The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Operation of Various Pumps interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Operation of Various Pumps Interview

Q 1. Explain the difference between centrifugal and positive displacement pumps.

Centrifugal and positive displacement pumps are the two primary categories of pumps, distinguished by how they move fluids. Centrifugal pumps use rotational energy to impart velocity to the fluid, increasing its pressure, whereas positive displacement pumps trap a fixed volume of fluid and force it into the discharge line.

Think of it like this: a centrifugal pump is like a fan; it pushes the air (fluid) outwards by spinning. A positive displacement pump is like a syringe; it pulls a specific volume of fluid and then pushes it out.

- Centrifugal Pumps: These are typically used for high flow rate, low pressure applications. They’re simple, relatively inexpensive, and handle a wide range of fluids.

- Positive Displacement Pumps: These are better suited for high pressure, low flow rate applications. They offer excellent volumetric efficiency but can be more complex and expensive.

Q 2. Describe the operating principle of a centrifugal pump.

A centrifugal pump operates on the principle of converting rotational energy into fluid energy. The fluid enters the pump impeller (a rotating disc with vanes) at the center. As the impeller spins, the vanes accelerate the fluid outwards, increasing its velocity and kinetic energy. This high-velocity fluid then enters the volute (a spiraling casing), where the kinetic energy is converted into pressure energy.

Imagine a spinning pinwheel throwing water outwards. The water’s speed increases as it moves away from the center, and then this speed is converted into pressure as it gets pushed into a narrower space in the volute.

The increased pressure forces the fluid through the discharge pipe. The higher the impeller speed, the higher the fluid pressure and flow rate.

Q 3. What are the common types of positive displacement pumps?

Positive displacement pumps come in various types, each designed for specific applications. Some of the most common include:

- Reciprocating Pumps: These use a piston or plunger to draw in and expel fluid, similar to a human heart. They are often used for high pressure applications and viscous fluids.

- Rotary Pumps: These use rotating components such as gears, lobes, or screws to displace fluid. Gear pumps are common for low-viscosity fluids, lobe pumps handle slightly more viscous fluids, and screw pumps are suited for high viscosity or shear-sensitive fluids.

- Diaphragm Pumps: These use a flexible diaphragm to pump fluid. They’re known for their ability to handle abrasive or corrosive fluids and are often used in chemical processing.

Q 4. How do you select the appropriate pump for a specific application?

Selecting the right pump involves carefully considering several factors:

- Fluid Properties: Viscosity, density, temperature, corrosiveness, abrasiveness.

- Flow Rate: The volume of fluid to be pumped per unit time (e.g., gallons per minute or liters per second).

- Pressure Requirements: The pressure needed to overcome system resistance (e.g., elevation changes, pipe friction).

- Operating Conditions: Ambient temperature, duty cycle, required reliability.

- Budget and Maintenance Requirements: Initial cost, operating cost, ease of maintenance.

Often, a pump curve (showing the relationship between flow rate and pressure) is crucial for this selection process. Matching the pump curve to the system requirements ensures optimum performance.

Q 5. Explain Net Positive Suction Head (NPSH) and its importance.

Net Positive Suction Head (NPSH) is the difference between the absolute pressure at the pump suction and the fluid’s vapor pressure. It’s a critical parameter that indicates the pump’s ability to prevent cavitation. Available NPSH (NPSHa) must be greater than required NPSH (NPSHr) to ensure proper operation. NPSHa is determined by system pressure and elevation, while NPSHr is a characteristic of the pump itself and is provided by the manufacturer.

Insufficient NPSH leads to cavitation, which is harmful to the pump. Imagine trying to suck liquid through a straw that’s almost completely blocked – the pressure is not enough to overcome the resistance and you’ll only draw air into the straw. Similarly, without sufficient NPSH, vapor bubbles may form in the pump which collapse violently, causing damage and reducing pump efficiency.

Q 6. What are the causes and consequences of cavitation in pumps?

Cavitation occurs when the pressure within the pump drops below the fluid’s vapor pressure, causing vapor bubbles to form. These bubbles then collapse violently when they enter a region of higher pressure, creating shock waves that damage the pump’s internal components. This erosion leads to reduced efficiency, noise, vibrations, and ultimately, pump failure.

