Cracking a skill-specific interview, like one for Pipefitter Apprentice, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Pipefitter Apprentice Interview

Q 1. What are the different types of pipe materials used in pipefitting?

Pipe materials are chosen based on factors like the fluid being transported, pressure, temperature, and cost. Common materials include:

- Steel: A strong and durable option, often used for high-pressure applications. Different grades exist, offering varying levels of strength and corrosion resistance. Think of the large pipes you see in industrial plants.

- Copper: Excellent corrosion resistance and relatively easy to work with, making it suitable for plumbing in residential and commercial buildings. It’s often used for water lines.

- PVC (Polyvinyl Chloride): A lightweight and cost-effective plastic pipe, commonly used for drainage and lower-pressure applications. You’ll find this frequently in home plumbing systems.

- CPVC (Chlorinated Polyvinyl Chloride): A stronger and higher-temperature-resistant version of PVC, often used in hot water systems.

- Cast Iron: Historically common, but less frequent now due to its weight and susceptibility to corrosion. It’s still seen in older infrastructure.

- Stainless Steel: Offers exceptional corrosion resistance and is used where hygiene is paramount, such as in food processing plants or pharmaceutical facilities.

The selection process involves careful consideration of the project’s specific demands to ensure longevity and safety.

Q 2. Explain the process of cutting and threading pipes.

Cutting and threading pipes is a crucial skill for any pipefitter. The process usually involves these steps:

- Measuring and Marking: Accurately measure the required pipe length and mark the cut point.

- Cutting: Use a pipe cutter (for clean cuts on smaller pipes) or a hacksaw (for larger pipes). Ensure a square cut to avoid leaks.

- Deburring: Remove any sharp edges or burrs from the cut end using a deburring tool. This prevents damage to threads and ensures a smooth, safe surface.

- Threading: Use a pipe threading machine (for efficiency and precision) or hand dies (for smaller jobs). Proper lubrication is essential to prevent thread damage and improve the quality of the thread.

- Inspection: Carefully inspect the threads to ensure they are clean, straight, and free from damage.

For example, when working on a gas line, precision is paramount. A poorly cut or threaded pipe could lead to gas leaks, so meticulous attention to detail is critical.

Q 3. Describe different pipe fitting methods (e.g., soldering, welding).

Pipe fitting methods vary depending on the material and application. Key methods include:

- Soldering: Used with copper pipes, it involves melting solder (a metal alloy) to create a strong, leak-proof joint. Flux is used to clean the surfaces and aid in the soldering process. This method requires a specific temperature range and good ventilation.

- Welding: Used for steel and other metals, welding involves fusing the pipe ends together using high heat. Different welding techniques like arc welding or MIG welding are used based on the project requirements. This is often used in high-pressure applications and requires proper safety equipment.

- Threaded Connections: Common for steel and other types of pipes, threaded connections use fittings that screw onto the pipe threads. Teflon tape or pipe dope is often applied to create a seal. This is a relatively quick and easy method for joining pipes.

- Solvent Welding: Used for PVC and CPVC pipes, it involves applying a solvent cement that melts the surfaces of the pipes and fittings, creating a strong, chemical bond. Appropriate ventilation is crucial due to solvent fumes.

- Compression Fittings: These fittings use a compression ring to create a seal around the pipe. They are often used for quick repairs or temporary connections and require specific tools.

Each method demands specialized skills and safety protocols, and choosing the right one is based on project needs and material characteristics.

Q 4. What safety precautions must be followed while working with pipes?

Safety is paramount in pipefitting. Essential precautions include:

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and appropriate footwear to protect against cuts, burns, and other hazards. Respiratory protection might be needed when working with solvents or welding.

- Confined Space Entry: Follow strict procedures when working in confined spaces, including proper ventilation and atmospheric monitoring to prevent asphyxiation.

- Fall Protection: Use harnesses and fall protection equipment when working at heights.

- Lockout/Tagout Procedures: Always lock out and tag out energy sources (electricity, gas, etc.) before starting work to prevent accidental activation.

- Fire Safety: Be aware of fire hazards associated with welding and soldering, having fire extinguishers readily available.

- Material Safety Data Sheets (MSDS): Familiarize yourself with MSDSs for all materials used to understand their potential hazards and proper handling procedures.

