Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Paving and Asphalt Laying interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Paving and Asphalt Laying Interview

Q 1. Describe your experience with different types of asphalt.

My experience encompasses a wide range of asphalt types, each with unique properties suited to different applications. For instance, I’ve worked extensively with dense-graded asphalt concrete, the workhorse of pavement construction, known for its durability and load-bearing capacity. This is frequently used for high-traffic roads and highways. I’ve also had significant experience with open-graded asphalt concrete, which is designed for better drainage and reduced noise. This is often used in areas prone to flooding or where noise reduction is critical, like near schools or residential areas. Furthermore, I’m familiar with stone mastic asphalt (SMA), a high-performance mix offering excellent resistance to rutting and fatigue cracking, often used in high-stress pavement sections. Finally, I’ve worked with various specialized mixes, such as those incorporating recycled materials, designed for sustainability and cost-effectiveness. Each mix requires a tailored approach to ensure optimal performance.

Q 2. Explain the process of asphalt compaction and its importance.

Asphalt compaction is the crucial process of densifying the asphalt mixture after it’s laid, removing air voids and ensuring a strong, durable pavement. Think of it like squeezing a sponge – we’re removing the air to leave a solid, compact structure. We achieve this primarily using rollers, starting with smaller rollers to initially compact the material and then progressing to heavier rollers for final compaction. The process is carefully monitored by measuring the density achieved using specialized testing equipment like nuclear gauges. Proper compaction is paramount because inadequate compaction leads to increased porosity and susceptibility to water damage, rutting (formation of depressions under heavy loads), and premature pavement failure. Imagine a poorly compacted pavement – it’s like building a sandcastle without packing the sand; it’ll collapse easily under stress. In contrast, well-compacted asphalt forms a stable, resilient surface that can withstand significant traffic loads and environmental stresses.

Q 3. What are the key factors influencing asphalt mix design?

Asphalt mix design is a complex process heavily influenced by several key factors. The primary consideration is the aggregate gradation – the particle size distribution. This determines the mix’s stability and density. Then there’s the binder content (the asphalt cement), which dictates the mix’s stiffness, viscosity, and temperature susceptibility. Aggregate type plays a vital role in the mix’s durability and performance characteristics. The type and amount of filler material influences void space and workability. Environmental conditions, specifically temperature and anticipated traffic loads, significantly influence design choices as higher traffic volume necessitates a more robust mix design. For example, a high-traffic highway will require a denser, stronger mix compared to a low-traffic residential street. Finally, cost considerations and the availability of local materials always play a role in the final decision.

Q 4. How do you ensure proper grading and leveling during asphalt paving?

Ensuring proper grading and leveling is essential for a smooth, even pavement surface. This process begins with meticulous preparation of the base layer, ensuring it’s properly compacted and level. We then use a combination of techniques, including stringlines and grade stakes, for precise elevation control. Modern paving equipment often incorporates sophisticated automated systems that ensure the desired grade is maintained during the paving process. However, constant monitoring and adjustments are critical, with skilled operators making minute corrections as needed to maintain the desired level. Regular checks with levels and straight edges are vital throughout the process to correct any deviations immediately and prevent issues in the finished pavement. Failing to maintain proper grade can lead to uneven surfaces, ponding water, and structural issues in the long run.

Q 5. What are the common causes of asphalt pavement cracking and how can they be prevented?

Asphalt pavement cracking is a common problem with several causes. Thermal cracking occurs due to repeated expansion and contraction of the asphalt under temperature variations. Fatigue cracking results from the repetitive stress of traffic loading. Reflective cracking happens when cracks in the underlying base layer propagate upwards. Alligator cracking, characterized by interconnected cracks, often indicates inadequate compaction or poor mix design. Shrinkage cracking can occur from the loss of volatiles in the asphalt. Prevention strategies involve proper mix design to resist cracking, robust base preparation, ensuring adequate compaction, and implementing joint sealing to minimize water ingress. Furthermore, using appropriate crack sealing techniques promptly addresses existing cracks and prevents their progression.