Causes of cavitation include insufficient NPSH, excessive pump speed, clogged suction line, or a leak in the suction line. The consequences are reduced flow rate, increased noise and vibration, premature pump wear, and eventual pump failure.

Q 7. How do you troubleshoot a pump that is not delivering the required flow rate?

Troubleshooting a pump with low flow rate requires a systematic approach:

- Check the suction side: Ensure there is no blockage in the suction line, the strainer is clean, and the suction head is sufficient. Check for leaks.

- Check the discharge side: Verify the discharge line is not blocked or restricted. Check valves and pressure gauges.

- Inspect the pump: Check for wear and tear on impeller, seals, and bearings. Look for signs of cavitation damage.

- Verify the motor: Check the motor speed and power supply. A malfunctioning motor will directly affect pump performance.

- Check for leaks: Leaks in the pump casing or piping can significantly reduce flow rate.

- Check the system curve: Compare the pump curve to the system curve. Any discrepancy might indicate a problem.

A detailed inspection and understanding of the system dynamics are essential for identifying the root cause of low flow rate.

Q 8. Describe the different types of pump seals and their applications.

Pump seals are critical components preventing leakage between the pump shaft and the pumped fluid. The choice of seal depends heavily on the fluid’s properties (temperature, pressure, corrosiveness), the pump’s operating conditions, and cost considerations. Here are some common types:

- Packing Seals: These are traditional seals consisting of rings of flexible material (e.g., braided asbestos, PTFE, graphite) compressed around the shaft. They are relatively inexpensive but require regular adjustment and maintenance due to wear. Think of them as a tightly wound rope around the shaft, squeezing to prevent leakage. They’re often found in older or less demanding applications.

- Mechanical Seals: These are more sophisticated seals consisting of stationary and rotating faces pressed together to create a leak-tight barrier. They offer superior reliability and longer life than packing seals but are more expensive. Mechanical seals are classified further into different types based on their design and construction (e.g., single, double, cartridge). A common type is the face seal. Imagine two perfectly smooth, slightly overlapping discs, constantly being pushed together – that’s the core principle of a mechanical seal.

- Magnetic Couplings: For applications involving highly corrosive or hazardous fluids, magnetic couplings provide a completely seal-less option. The pump shaft is connected to a magnetic driver which rotates an impeller in a separate sealed chamber. This eliminates leakage completely, but adds cost and may have some limitations on rotational speed.

Applications: Packing seals might be suitable for low-pressure, non-critical applications, while mechanical seals are preferred for high-pressure, high-temperature processes in the chemical industry, or even in clean-in-place (CIP) systems in the food and beverage industry. Magnetic couplings are ideal for handling toxic chemicals or in situations where even minute leakage cannot be tolerated.

Q 9. Explain the importance of pump lubrication and maintenance.

Pump lubrication and maintenance are paramount for ensuring optimal performance, extending lifespan, and preventing costly failures. Lubrication reduces friction between moving parts, preventing wear and tear. Think of it as the lifeblood of the pump’s mechanical parts. Without proper lubrication, metal-on-metal contact leads to increased heat, seizing, and ultimately, pump failure. This is especially critical in high-speed pumps and those handling high-viscosity fluids.

Importance:

- Reduced friction and wear: Lubrication minimizes wear on bearings, seals, and other moving parts, extending their service life.

- Improved efficiency: Less friction means less energy is lost to heat, resulting in better pump efficiency.

- Reduced heat generation: Lubrication helps dissipate heat generated during operation, preventing overheating and damage.

- Extended lifespan: Regular lubrication and maintenance significantly extend the operational life of the pump, reducing downtime and replacement costs.

Maintenance: Includes scheduled lubrication changes, bearing inspections, seal checks, vibration analysis, and cleaning. Failing to adhere to a proper maintenance schedule can lead to catastrophic failure, potentially resulting in significant environmental damage and economic losses, especially in applications like pipelines or water treatment plants.

Q 10. How do you perform a pump vibration analysis?

Pump vibration analysis is a crucial diagnostic technique used to identify potential problems before they lead to major failures. Excessive vibration indicates problems within the pump or its connected systems. The process typically involves these steps:

- Baseline Data Acquisition: Initially, collect baseline vibration data from the pump under normal operating conditions. This establishes a reference point for comparison.

- Vibration Measurement: Use vibration sensors (accelerometers) to measure vibration levels at various points on the pump casing. These sensors convert mechanical vibrations into electrical signals.

