Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential PLC and SCADA Systems Integration interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in PLC and SCADA Systems Integration Interview

Q 1. Explain the difference between a PLC and a PAC.

While both PLCs (Programmable Logic Controllers) and PACs (Programmable Automation Controllers) are industrial computers used for automation, key differences exist. Think of a PLC as a specialized workhorse, optimized for high-speed, deterministic control of discrete I/O (inputs and outputs like sensors and actuators). They excel at tasks like controlling conveyor belts or managing simple machine operations. A PAC, on the other hand, is more of a versatile multi-tasker. It combines the real-time control capabilities of a PLC with the advanced processing power of an industrial PC, allowing for more complex tasks like data acquisition, motion control, and advanced process control. This means PACs can handle sophisticated algorithms and integrate more seamlessly with enterprise systems.

For example, a PLC might be ideal for managing a simple bottling line, while a PAC might be better suited for a complex chemical process requiring advanced calculations and extensive data logging. The choice depends entirely on the application’s complexity and demands.

Q 2. Describe the different types of PLC programming languages (e.g., Ladder Logic, Function Block Diagram).

PLCs support various programming languages, each with its strengths and weaknesses. The most common is Ladder Logic (LD), visually representing logic circuits using rungs and contacts—intuitively familiar to electricians. It’s excellent for simple control tasks, easy to understand and maintain.

- Ladder Logic (LD): Resembles electrical relay logic diagrams, making it accessible to electricians and technicians.

Example: If Input1 AND Input2 THEN Output1 := TRUE; - Function Block Diagram (FBD): Uses graphical blocks representing functions, interconnected by data flows. This is useful for modular programming and complex algorithms.

Example: A block representing a PID controller takes setpoint, process value, and output as inputs. - Structured Text (ST): A high-level text-based language similar to Pascal or C. It’s ideal for complex logic and mathematical calculations but may require more programming expertise.

Example: IF temperature > 100 THEN fan := TRUE; END_IF; - Instruction List (IL): A low-level mnemonic language. Useful for small tasks but can become difficult to read and maintain for large projects.

- Sequential Function Chart (SFC): Used for representing sequential processes, ideal for describing processes with different steps and transitions between them.

The choice of programming language depends on the project’s complexity, the programmer’s experience, and maintainability considerations. Larger projects often benefit from a combination of languages to leverage each one’s strengths.

Q 3. What are the advantages and disadvantages of using different communication protocols (e.g., Modbus, Ethernet/IP, Profibus)?

Various communication protocols allow PLCs and SCADA systems to exchange data. Each has its own advantages and disadvantages:

- Modbus: A simple, widely used, and open protocol. It’s relatively easy to implement and troubleshoot but can be slow for large data transfers. It’s a good option for simpler applications where speed isn’t critical.

- Ethernet/IP: A high-speed, robust protocol specifically designed for industrial automation environments. It offers excellent performance and features like device-level ring topology and integrated diagnostics, making it ideal for larger, complex systems where speed and reliability are essential. However, it is a proprietary protocol from Rockwell Automation.

- Profibus: A fieldbus protocol offering high speed and determinism. It is a widely accepted standard but can be more complex to set up and maintain compared to Modbus. It’s frequently used in factory automation environments.

The best protocol depends on the system’s requirements—speed, reliability, cost, and compatibility with existing hardware.

Q 4. How do you troubleshoot a PLC program?

Troubleshooting a PLC program involves a systematic approach. I typically start by reviewing the program’s logic, looking for any obvious errors or inconsistencies. Then, I utilize the PLC’s diagnostics tools to check the status of I/O points, identify any faults, and examine program execution history. Online monitoring and debugging features within the PLC programming software are invaluable. If the issue persists, I might use a logic analyzer to examine signals and pinpoint any discrepancies between expected and actual behavior. Step-by-step debugging helps narrow down potential causes. I also consider environmental factors—power issues, faulty wiring, or sensor malfunctions—as they might affect PLC operation.

For example, if a conveyor belt isn’t starting, I’d first check if the start button signal is reaching the PLC correctly. If that’s fine, I’d trace the program logic to see if the appropriate output is being activated. If not, I’d investigate further for programming faults, faulty wiring, or problems with the motor controller.

Q 5. Explain the concept of a SCADA system and its components.

A SCADA (Supervisory Control and Data Acquisition) system is a software and hardware system used to monitor and control industrial processes. Think of it as a central nervous system for an industrial plant. Its primary components include:

- PLCs/RTUs (Remote Terminal Units): The field devices collecting data from sensors and actuators.

- Communication Network: Connects the PLCs/RTUs to the SCADA server. This can include various protocols like Modbus, Ethernet/IP, or Profibus.