A lack of safety awareness can lead to serious injuries, so adhering to these measures is non-negotiable.

Q 5. How do you identify different pipe sizes and schedules?

Pipe sizes are typically expressed in nominal diameter (inches or millimeters), and schedules indicate wall thickness. Nominal diameter is not the exact inside diameter but a standard designation. Schedules are represented by numbers (e.g., Schedule 40, Schedule 80). Higher schedule numbers indicate thicker walls and greater pressure ratings.

For example, a 2-inch Schedule 40 pipe has a nominal diameter of 2 inches but a different actual inside and outside diameter than a 2-inch Schedule 80 pipe, with the latter having a much thicker wall.

Pipe size and schedule markings are usually stamped onto the pipe itself, allowing for easy identification. This information is crucial for selecting appropriate fittings and ensuring the pipeline can withstand the intended pressure.

Q 6. What are the common tools used in pipefitting?

The tools used in pipefitting are diverse, depending on the task. Essential tools include:

- Pipe Cutters: For cutting pipes cleanly and accurately.

- Hacksaws: For cutting larger pipes or materials that pipe cutters can’t handle.

- Pipe Wrenches: For tightening and loosening threaded fittings.

- Pipe Threading Machine/Dies: For creating threads on pipes.

- Soldering Iron/Torch: For soldering copper pipes.

- Welding Machine: For welding steel and other metal pipes.

- Level: For ensuring pipes are properly aligned.

- Measuring Tapes/Rules: For accurate measurements.

- Pipe Vise: To securely hold pipes during cutting and threading.

- Deburring Tools: For smoothing the edges of cut pipes.

Having the right tools makes the job much easier, safer, and results in a more professional-looking and functional installation.

Q 7. Explain the concept of pipe expansion and contraction.

Pipes expand when heated and contract when cooled. This thermal expansion and contraction is significant, especially in long pipelines or those carrying hot fluids. Failure to account for this can lead to stress on the pipes, causing leaks or even pipe failure.

Imagine a long metal rod heated; it will noticeably lengthen. Pipes behave similarly. To mitigate these effects, expansion loops or bellows are incorporated into the pipeline design. These flexible sections absorb the expansion and contraction, preventing stress buildup. Proper pipe support and anchoring are also essential to prevent movement and damage.

Understanding and managing thermal expansion and contraction is critical for ensuring the long-term reliability and safety of pipe systems.

Q 8. How do you interpret pipefitting blueprints and schematics?

Interpreting pipefitting blueprints and schematics is fundamental to a pipefitter’s job. It’s like reading a map for a complex plumbing system. These documents provide detailed information about pipe sizes, materials, locations, and connections. I start by understanding the overall layout of the system – identifying the main pipelines, branches, and equipment connections. Then, I meticulously examine each section, paying close attention to:

- Pipe size and material: The blueprint clearly indicates the diameter and type of pipe (e.g., steel, PVC, copper) needed for each section.

- Pipe routing and elevation: This guides the precise path of the pipes, considering factors like slopes for drainage and clearances around other equipment.

- Fittings and valves: The schematics show the various fittings (elbows, tees, unions) and valves needed to control flow and direction. Knowing the purpose of each fitting is crucial.

- Support and anchoring points: The drawings indicate locations for pipe supports, crucial for preventing sagging and stress on the system.

- Isometric drawings: These 3D views are invaluable for complex systems, helping to visualize the spatial relationships between pipes and fittings.

For example, I once worked on a project where a complex isometric drawing showed a series of intertwined pipes running through a tight space. By carefully studying the angles and distances in the isometric, I was able to precisely cut and assemble the pipes, ensuring a perfect fit.

Q 9. What is the importance of proper pipe support and anchoring?

Proper pipe support and anchoring are paramount for the safety and longevity of any piping system. Imagine a long chain – if unsupported, it will sag and eventually break. Similarly, unsupported pipes are subject to stress, vibration, and potential failure, leading to leaks, damage to equipment, and even safety hazards. Proper support:

- Reduces stress and strain: Prevents sagging and deformation of the pipe, extending its lifespan.

- Minimizes vibration: Dampens vibrations caused by fluid flow, reducing noise and wear.

- Ensures system stability: Supports the weight of the pipes and their contents, preventing collapses.

