Cracking a skill-specific interview, like one for Petrochemical Production and Processing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Petrochemical Production and Processing Interview

Q 1. Describe the different types of cracking processes used in petrochemical refining.

Cracking is a crucial process in petrochemical refining that breaks down large hydrocarbon molecules (like those found in crude oil) into smaller, more valuable ones. There are several types, each with its own advantages and applications:

- Thermal Cracking: This oldest method uses high temperatures (450-550°C) and pressures to break hydrocarbon bonds. It’s relatively simple but less selective, resulting in a broader range of products. Think of it like violently shaking a complex Lego structure – you get a mix of smaller pieces.

- Fluid Catalytic Cracking (FCC): This is the most widely used cracking process. It uses a catalyst (usually zeolites) and high temperatures (500-550°C) but lower pressures than thermal cracking. The catalyst significantly improves selectivity, yielding more gasoline and other valuable products. Imagine using a specialized tool to carefully disassemble the Lego structure, leading to more useful components.

- Hydrocracking: This process combines cracking with hydrogenation. High pressure, high temperature, and a catalyst are used to break down large molecules and saturate unsaturated ones (adding hydrogen). It produces high-quality products with a lower sulfur content, ideal for producing diesel and jet fuel. It’s like carefully dismantling the Lego structure and strengthening the individual pieces.

- Steam Cracking: Primarily used to produce ethylene and other olefins (unsaturated hydrocarbons). It involves high temperatures (850-900°C) and very short contact times with steam. This process favors the formation of simpler molecules used in the production of plastics and synthetic fibers. Consider this a high-energy approach, similar to melting the Lego structure down to its raw materials.

The choice of cracking process depends on the desired product slate and economic factors. For example, FCC is favored for gasoline production, while steam cracking is essential for the petrochemical industry.

Q 2. Explain the concept of fractional distillation and its importance in petrochemical processing.

Fractional distillation is a separation process based on the differing boiling points of components in a liquid mixture. In petrochemical processing, it’s used to separate crude oil into various fractions (e.g., gasoline, kerosene, diesel, etc.). Imagine boiling a pot of mixed candies – each candy with a different melting point will melt at a different temperature.

Crude oil is heated in a furnace to vaporize it. The vapor enters a tall distillation column where it gradually cools as it rises. Different fractions condense at different heights, based on their boiling points. The lower the boiling point, the higher the fraction will rise and condense. This allows for the separation of numerous products with differing boiling points and chemical compositions.

Its importance lies in efficiently separating crude oil into marketable products. Without fractional distillation, we would be left with a single, unusable crude oil stream. It’s a fundamental process that enables the vast downstream petrochemical industry.

Q 3. What are the key safety considerations in handling hazardous materials in a petrochemical plant?

Safety is paramount in petrochemical plants, given the inherent hazards of handling flammable, toxic, and corrosive materials. Key safety considerations include:

- Process Safety Management (PSM): Implementing comprehensive programs to identify, analyze, and control hazards. This includes HAZOP (Hazard and Operability) studies and Layer of Protection Analysis (LOPA).

- Emergency Response Planning: Developing detailed plans for handling emergencies like fires, explosions, and chemical spills, including evacuation procedures and personnel training.

- Personal Protective Equipment (PPE): Ensuring workers use appropriate PPE, such as respirators, protective clothing, and safety glasses, depending on the specific hazards.

- Process Instrumentation and Control: Implementing robust instrumentation, including safety instrumented systems (SIS), to monitor and control critical process parameters and shut down operations in case of abnormal conditions. Think of these as the ‘brakes’ on the process.

- Material Handling and Storage: Safe storage and handling of materials, including proper labeling, segregation, and containment systems to prevent leaks or spills.

- Regular Inspections and Maintenance: Implementing regular inspections and maintenance to ensure that equipment is functioning properly and safety systems are in place.

A significant safety incident can have devastating consequences, hence a culture of safety and continuous improvement is essential.

Q 4. How do you monitor and control process parameters to ensure product quality and yield?

Monitoring and controlling process parameters are crucial for ensuring product quality and yield. This involves using a combination of advanced process control (APC) techniques and online analyzers.

We continuously monitor critical parameters such as temperature, pressure, flow rates, and compositions using a variety of sensors and instruments. These data are fed into a distributed control system (DCS) which monitors and controls the process in real-time. Deviations from the setpoints are addressed through automated control actions or operator intervention.

Online analyzers provide real-time information on the composition of streams. This allows for immediate adjustments to maintain product specifications and maximize yield. For instance, in a distillation column, we might adjust reflux ratios or reboiler heat duty based on online analysis of the product quality.

