentation is typically stored in a centralized database or a secure filing system, accessible to authorized personnel. A well-maintained record is crucial not only for compliance but also for identifying trends and potential problems with instruments. A digital system adds efficiency, allowing easy search and retrieval of past records.

Q 12. Describe your experience with using calibration software.

I have extensive experience with various calibration software packages, including Fluke Calibration software and Beamex CMX. These systems are extremely useful for streamlining the calibration process and ensure data integrity. They automate much of the paperwork, track calibration schedules, and generate reports. For example, using Beamex CMX I can electronically manage instrument details, including the device’s location, calibration history, and maintenance schedules. The software also assists in creating calibration certificates that are easily exportable and meet regulatory requirements. It has automated features for calibrating multiple instruments simultaneously, reducing manual effort significantly. The software generates detailed reports, including charts and graphs, which can be used to identify instrument performance trends over time. This makes spotting potential problems easier and allows for preventative maintenance, maximizing instrument lifespan and data accuracy.

Q 13. What are the common standards and regulations related to instrument calibration?

Common standards and regulations governing instrument calibration include ISO 9001 (Quality Management Systems), ISO 17025 (Testing and Calibration Laboratories), and industry-specific standards relevant to the processes involved. For example, in the pharmaceutical industry, we follow stringent GMP (Good Manufacturing Practice) guidelines that mandate precise instrument calibration and thorough documentation. In addition, various national and international standards organizations provide detailed specifications for calibrating specific instruments (e.g., temperature, pressure, flow). Adherence to these standards is crucial for maintaining product quality, safety, and regulatory compliance. Non-compliance can lead to serious consequences, from fines and legal actions to product recalls and reputational damage. These standards offer a framework for creating consistent, accurate measurements across facilities and industries.

Q 14. How do you handle discrepancies found during calibration?

Discrepancies discovered during calibration are handled systematically. First, we verify the discrepancy through repeat measurements, checking for human error or instrument malfunction. If the discrepancy is confirmed, we investigate the root cause. This could involve checking the sensor for damage or contamination, verifying the calibration equipment, or assessing the installation for issues. A thorough investigation is essential before taking any corrective measures. If the problem is with the instrument, it might need repair or replacement. Then, we update the calibration records to reflect the findings, including any corrective actions, and issue a revised calibration certificate if necessary. We also inform the relevant personnel about the discrepancy and any potential impact on the process, ensuring appropriate action is taken to prevent future occurrences. A thorough, documented investigation helps to prevent future errors and ensure that instrument calibration is maintained within acceptable limits.

Q 15. Explain your experience with different types of valves and actuators.

My experience encompasses a wide range of valves and actuators, crucial components in process control. I’m proficient with various valve types, including ball valves (for on/off or throttling), globe valves (ideal for precise flow regulation), butterfly valves (for large flow applications), and control valves (used for precise automated flow control). Actuator types I’ve worked with extensively include pneumatic (air-powered), electric (motor-driven), and hydraulic (liquid-powered) actuators. Each type has its strengths and weaknesses depending on the application. For instance, pneumatic actuators are simple, reliable, and often fail-safe, making them suitable for safety-critical applications; electric actuators offer precise control and are well-suited for integration into automated systems; and hydraulic actuators provide high force in compact sizes, ideal for high-pressure systems.

In one project, we replaced aging pneumatic actuators on a series of globe valves in a chemical processing plant with electric actuators. This upgrade improved control precision, reduced maintenance downtime, and allowed for remote monitoring and control, enhancing overall plant efficiency. I’ve also extensively troubleshooted issues with faulty actuators, identifying problems ranging from air leaks in pneumatic systems to faulty motor windings in electric actuators.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain the accuracy of calibrated instruments over time?

Maintaining the accuracy of calibrated instruments is paramount for reliable process control. We achieve this through a multi-faceted approach that involves regular calibration checks, preventative maintenance, and meticulous record-keeping. Calibration checks are performed according to a predetermined schedule, often based on instrument type, usage frequency, and manufacturer recommendations. This involves comparing the instrument’s readings to a known standard, documenting any deviations, and adjusting the instrument accordingly if necessary. Preventative maintenance, like cleaning sensors and checking for leaks, minimizes drift and extends the lifespan of instruments.