Q 6. Describe your experience with different types of paving equipment.

My experience with paving equipment includes the operation and maintenance of a wide range of machinery, including pavers (both smaller and large capacity machines suitable for various project scales), tandem rollers (for initial and final compaction), pneumatic rollers (for improved compaction of cohesive soils), and finishing machines, which provide a perfect surface. I’m familiar with different types of milling machines used for surface repairs and overlay work. I’m equally comfortable using hand tools like rakes and shovels for finishing touches and quality checks. The experience also includes working with GPS and laser-guided paving technology for improved accuracy and efficiency.

Q 7. How do you troubleshoot common equipment malfunctions on a paving project?

Troubleshooting equipment malfunctions requires a systematic approach. I start by identifying the specific problem, analyzing symptoms, and checking for immediate causes, like fuel supply issues, low oil, or damaged belts. I then check hydraulic systems for leaks or malfunctions, inspect electrical connections and circuits, and review the machine’s operational log for error codes. If the issue persists, I consult the equipment’s maintenance manuals and contact the manufacturer’s technical support for guidance. Preventative maintenance plays a crucial role; regular inspections and timely servicing prevent many problems. My experience emphasizes the importance of safety: always ensure the machine is turned off and locked out before attempting any repairs.

Q 8. What safety measures do you employ during asphalt paving operations?

Safety is paramount in asphalt paving. We implement a multi-layered approach, starting with comprehensive pre-job safety briefings covering potential hazards like heavy machinery, hot asphalt, and traffic. This includes detailed explanations of Personal Protective Equipment (PPE) requirements – hard hats, safety glasses, high-visibility vests, gloves, and steel-toed boots are mandatory. We establish clear traffic control measures, using cones, barricades, and flaggers to safely manage traffic flow around the worksite. Regular equipment inspections are vital to prevent malfunctions that could lead to accidents. For example, we meticulously check the paving machine’s components before each use, ensuring all safety guards are in place and functioning correctly. Furthermore, we enforce strict adherence to all OSHA regulations and conduct regular safety training sessions to refresh knowledge and address any emerging concerns.

We also implement a ‘buddy system’ where workers operate in pairs, ensuring continuous supervision and immediate assistance in case of emergencies. Finally, we maintain a clean and organized worksite to minimize tripping hazards and promote safe movement of personnel and equipment.

Q 9. How do you manage a paving crew and ensure efficient teamwork?

Managing a paving crew efficiently involves clear communication, defined roles, and a collaborative spirit. Before each project, I hold a pre-job meeting to outline the plan, individual responsibilities, and expected timelines. I delegate tasks based on each team member’s skill set and experience. For instance, experienced workers often lead the paving operations, while newer members assist with tasks like cleanup or material handling. This approach fosters a sense of responsibility and empowers team members.

Regular communication is key. I utilize daily stand-up meetings to address any challenges, clarify instructions, and ensure everyone is on the same page. Open feedback is encouraged, creating an environment where everyone feels comfortable voicing concerns or suggesting improvements. I also emphasize the importance of teamwork and mutual respect, promoting a positive and productive work atmosphere. Think of it like a well-oiled machine: each part plays its role perfectly for seamless operation. This collaborative approach increases productivity and overall project efficiency.

Q 10. Explain your experience with quality control procedures in asphalt paving.

Quality control is non-negotiable in asphalt paving. It starts with ensuring the quality of the materials used—we rigorously test the aggregate blend to meet the project specifications, confirming proper gradation and density. During the paving process, we continuously monitor the asphalt temperature, ensuring it’s within the optimal range for proper compaction. We use sophisticated equipment like nuclear density gauges to check the density of the compacted asphalt at regular intervals. This ensures that the final pavement achieves the required strength and durability.