- Data Analysis: Analyze the collected data using specialized software. This involves examining vibration frequency, amplitude, and phase. Unusual frequencies or excessively high amplitudes usually indicate a problem.

- Troubleshooting: Based on the analysis, identify the root cause of the excessive vibration. Possible causes include misalignment, bearing wear, imbalance, cavitation, or resonance.

- Corrective Actions: Implement the necessary corrective actions, which might involve realignment, bearing replacement, impeller balancing, or adjustments to the piping system. Sometimes, more extensive troubleshooting or a second opinion from a specialist might be necessary.

Tools & Techniques: Vibration analysis typically uses sophisticated equipment like handheld data collectors and spectral analyzers. Sophisticated software packages can visualize frequency spectra, helping identify specific frequencies associated with various mechanical components. For instance, a specific frequency might indicate bearing damage, while another could point towards impeller imbalance.

Q 11. What are the safety procedures for working with pumps?

Safety procedures for working with pumps are critical, as they often handle high pressures, hazardous fluids, and rotating machinery. These procedures must always be followed diligently:

- Lockout/Tagout Procedures: Before any maintenance or repair, always perform proper lockout/tagout procedures to isolate the pump from its power source, preventing accidental start-up.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and hearing protection. For hazardous fluids, specialized protective clothing might be required.

- Confined Space Entry Procedures: If working in a confined space near a pump, follow all confined space entry protocols. This often involves atmospheric monitoring and rescue standby.

- Pressure Relief Procedures: Understand the pump’s pressure relief system and ensure it’s functioning correctly. Never exceed the pump’s maximum operating pressure.

- Emergency Shutdown Procedures: Know the location and operation of emergency shutdown devices. This is critical in case of unexpected events.

- Hot Work Permits: Obtain necessary permits for hot work (welding, cutting) near a pump to prevent fire hazards.

- Training and Competency: All personnel working with pumps should receive adequate training and be competent in safe handling procedures.

Example: Before opening a pump for maintenance, it is absolutely essential to first isolate the pump from the power source by locking out the circuit breaker. This prevents accidental power restoration, protecting personnel from serious injury.

Q 12. Describe the different types of pump impellers.

Pump impellers are the heart of centrifugal pumps, responsible for converting rotational energy into fluid energy. The impeller’s design significantly impacts the pump’s performance characteristics. Several types exist:

- Radial Impellers: These have vanes that curve backward, providing efficient flow at higher pressures. They’re commonly used in high-pressure applications.

- Axial Impellers: These have vanes that are parallel to the shaft, pushing the fluid in a direction parallel to the axis of rotation. They’re often found in low-head, high-flow applications.

- Mixed-Flow Impellers: These combine characteristics of both radial and axial impellers, suitable for moderate head and flow applications.

- Closed Impellers: The vanes extend completely around the impeller’s circumference. These are ideal for preventing recirculation and improving efficiency.

- Open Impellers: The vanes do not extend fully around the circumference. They are commonly employed for pumping fluids with suspended solids, as they are less prone to clogging.

Selection: The choice of impeller depends on the specific application requirements. For instance, a radial impeller is ideal for high-pressure applications like boiler feed pumps, while an axial impeller might be chosen for large-volume water circulation systems.

Q 13. How do you measure pump efficiency?

Pump efficiency is a measure of how effectively the pump converts input power into fluid power. It’s expressed as a percentage and calculated as:

Efficiency = (Hydraulic Power Output / Input Power) x 100%

Hydraulic Power Output is calculated using the fluid’s flow rate, pressure, and density. Input Power is measured directly using power meters connected to the pump’s motor. For example:

- A pump with an input power of 10 kW and a hydraulic power output of 8 kW has an efficiency of (8/10) * 100% = 80%.

Measuring Efficiency: Requires precise measurements of input power and hydraulic power output. Input power is measured using a power meter or by calculating from the motor’s current and voltage. The hydraulic power output is derived from measurements of flow rate and pressure using flow meters and pressure gauges. Specialized test rigs can accurately determine pump efficiency under various operating conditions.

Factors Affecting Efficiency: Efficiency is impacted by factors such as pump design, fluid properties, operating point, wear and tear, and maintenance. A well-maintained pump operating at its optimal design point will exhibit higher efficiency.

Q 14. What is the significance of pump curves?

