Cracking a skill-specific interview, like one for Pipe Fitting and System Fabrication, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Pipe Fitting and System Fabrication Interview

Q 1. Explain the different types of pipe fittings and their applications.

Pipe fittings are essential components that connect, terminate, change direction, or branch pipe sections. They come in various types, each designed for specific applications. Choosing the right fitting is crucial for system integrity and performance.

- Elbows: Change the direction of the pipe flow. These can be 45-degree, 90-degree, or even sweeping elbows for smoother flow. Think of them like corners in a road network.

- Tees: Create a branch connection, allowing for splitting or joining flows. They’re like junctions where roads meet.

- Couplings: Connect two pipes of the same diameter. They ensure a continuous flow without any significant pressure drop.

- Reducers: Connect pipes of different diameters. Imagine connecting a major highway to a smaller street.

- Caps: Close off the end of a pipe, acting like a stopper.

- Unions: Allow for the disconnection and reconnection of pipes without disturbing other components. They’re extremely useful for maintenance and repairs.

- Flanges: Provide a robust connection, often used for larger diameter pipes and high-pressure applications. They’re strong, allowing large forces to be applied, similar to strong bolted connections in bridges.

- Nipples: Short pipe sections used as connectors between other fittings. These are like short connector roads between major junctions.

The application of each fitting depends heavily on factors such as pipe diameter, pressure rating, material, and the overall system design. For instance, high-pressure steam lines would require robust fittings like flanges, while low-pressure water lines might use simpler couplings.

Q 2. Describe the various methods used for cutting and threading pipes.

Cutting and threading pipes are crucial steps in pipe fitting. Several methods exist, each with its own advantages and disadvantages.

- Cutting: Pipes can be cut using various tools, including:

- Hand saws: Suitable for smaller pipes and slower, more precise cuts. Think of it as hand-carving a precise section.

- Power saws (e.g., reciprocating saws, chop saws): Faster and more efficient for larger pipes. They’re like using power tools for more efficient cuts.

- Pipe cutters: Designed specifically for clean, burr-free cuts on various pipe materials. These are specialized tools for clean cuts.

- Threading: After cutting, pipes often need threads for connecting fittings. Methods include:

- Hand dies: Require manual operation and are suitable for smaller pipes. It’s like crafting the threads carefully by hand.

- Power dies: Faster and more efficient for larger pipes, using a machine to create threads.

- Threading machines: Automated systems for high-volume threading operations. These are efficient for large-scale piping systems.

Choosing the correct cutting and threading method depends on the pipe material, diameter, and the overall project requirements. Safety precautions such as using appropriate personal protective equipment (PPE), like gloves and safety glasses, are always paramount.

Q 3. What are the safety precautions you take while working with high-pressure piping systems?

High-pressure piping systems pose significant risks. Safety precautions are not optional; they’re mandatory.

- Pressure testing: Before putting the system into service, a thorough pressure test is crucial to identify weak points. This is like stress testing the structure before use.

- Proper material selection: Using pipes and fittings with pressure ratings exceeding the operating pressure is non-negotiable. The materials must be rated for much higher pressures than are expected.

- Regular inspections: Visual inspections and possibly non-destructive testing (NDT) should be performed routinely to detect potential issues like corrosion or cracking. This is like checking for signs of wear and tear frequently.

- Pressure relief valves: Incorporating pressure relief valves is vital to prevent catastrophic failures in case of pressure surges. These valves are safety switches to prevent failure.

- Lockout/Tagout (LOTO) procedures: Strict LOTO procedures must be followed before any maintenance or repair work is conducted. LOTO is your procedure to prevent accidental start-ups during maintenance.

- Personal Protective Equipment (PPE): Using appropriate PPE, including safety glasses, gloves, and safety shoes, is crucial to protect against injuries. This is a must-have, ensuring your safety.

Failure to follow these safety measures can lead to serious injuries, property damage, and even fatalities. It’s always better to be overly cautious when working with high-pressure systems.

Q 4. How do you ensure the proper alignment of pipes during installation?