- SCADA Server: The central computer running SCADA software. It processes data from the field devices, performs calculations, and provides visualization tools.

- HMI (Human-Machine Interface): The user interface allowing operators to monitor and interact with the system. Typically, this is a graphical display, showing real-time data and offering control functionalities.

- Databases: Used for storing historical data and alarms for analysis and reporting.

A SCADA system provides centralized control and monitoring of distributed industrial processes, leading to improved efficiency and safety.

Q 6. Describe your experience with HMI design and development.

I have extensive experience in HMI design and development, employing various tools and methodologies to create intuitive and effective interfaces. My approach centers around understanding the user’s needs and the process being controlled. I strive to create clear, concise displays that convey crucial information at a glance. I leverage tools such as Wonderware InTouch, Ignition, and Siemens WinCC to develop HMIs, selecting the most appropriate tool based on the project’s needs and client preferences. I incorporate best practices for color coding, alarm management, and navigation to improve operator efficiency and reduce errors. I’ve worked on projects ranging from simple dashboards for small-scale systems to complex interfaces for large-scale industrial plants.

For example, in one project, we designed an HMI with a geographically organized layout for a large water treatment plant. This allowed operators to easily identify and respond to issues in specific sections of the plant. User feedback was crucial in refining the design and ensuring optimal usability.

Q 7. How do you handle data acquisition and logging in a SCADA system?

Data acquisition and logging in a SCADA system is vital for monitoring, analysis, and reporting. Data is collected from PLCs and RTUs through communication protocols. The SCADA server then processes and stores this data in a database, usually a historical database, typically an SQL database or a dedicated SCADA database. Data logging is configured to record specific parameters at defined intervals or triggered by events like alarms. The frequency of data logging depends on the application’s requirements. Real-time data is presented on the HMI, and historical data enables trend analysis, performance monitoring, and troubleshooting.

For instance, in a power generation plant, we might log parameters such as voltage, current, frequency, and temperature at one-second intervals. This detailed logging allows us to monitor the plant’s performance and identify potential issues before they escalate. Alarms are often triggered to alert operators to critical events.

Q 8. Explain the role of alarm management in a SCADA system.

Alarm management in a SCADA system is crucial for monitoring the operational status of industrial processes and ensuring timely responses to abnormal situations. It involves the detection, notification, and management of events that deviate from predefined setpoints or normal operating conditions. Think of it like a sophisticated early warning system for your factory floor.

A well-designed alarm system should:

- Detect Events: Continuously monitor process variables (temperature, pressure, flow, etc.) and trigger alarms based on pre-configured thresholds (high/low limits, rate-of-change limits).

- Prioritize Alarms: Categorize alarms based on severity (critical, major, minor) to guide operator response and prevent alarm flooding (too many alarms at once). Imagine a fire alarm versus a low-ink warning – you handle them very differently.

- Notify Operators: Use various methods like audible alarms, visual indicators on HMIs (Human-Machine Interfaces), and email/SMS notifications to alert operators.

- Facilitate Acknowledgement & Response: Provide a mechanism for operators to acknowledge alarms, indicating they’ve been reviewed. The system should also help operators diagnose the cause of alarms and provide guidance on corrective actions.

- Record Alarm History: Maintain a detailed log of all alarms, including timestamps, severity, and operator actions. This is vital for troubleshooting, performance analysis, and regulatory compliance.

Poor alarm management can lead to missed critical events, delayed responses, and even safety hazards. Effective alarm management ensures process stability, improves operational efficiency, and enhances safety.

Q 9. Describe your experience with different SCADA software platforms (e.g., Ignition, Wonderware, Siemens WinCC).

I have extensive experience with several leading SCADA platforms, including Ignition, Wonderware System Platform, and Siemens WinCC. My work has spanned diverse industrial settings, from water treatment plants to manufacturing facilities.

- Ignition: I’ve utilized Ignition’s open-source nature and its extensive library of add-ons to develop customized SCADA solutions with great flexibility. Its ease of use and powerful scripting capabilities made it ideal for rapid prototyping and deployment in several projects.

- Wonderware System Platform: I’ve leveraged Wonderware’s robust features for large-scale applications demanding high reliability and security. Its integrated historian and advanced alarming capabilities have been particularly valuable in complex process control environments.

- Siemens WinCC: My experience with WinCC includes integrating it with Siemens PLCs (like S7-1200 and S7-1500) for seamless communication and control. I’ve found its strong integration with the broader Siemens automation ecosystem advantageous for projects with a predominantly Siemens automation infrastructure.

Each platform offers unique strengths; the choice depends on the project’s specific needs, budget, and existing infrastructure. I am proficient in adapting my skills to various platforms and can effectively evaluate the best solution for any given scenario.