- Enhances safety: Prevents pipes from falling, potentially causing injury or damage.

The type of support used depends on factors such as pipe size, material, pressure, temperature, and the surrounding environment. Common supports include hangers, clamps, and restraints. For instance, in a high-pressure steam system, specialized supports are necessary to withstand the high temperatures and potential expansion of the pipes. Ignoring proper support is a recipe for disaster; I’ve seen projects delayed and even costly repairs required because of inadequate support.

Q 10. Describe your experience with different types of pipe joints.

My experience encompasses a wide range of pipe joints, each with its own advantages and disadvantages. The choice of joint depends on factors such as pipe material, pressure, temperature, and accessibility. Some common types include:

- Threaded joints: Relatively simple and inexpensive for smaller pipes, but can be time-consuming for larger diameters and may leak if not properly sealed.

- Flanged joints: Strong and reusable, ideal for high-pressure applications, but require more space and components.

- Welding joints: Offer excellent strength and leak tightness for permanent connections, suitable for high-pressure and high-temperature applications, but require specialized skills and equipment.

- Socket weld joints: Similar to welding but with a smaller weld area, suitable for smaller pipes.

- Compression fittings: Quick and easy to install, ideal for smaller diameter pipes, but may not be suitable for high-pressure applications.

I’ve worked extensively with all these types, adapting my approach based on the project requirements. For instance, on a recent project involving a high-pressure gas line, we used flanged joints to ensure a robust and easily maintainable connection. Conversely, for low-pressure water lines in a residential setting, compression fittings were a more efficient and cost-effective option.

Q 11. Explain the process of pressure testing pipes.

Pressure testing is a crucial step in ensuring the integrity of a piping system before it goes into operation. It’s like giving the system a thorough check-up to identify any leaks or weaknesses. The process generally involves:

- Preparing the system: Ensure all connections are tight, valves are properly positioned, and the system is clean.

- Pressurizing the system: Using a pressure pump or compressed air, the system is pressurized to a specific test pressure, which is usually higher than the system’s operating pressure. This is often specified in the project’s design documents.

- Monitoring the pressure: The pressure is closely monitored for any drops, which indicate a leak.

- Locating leaks: If pressure drops are observed, careful inspection is necessary to pinpoint the leak location. Soap solution can be applied to joints and welds to reveal bubbles, indicating a leak.

- Repairing leaks: Any leaks identified must be repaired before proceeding further.

- Final pressure test: Once repairs are complete, a final pressure test is performed to confirm the system’s integrity.

Safety is paramount during pressure testing. Appropriate safety precautions must be taken to prevent injury from potential bursts or leaks. I have personally overseen many pressure tests, always ensuring strict adherence to safety protocols.

Q 12. How do you identify and resolve common pipefitting problems?

Identifying and resolving pipefitting problems requires a systematic approach. I often use a troubleshooting checklist, starting with the most obvious issues:

- Visual inspection: Carefully examine the entire system for visible leaks, corrosion, or damage.

- Pressure testing: As mentioned before, pressure testing is a crucial method for detecting leaks.

- Check valve operation: Ensure all valves are functioning properly and are in the correct position.

- Examine supports and anchors: Check for loose or damaged supports, which could cause pipe sagging or stress.

- Review blueprints and schematics: Verify that the system was installed according to the design specifications.

If a problem is found, the solution will depend on the nature of the issue. A simple leak might be resolved by tightening a connection or applying sealant. More serious issues, such as corrosion or significant damage, may require pipe replacement or extensive repairs. For example, I once encountered a recurring leak on a specific joint despite tightening. Upon closer inspection, I discovered a microscopic crack in the pipe itself. This led to the strategic replacement of that section of the pipe, preventing further issues.

Q 13. What are the different types of pipe insulation?

Pipe insulation serves to control the temperature of the fluid inside the pipe, preventing energy loss or protecting against freezing. The choice of insulation depends on factors such as temperature, pipe material, and environmental conditions. Common types include:

- Fiberglass insulation: A common and cost-effective option, suitable for a wide range of temperatures.

- Calcium silicate insulation: Excellent for high-temperature applications, such as steam lines.

- Polyurethane foam insulation: Offers good thermal performance and is often used for cold water lines or in areas with significant temperature fluctuations.

- Mineral wool insulation: Provides good fire resistance and sound insulation, often used in industrial settings.

