Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Plow Machine Operations interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Plow Machine Operations Interview

Q 1. Describe your experience operating different types of plow machines.

My experience encompasses a wide range of plow machines, from smaller, single-axle units ideal for residential driveways and smaller parking lots, to large, heavy-duty snowplows mounted on trucks, capable of clearing major highways and extensive commercial areas. I’m proficient with both blade-style plows, which are versatile and effective for various snow depths, and V-plows, which excel in moving large volumes of snow quickly, particularly in heavy snowfall situations. I’ve also operated specialized plows, such as those equipped with wings for increased clearing width, and those designed for specific terrain, like steep inclines or narrow city streets. Each type requires a different operating technique and understanding of its limitations. For example, the speed and angle of the blade on a V-plow needs constant adjustment to efficiently move snow without causing damage to the plow or the road surface.

Operating these diverse machines has provided me with a deep understanding of their mechanical components, their strengths and weaknesses in different conditions, and the specific safety precautions required for each type.

Q 2. Explain the pre-operation checklist you follow for a plow machine.

My pre-operation checklist is meticulous and ensures the machine is safe and ready for operation. It begins with a visual inspection of the plow, checking for any visible damage, loose bolts, or hydraulic leaks. I then verify that all lights and safety features are functioning correctly – this includes headlights, taillights, hazard lights, and any backup alarms. I inspect the tires for proper inflation and look for any signs of wear or damage. The hydraulic fluid levels are checked, and the engine fluids (oil, coolant) are topped off if necessary. Next, I test all operational functions, including raising and lowering the plow, adjusting the angle, and checking the responsiveness of the hydraulics. Finally, I ensure the plow is properly attached to the vehicle and secured with locking pins, paying particular attention to correct alignment. This entire process is documented in a pre-trip inspection report. Think of it like a pilot’s pre-flight check – a critical step for ensuring a safe and efficient operation.

Q 3. How do you ensure the safety of yourself and others while operating a plow machine?

Safety is my paramount concern. Before starting, I always assess the area to be plowed, identifying any potential hazards like pedestrians, parked vehicles, power lines, or hidden obstacles like fire hydrants or mailboxes. I maintain a safe following distance from other vehicles, especially when plowing in traffic, and communicate effectively with other drivers when necessary. High-visibility clothing and safety lights are always worn. During operation, I maintain a safe speed appropriate for the conditions, avoiding sudden movements or jerky turns that could lead to loss of control. I am always aware of my surroundings and any potential blind spots. I never operate the plow if I am fatigued or under the influence of drugs or alcohol. If I encounter unexpected conditions or malfunctions, I immediately stop the plow, assess the situation, and take appropriate corrective actions before continuing. Proper training and adherence to safety regulations is fundamental, and I treat each plowing operation as though it could be the most demanding I’ve ever done.

Q 4. What are the common maintenance tasks you perform on a plow machine?

Regular maintenance is crucial for ensuring optimal performance and extending the lifespan of the plow. My routine maintenance tasks include inspecting and lubricating all moving parts, checking and tightening all bolts and connections, regularly cleaning and inspecting the hydraulic system, and monitoring fluid levels. I carefully inspect the plow blade for any signs of wear, damage, or corrosion and address them promptly. Regular lubrication of the blade helps prevent rust and prolongs its life. I also perform preventative maintenance on the vehicle itself, ensuring that the engine, transmission, and other critical systems are in top condition. I maintain detailed records of all maintenance performed, adhering to the manufacturer’s recommended schedule. This preventative approach minimizes downtime and prevents potentially serious malfunctions.

Q 5. How do you handle different types of snow and ice conditions while plowing?

Handling diverse snow and ice conditions requires adaptability and experience. For light, fluffy snow, I can use a higher speed and a shallower angle on the plow. For heavy, wet snow, which is significantly more demanding, I reduce the speed considerably, increase the angle of the plow to prevent buildup, and make more frequent passes. Icy conditions require even more caution; slow speeds and careful maneuvering are essential to avoid skidding and accidents. I adjust the plow angle and speed based on the type of snow and ice encountered, and even switch between different types of plows if the conditions warrant. For example, a V-plow might be more efficient for moving large amounts of heavy snow, while a straight blade might be better suited for ice removal. Understanding the nuances of snow and ice and adjusting my technique accordingly is critical to effective and safe snow removal.