Advanced process control techniques such as model predictive control (MPC) can optimize the process parameters based on a predictive model, leading to improved product quality and higher yields.

Q 5. Describe your experience with process optimization techniques.

My experience with process optimization techniques includes the application of various strategies for enhancing efficiency, improving product quality, and reducing operational costs. I have been involved in projects using:

- Statistical Process Control (SPC): Using statistical methods to monitor and control process variability, reducing defects, and improving product consistency.

- Design of Experiments (DOE): Employing experimental designs to identify the optimal operating conditions for a process, maximizing yield and minimizing waste.

- Model Predictive Control (MPC): Implementing advanced control strategies that predict future process behavior and adjust control actions accordingly, leading to improved performance and stability.

- Data Analytics and Machine Learning: Leveraging large datasets from process sensors and online analyzers to identify patterns, predict process anomalies, and optimize decision-making.

For example, in one project, we used DOE to optimize the operating conditions of a fluid catalytic cracking unit, resulting in a 5% increase in gasoline yield and a reduction in byproduct formation. This involved carefully varying parameters like temperature, pressure, and catalyst circulation rate while meticulously monitoring the outcomes.

Q 6. Explain the different types of reactors used in petrochemical production.

Petrochemical production utilizes various reactor types, each suitable for specific reactions and operating conditions:

- Fixed-bed Reactors: These reactors contain a stationary bed of catalyst through which the reactants flow. They are simple in design but can suffer from pressure drop issues and catalyst deactivation. Imagine a water filter – the water flows through the filter media (catalyst) undergoing a change.

- Fluidized-bed Reactors: The catalyst particles are suspended in a gas stream, creating a fluidized bed. This provides excellent heat and mass transfer, making them suitable for highly exothermic or endothermic reactions. Think of a bubbling fluidized bed like a boiling pot of water with sand – the sand particles move freely.

- Moving-bed Reactors: The catalyst continuously flows through the reactor, allowing for continuous regeneration and longer catalyst life. This is useful for reactions where catalyst deactivation is significant. This operates much like a conveyor belt carrying the catalyst through the reaction zone.

- Tubular Reactors: These are typically used for homogeneous reactions, where the catalyst is dissolved in the reaction mixture. The reactants flow through a series of tubes, which provide high surface area-to-volume ratios.

- Stirred-tank Reactors (CSTR): These are used for liquid-phase reactions where good mixing is needed to maintain uniform conditions. The reactor contents are constantly stirred, ensuring homogeneous composition.

The choice of reactor depends on factors such as the reaction kinetics, heat transfer requirements, catalyst properties, and operating conditions.

Q 7. How do you troubleshoot process upsets and deviations from normal operating parameters?

Troubleshooting process upsets and deviations starts with understanding the root cause. My approach follows a structured methodology:

- Identify the Deviation: Identify the specific parameter that is deviating from its setpoint and the magnitude of the deviation. Is it a temperature spike, pressure drop, or change in product composition?

- Gather Data: Collect data from various sources like DCS, online analyzers, and process sensors to understand the context of the upset. What happened before the deviation? Are there any other related changes?

- Analyze the Data: Examine the data to determine the cause of the deviation. This could involve using process simulations, analyzing trends, and comparing the current state with historical data.

- Implement Corrective Actions: Based on the root cause analysis, implement appropriate corrective actions to bring the process back to normal operating conditions. This might include adjusting setpoints, adding or removing feedstock, or restarting the process unit.

- Document and Investigate: Thoroughly document the upset, including the cause, corrective actions taken, and the effectiveness of the actions. A post-mortem analysis will help prevent similar situations in the future.

For example, if we observe a decrease in the yield of a particular product, we might analyze the feedstock quality, catalyst activity, or operating parameters to determine the root cause. Based on this analysis, we might change the catalyst, adjust the operating temperature, or switch to a different feedstock.

Q 8. Describe your understanding of process simulation software and its applications.

Process simulation software is crucial in the petrochemical industry for designing, optimizing, and troubleshooting chemical processes. These software packages use mathematical models to mimic the behavior of a real-world plant, allowing engineers to test different scenarios without the cost and risk of physical experimentation. Popular examples include Aspen Plus, HYSYS, and Pro/II.

Applications span various stages: During the design phase, simulation helps determine optimal equipment sizing, operating conditions (temperature, pressure, flow rates), and energy consumption. In the operational phase, it helps optimize production, predict bottlenecks, and improve efficiency. Troubleshooting involves using simulation to diagnose problems and explore potential solutions, such as identifying the root cause of reduced yield or unexpected emissions.