Proper pipe alignment is critical for preventing stress, leaks, and ensuring efficient fluid flow. Several methods ensure this:

- Pipe supports and hangers: These provide structural support and prevent sagging or misalignment. They’re the foundation of a well-aligned pipe.

- Lasers and levels: These tools help achieve accurate alignment, particularly over long distances. These are the precision tools for accurate alignment.

- Alignment tools: Specialized tools, such as pipe clamps and alignment guides, ensure precise alignment during assembly. These are the specialized helpers during assembly.

- Visual inspection: A thorough visual inspection is crucial to verify alignment at each stage of installation. Careful observation is important.

- Temporary supports: Temporary supports should be used until the final pipe supports are installed, ensuring stability during construction. Temporary measures are used to ensure stability.

Inaccurate alignment can lead to stress concentrations, causing leaks or even pipe failures. Precise alignment is therefore a cornerstone of safe and efficient piping systems.

Q 5. Explain the process of bending pipes using different techniques.

Pipe bending is a common practice that avoids the need for multiple fittings. Several techniques exist:

- Hand bending: Suitable for small-diameter, soft metal pipes. It’s a hands-on method, requiring skill and experience.

- Hydraulic benders: Use hydraulic pressure to bend pipes precisely and consistently. These are machines for precise bending.

- Spring bending: A spring is inserted into the pipe to support it during bending, preventing kinks. The spring helps in uniform bending.

- Mandrel bending: A mandrel is used inside the pipe to maintain its shape during bending, ensuring the internal diameter is preserved. The mandrel acts as a support to maintain shape.

The choice of technique depends on the pipe material, diameter, and the required bend radius. Incorrect bending can weaken the pipe, leading to failure, so proper technique is crucial.

Q 6. What are the different types of pipe materials and their suitability for various applications?

Pipes are made from various materials, each with unique properties.

- Steel: Strong, durable, and suitable for high-pressure applications, but can be susceptible to corrosion. Think of it as the workhorse for strength.

- Copper: Highly corrosion-resistant, used for water and plumbing systems, but more expensive than steel. It’s known for its long life and resistance to corrosion.

- PVC (Polyvinyl Chloride): Lightweight, corrosion-resistant, and cost-effective, ideal for low-pressure applications but has limitations at higher temperatures. It’s a practical choice for lower-pressure applications.

- CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC but can withstand higher temperatures, suitable for hot water systems. It’s PVC’s heat-resistant cousin.

- PEX (Cross-linked Polyethylene): Flexible, corrosion-resistant, and easy to install, widely used in modern plumbing systems. It’s the flexible and easy-to-install option.

Material selection is critical, considering factors like pressure, temperature, corrosion resistance, and cost. The wrong material choice can lead to system failure.

Q 7. How do you identify and address pipe leaks?

Pipe leaks can be dangerous and costly. Identifying and addressing them promptly is essential.

- Visual inspection: Look for signs like water stains, dampness, or visible dripping. This is the first step to detecting leaks.

- Pressure testing: Pressurize the system and monitor for pressure drops, indicating leaks. This helps pinpoint the location of a leak.

- Ultrasonic leak detection: This non-destructive method uses sound waves to detect leaks, even hidden ones. This is a precise and non-invasive method.

- Dye penetrant testing: A dye is applied to the pipe surface, revealing leaks through cracks or imperfections. This helps detect surface leaks.

- Repair methods: Repair methods depend on the type and location of the leak. These range from simple tightening of fittings to replacing sections of pipe.

Ignoring leaks can lead to significant water damage, structural issues, and health hazards. Prompt identification and repair are paramount for safety and cost-effectiveness.

Q 8. Explain the importance of proper pipe support and hangers.

Proper pipe support and hangers are absolutely critical for the longevity and safe operation of any piping system. Think of it like building a bridge – without adequate supports, the structure will collapse under its own weight or from external forces. In piping, insufficient support leads to pipe sag, stress concentration points, and potential leaks or even catastrophic failures.