Q 6. Describe your experience with GPS-guided plow systems.

I have extensive experience with GPS-guided plow systems. These systems greatly enhance efficiency and accuracy, especially in large areas. The GPS provides real-time positioning, allowing for precise route planning and ensuring complete snow removal coverage. The systems can automatically adjust the plow’s angle and speed based on pre-programmed routes and terrain data, minimizing overlap and maximizing efficiency. These systems also allow for remote monitoring and management, which can be invaluable for larger operations. For instance, I can track the progress of the plow remotely, adjust settings as needed, and receive real-time alerts of any potential issues. This technology significantly improves the overall safety and effectiveness of the plowing process, especially during adverse weather conditions.

Q 7. How do you determine the appropriate plowing speed and technique for varying conditions?

Determining the appropriate plowing speed and technique depends heavily on the prevailing conditions. Factors such as snow depth, snow type (light, fluffy; heavy, wet; icy), visibility, traffic density, and terrain all influence the decisions I make. Generally, I maintain a slower speed in challenging conditions and increase speed in more favorable circumstances. For example, in heavy snowfall, a slower speed allows for more thorough snow removal and prevents overloading the plow. A higher speed is appropriate for light, fluffy snow, but speed must always be consistent with safety and visibility. The plow angle also plays a significant role – a shallower angle is used for light snow, while a steeper angle is preferred for deeper, heavier snow to prevent accumulation and clogging. Experience and constant situational awareness are paramount in determining the optimal speed and technique.

Q 8. What are the signs of potential mechanical failure in a plow machine?

Identifying potential mechanical failures in a plow machine requires a keen eye and regular inspections. Think of it like a doctor’s check-up – preventative measures are key. Signs can range from subtle to obvious. Subtle signs might include unusual noises – a grinding sound could indicate worn bearings or gears, while a rhythmic knocking might point to loose bolts or a failing hydraulic component. Obvious signs are more critical and often indicate immediate action is needed; these include hydraulic fluid leaks (easily spotted by pooling fluid or wet spots), overheating (noticeable through excessive steam or smoke), and complete system failure (the plow simply refusing to function).

- Unusual Noises: Grinding, knocking, squealing, or whining sounds during operation.

- Fluid Leaks: Hydraulic fluid, engine oil, or transmission fluid leaking from seals, hoses, or connections.

- Overheating: Excessive heat radiating from the engine or hydraulic system, often accompanied by steam or smoke.

- Reduced Performance: Noticeable decrease in plowing depth or speed, despite consistent engine power.

- Vibration: Excessive shaking or vibration in the machine’s structure during operation, often indicating imbalance or worn components.

- Malfunctioning Lights or Indicators: Warning lights on the dashboard indicating low fluid levels, high temperature, or other issues.

Regular preventative maintenance, including lubrication and inspection of all moving parts, is crucial in preventing these failures.

Q 9. How do you troubleshoot common plow machine malfunctions?

Troubleshooting plow machine malfunctions requires a systematic approach. Think of it like solving a puzzle – you need to identify the individual pieces and how they fit together. First, ensure safety by turning off the machine and disengaging power. Next, systematically check each potential problem area.

- Identify the Problem: What exactly is malfunctioning? Is the plow not engaging, is it not plowing deep enough, or are there strange noises?

- Visual Inspection: Check for obvious problems like leaks, loose connections, broken parts, or obstructions.

- Check Fluid Levels: Ensure all fluid levels (hydraulic, engine oil, transmission fluid) are correct. Low fluid levels can severely impact performance.

- Test Individual Components: If the problem is related to a specific function (like lift or blade angle adjustment), test that individual component. Are the hydraulic lines properly connected? Is the electrical system functioning?

- Check Electrical Connections: Loose or corroded electrical connections can interrupt the flow of power.

- Consult the Manual: The operator’s manual provides detailed information on troubleshooting specific problems. This is your bible during troubleshooting!