For instance, imagine designing a new ethylene cracker. Simulation allows engineers to virtually test various feedstock compositions, reactor configurations, and operating parameters to find the most economical and efficient design that meets product specifications. This avoids costly mistakes and ensures a profitable operation.

Q 9. Explain the importance of maintaining proper inventory levels of raw materials and finished products.

Maintaining optimal inventory levels is critical for smooth and efficient petrochemical operations. Insufficient raw materials lead to production halts and lost revenue. Excessive inventory ties up capital and increases storage costs, risks degradation or obsolescence, particularly for temperature-sensitive materials, and adds to safety hazards.

Effective inventory management requires a balance between supply and demand forecasting, accurate tracking of materials, and efficient logistics. Techniques like Just-In-Time (JIT) inventory control attempt to minimize storage while ensuring timely availability. Sophisticated inventory management systems (IMS) use algorithms to predict demand based on historical data, production schedules, and market trends.

Consider a naphtha cracker: A sudden shortage of naphtha could shut down the entire plant, resulting in significant financial losses. Conversely, excessive naphtha storage increases the risk of fire or explosion due to the flammability of naphtha. Careful inventory management, combining forecasting with a robust supply chain, prevents both shortages and surpluses.

Q 10. What are the environmental regulations relevant to petrochemical production?

Environmental regulations in petrochemical production are stringent and constantly evolving, aiming to minimize the industry’s environmental footprint. These regulations address various aspects including air emissions, wastewater discharge, and waste management. Key regulations often include those related to greenhouse gas emissions (e.g., carbon dioxide, methane), volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and specific pollutants like sulfur oxides (SOx) and nitrogen oxides (NOx).

Regulations are typically dictated at national and regional levels and may vary widely based on geographical location and local sensitivities. Compliance requires rigorous monitoring, reporting, and investment in pollution control technologies, such as scrubbers, catalytic converters, and advanced wastewater treatment systems. Failure to comply results in significant fines and penalties and can severely damage a company’s reputation.

For example, the Clean Air Act in the US sets limits on various air pollutants. Similarly, the European Union’s Industrial Emissions Directive (IED) regulates major hazards and pollutants from industrial installations, including petrochemical plants. Compliance involves using advanced emission control technologies and meticulously documenting emissions levels to meet regulatory requirements.

Q 11. Describe your experience with process safety management systems (PSM).

Process Safety Management (PSM) systems are paramount in petrochemical plants to prevent accidents and protect workers, the environment, and surrounding communities. A robust PSM system involves a comprehensive framework of processes, procedures, and technologies designed to identify, assess, and control hazards throughout the entire lifecycle of a facility.

My experience encompasses various aspects of PSM, including hazard identification (HAZOP studies, What-If analysis), risk assessment (quantitative and qualitative risk analysis), development of safe operating procedures (SOPs), emergency response planning, and training programs. I’ve been involved in implementing and maintaining PSM systems in compliance with regulations such as OSHA’s Process Safety Management standard (29 CFR 1910.119) and other relevant industry best practices.

In a previous role, I was responsible for leading a HAZOP study on a new polymerization unit. This involved systematically reviewing all aspects of the process to identify potential hazards and recommend mitigation measures. This resulted in the implementation of additional safety interlocks, improved alarm systems, and a revised emergency shutdown procedure, significantly reducing the risk of a major incident.

Q 12. Explain the different types of pumps and compressors used in petrochemical plants.

Petrochemical plants employ a wide array of pumps and compressors, each suited for specific applications based on fluid properties, flow rate, pressure requirements, and the presence of corrosive or abrasive substances.

- Pumps: Centrifugal pumps are commonly used for moving large volumes of liquids at moderate pressures. Positive displacement pumps, such as piston or diaphragm pumps, are preferred for handling high-viscosity fluids or those containing solids. Rotary pumps are used for transferring liquids and semi-liquids. Specific materials of construction are crucial, for example, using stainless steel or specialized alloys for corrosive fluids.

- Compressors: Reciprocating compressors are used for high-pressure applications and smaller flow rates. Centrifugal compressors are better suited for high flow rates at moderate pressures. Rotary screw and axial compressors handle large volumes at moderate to high pressures. Selection depends on factors like gas properties, compression ratio, and efficiency requirements.

For example, centrifugal pumps might handle large flows of cooling water, while positive displacement pumps might transfer viscous process streams. In gas compression, centrifugal compressors are commonly used for the initial compression stages, while reciprocating compressors handle the final, high-pressure stages.