Proper supports prevent excessive stress on the pipes, joints, and valves, reducing the risk of fatigue cracking and extending the lifespan of the entire system. They also minimize vibration and noise, particularly important in sensitive environments like hospitals or laboratories. The type of support needed varies greatly based on pipe size, material, contents (e.g., pressure, temperature, corrosiveness), and the overall system design.

- Examples of supports: These include spring hangers (allowing for thermal expansion), rigid supports (for fixed points), and constant support hangers (maintaining a consistent pipe elevation).

- Practical application: In a large industrial plant, inadequate pipe support might lead to a major leak, causing costly downtime, environmental damage, and safety hazards. A well-supported system ensures efficient and safe operation.

Q 9. Describe the process of installing valves and their various types.

Valve installation is a precise process requiring careful attention to detail. Incorrect installation can lead to leaks, malfunctions, and even safety hazards. The process typically involves several steps: selecting the right valve type for the application, preparing the pipe, installing the valve body, ensuring proper torque on the connections, and finally, testing for leaks.

Types of Valves: There’s a vast array of valve types, each designed for specific applications. Some common examples include:

- Gate Valves: Used for fully opening or closing flow, generally not for throttling.

- Globe Valves: Excellent for throttling (regulating flow), but have higher pressure drop than gate valves.

- Ball Valves: Simple, quick on/off operation, but not ideal for precise flow control.

- Check Valves: Prevent backflow in a piping system.

- Butterfly Valves: Used for larger diameter pipes, often for on/off control.

Installation Process: It always begins with careful pipe preparation, ensuring clean, square cuts and proper alignment. The valve is then installed, ensuring proper orientation and tightness of all connections. This often involves the use of specialized tools and techniques to avoid damaging the valve or the pipe. Finally, a thorough leak test is essential to verify a successful installation.

Example: Installing a globe valve in a high-pressure steam line requires specialized tools and careful attention to torque values to prevent leaks and potential burns.

Q 10. What are the common welding techniques used in pipe fitting?

Welding is a fundamental process in pipe fitting, creating strong and permanent joints. The choice of technique depends on factors like pipe material, diameter, and application requirements.

- Shielded Metal Arc Welding (SMAW): A common and versatile method, often called stick welding. It uses a consumable electrode coated with flux to protect the weld from atmospheric contamination. It’s robust and portable, suitable for various pipe materials and sizes.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, it uses a continuous wire electrode fed automatically. It’s faster than SMAW and produces cleaner welds, commonly used in automated systems.

- Gas Tungsten Arc Welding (GTAW): Or TIG welding, it uses a non-consumable tungsten electrode and an inert shielding gas like argon. This method creates high-quality, precise welds, ideal for thin-walled pipes and critical applications, but it’s slower than SMAW or GMAW.

Practical application: In offshore oil and gas platforms, GTAW is often preferred for its high-quality weld integrity due to the critical nature of the environment and the high pressures involved. In contrast, SMAW might be more suitable for field repairs where portability and ease of use are prioritized.

Q 11. How do you interpret piping and instrumentation diagrams (P&IDs)?

Piping and Instrumentation Diagrams (P&IDs) are the blueprints of a piping system. They’re schematic representations that show the arrangement of pipes, valves, instruments, and equipment, along with their interconnections. Interpreting P&IDs requires a solid understanding of piping symbols and engineering principles.

Interpretation process: It typically involves a systematic approach:

- Identify the key components: Understand the symbols for different valves, pumps, tanks, and instruments.

- Trace the flow path: Follow the lines representing pipes to understand the flow of fluids through the system.

- Analyze instrumentation: Understand the function of various instruments (pressure gauges, temperature sensors, flow meters, etc.) and their location within the system.

- Check for safety devices: Locate safety relief valves, pressure-reducing valves, and other safety-critical components.

- Examine line sizing and material specifications: P&IDs often include information about pipe size, material, and pressure ratings.

Example: A P&ID might show a process flow, starting with a pump, passing through a heat exchanger, and then proceeding to a storage tank, with various valves and instrumentation along the way to monitor and control the process.

Q 12. Explain the importance of pressure testing in pipe systems.