Q 10. How do you ensure the cybersecurity of a PLC and SCADA system?

Cybersecurity is paramount in PLC and SCADA systems, as a compromise can lead to significant operational disruptions, safety hazards, and even financial losses. My approach to securing these systems is multi-layered and follows a defense-in-depth strategy.

- Network Segmentation: Isolate the PLC and SCADA network from the corporate network and the internet. This limits the impact of a breach.

- Firewall & Intrusion Detection: Employ firewalls to control network traffic and intrusion detection systems (IDS) to monitor for malicious activity.

- Access Control: Implement strong password policies and role-based access control to limit access to authorized personnel only. Use multi-factor authentication where possible.

- Regular Software Updates & Patching: Keep all software and firmware up-to-date with the latest security patches. Outdated software is a major vulnerability.

- Security Hardening: Configure PLCs and SCADA servers with the most restrictive security settings possible, disabling unnecessary services and protocols.

- Intrusion Prevention Systems (IPS): Deploy IPS to actively block malicious traffic and prevent attacks before they reach the system.

- Regular Security Audits & Penetration Testing: Conduct regular security assessments to identify vulnerabilities and ensure the effectiveness of security measures. Penetration testing simulates real-world attacks to uncover weaknesses.

Beyond technical measures, a strong security culture is crucial. This includes regular employee training on cybersecurity best practices and incident response procedures.

Q 11. Explain the concept of redundancy and its importance in industrial automation.

Redundancy in industrial automation refers to the inclusion of backup components or systems to ensure continued operation even if a primary component fails. It’s like having a spare tire in your car – you hope you never need it, but it’s essential to have in case of a flat.

Redundancy is critical because:

- Increased Reliability: Minimizes downtime and maximizes uptime, reducing production losses and improving overall efficiency.

- Improved Safety: Prevents catastrophic failures that could lead to safety hazards or environmental damage.

- Enhanced System Availability: Ensures continuous operation of critical processes, even during equipment malfunctions or power outages.

Examples of redundancy include redundant PLCs, power supplies, network switches, and communication links. The specific implementation depends on the application’s criticality and cost considerations. A simple example is having two PLCs running in parallel, with one acting as a hot standby, taking over immediately if the primary PLC fails. More complex implementations may use sophisticated failover mechanisms and automatic switching.

Q 12. Describe your experience with industrial networking and protocols.

My experience encompasses a wide range of industrial networking and protocols, including:

- Ethernet/IP: Commonly used in industrial automation for its speed and efficiency. I’ve used it extensively for integrating PLCs, HMIs, and other devices in various projects.

- PROFINET: Siemens’ proprietary industrial Ethernet protocol. I’ve worked with PROFINET in projects involving Siemens PLCs and automation components, benefiting from its seamless integration within the Siemens ecosystem.

- Modbus TCP/RTU: A widely adopted serial and Ethernet communication protocol. Its versatility makes it suitable for diverse applications and device integration.

- Profibus: Another fieldbus protocol, predominantly used in the process automation sector. I have experience integrating Profibus devices in some of the larger scale process automation projects.

- OPC UA: A platform-independent standard for data exchange in industrial automation. I’ve used OPC UA for interoperability between various devices and software platforms from different vendors, reducing integration complexity.

Understanding these protocols and their strengths is crucial for building efficient and reliable industrial communication networks. My expertise allows me to select the appropriate protocols based on the specific project requirements, ensuring optimal performance and interoperability.

Q 13. How do you handle data archiving and historical trending in a SCADA system?

Data archiving and historical trending are vital for monitoring process performance, identifying trends, diagnosing issues, and complying with regulatory requirements. In a SCADA system, this is typically managed using a historian database.

The historian stores vast amounts of process data over extended periods, providing valuable insights into past operations. This data is used for:

- Performance Analysis: Identifying areas for improvement and optimization.

- Troubleshooting: Investigating the root cause of past problems.

- Regulatory Compliance: Meeting data retention requirements mandated by various industries.

- Predictive Maintenance: Predicting potential equipment failures based on historical data analysis.

Common historian databases include:

- PI System (OSIsoft): A widely used industry-standard historian known for its scalability and reliability.

- Wonderware Historian: Tightly integrated with Wonderware System Platform, offering efficient data management within that environment.

- Ignition’s built-in historian: Offers a good balance of functionality and ease of use for smaller deployments.

Historical trending allows visualizing process variables over time, facilitating easy identification of patterns and anomalies. Data is often archived in a compressed format to manage storage space effectively.

Q 14. What is a PID controller and how does it work?