Pump curves are graphical representations of a pump’s performance characteristics, showing the relationship between flow rate (Q), head (H), efficiency (η), and power (P) at different operating points. They are crucial for selecting the right pump and ensuring optimal operation.

Significance:

- Pump Selection: Pump curves help determine the suitable pump for a given application by matching the required flow rate and head with the pump’s performance.

- System Matching: The pump curve is used in conjunction with the system curve (representing the head loss in the pipeline) to determine the operating point of the pump.

- Efficiency Optimization: Pump curves identify the operating point with maximum efficiency, helping optimize energy consumption.

- Troubleshooting: Deviations from expected performance indicated by the pump curve can help identify potential problems like wear, cavitation, or blockage.

Interpreting Curves: A typical pump curve shows flow rate on the x-axis and head on the y-axis. Overlaying the system curve onto the pump curve determines the operating point (the intersection of the two curves). The efficiency and power curves are also shown to help evaluate energy consumption and performance.

Example: A pump curve can show that at a flow rate of 100 liters/minute, the pump delivers a head of 20 meters and operates at 80% efficiency. This information is essential for system design and performance analysis.

Q 15. How do you calculate pump head?

Pump head, also known as total dynamic head (TDH), represents the total energy added to the fluid by the pump. It’s measured in units of height (feet or meters) and reflects the combined effect of static head (elevation difference), friction head (energy loss due to fluid friction in pipes), and velocity head (energy due to fluid movement).

Calculating pump head involves summing these components:

- Static Head: The vertical distance between the pump’s suction and discharge points. For example, if the pump is drawing water from a well 10 meters below ground and discharging it to a tank 20 meters above ground, the static head is 30 meters.

- Friction Head: This depends on factors such as pipe length, diameter, roughness, and flow rate. Specialized formulas (like the Darcy-Weisbach equation) or readily available charts are used to estimate this. Friction losses increase with flow rate and pipe length. Think of it like the energy lost when pushing water through a long, narrow straw versus a wide, short one.

- Velocity Head: This accounts for the kinetic energy of the fluid. While often smaller compared to static and friction head, it is still considered in precise calculations. It’s calculated using the fluid’s velocity and density.

Therefore, total dynamic head (TDH) = Static Head + Friction Head + Velocity Head. Accurate head calculations are crucial for selecting the right pump for a given application because an improperly sized pump can lead to inefficiency and premature failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of pump affinity laws.

Pump affinity laws describe the relationship between a centrifugal pump’s performance characteristics (flow rate, head, power) and its operating speed. These laws are approximate, meaning they hold true for geometrically similar pumps operating under similar conditions, but deviations might occur in practice. They are extremely useful for predicting changes in pump performance without conducting extensive testing.

The key relationships are:

- Flow rate (Q) is directly proportional to speed (N):

Q1/Q2 = N1/N2. Doubling the speed roughly doubles the flow rate. - Head (H) is proportional to the square of the speed:

H1/H2 = (N1/N2)². Doubling the speed quadruples the head. - Power (P) is proportional to the cube of the speed:

P1/P2 = (N1/N2)³. Doubling the speed increases the power by a factor of eight.

Practical Application: Imagine a pump operating at 1750 RPM delivers 100 GPM and 50 feet of head. Using the affinity laws, we can estimate the performance if the speed is increased to 1850 RPM. This allows for quick, initial design and troubleshooting without complex fluid dynamic calculations.

Q 17. What are the common causes of pump failure?

Pump failures stem from a variety of causes, often interconnected. They can be broadly categorized as mechanical, hydraulic, or electrical.

- Mechanical Failures: These include bearing wear and tear (leading to vibration and eventual seizure), seal leakage (due to wear, improper installation, or contamination), shaft misalignment (causing excessive vibration and stress), impeller damage (from cavitation or foreign objects), and corrosion of pump components.

- Hydraulic Failures: Cavitation (formation of vapor bubbles in the liquid that collapse violently, damaging the impeller), excessive suction pressure (resulting in cavitation or pump starvation), and foreign objects entering the pump (blocking flow or damaging internal components).

- Electrical Failures: Motor burnout (due to overheating, overloading, or power surges), faulty wiring, control system malfunctions, and improper voltage supply.