After compaction, visual inspections are crucial to identify any surface irregularities, such as segregation or voids. We use precision measuring tools to ensure the pavement thickness meets specifications. Detailed documentation, including photographs and test results, are meticulously maintained throughout the process. This comprehensive approach allows for quick identification and resolution of any issues, leading to consistently high-quality results. Think of it as a recipe – careful measurement and adherence to the recipe (specifications) leads to a perfect pavement ‘cake’.

Q 11. What are your strategies for meeting project deadlines and budgets?

Meeting deadlines and budgets requires meticulous planning and efficient execution. We start by developing a detailed project schedule, breaking down the work into manageable tasks with assigned deadlines. This schedule considers potential delays and includes buffer time for unforeseen circumstances. We use project management software to track progress, identify potential bottlenecks, and proactively address any issues.

Material procurement is carefully planned to avoid delays. We establish strong relationships with reliable suppliers to ensure timely delivery. Our efficient team workflow, as discussed earlier, ensures optimized labor utilization and cost-effectiveness. Regular progress reports and open communication with clients are maintained to keep everyone informed and avoid misunderstandings that could affect the project timeline or budget. This proactive approach ensures we deliver projects on time and within budget, building strong client relationships based on trust and reliability.

Q 12. How do you handle unexpected challenges or delays on a paving project?

Unexpected challenges are inevitable in construction. Our approach focuses on proactive risk management and contingency planning. This involves identifying potential problems before they arise, such as unexpected weather delays or material shortages. For weather delays, for instance, we have backup plans, such as relocating resources to other projects or adjusting the schedule accordingly.

When unexpected issues do arise, our immediate response involves a thorough assessment to understand the nature and scope of the problem. We then collaborate with the team to develop a solution, involving potentially adjusting the schedule, procuring replacement materials, or requesting necessary approvals from relevant stakeholders. Open communication with clients is crucial to keep them informed and to maintain transparency. Our experience allows us to swiftly adapt, minimize disruptions, and mitigate potential cost overruns and delays.

Q 13. Describe your experience with asphalt pavement maintenance and repair.

Asphalt pavement maintenance and repair are crucial for extending the lifespan of pavements and ensuring safety. My experience encompasses a wide range of techniques, from routine crack sealing to more extensive repairs. Crack sealing, for example, involves filling cracks with specialized sealant to prevent water infiltration and further damage.

For more significant repairs, we might use techniques like patching or milling and overlaying. Patching involves removing damaged asphalt and replacing it with new material, while milling involves removing a layer of asphalt to create a smooth surface before applying a new overlay. We utilize specialized equipment for each repair type, ensuring the repair is durable and seamlessly integrates with the existing pavement. Regular inspections and preventative maintenance are key to minimizing the need for extensive repairs and extending the pavement’s life. It’s like regularly servicing a car – smaller interventions prevent major problems down the line.

Q 14. What are the environmental considerations related to asphalt paving?

Environmental considerations are increasingly important in asphalt paving. We prioritize minimizing the environmental impact throughout the project lifecycle. This starts with responsible material sourcing, favoring recycled materials whenever feasible. Reducing fuel consumption during paving operations is another focus, employing fuel-efficient equipment and optimizing our work processes.

We manage construction waste carefully, implementing robust recycling and disposal programs to minimize landfill contributions. We also implement measures to control dust and emissions, such as using dust suppressants and employing environmentally friendly cleaning agents. Careful planning helps minimize disruption to surrounding ecosystems and adherence to relevant environmental regulations is paramount, ensuring our operations are sustainable and environmentally responsible. Environmental responsibility isn’t just a trend; it’s a commitment to a sustainable future.

Q 15. What are the different types of asphalt sealants and their applications?

Asphalt sealants are crucial for extending the lifespan and improving the performance of asphalt pavements. They protect the asphalt from the damaging effects of water, UV radiation, and traffic wear. Different sealants cater to specific needs.

- Seal Coat: This is a thin, penetrating application of an emulsion or liquid asphalt. It’s ideal for preventative maintenance on relatively new pavements, filling minor cracks and refreshing the surface. Think of it as giving your asphalt a protective ‘sunblock’. I’ve used seal coats extensively on residential driveways and smaller parking lots to prevent premature aging.