- Seek Professional Help: If you can’t identify the problem, it’s always best to contact a qualified mechanic.

Remember, always prioritize safety. If you are unsure about anything, don’t hesitate to call for assistance.

Q 10. Explain your understanding of blade angles and their impact on plowing efficiency.

Blade angle is crucial for plowing efficiency. Imagine trying to cut a cake with a knife at the wrong angle – it wouldn’t be clean or efficient. The angle determines how well the soil is turned and how deeply the plow penetrates. Different angles are optimal for different soil types and conditions.

- Straight Blades: These are best for lighter soils and shallow plowing depths. They offer a clean cut, suitable for turning over the topsoil for seedbeds.

- V-Shaped Blades: These are better suited for heavier, more compacted soils. The V-shape helps the plow to penetrate deeper and more effectively break up hard ground.

- Moldboard Plows: These have a curved blade that gradually lifts and turns the soil, creating a clean furrow. The angle affects the amount of soil overturned and the depth of the plowing.

A properly adjusted blade angle ensures the plow cuts through the soil smoothly, avoiding excessive friction and wear. An incorrectly set angle can lead to inefficient plowing, poor soil turnover, and increased stress on the machine.

Optimizing blade angles depends on factors like soil type, desired plowing depth, and the type of plow being used. Farmers often adjust angles based on experience and observation. Improper angle adjustment could result in incomplete soil turnover, leaving clods and interfering with seedbed preparation or drainage.

Q 11. What safety measures do you take when working at night or in low-visibility conditions?

Nighttime or low-visibility plowing presents significant safety challenges. Think of it like driving at night – extra caution and awareness are essential. Here’s a breakdown of safety precautions:

- High-Visibility Clothing: Wearing bright, reflective clothing makes the operator more visible to others.

- Multiple Lights: Ensure the plow has fully functional headlights, taillights, and other safety lights, including rotating beacons or strobe lights.

- Slow Speed: Reduce speed considerably in low visibility to increase reaction time.

- Communication: Maintain clear communication with dispatch or other personnel, using radios or other methods. This is crucial for coordination and avoiding accidents.

- Extra Awareness: Be extremely vigilant for unexpected obstacles or changes in terrain. It’s advisable to have a second person as a spotter in extremely low visibility conditions.

- Proper Maintenance: Ensure all lights and safety equipment are in perfect working order before commencing operations.

By taking these precautions, the risks associated with night or low-visibility plowing are considerably reduced. Safety is paramount; always prioritize personal safety and the safety of others.

Q 12. How do you manage fuel consumption and optimize plowing efficiency?

Managing fuel consumption and optimizing plowing efficiency go hand-in-hand. It’s about being both productive and cost-effective. Several strategies contribute to this balance:

- Regular Maintenance: A well-maintained engine burns fuel more efficiently. This includes regular oil changes, air filter replacements, and tune-ups.

- Proper Blade Angle and Depth: An optimally adjusted blade angle and plowing depth reduces the load on the engine, leading to lower fuel consumption. Overly deep or shallow plowing leads to wasted effort and fuel.

- Suitable Speed: Selecting an appropriate speed for the soil type and plow will maximize efficiency and minimize wasted fuel. Going too fast can result in incomplete plowing, while going too slow wastes time and fuel.

- Terrain Management: Planning the route to minimize the number of turns and changes in direction also helps to maximize efficiency and reduce fuel use.

- Engine Condition: An engine with consistent power and minimal wear will consume less fuel in comparison to a worn-out or improperly maintained engine.

By implementing these strategies, fuel costs can be lowered while still maintaining a high level of productivity. Think of it like driving a car – smooth acceleration and consistent speed are more fuel-efficient than aggressive driving.

Q 13. Describe your experience working with different types of plow blades (e.g., straight, V-shaped).

My experience encompasses working with various plow blade types, each suited for specific soil conditions and plowing tasks. I’ve worked extensively with straight blades, V-shaped blades, and moldboard plows.

- Straight Blades: Ideal for lighter soils requiring shallow plowing, offering a clean cut and minimal soil disturbance. I’ve used these extensively for preparing seedbeds.