Regular maintenance and preventative measures, such as lubricating bearings, inspecting seals, and performing regular vibration analysis, can significantly reduce the likelihood of these failures. A well-maintained pump, like a well-maintained car, lasts much longer and requires less emergency repair.

Q 18. How do you diagnose and repair a leaking pump seal?

Diagnosing a leaking pump seal requires a systematic approach. First, locate the source of the leak and determine if it originates from the shaft seal itself or another component. Look for visible signs of leakage, listen for unusual sounds, and possibly use pressure gauges to check for pressure loss.

Repair steps:

- Isolate the pump: Turn off the power and release any pressure within the system.

- Disassemble as necessary: Carefully remove the pump casing and components to access the seal. Often, this will involve removing the pump coupling and potentially the motor. Use the pump manufacturer’s instructions, if available.

- Inspect the seal and surrounding components: Look for wear, damage, or misalignment. Check the shaft for scoring, corrosion, or unusual wear. Inspect the seal housing for cracks or damage.

- Replace the seal: Install a new seal, ensuring proper lubrication and alignment following the manufacturer’s specifications. The seal should be correctly seated to prevent leakage. Don’t forget to use the correct type of seal for your pump and the fluid being pumped.

- Reassemble the pump: Put the pump back together, paying close attention to correct alignment and torque specifications. Double-check that all components are correctly secured.

- Test the pump: Run the pump and monitor for leaks. If leakage persists, there may be other underlying issues to address.

Important Note: Safety is paramount. Always follow lockout/tagout procedures before starting any repair work.

Q 19. Describe the process of aligning a pump coupling.

Pump coupling alignment is critical for smooth operation and preventing premature wear and tear on the pump and motor. Misalignment causes excessive vibration, leading to bearing failures, seal damage, and reduced lifespan.

Methods for aligning couplings include:

- Face alignment: Uses a straight edge or dial indicator to check the parallelism of the pump and motor faces. This is a simple method, but less precise.

- Reverse dial indicator method: Utilizes dial indicators to measure both radial and axial misalignment. This method is more accurate.

- Laser alignment tools: Advanced tools employing lasers to precisely measure misalignment and provide digital readings. This method offers superior accuracy and simplifies the alignment process.

Alignment Process (general steps):

- Prepare the equipment: Ensure the pump and motor are properly supported and accessible.

- Use the chosen alignment method: Follow the specific instructions for your selected method. Measure the misalignment in both horizontal and vertical planes.

- Adjust coupling alignment: Use shims or adjusting bolts to correct the identified misalignment. Make small adjustments and re-measure to ensure precision.

- Verify alignment: After adjustments, re-check the alignment to ensure it is within acceptable tolerances.

Proper alignment isn’t just a matter of tightening bolts; it’s precision engineering to prevent costly breakdowns.

Q 20. What are the different types of pump bearings?

Pumps use various bearing types, each with its strengths and weaknesses. Common types include:

- Sleeve bearings: These are simple and relatively inexpensive. They consist of a cylindrical sleeve that surrounds the shaft. They are lubricated by oil, grease, or the pumped fluid itself. They are suitable for lower speeds and loads.

- Ball bearings: These use rolling elements (balls) to reduce friction. They are capable of handling higher speeds and loads compared to sleeve bearings. They require periodic lubrication and are more expensive.

- Roller bearings: Similar to ball bearings but utilize cylindrical or tapered rollers. They are better suited for high radial loads and provide better support than ball bearings in certain applications. They are also more expensive.

- Magnetic bearings: These bearings use magnetic forces to support the shaft, eliminating the need for physical contact. This reduces friction and wear, leading to longer lifespan and higher efficiency. They are more complex and expensive.

The choice of bearing depends on factors like pump speed, load, operating temperature, fluid type, and budget. Selecting the wrong bearing type can lead to premature failure and increase maintenance costs.

Q 21. Explain the importance of regular pump inspections.

Regular pump inspections are crucial for ensuring reliable operation, preventing costly failures, and maximizing pump lifespan. Think of it like getting regular checkups for your health. Early detection of problems can prevent major issues later on.

Regular inspection should include:

- Visual Inspection: Check for leaks, corrosion, loose bolts, and signs of vibration or wear. Look for obvious damage and signs of unusual wear.

- Vibration Monitoring: Measure vibration levels to detect imbalance, misalignment, or bearing problems. Increased vibration is often an early warning sign of problems.