- Crack Sealant: Specifically designed to fill cracks and prevent water intrusion. Hot-applied crack sealants are more durable than cold-applied ones and are my preferred choice for larger cracks and high-traffic areas. Imagine these sealants as ‘stitches’ for the asphalt, preventing further damage.

- Chip Seal: This involves applying a layer of asphalt emulsion followed by an application of aggregate (small stones). The aggregate embeds into the emulsion, providing a durable, textured surface. Chip seals are commonly used on low-volume roads and driveways where skid resistance is important. I’ve used this method on rural roads where cost-effectiveness is a major factor.

- Micro-surfacing: A slurry seal consisting of asphalt emulsion, aggregate, and fine fillers. It’s applied as a thin layer to rejuvenate the pavement, improving its texture and sealing minor imperfections. Micro-surfacing is great for extending the life of older pavements without the expense of a full overlay. I’ve seen remarkable results using micro-surfacing on heavily trafficked parking areas.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your knowledge of relevant paving industry regulations and standards.

Adherence to industry regulations and standards is paramount in paving. My work consistently aligns with guidelines established by organizations like the American Association of State Highway and Transportation Officials (AASHTO) and relevant local and state Departments of Transportation. Key standards I follow include those pertaining to:

- Material Specifications: This includes ensuring the asphalt binder, aggregates, and other materials meet the required quality standards for gradation, density, and other physical properties. Deviation from these specifications can severely impact the pavement’s durability. I always verify material certifications before beginning any project.

- Construction Methods: Proper compaction, paving techniques, and quality control procedures are critical. This involves using appropriate equipment and following best practices to achieve the desired density and smoothness of the asphalt layer. For example, we use nuclear density gauges to ensure proper compaction is achieved at each stage of construction.

- Environmental Regulations: We adhere to all environmental protection measures during construction, including managing stormwater runoff and disposing of waste materials properly. This often includes using permitted disposal sites and implementing erosion control measures.

- Safety Regulations: Safety for both the workers and the public is paramount. This includes following OSHA regulations and implementing proper safety protocols on-site, such as ensuring proper signage, personal protective equipment (PPE), and traffic control measures.

Regular audits and inspections are integral to my workflow, ensuring compliance and maintaining high standards.

Q 17. How do you ensure the proper curing of asphalt pavements?

Proper curing is vital for the long-term performance of asphalt pavements. It’s the process where the asphalt binder cools and hardens, achieving its final strength and stability. Several factors influence curing and I employ strategies to optimize the process:

- Temperature Control: Higher temperatures accelerate curing, but excessively high temperatures can lead to cracking. We monitor ambient temperatures and adjust paving schedules accordingly. For example, in extremely hot conditions, we may need to adjust our paving times to cooler parts of the day.

- Compaction: Proper compaction helps to remove air voids and increases density, leading to faster and more efficient curing. We use rollers of appropriate weight and type to achieve optimal compaction. Insufficient compaction leads to weakening of the asphalt layer.

- Protection from Environmental Factors: Exposure to rain or excessive wind can disrupt curing. We take measures to protect newly laid asphalt, including covering it with tarps or employing other protective methods until it’s sufficiently cured.

- Time: Sufficient curing time is essential, varying based on factors like temperature, asphalt type, and layer thickness. We usually allow several days for proper curing before opening the area to traffic. This waiting period is crucial for achieving the desired pavement strength.

Regular testing using methods like the nuclear density gauge ensures we have achieved adequate compaction and curing.

Q 18. What is your experience with different types of paving aggregates?

Paving aggregates are the granular materials that make up a significant portion of asphalt concrete. Different aggregates impart different properties to the pavement. My experience includes working with a wide variety of aggregates, including:

- Crushed Stone: This is a common and versatile aggregate offering good strength and durability. The type of stone (limestone, granite, etc.) affects its properties, influencing its suitability for different applications. I’ve extensively used crushed limestone for its cost-effectiveness and widespread availability.