A Proportional-Integral-Derivative (PID) controller is a feedback control loop mechanism widely used in industrial automation to maintain a desired process variable at a setpoint. Think of it like a thermostat in your house – it continuously monitors the temperature and adjusts the heating/cooling to keep the temperature at your desired setting.

The PID controller uses three terms to calculate the control output:

- Proportional (P): The output is proportional to the error (difference between the setpoint and the measured value). A larger error results in a larger output.

- Integral (I): The output is proportional to the integral of the error over time. This term addresses persistent errors that the proportional term alone might not correct. Imagine a slow temperature drift – the integral term helps to eliminate it gradually.

- Derivative (D): The output is proportional to the rate of change of the error. This term anticipates future errors and prevents overshoot or oscillations. Think of it as a braking system to slow things down as the desired value is approached.

The overall control output is a combination of these three terms: Output = Kp * Error + Ki * ∫Error dt + Kd * dError/dt, where Kp, Ki, and Kd are tuning parameters that need to be adjusted to optimize the controller’s performance for a specific application.

Proper tuning of these parameters is crucial for achieving stable and efficient process control. Poorly tuned PID controllers can lead to instability, oscillations, or sluggish response.

Q 15. Describe your experience with different types of sensors and actuators.

My experience with sensors and actuators spans a wide range of technologies used in industrial automation. Think of sensors as the ‘eyes and ears’ of a system, providing data about the real world, while actuators are the ‘muscles,’ carrying out actions based on that data.

- Temperature Sensors: I’ve extensively worked with thermocouples, RTDs (Resistance Temperature Detectors), and thermistors for precise temperature measurement in various applications, from oven control to HVAC systems. For example, I once integrated a thermocouple into a PLC system controlling a high-temperature furnace, ensuring accurate temperature regulation and safety.

- Pressure Sensors: I’m familiar with different pressure sensor technologies, including piezoresistive and capacitive sensors. These are frequently used in process control applications, like monitoring pressure in pipelines or hydraulic systems. I remember troubleshooting a pressure sensor issue in a water treatment plant, which involved analyzing the sensor’s signal and calibrating it to ensure accurate readings.

- Proximity Sensors: Inductive, capacitive, and photoelectric proximity sensors are vital for detecting the presence or absence of objects without physical contact. These are common in robotic systems, conveyor belt monitoring, and machine safety systems. In one project, I used photoelectric sensors to detect product jams on a high-speed packaging line.

- Actuators: My experience includes working with pneumatic and electric actuators. Pneumatic actuators, using compressed air, are robust and reliable in harsh environments. Electric actuators, such as servo motors and stepper motors, offer precise positioning and control. I’ve utilized servo motors in a robotics project to achieve very accurate movements.

Understanding the limitations and strengths of each sensor and actuator type is crucial for effective system design and troubleshooting. For example, a thermocouple might be preferable for high-temperature applications, while a capacitive sensor might be better suited for detecting liquids. Choosing the right technology often involves careful consideration of factors such as cost, accuracy, and environmental conditions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform a system backup and restore?

System backups and restores are crucial for maintaining data integrity and ensuring business continuity. My approach follows a robust, multi-layered strategy.

- Regular Backups: I schedule automatic backups of the PLC program, SCADA configuration files, historical data, and database information at regular intervals (often daily or even more frequently for critical systems). The frequency depends on the criticality of the system and the rate of data change.

- Multiple Backup Locations: Backups are stored in at least two different locations, one on-site and one off-site (e.g., cloud storage or a separate server). This safeguards against data loss due to local disasters or hardware failures.

- Version Control: I leverage version control systems (discussed in detail later) to track changes to the PLC and SCADA programs, allowing for easy rollback to previous versions if necessary.

- Backup Verification: I regularly test the restore process by periodically restoring a backup to a separate test environment to ensure its integrity and recoverability.

- Documentation: Detailed documentation accompanies each backup, including the date, time, and version number, as well as any specific notes or changes made since the last backup.

During a restore, I follow a documented procedure to ensure minimal downtime. This typically involves shutting down the system safely, restoring the backup to the designated location, and then verifying the system’s functionality after the restore.

Q 17. Explain your experience with version control systems for PLC and SCADA projects.

Version control is indispensable for managing PLC and SCADA projects, allowing for collaboration, tracking changes, and easy rollback to previous versions. My experience primarily involves using Git, a distributed version control system, although I’m also familiar with SVN.

- Branching and Merging: I utilize Git branches to develop and test new features or bug fixes in isolation from the main codebase. Once tested, these changes are merged into the main branch, ensuring a clean and controlled update process.

- Commit Messages: Clear and concise commit messages are essential for documenting each change. This allows others (and my future self) to understand the purpose and impact of each modification. I strive for descriptive messages that clearly explain the ‘what’ and ‘why’ of each code change.