- Temperature Monitoring: Check the pump and motor temperatures to identify potential overheating issues. High temperatures can indicate problems with lubrication or excessive load.

- Lubrication Check: Inspect the condition of lubricants and ensure adequate lubrication for bearings and seals.

- Pressure and Flow Rate Checks: Verify that the pump is operating at the correct pressure and flow rate. Deviations from expected values may indicate a problem.

- Seal Inspection: Check the condition of the seals and look for any signs of leakage.

A well-defined inspection schedule, tailored to the specific pump and its application, is a cornerstone of preventative maintenance. This proactive approach reduces downtime, extends pump life, and ensures safe, efficient operation.

Q 22. How do you handle a pump emergency shutdown?

A pump emergency shutdown requires a swift and systematic response to prevent damage and ensure safety. The first step is to identify the cause of the shutdown. This might involve checking for high vibration, low flow, high temperature, or pressure anomalies, often indicated by alarm systems.

Once the cause is understood (or at least the immediate trigger is identified), the next step is to isolate the pump. This involves closing valves to prevent further flow and disconnecting power. Never attempt to restart a pump immediately after a shutdown; investigate the problem first. After isolation, we must perform a thorough inspection to pinpoint the root cause – a faulty bearing, clogged impeller, electrical fault, or something else. Depending on the complexity, this may involve disassembling parts of the pump. Thorough documentation of the incident, including corrective actions, is crucial for preventative maintenance in the future. For instance, a recurring high-temperature shutdown might indicate a need for improved cooling systems or a lubrication schedule change.

Finally, after repair and testing, the pump can be carefully restarted, closely monitoring its parameters (pressure, flow, vibration, temperature) during the initial operation.

Q 23. Describe different methods for controlling pump speed.

Controlling pump speed is essential for optimizing efficiency and managing the process it serves. Several methods exist:

- Variable Frequency Drives (VFDs): This is the most common and efficient method. VFDs alter the frequency of the electrical power supplied to the motor, thus changing its speed. This allows for precise speed control and reduces energy consumption by avoiding throttling. Imagine adjusting the speed of a car – a VFD does something similar for a pump motor.

- Throttle Valves: These valves restrict the flow rate at the pump discharge, thereby indirectly controlling the speed. However, this method is less efficient as energy is wasted through throttling. Think of partially blocking a water hose – the flow reduces, but energy is lost in the friction.

- Variable Displacement Pumps: These pumps can change their displacement (the volume of fluid pumped per revolution) to alter the flow rate, thus controlling the speed indirectly. These are typically used in hydraulic systems where precise control is needed.

- Mechanical Speed Controls: Older systems might employ mechanical means such as pulleys and belts to adjust pump speed. These are less common due to limitations in precision and efficiency.

The choice of method depends on factors like the type of pump, the required precision of control, the budget, and the overall system design.

Q 24. How do you prevent pump cavitation?

Cavitation, the formation and collapse of vapor bubbles within a pump, is a major concern leading to damage and inefficiency. The collapsing bubbles create shock waves that erode internal pump components and reduce efficiency. We prevent cavitation primarily by ensuring adequate Net Positive Suction Head (NPSH). NPSH is the difference between the pump’s inlet pressure and the vapor pressure of the liquid being pumped.

Here’s how we prevent it:

- Sufficient NPSH: Ensuring the pump has enough NPSH available is paramount. This involves checking suction line pressure, liquid temperature, and altitude to ensure the available NPSH exceeds the pump’s required NPSH (NPSHr).

- Proper Suction Piping Design: Avoid sharp bends, long suction lines, and restrictions. Smooth, straight piping minimizes pressure losses.

- Leak Detection and Repair: Leaks in the suction line reduce NPSH, so regular inspection is vital. This should involve checking fittings and gaskets for leaks.

- Maintaining Correct Fluid Level: Ensuring that the fluid supply remains adequately high above the pump inlet prevents vapor entry into the pump.

- Avoiding High Temperatures: Higher temperatures lower the liquid’s vapor pressure, reducing the available NPSH. Hence, effective cooling systems might be needed.

Ignoring cavitation can lead to premature pump failure, costly repairs, and even system downtime. Regular monitoring of operating parameters and preventative maintenance is key.

Q 25. What are the environmental considerations related to pump operation?