Q 13. What are your experiences with different types of heat exchangers?

Heat exchangers are fundamental in petrochemical processes for transferring heat between fluids. Various types exist, each with advantages and disadvantages based on application and process requirements.

- Shell and Tube Heat Exchangers: These are the most common type, consisting of a bundle of tubes inside a shell. One fluid flows through the tubes, and the other flows across the tubes. They are versatile and suitable for a wide range of applications, but can be bulky and expensive for large duties.

- Plate Heat Exchangers: These consist of thin, corrugated plates stacked together. Fluids flow alternately between the plates. They are compact, efficient, and easy to clean, but are generally limited to lower pressure and temperature applications.

- Air-cooled Heat Exchangers: These use air as the cooling medium, often employed when water is scarce or expensive. They require a significant footprint but eliminate the need for a cooling water system.

Selection depends on the heat duty, pressure and temperature requirements, fluid properties, fouling potential, and cost considerations. For instance, a shell and tube exchanger might be used for cooling a process stream under high pressure, while a plate heat exchanger might be used for heating a less aggressive fluid.

Q 14. Describe your understanding of mass and energy balances in chemical processes.

Mass and energy balances are fundamental principles in chemical engineering, forming the basis for process design, optimization, and troubleshooting. A mass balance ensures that the total mass entering a system equals the total mass leaving the system, accounting for any accumulation or depletion within the system. Similarly, an energy balance tracks the flow of energy into and out of a system, ensuring that energy is conserved.

These balances are expressed through equations that relate the flow rates and compositions of different streams. For example, a simple mass balance on a reactor might be expressed as:

Mass in = Mass out + Mass accumulatedSimilarly, energy balances consider various forms of energy, including heat, work, and potential/kinetic energy. These balances are essential for designing efficient and safe processes, determining equipment sizing (e.g., reactors, heat exchangers), and optimizing operating conditions.

For example, in designing an ethylene cracker, a thorough mass balance allows engineers to determine the optimal feedstock rates and product yields, while an energy balance helps determine the energy requirements for heating and cooling the reactor and other unit operations.

Q 15. Explain the different types of control valves and their applications.

Control valves are essential components in petrochemical processes, regulating the flow of fluids and gases. Different types exist, each suited to specific applications based on factors like flow characteristics, pressure, temperature, and the nature of the fluid.

- Globe Valves: These are among the most common, using a disc to regulate flow. They offer good throttling capabilities (precise flow control) and are suitable for a wide range of applications. Think of them like a faucet in your home – you can finely adjust the flow.

- Ball Valves: These use a rotating ball with a hole to control flow. They’re excellent for on/off service and are quick-acting, but less precise for throttling. Imagine a simple switch – either fully open or fully closed.

- Butterfly Valves: These use a rotating disc within a circular casing. They’re best for large-diameter pipes and are relatively inexpensive. Their throttling capability is less precise than globe valves.

- Diaphragm Valves: These use a flexible diaphragm to control flow, offering excellent isolation capabilities and being particularly suitable for handling slurries or corrosive fluids. They’re good for applications where preventing leaks is paramount.

- Pinch Valves: These squeeze a flexible tube to regulate flow, suitable for handling abrasive or viscous fluids. Think of it like squeezing a toothpaste tube.

The choice of valve depends heavily on the specific application. For example, a globe valve might be preferred for precise temperature control in a reactor, while a ball valve might be used for quickly isolating a section of pipe during maintenance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with safety and environmental regulations?

Compliance with safety and environmental regulations is paramount in the petrochemical industry. My approach involves a multi-faceted strategy:

- Strict Adherence to Codes and Standards: We meticulously follow relevant codes like API, ASME, and OSHA standards. This ensures all equipment, processes, and procedures meet established safety and environmental criteria.

- Comprehensive Risk Assessments: Regular and thorough hazard identification and risk assessment studies, like HAZOPs (Hazard and Operability studies) and LOPA (Layer of Protection Analysis), are crucial. These help identify potential hazards and implement appropriate safeguards.

- Robust Permitting and Work Authorization Systems: All work, especially maintenance activities, requires detailed permits and work authorizations to ensure proper procedures are followed. This minimizes the chances of human error leading to accidents.

- Regular Inspections and Audits: We conduct routine inspections of equipment, processes, and safety systems. Internal and external audits ensure our compliance with regulations and identify areas for improvement. This is analogous to getting regular car maintenance – preventative measures are key.