- Gravel: Naturally occurring aggregates, gravels offer varying properties depending on their composition. Their rounded shape can impact compaction, sometimes requiring modifications to the construction process. I’ve encountered projects where the use of gravel has necessitated adjustments to the compaction methods.

- Recycled Materials: Sustainability is a growing concern, and I have experience incorporating recycled materials like reclaimed asphalt pavement (RAP) into the mix. RAP reduces the need for virgin materials and can be an environmentally friendly and cost-effective option. I’ve found that carefully controlled usage of RAP improves cost-effectiveness while maintaining the integrity of the pavement.

The selection of appropriate aggregate is crucial for achieving the desired pavement strength, durability, and skid resistance. I always consider the specific project requirements and local aggregate availability when making my selections. Detailed testing of aggregate properties is always performed prior to the project.

Q 19. How do you determine the required thickness of an asphalt layer?

Determining the required thickness of an asphalt layer is a critical aspect of pavement design, and it’s not a simple matter. It depends on several interacting factors:

- Traffic Volume and Load: Higher traffic volumes and heavier loads necessitate thicker layers to withstand the stress. I use traffic load analysis and design charts like the AASHTO design guide to determine the appropriate thickness based on the expected traffic loads.

- Subgrade Strength: A strong subgrade (the base layer beneath the asphalt) allows for thinner asphalt layers, whereas a weaker subgrade requires a thicker layer to distribute the load. I always conduct soil analysis to determine the subgrade’s bearing capacity.

- Pavement Design Life: The desired lifespan of the pavement influences the thickness. Longer lifespans typically require thicker layers.

- Environmental Conditions: Factors like climate and soil conditions can influence the thickness required to withstand environmental stressors, like freeze-thaw cycles or water infiltration. This is where detailed knowledge of local soil conditions and weather patterns becomes crucial.

I often utilize specialized pavement design software to account for these variables, optimizing the thickness for both performance and cost-effectiveness. Over-designing leads to unnecessary expenses, while under-designing results in premature pavement failure. A detailed analysis is always required before making a final determination.

Q 20. Explain your experience with using GPS and surveying equipment in paving.

GPS and surveying equipment are invaluable tools for modern paving projects. They enhance accuracy, efficiency, and overall quality. My experience involves utilizing these tools in various aspects of paving:

- Accurate Layout and Grading: GPS systems allow for precise grading and setting of pavement boundaries, minimizing errors and ensuring consistent pavement thickness. This results in a more uniform and stable pavement surface, which improves ride quality and reduces the risk of premature failure.

- Real-Time Monitoring of Paving Operations: GPS data can be used to monitor the progress of paving operations, allowing for timely adjustments and optimal resource allocation. I use this data to track paving progress and ensure adherence to the project schedule and specifications.

- As-Built Documentation: GPS data provides accurate as-built documentation, invaluable for future maintenance and repairs. This documentation can be used to easily locate previous pavement work and plan future maintenance tasks.

- Integration with Paving Machines: Modern paving machines can integrate with GPS systems for automated guidance, ensuring consistent paving thickness and alignment. This helps improve the overall efficiency and quality of paving operations.

My proficiency extends to using various types of surveying equipment, including total stations and levels, for establishing benchmarks and verifying the accuracy of GPS data. These are integral to ensuring accurate alignment and elevation for optimal paving outcomes.

Q 21. Describe your experience with managing materials on a paving project.

Effective materials management is crucial for successful paving projects. It minimizes waste, controls costs, and ensures timely completion. My approach involves:

- Accurate Material Quantity Estimation: I use detailed plans and specifications to accurately estimate the required quantities of asphalt, aggregates, and other materials. This prevents material shortages or overstocking, which can lead to project delays or increased expenses. Detailed material takeoffs are always performed prior to any project.

- Just-in-Time Delivery Scheduling: Coordinating material delivery to coincide with paving operations minimizes storage costs and reduces the risk of material degradation. This requires close coordination with material suppliers and the paving crew.