Pressure testing is a crucial step in verifying the integrity of a piping system. It ensures that the system can withstand the designed operating pressure without leaks or failures. This prevents costly leaks, environmental damage, and safety hazards during operation.

The process: Typically involves pressurizing the system to a predetermined test pressure, usually higher than the operating pressure, and then monitoring for leaks. The test pressure and duration are determined based on the design specifications and applicable codes.

Methods: Pressure testing might involve using air, water, or other suitable fluids. Leaks are typically detected by visual inspection, pressure gauges, or specialized leak detection equipment.

Importance: Imagine a new pipeline carrying natural gas. A pressure test before commissioning is vital to prevent a potentially catastrophic failure that could cause significant damage and pose serious safety risks.

Q 13. What are the different types of pipe insulation and their applications?

Pipe insulation is essential for maintaining the temperature of fluids within a piping system. The choice of insulation depends on several factors: operating temperature, environmental conditions, and cost considerations.

- Fiberglass insulation: Common for moderate temperatures, relatively inexpensive, and easy to install.

- Calcium silicate insulation: Suitable for high-temperature applications, offering excellent thermal performance and fire resistance.

- Polyurethane foam insulation: Offers excellent thermal performance, lightweight, and often used for cryogenic applications.

- Mineral wool insulation: Excellent thermal and acoustical properties, good for fire protection.

Applications: In a steam line, high-temperature insulation like calcium silicate would be necessary to prevent heat loss and maintain steam pressure. In chilled water lines, polyurethane foam might be used to minimize energy loss and maintain cold temperatures. The selection of insulation impacts operational efficiency and minimizes energy costs and reduces environmental impact.

Q 14. How do you ensure the proper sizing of pipes for a given application?

Proper pipe sizing is critical for efficient and safe operation of a piping system. Undersized pipes lead to increased pressure drop, reduced flow rates, and potential equipment damage. Oversized pipes are inefficient and costly.

Sizing process: It involves several factors:

- Flow rate: The volume of fluid to be transported per unit time.

- Fluid properties: Viscosity, density, and temperature affect flow characteristics.

- Pressure drop: The pressure difference between the inlet and outlet of the pipe section.

- Pipe material: Roughness of the internal surface affects friction losses.

- Applicable codes and standards: These provide guidelines for acceptable pressure drops and velocity limits.

Methods: Pipe sizing is often done using specialized software or hand calculations based on established engineering formulas and standards such as those from ASME (American Society of Mechanical Engineers). The goal is to balance flow rate, pressure drop, and cost-effectiveness.

Example: If you’re designing a fire sprinkler system, undersizing the pipes could result in insufficient water flow to effectively suppress a fire. Using engineering software and adhering to relevant fire codes are essential to ensure the right pipe size is selected.

Q 15. What are the common codes and standards followed in pipe fitting?

Pipe fitting adheres to a variety of codes and standards, ensuring safety, functionality, and consistency across projects. The specific codes depend on the geographic location, the type of fluid being transported (e.g., water, gas, chemicals), and the application (e.g., industrial, residential). Some of the most common include:

- ASME B31.1: Power Piping – This covers piping systems in power generation facilities, focusing on pressure vessels and high-pressure applications. It’s rigorous, demanding precise calculations and material selection.

- ASME B31.3: Process Piping – This is crucial for chemical plants, refineries, and similar industrial settings. It addresses various process fluids and necessitates detailed consideration of corrosion and material compatibility.

- ASME B31.4: Pipeline Transportation Systems for Liquids and Slurries – Deals with large-scale pipelines often used for transporting oil or gas over long distances. This involves significant considerations for environmental impact and pipeline integrity.

- ASME B31.8: Gas Transmission and Distribution Piping Systems – Focuses on the safe and reliable transportation of natural gas. It addresses issues specific to gas pressure regulation and leak detection.

- National and Local Codes: Many countries and regions have their own building codes and regulations that must be followed, often referencing or adopting aspects of these ASME standards. These might include specifics related to fire safety, accessibility, or material approvals.