Proper installation of insulation is critical for its effectiveness. It should be applied neatly and completely, with no gaps or air pockets. Incorrect insulation can result in heat loss or gain, leading to increased energy consumption or equipment failure. I’ve seen instances where improperly installed insulation resulted in significant heat loss and a considerable increase in the energy bill for the facility.

Q 14. How do you work with different types of pipe hangers and supports?

Pipe hangers and supports are crucial for providing stability and preventing stress on the piping system. The type of hanger or support used depends on factors such as pipe size, weight, material, and the environment. Some common types include:

- Constant support hangers: Provide consistent support throughout the length of the pipe.

- Variable spring hangers: Compensate for thermal expansion and contraction, preventing stress on the pipes.

- Rigid supports: Provide fixed points of support, often used for anchoring the system.

- Trapeze hangers: Used for supporting multiple pipes or heavy components.

Proper installation of hangers and supports is crucial to prevent sagging, vibrations, and premature failure of the pipe system. For example, during my apprenticeship, I learned that incorrect installation of spring hangers can lead to unnecessary stress on the pipe and ultimately cause leaks. My instructor stressed the importance of carefully calculating the spring tension and ensuring correct alignment during installation.

Q 15. What is your experience with working in confined spaces?

Working in confined spaces is a regular part of a pipefitter’s job, and safety is paramount. My experience includes working inside tanks, trenches, and other enclosed areas. Before entering any confined space, I always ensure that a permit-to-work is in place, which outlines the necessary safety precautions. This includes checking for atmospheric hazards like oxygen deficiency or the presence of flammable gases using appropriate monitoring equipment. I’m trained in the use of breathing apparatus and understand the importance of having a designated attendant outside the confined space who can monitor my condition and provide assistance if needed. One specific instance involved working inside a large water tank during a maintenance project. We meticulously followed the permit-to-work procedures, and the presence of a standby worker was crucial when a piece of equipment malfunctioned, requiring a quick exit.

Furthermore, I’m proficient in using various safety harnesses and retrieval systems in case of emergencies. We regularly practice confined space rescue techniques and emergency procedures to maintain preparedness and teamwork.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with various pipe welding techniques.

I’m experienced in several pipe welding techniques, including:

- Shielded Metal Arc Welding (SMAW): A common and versatile technique, particularly useful in various positions and for outdoor applications. I’m proficient in selecting the appropriate electrodes for different pipe materials and thicknesses. For example, I’ve used E6010 for vertical-up welding and E7018 for critical applications needing high strength.

- Gas Metal Arc Welding (GMAW): Excellent for high-speed welding and producing consistent welds. I’ve used GMAW extensively on stainless steel pipes, appreciating its clean weld appearance and ability to weld thin materials. I am familiar with different wire feed speeds and gas mixtures to optimize the weld quality.

- Gas Tungsten Arc Welding (GTAW): This technique is ideal for precise welds on intricate joints and critical applications where high-quality is crucial. I utilize GTAW for stainless steel and other specialty metal piping, valuing its control over heat input and ability to achieve excellent weld penetration.

I’m also familiar with the importance of proper joint preparation, preheating, and post-weld heat treatment to ensure the integrity and longevity of the welds. My welding certifications demonstrate my compliance with relevant industry safety codes.

Q 17. Explain your understanding of different pipe fitting codes and standards.

My understanding of pipe fitting codes and standards is comprehensive. I’m familiar with ASME B31.1 (Power Piping), ASME B31.3 (Process Piping), and ANSI/ASME B16.5 (Flanges and Flanged Fittings). These codes cover crucial aspects like material selection, design pressure, stress calculations, and welding procedures. I understand the implications of adhering to these standards, which directly impacts the safety and longevity of the piping systems. For instance, choosing the wrong material for a high-temperature application could lead to catastrophic failure. Similarly, incorrect welding techniques can compromise the structural integrity of the joints. I always cross-reference design drawings with the appropriate codes to ensure compliance.

I’m also proficient in interpreting isometric drawings, which are essential for understanding the routing and orientation of pipes within a system.

Q 18. How do you maintain cleanliness and orderliness in your work area?