- Inventory Tracking and Management: Maintaining a detailed inventory of all materials helps in monitoring usage and identifying potential problems. This often involves using inventory tracking software to maintain accurate records of materials received, used, and remaining.

- Waste Minimization Strategies: Implementing strategies to reduce waste, such as optimizing mix designs and using recycled materials, contributes to both cost savings and environmental sustainability. This often involves analyzing mix designs to find the optimal ratio of materials to reduce excess and improve efficiency.

My experience in materials management extends to working with various suppliers, managing material storage, and ensuring material quality control throughout the project lifecycle. It’s an essential component of successful project execution.

Q 22. How do you calculate the quantity of asphalt needed for a project?

Calculating the asphalt needed for a paving project involves several steps. First, you need precise measurements of the area to be paved. This usually involves surveying the site and creating a detailed plan showing the length, width, and depth of the asphalt layer. The depth depends on the project’s requirements and traffic load – a busy highway needs a thicker layer than a residential driveway. Then, you convert these measurements into cubic yards or cubic meters.

Next, you account for compaction. Asphalt compresses after being laid, reducing its volume. This compaction factor, typically ranging from 10-15%, needs to be added to the initial volume calculation to ensure you have enough material. For example, if your calculations show you need 100 cubic yards before compaction, you would increase this by 10-15% (110-115 cubic yards) to account for this loss.

Finally, you add a small percentage (around 5%) for waste and spillage. This accounts for unavoidable losses during transportation and the paving process. This ensures you have enough material to complete the project without running short. Let’s say you calculated 110 cubic yards after accounting for compaction. Adding 5% for waste gives you a final quantity of roughly 115.5 cubic yards.

Therefore, the formula can be simplified as:

Total Asphalt Needed = (Length x Width x Depth) x Compaction Factor x Waste FactorQ 23. What is your experience with different paving techniques (e.g., full-depth reclamation)?

My experience encompasses a wide range of paving techniques, including full-depth reclamation (FDR). FDR is a highly effective method for rehabilitating existing pavements, especially when dealing with significant deterioration or base instability. It involves removing the existing asphalt surface and a portion of the underlying base material. This material is then processed, often with the addition of stabilizing agents, and reused as the base for a new asphalt layer. This process can be significantly more cost-effective than complete pavement removal and replacement, and it also reduces the environmental impact by reusing existing materials.

I’ve also worked extensively with other methods like cold in-place recycling (CIR), which involves mixing the existing asphalt with a rejuvenating agent and then recompacting it; and conventional overlay techniques, where a new layer of asphalt is placed directly on top of the existing pavement. The choice of technique depends heavily on the condition of the existing pavement, the project budget, and the desired service life of the new pavement.

In one particular project involving a heavily trafficked section of highway, we opted for FDR because the existing base was showing signs of significant distress. By reclaiming and reusing the existing materials, we were able to deliver a robust and durable pavement while minimizing disruption and costs. This significantly improved the highway’s lifespan and reduced the need for frequent repairs.

Q 24. How do you ensure the longevity and durability of asphalt pavements?

Ensuring the longevity and durability of asphalt pavements requires a multifaceted approach starting with proper design and material selection. This includes using high-quality asphalt binder with appropriate viscosity and penetration grades, carefully selecting aggregates based on their grading, strength, and durability, and ensuring proper compaction during the paving process. Insufficient compaction can lead to rutting and cracking. Using appropriate equipment and skilled operators are essential for achieving optimum compaction levels.

Beyond material and construction, proper drainage is crucial. Water ingress is a major contributor to pavement failure. We employ techniques such as proper crown design, adequate drainage ditches, and the use of geotextiles to prevent water from infiltrating the pavement structure. Regular maintenance, including crack sealing and pothole patching, plays a key role in preventing minor issues from escalating into major problems. Regular inspections are also critical to identifying and addressing potential problems early before extensive damage occurs.