Ignoring these standards can lead to catastrophic failures, environmental damage, and severe safety hazards. Adherence is crucial for project success and liability protection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different pipe joining methods (e.g., welding, threading, flanging).

My experience spans a wide range of pipe joining methods, each suitable for different applications and material types. I’ve worked extensively with:

- Welding: This is a common method for joining steel pipes, offering high strength and durability. I’m proficient in various welding techniques including SMAW (stick welding), GMAW (MIG welding), and GTAW (TIG welding), selecting the appropriate method based on the pipe material, diameter, and project requirements. For instance, TIG welding is often preferred for high-purity applications to minimize contamination.

- Threading: Ideal for smaller diameter pipes made from materials like black iron or galvanized steel, threading provides a relatively quick and easy connection. However, it’s less suitable for high-pressure applications compared to welding. I’ve extensively used threading tools and understand the importance of proper thread preparation and sealing to prevent leaks.

- Flanging: Flanged joints are essential for larger diameter pipes and high-pressure applications, allowing for easier disassembly and maintenance. The process involves installing flanges onto the pipe ends and connecting them using bolts and gaskets. This method requires precision in alignment and torque control to ensure a leak-free, robust connection. I’ve worked with various flange types including slip-on, weld-neck, and blind flanges.

- Other methods: My experience also includes using compression fittings, mechanical couplings, and solvent welding (for plastic pipes), each chosen according to material, pressure, and project-specific requirements.

Choosing the right joining method is critical to the project’s success, requiring a thorough understanding of material properties, application demands, and safety considerations.

Q 17. How do you handle unexpected problems or challenges during pipe fitting projects?

Unexpected problems are inherent in pipe fitting. My approach involves a structured problem-solving methodology:

- Assessment: First, I thoroughly assess the nature and extent of the problem. This includes identifying the cause, potential impacts, and any safety hazards.

- Risk Mitigation: Next, I prioritize safety and take immediate steps to mitigate any risks associated with the problem, ensuring the safety of myself and others on the site.

- Problem-solving: I systematically explore solutions. This often involves consulting relevant codes, engineering drawings, and experienced colleagues. I might need to rework sections, adjust calculations, or source alternative materials.

- Documentation: I meticulously document all steps taken, including the problem, the implemented solution, and any lessons learned. This is vital for future reference and continuous improvement.

- Prevention: After resolving the issue, I analyze the root cause to implement preventive measures and avoid similar problems in future projects. This might involve refining processes, improving training, or recommending changes to the design.

For example, discovering a previously undetected pipe corrosion during a routine inspection required immediate action. We temporarily isolated the section, investigated the extent of the damage, and repaired the pipe using appropriate welding techniques, documenting every step and taking preventive measures to monitor for future corrosion.

Q 18. Explain your experience with different types of pipe supports and hangers.

Pipe support selection is crucial for preventing stress and ensuring the longevity of the piping system. My experience includes working with various types:

- Rigid Supports: These provide fixed points of support, often used for anchoring the piping system. Examples include weld-on supports, base plates, and concrete saddles. These are crucial for controlling expansion and contraction in the pipes.

- Flexible Supports: These allow for some movement of the pipes, accommodating thermal expansion and vibration. Examples include spring hangers, constant support hangers, and sway braces. Proper selection depends on the pipe material, diameter, operating temperature, and fluid type.

- Variable Spring Hangers: These are designed to compensate for variations in weight due to fluid changes or temperature fluctuations, maintaining constant support tension.

- Rod Hangers: These are simple and cost-effective supports used for lighter pipes and less demanding applications.

Incorrect support selection can lead to pipe stress, vibration, and ultimately, failure. I consider factors like pipe weight, fluid pressure, thermal expansion, vibration frequencies, and seismic activity when designing and implementing pipe support systems. Proper spacing and orientation of supports are key for optimized performance.

Q 19. What is your experience with pipe stress analysis?

Pipe stress analysis is essential for large-scale and complex piping systems to ensure structural integrity and prevent failures. My experience involves using specialized software (like CAESAR II or AutoPIPE) to perform these analyses. This involves:

- Creating a 3D model: Accurately modeling the piping system, including all components, supports, and connections.