- Code Reviews: Where possible, I incorporate code reviews into the workflow to ensure code quality and consistency. This helps to identify potential problems early on and promotes knowledge sharing within the team.

- Centralized Repository: The use of a centralized repository (like GitHub or GitLab) facilitates collaboration among team members and provides a secure backup of the project code.

For example, in a recent project involving a large SCADA system, using Git allowed multiple engineers to work concurrently on different parts of the system without interfering with each other’s work. When issues arose, we could easily revert to earlier versions to identify and fix problems quickly.

Q 18. Describe your experience with testing and commissioning of PLC and SCADA systems.

Testing and commissioning are critical phases of any PLC and SCADA project, ensuring the system operates safely, reliably, and meets the specified requirements. My approach is systematic and follows a structured methodology.

- Unit Testing: Individual components (sensors, actuators, PLC programs, SCADA screens) are tested in isolation to verify their proper function. This involves using simulated inputs and verifying expected outputs.

- Integration Testing: After unit testing, components are integrated and tested together to ensure proper communication and interaction. This involves verifying data flow between the PLC, SCADA system, and other devices.

- System Testing: The entire system undergoes rigorous testing under various operating conditions, including normal, abnormal, and failure scenarios. This involves simulating real-world scenarios and checking the system’s response. For example, a power failure simulation will verify the system’s backup power and fail-safe mechanisms.

- Factory Acceptance Testing (FAT): This testing is typically conducted at the vendor’s site to verify that the system meets the pre-defined specifications before shipment to the client’s site. This involves rigorous tests designed to validate the performance and functionality of the PLC/SCADA system.

- Site Acceptance Testing (SAT): After installation at the client’s site, SAT confirms that the system functions correctly within the actual operating environment. This often involves extensive field testing and close collaboration with client personnel.

Throughout this process, detailed test reports are created, documenting the tests performed, the results obtained, and any issues identified. These reports serve as crucial documentation for future troubleshooting and system maintenance.

Q 19. How do you document your PLC and SCADA projects?

Comprehensive documentation is essential for the success of any PLC and SCADA project. My documentation strategy emphasizes clarity, completeness, and accessibility.

- System Architecture Diagrams: High-level diagrams illustrating the overall system architecture, showing the interconnections between different components (PLCs, SCADA servers, sensors, actuators).

- PLC Program Documentation: Well-commented PLC code with clear variable names and structured logic. I also create detailed narratives explaining the functionality of each program section.

- SCADA Screen Documentation: Detailed descriptions of each SCADA screen, explaining the purpose, functionality, and interactions with other parts of the system.

- Database Design Documents: Comprehensive descriptions of the database schema and data structure. I strive to ensure that database design is efficient and adheres to database normalization principles.

- Hardware Specifications: A complete list of all hardware components used in the system, including model numbers, serial numbers, and vendor information.

- Test Procedures and Reports: Detailed documentation of all testing activities performed during commissioning and acceptance testing.

- Operator Manuals: Clear and concise manuals for operators, guiding them on the proper operation and maintenance of the system. Simple language and visual aids are incorporated to facilitate understanding for all technical skill levels.

I use a combination of documentation tools, including dedicated SCADA software tools, word processing software, and drawing software, to create a consistent and comprehensive documentation package.

Q 20. Describe your experience with different types of PLC architectures (e.g., rack-based, compact).

My experience encompasses various PLC architectures, each with its strengths and weaknesses. The choice of architecture depends on the size and complexity of the application.

- Rack-Based PLCs: These are modular systems with separate CPU, power supply, and I/O modules. They are highly scalable, allowing for easy expansion and customization. Rack-based systems are ideal for large, complex applications with numerous I/O points. I’ve used this architecture in large manufacturing plants requiring extensive monitoring and control.

- Compact PLCs: These are self-contained units with integrated CPU, power supply, and I/O in a single housing. They are compact, cost-effective, and suitable for smaller applications with limited I/O requirements. I used this in several smaller automation projects, such as controlling a single machine in a production line.

- Distributed Control Systems (DCS): DCS involves multiple PLCs communicating with each other and with a central supervisory system. This architecture is suited for large, geographically dispersed systems, providing redundancy and high availability. I’ve been involved in projects using DCS architectures in process industries requiring high reliability and safety.

The selection of the architecture is a crucial decision made during the design phase, considering factors such as the required I/O count, scalability needs, budget constraints, and redundancy requirements. For instance, a compact PLC would be sufficient for a simple machine control application, while a rack-based system or DCS would be necessary for a large, complex process control system.

Q 21. What are the different types of I/O modules used in PLC systems?