Maintaining a clean and orderly workspace is critical for safety and efficiency. Before starting any work, I organize my tools and materials logically, ensuring easy access to everything I need. As I work, I consistently clear away debris and scrap material, preventing accidents and ensuring a safe working environment for myself and others. At the end of each day, I leave my area tidy, storing tools properly and disposing of waste materials responsibly. This helps ensure a more organized, efficient, and safe working environment for the next day. A clean workspace is also a sign of respect for my colleagues and the overall worksite.

Q 19. What is your experience with using measuring and alignment tools?

Accurate measurements and alignment are fundamental to pipefitting. I’m experienced in using a variety of tools, including:

- Measuring tapes: For determining pipe lengths and distances.

- Levels: Ensuring pipes are properly leveled and aligned horizontally.

- Plumb bobs: To verify vertical alignment.

- Laser levels and alignment tools: To ensure precise alignment over long distances.

- Dial indicators: For precise measurement of alignment, often used in conjunction with laser levels to guarantee exact placement.

I understand the importance of using the right tool for each task and regularly inspect my tools to ensure their accuracy and functionality. For example, a worn-out measuring tape could lead to significant errors in measurements.

Q 20. How do you ensure the proper alignment and slope of pipes?

Ensuring proper alignment and slope is critical for the efficient flow of liquids or gases through a piping system. I use a combination of tools and techniques to achieve this. Initially, I carefully review the isometric drawings and specifications to understand the required alignment and slope. Then, I utilize levels, plumb bobs, and laser alignment tools for precise measurements and adjustments. For example, to ensure the correct slope for drainage, I calculate the required drop per unit length and use a level to fine-tune the pipe’s position. I also employ pipe supports and hangers to maintain the intended alignment and prevent sagging or misalignment. In situations with long runs of pipe, I often work with a team to ensure consistency and accuracy throughout the installation. I also cross-check my work against the blueprints throughout the process.

Q 21. What is your experience with different types of pipe valves?

My experience encompasses a wide range of pipe valves, including:

- Gate valves: Used for on/off control. I understand their limitations, such as not being ideal for throttling.

- Globe valves: Better for throttling and flow regulation than gate valves but offer higher pressure drop.

- Ball valves: Quick-opening valves ideal for on/off control and relatively low maintenance.

- Butterfly valves: Similar to ball valves but typically used for larger diameter pipes. I understand their potential for cavitation if not used correctly.

- Check valves: Prevent backflow in the piping system.

I understand the importance of selecting the appropriate valve for each application based on factors like pressure, temperature, fluid type, and required flow control. For example, a gate valve would be suitable for a large water main, while a globe valve may be preferred for precise flow control in a process line. Mismatched valves could result in inefficiency, leaks or even system failure.

Q 22. Describe your understanding of different pipe fitting systems.

Pipefitting systems vary greatly depending on the application, material, and pressure requirements. Understanding these systems is crucial for a pipefitter. Here are some key types:

- PVC (Polyvinyl Chloride): Common for lower-pressure applications like drainage and irrigation. It’s lightweight, relatively inexpensive, and easy to work with, but has temperature limitations. Joining methods usually involve solvent welding or using compression fittings.

- CPVC (Chlorinated Polyvinyl Chloride): A stronger and more heat-resistant version of PVC, often used in hot water systems. Joining methods are similar to PVC.

- Steel: Used for high-pressure applications and demanding industrial settings. Steel pipes require specialized tools for cutting, threading, and welding. Different types of steel exist, each with varying strength and corrosion resistance. Common joining methods include threading, welding (including arc welding and stick welding), and flanging.

- Copper: Known for its corrosion resistance and durability, often found in residential and commercial plumbing systems. Joining methods include soldering, brazing, and compression fittings.

- Cast Iron: Historically common, though less prevalent now, due to its weight and potential for corrosion. It’s still used in certain situations due to its strength and durability. Joining is often done with threaded connections or bell and spigot joints.

Each system demands specific knowledge of its properties and appropriate joining techniques. For instance, you wouldn’t use PVC for high-pressure steam lines, nor would you solder steel pipes.

Q 23. How do you handle unexpected problems during pipefitting?

Unexpected problems are commonplace in pipefitting. My approach focuses on a systematic problem-solving method:

- Assess the situation: Safety first! Identify the problem, its potential consequences (leaks, pressure loss, structural damage), and potential hazards.