Finally, understanding the anticipated traffic load is vital. Heavier traffic necessitates a thicker and stronger pavement design to withstand the increased stress.

Q 25. What is your experience with working with different types of clients?

Throughout my career, I’ve collaborated with a diverse clientele, including government agencies (state departments of transportation, municipalities), private developers, and property management companies. Each client brings a unique set of priorities and expectations. Government agencies often emphasize long-term durability, adherence to stringent specifications, and detailed documentation. Private developers prioritize cost-effectiveness and timely project completion to meet deadlines. Property management companies typically focus on aesthetic appeal, minimal disruption to residents or tenants, and efficient project execution.

My approach involves actively listening to each client’s needs and adapting my communication style to suit their preferences. I focus on clear and transparent communication to build trust and maintain open lines of communication. I ensure deliverables meet or exceed their expectations while remaining within budget and adhering to project timelines.

Q 26. Describe your approach to problem-solving in a fast-paced paving environment.

The paving environment is dynamic; unforeseen challenges often arise. My problem-solving approach relies on a structured methodology. First, I clearly define the problem, gathering all relevant information and assessing the urgency. Then, I brainstorm potential solutions, considering their impact on project timelines, budget, and safety. This often involves discussions with the team to leverage everyone’s expertise.

Next, I prioritize solutions based on feasibility, cost-effectiveness, and impact. I implement the chosen solution, monitoring its progress closely. If the chosen solution doesn’t prove effective, I’m prepared to adapt and try alternative approaches. Thorough documentation throughout the process is key to both resolving immediate issues and also learning for future projects. For example, during a recent project, a sudden rainstorm threatened to delay the paving. By quickly implementing a revised schedule and coordinating with the material supplier for an expedited delivery of materials, we were able to minimize delays.

Q 27. How do you prioritize tasks and manage multiple responsibilities on a paving project?

Managing multiple responsibilities on a paving project requires careful planning and effective prioritization. I utilize project management tools such as Gantt charts and critical path analysis to visually track tasks, dependencies, and deadlines. I break down large tasks into smaller, manageable components and assign responsibilities to team members based on their skills and availability. Regular team meetings are crucial for coordinating activities, addressing challenges, and ensuring everyone is aligned with the project goals.

I prioritize tasks based on urgency and criticality. Tasks that directly impact project timelines and safety are addressed first. I also build in buffers to account for unexpected delays. Communication is vital. I maintain constant communication with clients, subcontractors, and team members to address issues proactively and prevent escalation. My focus is always on efficient resource allocation and effective team coordination.

Q 28. What are your career goals within the paving and asphalt industry?

My career goals center on continued growth within the paving and asphalt industry. I aim to expand my expertise in sustainable paving practices, incorporating innovative and environmentally friendly materials and techniques. I’m also interested in enhancing my leadership and management skills, potentially taking on more responsibility in project management or business development. I envision myself as a leader in the industry, contributing to the advancement of sustainable and efficient paving solutions. I am keen to help the industry evolve towards more eco-conscious practices, such as the utilization of recycled materials and the reduction of carbon emissions.

Key Topics to Learn for Paving and Asphalt Laying Interview

- Site Preparation: Understanding grading, compaction techniques, and sub-base preparation for optimal asphalt performance. This includes knowing different soil types and their impact on the project.

- Asphalt Mix Design: Familiarize yourself with different asphalt binder types, aggregate properties, and their influence on the final product’s durability and performance. Consider how these choices impact the project budget and timeline.

- Laying Techniques: Master the practical aspects of asphalt paving, including paving equipment operation (pavers, rollers), achieving proper thickness and density, and understanding the importance of accurate paving temperature control. Think about how to handle unexpected situations like equipment malfunctions or material inconsistencies.

- Quality Control and Testing: Learn about common asphalt testing methods (density, air voids), quality control procedures, and how to ensure the project meets specifications. Be ready to discuss how you would address deviations from expected results.