- Emergency Response Planning: Comprehensive emergency response plans are developed, regularly practiced through drills, and readily accessible to all personnel. This preparedness minimizes impact in the event of an incident.

- Environmental Monitoring and Reporting: Regular monitoring of emissions, wastewater, and other environmental impacts is performed. We comply with all reporting requirements to ensure transparency and accountability.

Ultimately, safety and environmental protection are not just regulations to meet but are fundamental to our operational philosophy.

Q 17. Describe your experience with process instrumentation and control systems (ICS).

My experience with process instrumentation and control systems (ICS) spans several years and involves diverse applications. I’m proficient in various aspects of ICS, from installation and configuration to troubleshooting and optimization. This includes:

- Instrumentation: I’m familiar with a wide range of instruments including flow meters (coriolis, magnetic, orifice plate), pressure transmitters, temperature sensors (RTDs, thermocouples), level transmitters, and gas analyzers.

- Control Systems: I have experience with Distributed Control Systems (DCS) such as those from Honeywell, Emerson, and Siemens, as well as Programmable Logic Controllers (PLCs). I can configure these systems, develop control strategies, and troubleshoot system issues.

- Data Acquisition and Analysis: I’m adept at using ICS data for process optimization, performance monitoring, and identifying potential problems. This often involves using SCADA (Supervisory Control and Data Acquisition) systems.

- Safety Instrumented Systems (SIS): I understand the importance of SIS in preventing major accidents and have experience in configuring and testing safety instrumented functions (SIFs). These are critical systems, like emergency shutdowns.

For instance, in a recent project, I worked on optimizing a distillation column’s control strategy using a DCS, resulting in a 5% increase in product yield and a 3% reduction in energy consumption.

Q 18. Explain your understanding of HAZOP studies and their importance in process safety.

HAZOP (Hazard and Operability) studies are systematic, qualitative techniques used to identify potential hazards and operability problems in process systems. They involve a team of experts reviewing a process flow diagram (PFD) and considering deviations from the intended operation, such as changes in flow, temperature, pressure, or composition.

The importance of HAZOP lies in its proactive approach to safety. By identifying potential hazards early in the design phase or during modifications, we can implement preventative measures, mitigating risks before they cause incidents. This is far more cost-effective than reacting to accidents.

A typical HAZOP involves brainstorming sessions using predefined guide words (e.g., ‘more,’ ‘less,’ ‘no,’ ‘part of,’ ‘reverse’). The team systematically explores each process step, identifying potential deviations and their consequences. Each hazard is then assessed for its severity, likelihood, and potential for mitigation. This process leads to generating preventive or mitigating actions.

For example, a HAZOP study might reveal a potential for overpressure in a reactor. This could lead to the implementation of a pressure relief valve, a high-pressure alarm, and an emergency shutdown system.

Q 19. How do you manage process shutdowns and start-ups safely and efficiently?

Safe and efficient process shutdowns and start-ups are crucial for preventing accidents and optimizing production. My approach emphasizes a structured, documented process:

- Detailed Procedures: We develop and strictly adhere to detailed written procedures for both shutdowns and start-ups, covering all aspects of the process, including isolation of equipment, depressurization, purging, and energy isolation.

- Lockout/Tagout (LOTO) Procedures: Rigorous LOTO procedures ensure that equipment is properly isolated and de-energized before any maintenance or repair activities. This prevents accidental starts and protects personnel.

- Pre-Shutdown Checks: Before any shutdown, a thorough checklist of checks is completed to ensure the process is in a safe state to be shut down. This includes checking levels, pressures, and temperatures.

- Step-by-Step Approach: Shutdowns and start-ups follow a well-defined sequence of steps, avoiding shortcuts or deviations from the established procedures.

- Post-Shutdown Verification: Following a shutdown, checks are performed to ensure that the equipment is isolated and secured before maintenance activities can begin.

- Pre-Startup Checks: Before restarting a process, thorough checks are completed to ensure that systems are functioning correctly. This includes verifying the status of safety systems.

- Commissioning and Testing: Before returning to normal operations, testing and commissioning are conducted to verify safe and correct operation.

Training is essential; all personnel involved in shutdowns and start-ups receive comprehensive training to ensure competency and familiarity with the procedures.

Q 20. What are your experiences with Root Cause Analysis (RCA)?

Root Cause Analysis (RCA) is a systematic approach to identify the underlying causes of incidents or problems. My experience with RCA includes using various techniques such as:

- 5 Whys: A simple yet effective method where you repeatedly ask ‘why’ to drill down to the root cause. For example, why did the pump fail? Because it overheated. Why did it overheat? Because the cooling system malfunctioned. And so on.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps identify potential causes categorized by factors like equipment, people, processes, materials, and environment.