- Defining loads and constraints: Inputting all relevant loads such as pipe weight, fluid pressure, thermal expansion, wind loads, and seismic loads, as well as specifying boundary conditions and support restraints.

- Running the analysis: Using the software to perform the calculations and determine stresses, displacements, and reactions at various points in the system.

- Interpreting results: Analyzing the results to ensure that stresses are within allowable limits and that the system meets all design criteria. This may lead to adjustments in pipe routing, support configurations, or material specifications.

I use these analysis results to optimize pipe routing, support configurations, and material selection, preventing potential failures and ensuring the system’s long-term reliability. For instance, I recently identified a potential stress concentration in a high-pressure steam line during an analysis, allowing us to modify the support system before any issues occurred.

Q 20. Describe your experience with different types of pipe insulation materials and methods.

Pipe insulation is crucial for maintaining fluid temperature, preventing condensation, and improving energy efficiency. My experience covers various materials and methods:

- Insulation Materials: I’ve worked with materials such as fiberglass, calcium silicate, polyurethane foam, and mineral wool, selecting the best material based on temperature range, environmental conditions, and chemical compatibility. Factors like thermal conductivity, moisture resistance, and fire rating are carefully considered.

- Insulation Methods: I am familiar with various installation methods, including wrapping, lagging, and pre-fabricated insulation sections. Proper installation is vital for achieving effective insulation and avoiding thermal bridges or air gaps, which would reduce efficiency.

- Protective Jackets: I also have experience installing protective jackets over the insulation to protect it from damage and the environment. These jackets can be made from materials like aluminum, galvanized steel, or plastic.

Effective insulation is not merely about choosing the right material but also about proper installation techniques to prevent heat loss or gain and prolong the lifespan of the piping system. For example, I recently oversaw the installation of high-temperature insulation on a process line, paying close attention to minimizing heat loss and ensuring that the installation complied with all relevant safety regulations.

Q 21. How familiar are you with using different types of measuring tools and equipment?

Proficiency with various measuring tools is fundamental to accurate and efficient pipe fitting. I’m adept at using:

- Tape Measures: For measuring distances, pipe lengths, and overall dimensions of the system.

- Level and Plumb Bob: Ensuring proper alignment and verticality of pipes.

- Calipers and Micrometers: Precisely measuring pipe diameters and thicknesses for material selection and fitting.

- Laser Levels and Transits: For accurate alignment over longer distances and complex geometries.

- Pipe Thread Gauges: Verifying the correct thread size and type during threading operations.

- Torque Wrenches: Ensuring correct tightening of bolts and flanges to prevent leaks and damage.

Beyond the tools themselves, understanding their limitations and applying appropriate calibration procedures is crucial for ensuring accuracy and project success. Incorrect measurements can lead to fitting problems, leaks, and even safety hazards. I always ensure that all measuring instruments are regularly calibrated and used correctly to maintain quality and accuracy throughout the project.

Q 22. What is your experience with working in confined spaces?

Working in confined spaces is a regular part of pipefitting, often involving tanks, trenches, or ductwork. Safety is paramount. My experience includes thorough familiarity with confined space entry permits, atmospheric monitoring using gas detectors (to check for oxygen levels, flammables, and toxic gases), and the proper use of personal protective equipment (PPE) such as respirators, harnesses, and fall protection. I’ve participated in numerous confined space rescue training courses and always ensure a reliable communication system is in place before entering. For example, during a recent project involving a large underground water tank, we meticulously followed all confined space entry protocols, testing the atmosphere multiple times before commencing work and having a standby rescue team present throughout the operation.

Q 23. Describe your experience with working at heights?

Working at heights is another common aspect of pipefitting, particularly during the installation of overhead piping systems. I have extensive experience using fall protection equipment such as harnesses, lifelines, and anchor points. I’m proficient in various access methods including scaffolding, aerial lifts, and swing stages, always adhering to strict safety regulations. For instance, while installing a new HVAC system on a multi-story building, I supervised a team ensuring every worker had the correct harness and that all anchor points were properly inspected and secured. Regular safety meetings and toolbox talks emphasizing fall prevention were a key part of our process.