- Health and Safety: Demonstrate a strong understanding of relevant safety regulations and procedures for asphalt paving, including PPE requirements, hazard identification, and risk mitigation strategies. This includes knowing the proper response to emergencies on a job site.

- Project Management Basics: Even as a field worker, understanding project scheduling, resource allocation, and basic budgeting principles can significantly enhance your interview prospects. Consider how your role contributes to the overall project success.

- Troubleshooting and Problem Solving: Be prepared to discuss how you’ve handled challenges in the past, such as dealing with unexpected weather conditions, material shortages, or equipment failures. Focus on your problem-solving approach and ability to find effective solutions.

Next Steps

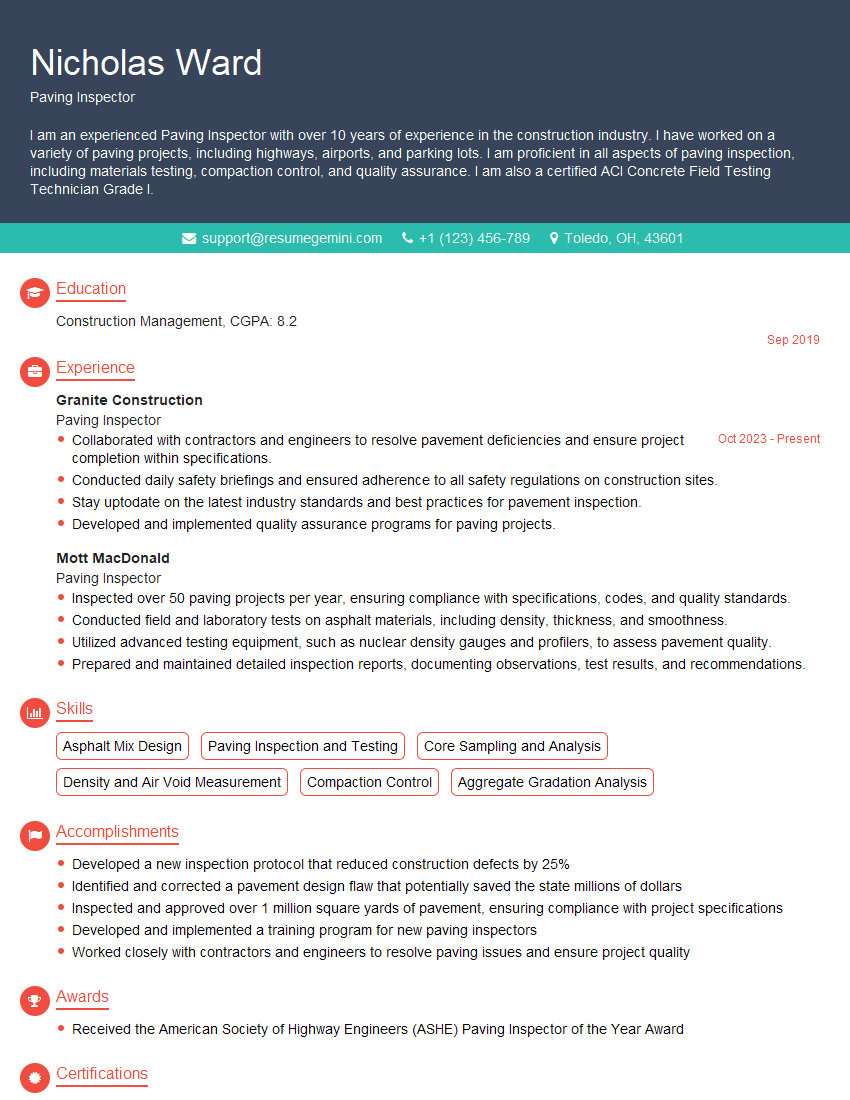

Mastering the intricacies of paving and asphalt laying opens doors to a rewarding career with excellent growth potential. This field demands skilled professionals who can handle diverse challenges and deliver high-quality results. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications stand out to potential employers. Examples of resumes tailored to the Paving and Asphalt Laying industry are available to guide you in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.