- Fault Tree Analysis (FTA): A deductive approach using logic gates to identify the combination of events leading to a specific undesirable event. It’s powerful for complex systems.

The key to effective RCA is to gather accurate data, interview witnesses, and systematically eliminate potential contributing factors until the root cause is identified. A thorough investigation is crucial to prevent similar incidents from recurring. Once identified, corrective actions are implemented to prevent future occurrences.

In one instance, I used FTA to analyze a process upset which resulted in identifying a flaw in the safety interlock system. Corrective actions included system improvements and better operator training to prevent future occurrences.

Q 21. Describe your understanding of different types of refinery products and their uses.

Refineries produce a wide array of products, each with specific applications. These can be broadly categorized:

- Fuels: This is the largest category, including gasoline, diesel fuel, jet fuel, and liquefied petroleum gas (LPG). These fuels are used in transportation, heating, and various industrial applications.

- Petrochemicals: These are the building blocks for plastics, synthetic fibers, fertilizers, and other chemicals. Examples include ethylene, propylene, benzene, and xylene.

- Lubricants: These are essential for reducing friction and wear in machinery, ranging from motor oils and greases to specialized industrial lubricants.

- Asphalt: Used extensively in road construction and roofing materials.

- Other Products: Refineries also produce waxes, solvents, and other specialty products.

The specific products a refinery produces depend on its configuration, feedstock, and market demands. For example, a refinery situated near a large petrochemical complex might emphasize the production of petrochemical feedstocks, whereas a refinery in a region with high demand for gasoline might focus on maximizing gasoline production.

Understanding the properties and uses of these products is critical for optimizing refinery operations and meeting market demands.

Q 22. Explain your experience with predictive maintenance techniques.

Predictive maintenance uses data analysis and machine learning to anticipate equipment failures before they occur, minimizing downtime and maximizing operational efficiency. Instead of relying on scheduled maintenance based on time intervals (preventive maintenance), we leverage real-time sensor data, historical performance records, and advanced algorithms to identify patterns and predict potential issues.

In my previous role, we implemented a system that monitored vibration levels in critical pumps. By analyzing the frequency and amplitude of vibrations, we could detect anomalies indicative of impending bearing failure. This allowed us to schedule maintenance proactively, preventing a costly shutdown and production loss. For example, a subtle shift in the vibration signature detected weeks in advance allowed for a planned bearing replacement during a scheduled turnaround, avoiding an emergency shutdown that would have cost hundreds of thousands of dollars and potentially injured personnel.

- Data Acquisition: Sensors collect data on temperature, pressure, vibration, and other critical parameters.

- Data Analysis: Algorithms analyze the data to identify trends and predict potential failures.

- Maintenance Scheduling: Maintenance tasks are scheduled proactively based on the predictions, optimizing maintenance frequency.

This approach not only reduces unplanned downtime but also extends the lifespan of equipment, lowering overall maintenance costs.

Q 23. How do you improve the efficiency and productivity of the petrochemical plant?

Improving the efficiency and productivity of a petrochemical plant is a multifaceted challenge requiring a holistic approach. It involves optimizing processes, improving equipment reliability, and enhancing workforce performance.

- Process Optimization: This involves analyzing process parameters (temperatures, pressures, flow rates) to identify bottlenecks and inefficiencies. Advanced process control (APC) systems and simulation tools can help refine operating conditions, reducing energy consumption and maximizing yield.

- Equipment Reliability: As discussed in the predictive maintenance section, minimizing downtime through proactive maintenance strategies is crucial. This also includes selecting and implementing robust equipment with longer lifespans and lower failure rates.

- Workforce Empowerment: Training employees on best practices, providing them with the right tools and technologies, and fostering a culture of continuous improvement significantly boosts productivity. Lean manufacturing principles, such as reducing waste and streamlining workflows, are essential in this context.

- Inventory Management: Efficient inventory management is key. Minimizing storage costs and ensuring timely availability of materials prevent production delays.

For example, in a previous project, we implemented an APC system that improved the yield of a key process by 5%, translating to millions of dollars in increased profitability annually. This demonstrates the significant impact even incremental improvements can have on a plant’s overall efficiency.

Q 24. Describe your experience working with cross-functional teams.

Throughout my career, I have consistently collaborated effectively within cross-functional teams. My experience includes working with engineers, technicians, operations personnel, safety specialists, and management to achieve common goals. I believe effective communication and mutual respect are paramount.