Furthermore, we utilize data logging systems to monitor instrument performance over time. This allows us to identify gradual drifts or anomalies early on, preventing inaccurate measurements. For instance, we encountered a gradual drift in a pressure transmitter over several months. Data logging revealed this trend, allowing for timely recalibration, preventing costly production errors. Proper environmental control, including temperature and humidity, is also critical as environmental factors can significantly impact instrument accuracy.

Q 17. Describe your experience with preventative maintenance of instrumentation.

Preventative maintenance of instrumentation is crucial for optimizing performance, reducing downtime, and preventing catastrophic failures. My experience includes developing and implementing comprehensive preventative maintenance plans tailored to specific instrument types and process conditions. This includes a scheduled inspection and cleaning routine for sensors, ensuring proper lubrication of moving parts in actuators and valves, and verifying the integrity of wiring and connections. We use checklists and documented procedures to ensure consistency and thoroughness in the maintenance process.

For example, in a refinery setting, we developed a preventative maintenance schedule for all level transmitters, including cleaning the sensor probes and verifying the calibration using a calibrated pressure gauge. We also performed routine checks on the electrical connections and the integrity of the housing to prevent damage from environmental factors. This proactive approach significantly reduced instrument failures and improved the overall reliability of the process.

Q 18. How do you troubleshoot a pneumatic instrument?

Troubleshooting a pneumatic instrument involves a systematic approach, focusing on isolating the problem by checking the air supply, signal transmission, and the instrument itself. I start by verifying sufficient air pressure and absence of leaks in the air supply line using a pressure gauge. Next, I inspect the pneumatic signal transmission, checking for blockages, leaks, or damaged tubing. Then, I examine the instrument itself, checking for any visible damage, leaks, or malfunctioning components. Depending on the specific instrument, this might involve checking diaphragms, bellows, or other internal components. If necessary, I use specialized tools like pressure gauges and air flow meters to accurately diagnose the issue.

For example, if a pneumatic level transmitter fails, I might first check the air supply pressure. If that’s adequate, I would then examine the tubing for leaks, using soapy water to detect minor leaks. If a leak is found, I would repair it and recalibrate the instrument. If no leaks are found, I’d investigate the internal components of the transmitter for potential issues, such as a diaphragm rupture or a clogged restriction.

Q 19. Explain your experience with digital communication protocols used in instrumentation.

I have extensive experience with digital communication protocols commonly used in instrumentation, including Profibus, Modbus, HART, and Foundation Fieldbus. These protocols enable seamless integration of instruments into distributed control systems (DCS) and supervisory control and data acquisition (SCADA) systems. Understanding these protocols is essential for configuring, monitoring, and troubleshooting instrumentation networks. I’m proficient in using configuration software to set up communication parameters, establish network connections, and diagnose communication errors.

For example, I’ve used HART protocol to configure and commission smart pressure transmitters, accessing their diagnostic information and changing parameters remotely. This streamlined commissioning and reduced the need for manual configuration. My experience also includes troubleshooting network problems by analyzing communication logs and using diagnostic tools to identify and resolve faults.

Q 20. How do you handle emergency situations related to instrumentation failure?

Handling emergency situations related to instrumentation failure requires a calm, decisive, and methodical approach. My first priority is ensuring the safety of personnel and the prevention of any potential hazards. This might involve shutting down parts of the process, isolating affected equipment, and activating emergency procedures as defined in the plant’s safety protocols. Simultaneously, I initiate a rapid troubleshooting process, focusing on identifying the root cause of the failure and implementing a temporary solution to restore the process to a safe state.

I’ll then work on a permanent solution. This may involve replacing a faulty instrument, making repairs, or implementing a workaround until the proper equipment can be obtained and installed. Throughout the process, I maintain clear and concise communication with operations personnel and supervisors, providing regular updates on the situation and the status of the corrective actions. Detailed reports documenting the incident, root cause, corrective actions, and lessons learned are crucial for preventing future incidents.