- Gather information: Check blueprints, specifications, and available tools. Consult with experienced colleagues or supervisors if necessary.

- Develop solutions: Brainstorm potential solutions. Consider temporary fixes to mitigate immediate issues and long-term solutions to address the root cause.

- Implement the solution: Carefully implement the chosen solution, ensuring adherence to safety regulations and best practices. Document the process.

- Test and evaluate: After implementing the solution, thoroughly test the system to ensure it’s functioning correctly and safely. Record observations.

For example, encountering a misaligned pipe section mid-project, I’d first ensure the area is safe, then review the blueprints to confirm the correct alignment. I would then carefully adjust the pipe using appropriate tools and techniques, ensuring proper support and stability, and finally test for leaks.

Q 24. What are your strengths and weaknesses as a pipefitter apprentice?

Strengths: I’m a quick learner, detail-oriented, and possess excellent problem-solving skills. My hands-on experience has provided me with a solid understanding of various pipefitting techniques and materials. I also strive to maintain a high level of safety awareness at all times.

Weaknesses: As an apprentice, my experience with certain specialized tools and techniques is still developing. I’m actively working to improve my proficiency in these areas through practice and mentorship. I sometimes need to improve time management on complex projects, but I am implementing techniques like breaking down tasks into smaller, manageable units to improve this area.

Q 25. Describe your experience working in a team environment.

I thrive in team environments. During my apprenticeship, I’ve consistently worked alongside journeymen and other apprentices. This collaborative experience has taught me the importance of clear communication, mutual respect, and effective teamwork. We rely on each other for support, problem-solving, and efficient task completion. For example, when installing a complex piping system, one team member might focus on cutting and threading pipes while another focuses on welding or installing supports. The successful completion of the project depends on our collaborative effort and clear communication.

Q 26. How do you prioritize tasks and manage your time effectively?

Prioritizing tasks and managing time effectively is crucial in pipefitting. I utilize several strategies:

- Project Breakdown: I break down large projects into smaller, manageable tasks. This approach makes the overall project less daunting and allows me to focus on individual steps.

- Prioritization Matrix: I use a prioritization matrix (like Eisenhower Matrix) to categorize tasks based on urgency and importance. This helps me tackle the most critical tasks first.

- Time Estimation: I try to realistically estimate the time required for each task, factoring in potential delays. This aids in creating a realistic schedule.

- Regular Check-ins: I regularly review my progress to ensure I’m on track and make adjustments as necessary.

For instance, on a project with multiple pipe sections to install, I’d first prioritize the sections critical to the system’s functionality before moving to less critical parts. This ensures the project remains on schedule and avoids potential bottlenecks.

Q 27. What are your career goals as a pipefitter?

My career goal is to become a highly skilled and proficient journeyman pipefitter. I aim to develop expertise in various pipefitting systems and welding techniques. Long-term, I aspire to take on leadership roles, potentially becoming a foreman or supervisor, mentoring future apprentices and contributing to the safety and efficiency of larger-scale projects. I also want to continue my professional development, keeping my skills current with advancements in technology and industry best practices.

Q 28. Are you comfortable working at heights and in various weather conditions?

Yes, I am comfortable working at heights and in various weather conditions. Safety is my paramount concern, and I always adhere to safety regulations and use appropriate safety equipment such as harnesses, fall protection systems, and appropriate clothing for different weather conditions. I understand that working at heights and in inclement weather requires extra caution and vigilance, and I’m prepared to handle such situations safely and effectively. My experience has included working on scaffolding, using aerial lifts, and working in both extreme heat and cold.

Key Topics to Learn for Pipefitter Apprentice Interview

- Blueprint Reading and Interpretation: Understanding technical drawings, including piping diagrams, isometrics, and specifications. Practice interpreting symbols and dimensions to visualize the planned pipe system.

- Pipefitting Materials and Their Properties: Familiarize yourself with various pipe materials (steel, copper, PVC, etc.), their strengths, weaknesses, and appropriate applications. Understand the importance of material selection for different pressures and environments.

- Pipe Fabrication Techniques: Gain a solid understanding of cutting, threading, bending, and joining pipes using different methods (welding, soldering, etc.). Be prepared to discuss safety procedures associated with each technique.