One significant project involved the implementation of a new safety system. This required extensive collaboration between process engineers, instrumentation technicians, safety managers, and operations personnel. I facilitated meetings, ensured clear communication of objectives, managed potential conflicts constructively, and actively sought input from all team members. This collaborative approach was crucial to the successful and timely completion of the project, exceeding safety standards and significantly improving operational safety.

My strengths in this area include: active listening, clear communication, conflict resolution, and fostering a collaborative and inclusive team environment.

Q 25. How do you handle pressure and prioritize tasks during emergencies or unplanned events?

Handling pressure during emergencies requires a calm, systematic approach. My strategy is based on a combination of prioritization, clear communication, and decisive action.

- Prioritization: During an emergency, I use a structured approach to prioritize tasks based on risk assessment and impact. The most critical issues, those posing the greatest safety or environmental threat, are addressed first.

- Communication: Clear and concise communication with all relevant personnel is essential. This includes providing updates, assigning tasks, and requesting support where necessary.

- Decisive Action: Once the priorities are established, decisive action must be taken. This may involve initiating emergency procedures, activating contingency plans, and mobilizing resources.

For example, during a sudden process upset, I successfully coordinated the emergency shutdown of a critical unit, preventing a potential major incident. This involved quickly assessing the situation, activating the emergency response plan, communicating with the control room and maintenance teams, and implementing corrective actions to restore stability.

Q 26. What are the key performance indicators (KPIs) you would monitor in a petrochemical plant?

Key Performance Indicators (KPIs) in a petrochemical plant are carefully selected to reflect overall performance, efficiency, safety, and environmental impact. The specific KPIs monitored will vary depending on the plant’s operations and strategic goals. However, several crucial KPIs commonly include:

- Production Volume & Yield: Measures the amount of product produced and the efficiency of the process.

- Operating Costs: Tracks energy consumption, raw material usage, and maintenance expenses.

- Uptime/Downtime: Reflects equipment reliability and the frequency of unplanned shutdowns.

- Safety Incidents: Records the number and severity of safety incidents, including near misses.

- Environmental Emissions: Monitors the release of pollutants into the air and water.

- Energy Efficiency: Measures energy consumption per unit of production.

- Waste Generation: Quantifies the amount of waste generated during the process.

Regular monitoring and analysis of these KPIs provide critical insights into operational effectiveness, allowing for timely intervention to address issues and improve overall performance.

Q 27. Describe your experience with data analysis and reporting in a petrochemical environment.

Data analysis and reporting are integral parts of my work in the petrochemical industry. I possess extensive experience in extracting, analyzing, and visualizing data from various sources, such as process control systems, sensor networks, and maintenance databases. This data provides critical insights into operational efficiency, equipment performance, and potential issues.

I use statistical software packages (such as R or Python) and data visualization tools (like Tableau or Power BI) to create comprehensive reports and dashboards. These tools help identify trends, anomalies, and areas for improvement. For example, by analyzing historical production data, I identified a correlation between specific process parameters and yield fluctuations, leading to process optimization efforts that improved efficiency and reduced waste.

My reports are designed to be clear, concise, and actionable, providing decision-makers with the necessary information to make informed decisions and optimize plant operations.

Q 28. How do you stay current with the latest advancements and technologies in the petrochemical industry?

Staying current with advancements in the petrochemical industry requires a multifaceted approach. I actively engage in continuous learning through several avenues:

- Industry Publications and Conferences: I regularly read industry journals, attend conferences, and participate in webinars to stay informed on the latest technologies and best practices.

- Professional Networks: I maintain active memberships in professional organizations (e.g., AIChE) and participate in industry forums to network with other professionals and share knowledge.

- Online Courses and Training: I leverage online learning platforms to acquire new skills and deepen my knowledge in specific areas, such as advanced process control or digital twin technologies.

- Collaboration and Knowledge Sharing: I actively participate in knowledge sharing within my team and across the organization, learning from the experiences of my colleagues and contributing my expertise.

This commitment to lifelong learning ensures that I remain at the forefront of innovation and apply the latest technologies and best practices to optimize plant operations and improve safety and environmental performance.

Key Topics to Learn for Petrochemical Production and Processing Interview

- Unit Operations: Understand the principles and applications of distillation, cracking, reforming, alkylation, and other key unit operations in petrochemical processing. Consider practical examples of troubleshooting common issues within these units.