Q 21. What is your experience with different types of sensors?

My experience encompasses a variety of sensor types, each chosen for its suitability to a specific measurement application. I’m familiar with temperature sensors (thermocouples, RTDs, thermistors), pressure sensors (capacitive, piezoresistive, strain gauge), flow sensors (differential pressure, ultrasonic, turbine), level sensors (capacitance, ultrasonic, radar), and analytical sensors (pH, conductivity, gas detectors). The choice of sensor depends heavily on the process conditions, the required accuracy, the range of measurement, and cost considerations.

For instance, in a high-temperature application, I would choose a thermocouple for its ability to withstand high temperatures, while for precise temperature control, I might opt for an RTD. Similarly, for measuring the level of a corrosive liquid, I would select a non-contacting sensor like a radar level sensor to avoid damage to the sensor. Understanding the principles of operation and limitations of each sensor type is critical for accurate measurement and proper selection.

Q 22. How familiar are you with HART communication?

HART (Highway Addressable Remote Transducer) communication is a digital protocol widely used in process automation for connecting smart field devices like pressure transmitters, temperature sensors, and flow meters to a control system. I’m very familiar with it. It allows for bi-directional communication, meaning I can not only read the measured value from the instrument but also configure it, diagnose potential issues, and even perform calibrations remotely. This significantly reduces downtime and improves efficiency compared to traditional analog methods. For instance, I’ve used HART to remotely adjust the zero and span of a level transmitter without having to physically access the instrument, saving valuable time and ensuring safety in hazardous areas.

Understanding HART involves familiarity with its communication layers – the physical layer (typically using 4-20mA current loop), the data link layer (handling the communication between the master and slave devices), and the application layer (containing the specific commands and data). I’m proficient in using HART communicators to access various device parameters, troubleshoot communication errors, and perform device configuration and diagnostics.

Q 23. Describe your experience with PLC programming and its relationship to instrumentation.

My experience with PLC programming is extensive, and it’s intrinsically linked to instrumentation. PLCs (Programmable Logic Controllers) are the brains of many industrial automation systems, and they rely heavily on data received from field instrumentation. I’m proficient in several PLC programming languages, including Ladder Logic and Structured Text. My work involves writing PLC programs that read signals from instruments, perform calculations based on those signals, implement control algorithms, and send commands to actuators. For example, I’ve developed PLC programs that monitor temperature readings from multiple RTDs (Resistance Temperature Detectors), compare them to setpoints, and activate cooling systems accordingly.

The relationship between PLC programming and instrumentation is crucial for efficient plant operation. The PLC receives raw data from instruments, processes it according to the programmed logic, and triggers actions based on pre-defined conditions. Accurate and reliable instrumentation is paramount; inaccurate sensor readings can lead to incorrect PLC actions, causing process upsets or even safety hazards. Therefore, regular calibration and maintenance of instruments are vital and are often factored into the PLC program through diagnostic checks and alarm routines.

Q 24. How do you interpret instrument loop diagrams?

Instrument loop diagrams are essential for understanding the flow of signals and data within a process control system. They visually represent the connection between field instruments, control valves, and the control system. I’m adept at interpreting these diagrams to quickly identify the components of a control loop, including the sensor (e.g., pressure transmitter), the transmitter signal, the control valve, the actuator, and the feedback loop to the controller. A typical loop diagram will show signal flow, instrument tags, calibration points, and other relevant information. I use these diagrams for troubleshooting, maintenance planning, and understanding the system’s behavior.

For example, by examining a loop diagram, I can trace a signal from a level transmitter through the 4-20mA loop to the PLC, allowing me to pinpoint the location of a fault if the level reading is incorrect. This includes identifying potential issues like a broken wire, faulty transmitter, or misconfiguration in the PLC program. This visual representation is critical for effective troubleshooting and efficient maintenance.

Q 25. Explain your experience with data acquisition and analysis related to instrumentation.