Q 24. What safety certifications do you hold relevant to pipe fitting?

I hold several safety certifications relevant to pipefitting, including OSHA 10-hour and 30-hour certifications, confined space entry certification, fall protection certification, and hazardous materials handling certification. I also possess certifications for specific equipment operation, such as aerial lift operation and crane signaling. These certifications demonstrate my commitment to safety and my knowledge of industry best practices. I regularly update my certifications to remain current with the latest safety regulations and technology.

Q 25. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace is crucial for safety and efficiency. My approach involves a combination of practices. First, I always begin with a thorough site assessment to plan the layout of tools, materials, and equipment. This minimizes wasted movement and prevents clutter. Secondly, I implement a system of regular cleanup throughout the workday, immediately putting tools and materials away after use. Thirdly, I utilize designated areas for different materials, tools, and waste disposal, keeping the workspace free of trip hazards. Think of it like a well-organized kitchen – everything has its place, making it easy to find what you need and preventing accidents. This is particularly important in tight spaces where even a small obstruction can cause a significant issue.

Q 26. Explain your understanding of pipe system flushing and cleaning procedures.

Pipe system flushing and cleaning are critical steps to remove debris, welding flux, and other contaminants before the system goes into operation. The process generally involves several stages. First, a thorough visual inspection of the entire system is performed. Then, a pre-flush with water is carried out to remove loose debris. Next, a chemical cleaning agent may be used to remove stubborn deposits followed by a thorough rinsing process. Finally, the system is carefully inspected again to ensure cleanliness and the absence of any remaining contaminants. For example, in a recent project involving a high-purity water system, we followed strict procedures based on industry standards like ASME B31.1, using specific cleaning chemicals and documenting every step of the process. The entire operation had to be rigorously documented and approved before commissioning.

Q 27. Describe your experience with the installation and maintenance of different types of pumps.

I have experience installing and maintaining various types of pumps, including centrifugal pumps, positive displacement pumps, and submersible pumps, across a range of applications including water supply, wastewater treatment, and chemical processing. This involves selecting the appropriate pump based on system requirements, installing it correctly, ensuring proper alignment, and conducting routine maintenance including lubrication, bearing inspection, and seal replacement. Troubleshooting pump issues is also a part of my experience. For example, I recently diagnosed and repaired a malfunctioning centrifugal pump by identifying a problem with the impeller. The problem was solved by replacing the impeller and carefully realigning the pump.

Q 28. What is your approach to troubleshooting problems in a piping system?

My approach to troubleshooting problems in a piping system is systematic and thorough. It begins with a careful assessment of the problem, gathering data through observation, pressure readings, flow measurements, and visual inspection. Then I use that data to create a hypothesis of the root cause. Next, I perform tests to confirm my hypothesis and rule out other potential causes. Once the cause is identified, I develop a plan for the repair or replacement, always prioritizing safety. For instance, if a system is experiencing low pressure, I’d systematically check for leaks, inspect the pump performance, and verify the valve settings before considering more complex issues like a blockage or pump failure. Documenting every step is crucial for future reference.

Key Topics to Learn for Your Pipe Fitting and System Fabrication Interview

Ace your interview by mastering these essential areas. Remember, understanding the “why” behind the “how” will set you apart.

- Blueprint Reading and Interpretation: Understanding technical drawings, isometric drawings, and specifications is crucial for accurate fabrication and installation.

- Pipe Material Selection and Properties: Know the characteristics of various pipe materials (steel, PVC, copper, etc.) and their suitability for different applications. Be ready to discuss factors influencing material choice like pressure, temperature, and corrosive environments.

- Cutting, Bending, and Joining Techniques: Demonstrate familiarity with various pipe fitting methods, including threading, welding (different types), soldering, and use of various joining fittings. Be prepared to explain the advantages and disadvantages of each method.

- Safety Regulations and Procedures: Highlight your understanding of OSHA regulations and best practices for working safely with tools and materials in pipefitting and system fabrication.