- Process Control and Instrumentation: Familiarize yourself with process control systems, instrumentation, and safety interlocks. Be prepared to discuss your experience with process optimization and troubleshooting using control systems data.

- Reactor Design and Operation: Grasp the fundamentals of reactor design, including kinetics, thermodynamics, and reaction mechanisms. Practice applying this knowledge to different reactor types used in petrochemical production.

- Feedstock and Product Analysis: Learn about the different analytical techniques used to characterize feedstocks and products. Be able to discuss quality control measures and their importance in maintaining product specifications.

- Safety and Environmental Regulations: Demonstrate a strong understanding of safety protocols, environmental regulations (e.g., emissions control), and risk management in the petrochemical industry. Be ready to discuss relevant safety procedures and emergency response plans.

- Process Simulation and Modeling: Gain experience with process simulation software (mentioning specific software isn’t required). Understanding process modeling enables effective problem-solving and optimization.

- Economic Evaluation of Processes: Develop the ability to assess the economic viability of different petrochemical processes, considering factors like capital costs, operating expenses, and profitability.

Next Steps

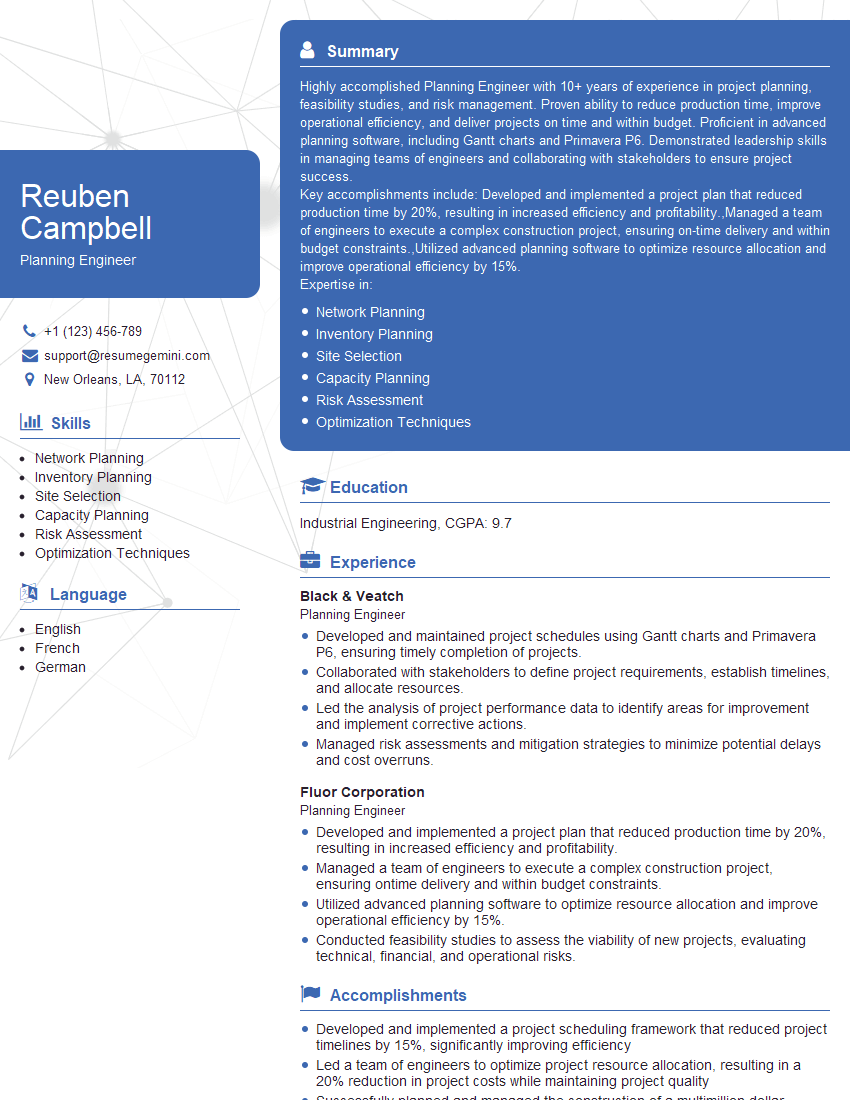

Mastering Petrochemical Production and Processing opens doors to exciting and rewarding careers within a dynamic and essential industry. Your expertise in this field will be highly sought after, leading to increased job opportunities and career advancement. To maximize your job prospects, it’s crucial to create a compelling and ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can significantly enhance your resume-building process, helping you craft a professional document that stands out to potential employers. Examples of resumes tailored specifically to the Petrochemical Production and Processing field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.