Data acquisition and analysis are fundamental aspects of my role. I have experience using various data acquisition systems to collect data from instrumentation, ranging from simple data loggers to sophisticated SCADA (Supervisory Control and Data Acquisition) systems. I’m proficient in using data analysis software to interpret this data, identifying trends, anomalies, and potential issues. This often involves creating charts, graphs, and reports to visualize the data and present findings effectively.

For instance, I recently used data from a flow meter to identify a gradual decrease in flow over several weeks. By analyzing this trend, we discovered a partially clogged pipe, preventing a potential production bottleneck. This type of predictive maintenance, enabled by data analysis, is critical for minimizing downtime and improving operational efficiency. I use statistical process control (SPC) techniques to establish baselines and detect deviations from normal operating parameters, facilitating timely interventions and preventing major failures.

Q 26. What are the key performance indicators (KPIs) for instrument calibration?

Key Performance Indicators (KPIs) for instrument calibration focus on accuracy, efficiency, and compliance. Some critical KPIs include:

- Calibration accuracy: Measured as the difference between the instrument reading and the reference standard. A low deviation indicates high accuracy.

- Calibration cycle time: The time taken to complete a calibration task. Shorter cycle times indicate efficiency.

- Calibration compliance rate: The percentage of instruments calibrated within their scheduled intervals. High compliance ensures regulatory compliance and minimizes risk.

- Mean Time Between Failures (MTBF): This KPI tracks the average time between instrument failures, demonstrating the reliability of the calibration processes and the overall health of the instrumentation.

- Calibration cost per instrument: This helps optimize calibration strategies and resource allocation.

Tracking these KPIs helps identify areas for improvement and ensures that the calibration process is both accurate and cost-effective.

Q 27. How do you prioritize calibration tasks in a busy plant environment?

Prioritizing calibration tasks in a busy plant environment requires a structured approach. I typically use a risk-based prioritization method, considering factors such as:

- Safety criticality: Instruments directly impacting safety systems are given the highest priority.

- Process criticality: Instruments impacting production quality or efficiency are prioritized next.

- Calibration due date: Instruments nearing their due date are prioritized to ensure compliance.

- Instrument history: Instruments with a history of frequent failures are given higher priority.

- Downtime cost: Instruments whose failure would incur significant downtime costs are prioritized.

I utilize a computerized maintenance management system (CMMS) to schedule and track calibrations, ensuring that critical instruments are calibrated promptly while managing resources efficiently. The CMMS allows for automated reminders and alerts, improving overall efficiency and reducing the risk of missed calibrations.

Q 28. Describe your experience with Root Cause Analysis related to instrumentation failures.

My experience with Root Cause Analysis (RCA) for instrumentation failures involves a systematic approach to identifying the underlying causes of failures, preventing recurrence, and improving system reliability. I typically follow a structured methodology, such as the “5 Whys” technique or a Fishbone diagram, to systematically investigate the issue.

For example, if a pressure transmitter fails, I wouldn’t just replace it; I’d investigate the reason for the failure. Using the “5 Whys,” I might ask: Why did the transmitter fail? (e.g., sensor drift). Why did the sensor drift? (e.g., exposure to high temperatures). Why was it exposed to high temperatures? (e.g., faulty insulation). Why was the insulation faulty? (e.g., improper installation). Why was it improperly installed? (e.g., lack of training). This process helps uncover the root cause, leading to corrective actions, like improving installation procedures or providing additional training to prevent similar failures in the future. This approach is crucial in preventing recurring problems and improving the overall reliability of the instrumentation system.

Key Topics to Learn for Operate and Calibrate Plant Instrumentation Interview

- Instrumentation Fundamentals: Understanding different types of plant instrumentation (pressure, temperature, flow, level sensors), their operating principles, and limitations.

- Calibration Techniques: Mastering calibration procedures for various instruments, including proper use of calibration tools and documentation, and understanding accuracy and precision.

- Troubleshooting and Diagnostics: Developing skills in identifying and resolving common instrumentation issues, using diagnostic tools and techniques, and understanding preventative maintenance.

- Safety Procedures: Understanding and adhering to all relevant safety regulations and protocols related to operating and calibrating plant instrumentation in industrial settings.