I/O modules are the interface between the PLC and the real-world devices (sensors and actuators). Different types of I/O modules are used depending on the type of signal being handled.

- Digital I/O Modules: These handle discrete signals, such as on/off switches, limit switches, and relay outputs. These modules are commonly used for simple control applications.

- Analog Input Modules: These handle analog signals, such as temperature, pressure, and flow measurements. They convert analog signals into digital values that the PLC can process. These are critical for applications requiring precise measurement and control.

- Analog Output Modules: These convert digital values from the PLC into analog signals for controlling analog devices, such as valves and variable-speed drives.

- Communication Modules: These enable communication between the PLC and other devices or systems, using protocols such as Ethernet/IP, Profibus, Modbus, or others. These are essential for integrating the PLC into a larger automation system.

- Specialized I/O Modules: There are also specialized I/O modules for specific applications, such as high-speed counters, pulse width modulation (PWM) outputs for motor control, and safety modules for implementing safety functions.

Choosing the correct I/O module is critical for ensuring reliable operation and accurate data acquisition. For instance, using an incorrect analog input module with the wrong signal range might lead to inaccurate measurements or system errors.

Q 22. Explain the concept of data logging and its importance in industrial automation.

Data logging in industrial automation is the continuous process of recording and storing data from various sources within a system, such as PLCs, sensors, and other devices. Think of it like a detailed diary for your industrial process. This data provides a historical record of system performance, allowing for analysis and optimization.

Its importance lies in several key areas:

- Troubleshooting: Identifying the root cause of malfunctions or unexpected behavior by examining historical data.

- Process Optimization: Analyzing trends and patterns to improve efficiency, reduce waste, and enhance product quality.

- Predictive Maintenance: Forecasting potential equipment failures based on historical data and preventing costly downtime.

- Regulatory Compliance: Meeting industry standards and regulations by documenting process parameters and events.

- Performance Monitoring: Tracking key performance indicators (KPIs) to assess system effectiveness.

For example, in a manufacturing plant, data logging might record temperature, pressure, and flow rate, allowing engineers to identify inefficiencies or deviations from optimal operating conditions.

Q 23. How do you handle different types of data formats (e.g., analog, digital, discrete)?

Handling diverse data formats is crucial in PLC/SCADA integration. We encounter analog signals (representing continuous values like temperature or pressure), digital signals (representing on/off states), and discrete signals (representing specific events).

The approach involves using appropriate hardware and software tools:

- Analog Data: Analog signals from sensors are typically converted to digital values using Analog-to-Digital Converters (ADCs) within the PLC. These digital values are then scaled and processed according to the sensor’s specifications. For example, a 0-10V analog signal representing temperature might be converted to an engineering unit like °C.

- Digital Data: Digital signals are directly read by the PLC’s input modules. These represent binary states (0 or 1) and often indicate on/off states of switches, sensors or limit switches.

- Discrete Data: Discrete signals represent specific events, such as a button press or a conveyor belt completing a cycle. These are usually handled as digital signals with additional logic within the PLC program to interpret their meaning.

Software plays a critical role. The SCADA system must be configured to understand the data type and scale it appropriately. Data formatting and conversion functions are often built into the SCADA software or can be implemented using scripting languages.

Q 24. Describe your experience with integrating PLCs with other systems (e.g., ERP, MES).

I’ve extensively integrated PLCs with various systems, including ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System). This typically involves communication protocols like OPC UA, Modbus TCP/IP, or proprietary protocols.

Example: ERP Integration: In one project, we integrated a PLC controlling a packaging line with an ERP system to track production quantities, material usage, and finished goods inventory. The PLC sent production data to the ERP using OPC UA, allowing real-time updates to inventory levels and production reporting. This streamlined production tracking and provided accurate inventory information across the enterprise.

Example: MES Integration: In another project, we integrated a PLC into an MES system to monitor machine performance, track production parameters, and perform automated quality checks. The PLC provided real-time data to the MES, enabling production monitoring, quality control, and improved overall equipment effectiveness (OEE).

These integrations require a deep understanding of data structures, communication protocols, and the specific requirements of each system. Proper mapping and validation are essential to ensure data integrity and system compatibility.

Q 25. Explain your experience with troubleshooting communication errors in a PLC/SCADA system.

Troubleshooting communication errors in PLC/SCADA systems requires a systematic approach. I typically follow these steps:

- Identify the error: Start by determining the nature of the error. Is it a complete communication failure, intermittent errors, or specific data loss? Examine the SCADA system’s alarm logs and PLC diagnostic messages.

- Check the physical connections: Verify all cables, connectors, and network devices are properly connected and functioning. Look for loose connections, damaged cables, or faulty network components.