Environmental considerations related to pump operation are crucial for sustainability. They include:

- Energy Efficiency: Pumps are significant energy consumers. Optimizing pump selection, speed control (using VFDs), and regular maintenance drastically reduces energy consumption, thereby lowering carbon footprint.

- Leak Prevention: Leaks of the pumped fluid can pollute the environment. Regular inspection and prompt repair of leaks are vital, especially for hazardous or environmentally sensitive fluids.

- Noise Pollution: Pumps can generate significant noise. Implementing noise reduction measures like acoustic enclosures or vibration dampeners helps minimize noise pollution.

- Wastewater Treatment: For pumps handling wastewater, ensuring proper treatment of effluent before discharge into the environment is mandatory. This might involve filtration, chemical treatment, or other processes.

- Spill Prevention and Containment: Having adequate spill containment systems in place is crucial to prevent environmental damage in case of accidental leaks or spills.

- Responsible Disposal: Proper disposal of pump components at the end of their lifespan is essential to avoid environmental hazards. This may involve recycling or specialized disposal methods.

Compliance with relevant environmental regulations and implementing environmentally responsible practices is vital for responsible pump operation.

Q 26. Explain the importance of proper priming in pumps.

Proper priming is essential for the operation of most pumps, especially centrifugal pumps. Priming means filling the pump casing and suction line with liquid before starting the pump. Without priming, the pump won’t be able to generate suction and will run dry, causing severe damage such as cavitation and bearing failure.

Imagine trying to suck water through a straw that has air in it – the water won’t come up. Similarly, a pump without sufficient prime cannot lift the liquid. The process of priming involves filling the pump housing with fluid, often using a dedicated priming system or by manual methods. This eliminates air pockets that obstruct the flow and prevent the impeller from developing suction. Failure to prime correctly will result in pump failure, and costly repairs are often needed.

Q 27. What are the different types of pump controls?

Pump controls can be categorized into several types:

- On/Off Control: The simplest form, where the pump is either fully on or fully off. This is suitable only for applications with minimal flow rate variations.

- Flow Control: Regulates the flow rate of the pumped fluid. This can be achieved using throttle valves or variable speed drives (VFDs).

- Pressure Control: Maintains a constant pressure in the system, adjusting the pump speed or flow rate as needed.

- Level Control: Maintains a constant liquid level in a tank or reservoir by adjusting the pump’s operation.

- Cascade Control: Uses multiple control loops to manage complex pump systems. For example, controlling both flow rate and pressure simultaneously.

- PLC-Based Control Systems: Programmable Logic Controllers (PLCs) provide sophisticated control capabilities, allowing for complex automation and monitoring of multiple pumps.

The optimal type of control depends on the specific application and its requirements. A water distribution network will need different controls than a simple process pump in a factory.

Q 28. How do you maintain pump documentation and records?

Maintaining accurate and up-to-date pump documentation and records is critical for efficient operation and maintenance. This documentation serves several purposes, from troubleshooting to compliance and safety. Key information to include:

- Pump Specifications: Model number, manufacturer, capacity, head, operating curves, etc.

- Installation Records: Date of installation, location, piping diagrams, etc.

- Maintenance Logs: Dates of all maintenance activities (inspections, repairs, overhauls), performed by whom, parts replaced, and any findings noted.

- Operating Data: Readings of pressure, flow rate, temperature, vibration, etc. at regular intervals.

- Spare Parts Inventory: A list of spare parts held and their location. Regular checks to avoid stockouts and ensure timely repairs.

- Calibration Records: Records of calibrations and verification of any instrumentation used with the pumps.

- Safety Records: Safety incidents, training records, risk assessments and permit-to-work procedures.

This information should be stored in a safe, organized, and easily accessible manner. Digital databases or maintenance management software are increasingly used to manage this information effectively. Regularly updating records ensures that a complete history of each pump’s performance and maintenance is available, facilitating informed decision-making and proactive maintenance planning.

Key Topics to Learn for Operation of Various Pumps Interview

- Centrifugal Pumps: Understanding their operating principles, including impeller design, head-flow characteristics, and NPSH requirements. Practical application: Troubleshooting common issues like cavitation and low flow.

- Positive Displacement Pumps: Differentiating between various types (e.g., piston, gear, diaphragm pumps) and their suitability for different fluids and applications. Practical application: Selecting the appropriate pump type for a specific industrial process.