- Measuring and Cutting Techniques: Precision is paramount. Be ready to discuss accurate measuring methods and the importance of minimizing waste and ensuring precise cuts for proper fitting.

- Safety Regulations and Procedures: Demonstrate knowledge of OSHA regulations and safety protocols relevant to pipefitting, including lockout/tagout procedures, proper use of personal protective equipment (PPE), and hazard identification.

- Pipe Support and Hanger Systems: Understand the principles of pipe support design and installation to ensure structural integrity and prevent damage to the piping system. Be able to discuss different types of hangers and supports.

- Troubleshooting and Problem-Solving: Prepare examples of how you’ve approached challenges in similar tasks, demonstrating your analytical and problem-solving skills. This could include scenarios related to leaks, incorrect measurements, or unexpected issues during installation.

- Basic Math and Geometry: Demonstrate proficiency in calculations related to pipe dimensions, angles, and volumes. Understanding basic geometry is crucial for successful pipefitting.

Next Steps

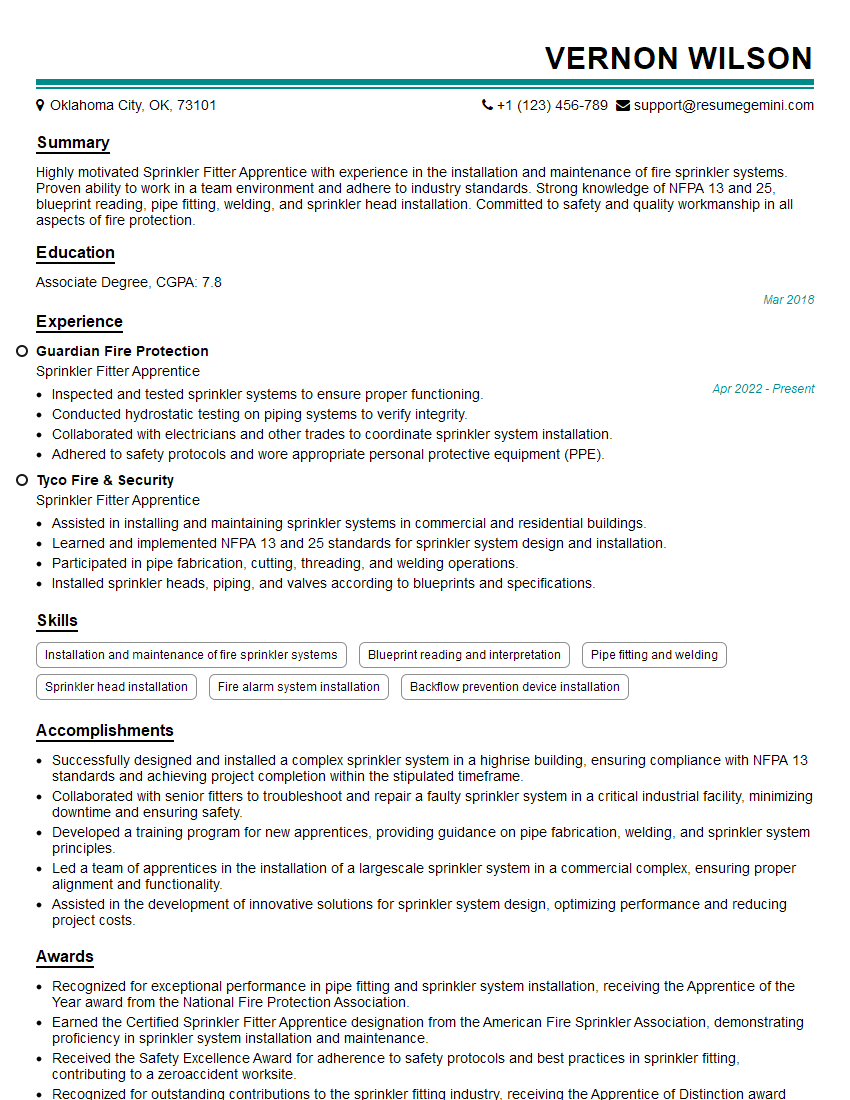

Mastering the skills and knowledge required for a Pipefitter Apprentice position is a crucial step towards a rewarding and stable career in the trades. A strong foundation in these areas will open doors to advancement and specialization within the field. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to Pipefitter Apprentice positions are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.