- Verify communication settings: Confirm that the communication parameters (IP address, port number, baud rate, etc.) are correctly configured on both the PLC and the SCADA system. Check for any mismatches or conflicts.

- Analyze network traffic: Utilize network monitoring tools to analyze network traffic between the PLC and SCADA system. This can reveal network bottlenecks, packet loss, or other network-related issues.

- Test the communication link: Use a loopback test or a dedicated communication test tool to isolate the problem to either the PLC, the network, or the SCADA system.

- Check PLC program logic: If communication issues are intermittent, the PLC program logic itself could be a contributing factor. Review the communication routines for errors or race conditions.

For example, if a Modbus TCP connection fails, I would first verify the IP address and port number, then use a network analyzer to check for network connectivity. If the network is fine, I’d examine the PLC’s Modbus configuration and the SCADA system’s Modbus client settings.

Q 26. How do you ensure the safety and reliability of a PLC and SCADA system?

Ensuring safety and reliability is paramount in PLC/SCADA systems. This involves a multi-layered approach:

- Redundancy: Implementing redundant PLCs, network components, and power supplies to ensure continuous operation in case of failures. This is especially crucial in critical applications where downtime is unacceptable.

- Safety Instrumented Systems (SIS): Incorporating SIS for critical safety functions, ensuring rapid shutdown in case of hazardous situations. These systems are independent of the main PLC and SCADA system.

- Regular maintenance and testing: Conducting periodic inspections, preventative maintenance, and functional tests to identify and address potential problems before they cause failures.

- Proper programming practices: Following structured programming techniques, using comments and clear variable names, and conducting thorough code reviews to ensure the system’s integrity and prevent programming errors.

- Access control: Implementing robust access control mechanisms to restrict unauthorized access to the PLC and SCADA system, preventing accidental or malicious modifications.

- Fail-safe design: Designing the system to fail safely in case of failures, ensuring that the system enters a safe state and avoids unintended consequences.

For example, in a process control application, using a redundant PLC with a fast failover mechanism ensures that the system can continue to operate even if one PLC fails.

Q 27. Describe your experience with using simulation software for PLC and SCADA projects.

Simulation software is invaluable for testing and validating PLC and SCADA projects before deployment. It allows for testing complex scenarios and identifying potential problems without risking the physical equipment.

My experience includes using software packages like Siemens TIA Portal Simulation, Rockwell Automation FactoryTalk Simulation, and others. These tools allow me to create virtual representations of the entire system, including PLCs, sensors, actuators, and the SCADA system.

Example: In a recent project involving a complex robotic arm, we used simulation software to test the robotic arm’s control algorithms and movements. This allowed us to fine-tune the algorithms, identify potential collisions, and verify the overall system performance before deploying it on the physical equipment. This saved significant time and resources during the commissioning phase.

Simulation reduces risks, enables thorough testing under various conditions, and allows for operator training on a virtual replica of the system.

Q 28. What are your preferred methods for debugging PLC code?

My preferred methods for debugging PLC code combine several approaches:

- Online Monitoring: Utilizing the PLC’s online monitoring capabilities to observe variable values, program execution, and identify potential issues in real-time.

- Step-by-step execution: Using the PLC’s debugging tools to execute the program step-by-step, allowing me to inspect the variables and trace the execution flow.

- Breakpoints: Setting breakpoints at specific points in the code to pause execution and inspect the program state at those points.

- Logic analyzers: Using logic analyzers to capture and analyze signals on the PLC’s input/output lines. This helps to identify timing issues and other hardware-related problems.

- Simulation: As mentioned earlier, simulation software enables testing and debugging in a risk-free environment.

- Code reviews: Peer reviews of the PLC code can identify potential errors or areas for improvement. Following structured programming and adhering to coding standards.

For example, if a motor fails to start, I might set breakpoints in the PLC code to examine the variable controlling the motor’s start signal, checking whether it’s receiving the correct value and if any associated safety interlocks are active. A combination of these techniques allows for a comprehensive and efficient debugging process.

Key Topics to Learn for PLC and SCADA Systems Integration Interview

- PLC Programming Fundamentals: Understanding ladder logic, function blocks, and structured text programming. Practical application: Designing a PLC program to control a simple conveyor system.

- SCADA System Architecture: Familiarize yourself with HMI design, data acquisition, communication protocols (e.g., Modbus, Profibus), and database integration. Practical application: Troubleshooting a SCADA system experiencing data communication issues.

- Network Communication and Protocols: Mastering industrial communication networks (Ethernet/IP, Profinet) and protocols relevant to PLC and SCADA integration. Practical application: Configuring a PLC to communicate with a remote SCADA system.