- Data Acquisition and Analysis: Familiarity with data acquisition systems, interpreting sensor readings, and identifying trends and anomalies in process data.

- Control Systems Integration: Understanding how instrumentation integrates with plant control systems (DCS, PLC), including signal transmission and data communication.

- Practical Application: Think through real-world scenarios. How would you troubleshoot a faulty temperature sensor affecting a critical process? How would you ensure the accuracy of your calibration procedures?

- Advanced Topics (for Senior Roles): Explore concepts like instrument selection, loop tuning, advanced process control, and predictive maintenance strategies.

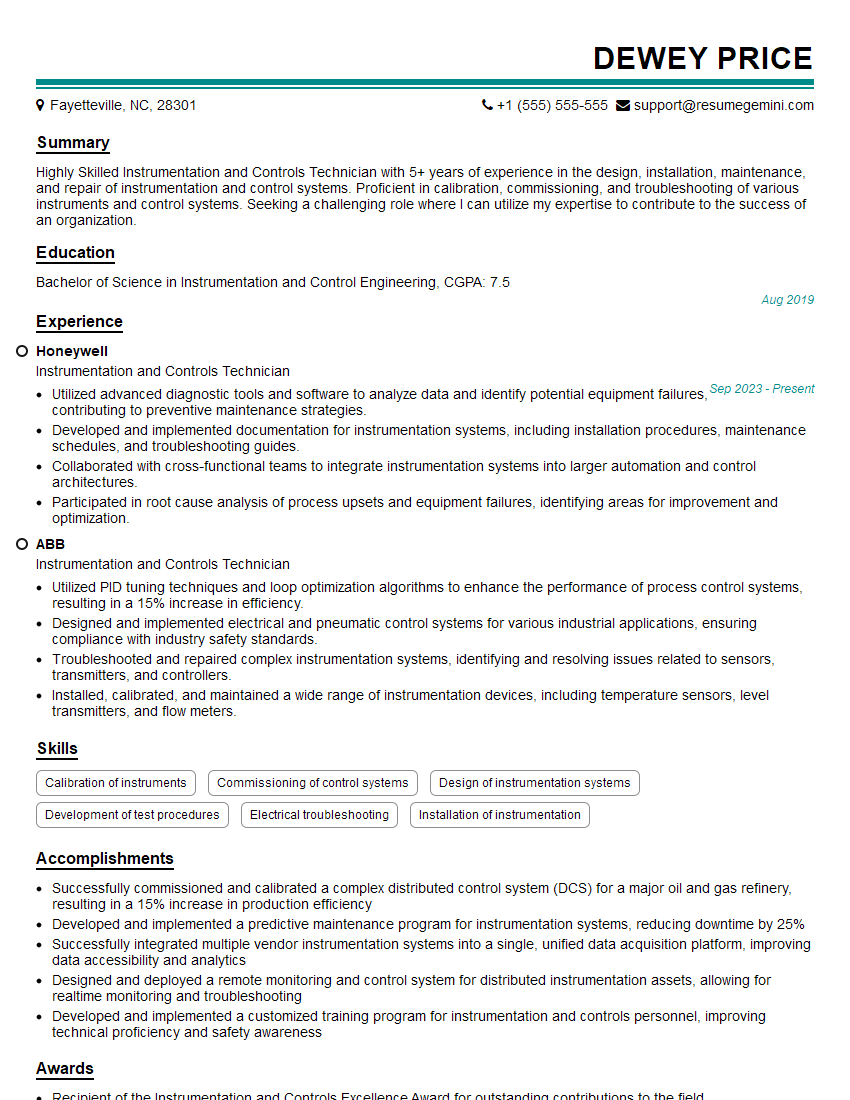

Next Steps

Mastering the operation and calibration of plant instrumentation is crucial for career advancement in many process industries. It demonstrates a strong foundation in process control and a commitment to safety and efficiency. To maximize your job prospects, creating a compelling and ATS-friendly resume is essential. ResumeGemini can help you build a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Operate and Calibrate Plant Instrumentation roles to help you get started. Invest time in crafting a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.