- Troubleshooting and Problem-Solving: Discuss your approach to identifying and resolving common issues encountered during installation and maintenance, such as leaks, pressure drops, and alignment problems.

- Fabrication Processes and Techniques: Explain your experience with different fabrication techniques, including prefabrication, on-site assembly, and the use of specialized tools and equipment.

- System Testing and Commissioning: Describe your knowledge of pressure testing, leak detection, and other methods used to ensure the proper functioning of fabricated systems.

- Measuring and Layout Techniques: Demonstrate understanding of accurate measurement and layout procedures to ensure proper fit and function of pipe systems.

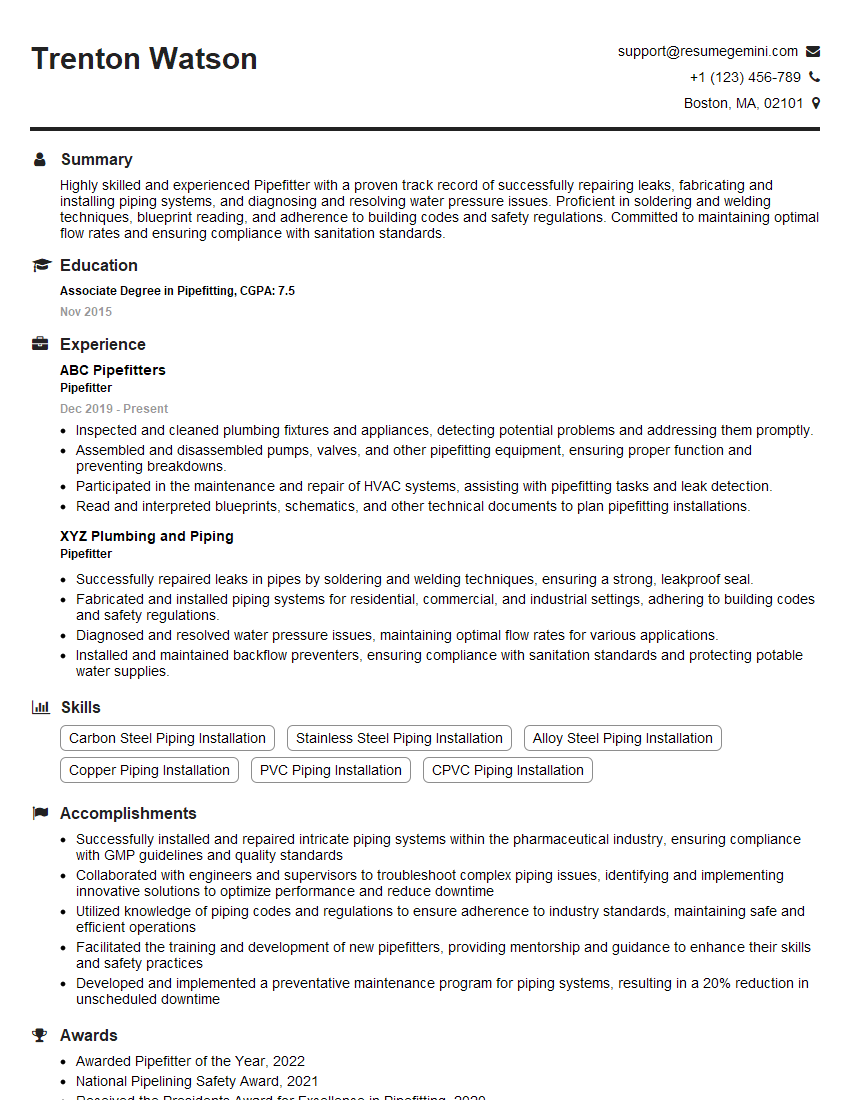

Next Steps: Building Your Future in Pipe Fitting and System Fabrication

Mastering pipe fitting and system fabrication opens doors to a rewarding career with excellent growth potential. To maximize your job prospects, a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the Pipe Fitting and System Fabrication industry to guide you. Take the next step towards your dream career – build a standout resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.