- Data Historians and Reporting: Understanding the role of data historians in data logging, analysis, and reporting for process optimization. Practical application: Generating reports based on historical data to identify trends and improve efficiency.

- Cybersecurity in Industrial Automation: Awareness of security vulnerabilities and best practices for securing PLC and SCADA systems. Practical application: Implementing security measures to protect against unauthorized access and cyberattacks.

- Troubleshooting and Diagnostics: Developing problem-solving skills for identifying and resolving issues in PLC and SCADA systems. Practical application: Diagnosing and fixing a malfunctioning PLC program or SCADA system component.

- Human-Machine Interface (HMI) Design Principles: Understanding the importance of user-friendly HMI design for effective operator interaction. Practical application: Designing an intuitive HMI for a complex industrial process.

- Process Control Strategies: Familiarization with various control strategies (PID control, advanced process control) used in industrial automation. Practical application: Tuning a PID controller for optimal performance.

Next Steps

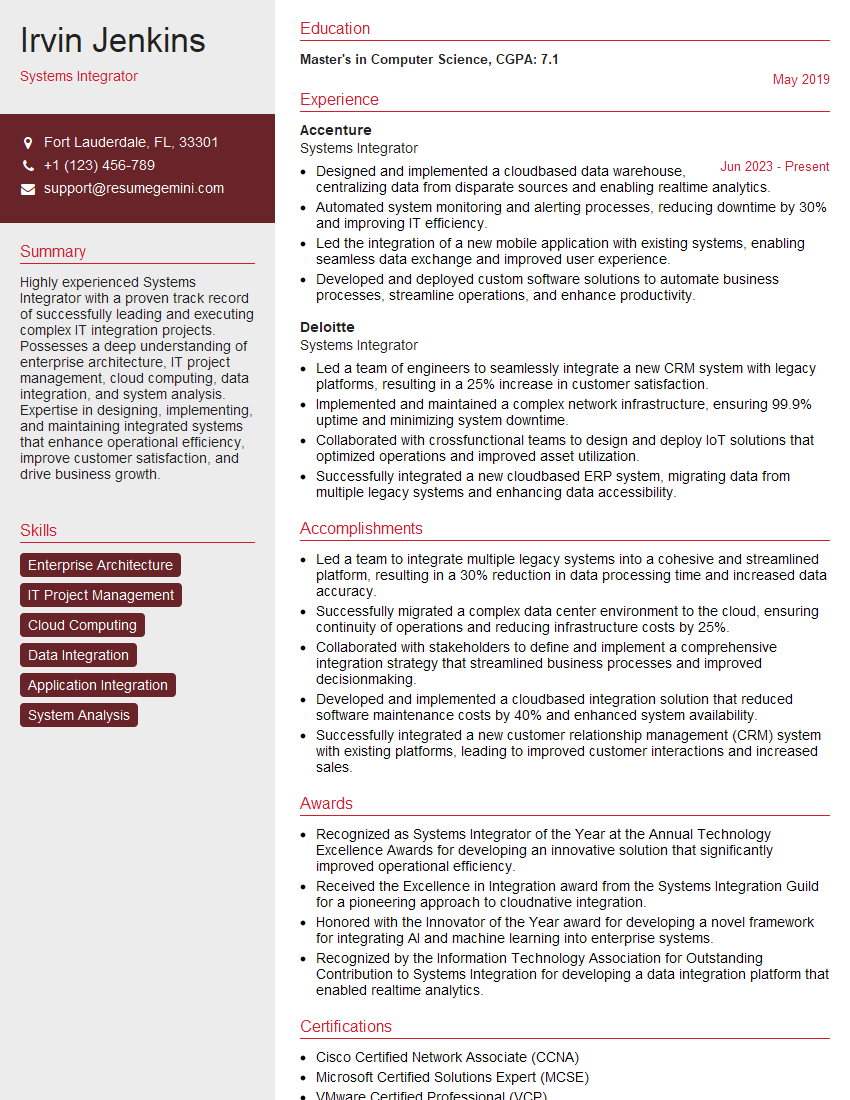

Mastering PLC and SCADA Systems Integration opens doors to exciting and rewarding careers in various industries. These skills are highly sought after, ensuring strong job security and excellent career growth potential. To maximize your job prospects, it’s crucial to have a resume that effectively showcases your expertise to Applicant Tracking Systems (ATS). Crafting an ATS-friendly resume is key to getting your application noticed. We recommend leveraging ResumeGemini as a trusted resource for building a professional and impactful resume. ResumeGemini provides examples of resumes tailored to PLC and SCADA Systems Integration roles, helping you present your skills and experience in the most compelling way possible.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.