- Pump System Design: Analyzing system curves, selecting appropriate pipe sizing and valves, and understanding the impact of friction losses on pump performance. Practical application: Optimizing a pumping system for energy efficiency.

- Pump Maintenance and Troubleshooting: Identifying common pump failures, performing routine maintenance tasks, and implementing preventative maintenance strategies. Practical application: Diagnosing and resolving pump malfunctions to minimize downtime.

- Safety Procedures: Understanding lockout/tagout procedures, proper handling of hazardous fluids, and adhering to relevant safety regulations. Practical application: Ensuring a safe working environment while operating and maintaining pumps.

- Instrumentation and Control: Familiarity with pressure gauges, flow meters, and level sensors used in pump systems, as well as basic control strategies. Practical application: Monitoring pump performance and making adjustments as needed.

- Energy Efficiency Considerations: Understanding the factors affecting pump energy consumption and methods for improving efficiency (e.g., variable speed drives). Practical application: Implementing strategies to reduce operational costs.

Next Steps

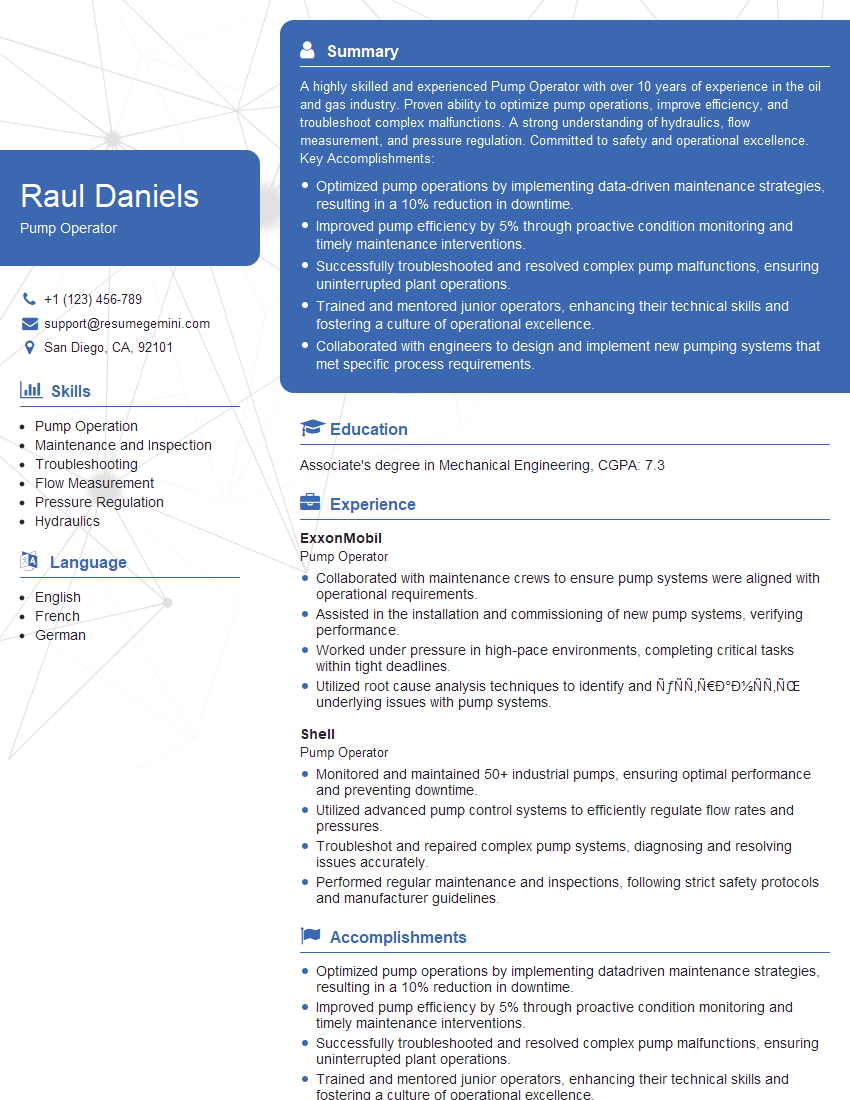

Mastering the operation of various pumps is crucial for career advancement in many industries, opening doors to specialized roles and higher earning potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience in operating various pumps. Examples of resumes tailored to this field are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.