- V-Shaped Blades: These are powerful tools for tackling heavier clay soils and breaking up compacted ground. They offer superior penetration depth and effective soil turnover. I’ve utilized these in challenging conditions requiring deep plowing.

- Moldboard Plows: These offer precise soil manipulation with a curved blade that turns and lifts the soil. They’re perfect for creating clean furrows and are very versatile. I’ve used these for a variety of tasks, from large-scale field preparation to more intricate soil management projects.

Selecting the appropriate blade type is crucial for efficiency and maximizing the effectiveness of the plowing operation. The wrong choice can lead to inefficient work, unnecessary wear and tear on the equipment, and even damage to the plow itself.

Q 14. How do you maintain proper communication with dispatch or other personnel while plowing?

Maintaining clear communication with dispatch or other personnel is paramount for safe and efficient plowing operations, especially in large-scale operations or during emergencies. Clear, concise communication prevents misunderstandings and ensures everyone is on the same page. I use a multi-faceted approach:

- Two-Way Radios: Regularly check in with dispatch to report progress, location, and any encountered issues. This ensures efficient coordination between the plow operator and the support team.

- Phone Calls: For more detailed updates or to report emergencies, a phone call provides a more direct communication channel.

- Pre-Planned Routes and Schedules: Communicating planned routes and schedules beforehand prevents confusion and ensures everyone is aware of the operation’s progress.

- Clear Terminology: Using precise terminology to describe location, problems, and required assistance ensures clear and accurate information is conveyed.

- Regular Check-Ins: Frequent check-ins ensure that any significant changes or potential risks are promptly identified and dealt with efficiently.

Effective communication is essential for both safety and productivity. Imagine a construction site where communication is lacking – chaos ensues! The same principle applies to plowing operations.

Q 15. What is your experience with using salt or other de-icing agents?

My experience with de-icing agents is extensive. I understand that the choice of salt or other chemicals depends heavily on the temperature and environmental considerations. For example, rock salt (sodium chloride) is effective down to about 20°F (-7°C), but can damage concrete and vegetation. At lower temperatures, we often use calcium chloride or magnesium chloride, which are more effective but also more expensive. I’m familiar with the proper application techniques to minimize environmental impact and ensure effective ice removal. This includes knowing the right amount to apply, preventing runoff into waterways, and understanding the potential for corrosion on the plow equipment itself. I always follow local regulations and best practices for responsible de-icing agent usage. In my previous role, we meticulously tracked salt usage to optimize efficiency and minimize costs while maintaining safe road conditions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected obstacles or situations while plowing (e.g., downed power lines)?

Encountering unexpected obstacles is part and parcel of snow plowing. My approach is always safety-first. If I encounter downed power lines, for instance, I immediately cease operations and contact the relevant emergency services (power company, police). I then secure the area, preventing any further access until the hazard is cleared. This involves establishing a safe perimeter and deploying warning signs or lights. Other scenarios, like encountering a stalled vehicle or a significant drift, require different tactics. For a stalled vehicle, I’ll try to clear a path around it, ensuring visibility and safety for both the vehicle and the plow. For large drifts, I’d adjust my plowing strategy, possibly needing multiple passes, using a different attachment if necessary, and potentially requesting assistance if the drift proves too difficult to manage alone. Thorough pre-trip inspections and awareness of weather conditions help significantly in mitigating unexpected events.

Q 17. Describe your experience with plow machine attachments and their operation.

I’m proficient with a range of plow attachments, including different types of blades (straight, V-shaped, wing), snow pushers, and even snow blowers for heavy snow accumulation. Each attachment has its strengths and weaknesses, and the choice depends on the specific situation. For example, a V-plow is excellent for moving large amounts of snow quickly, while a straight blade is better for precise work in tighter spaces. Wing blades offer extra width for clearing wider roadways. I know how to change and adjust these attachments quickly and safely, ensuring all locking mechanisms are properly engaged before operation. Regular maintenance and lubrication of these attachments is crucial for optimal performance and longevity. I’ve used hydraulically controlled attachments where the angle and position of the blade are adjusted from the cab, improving efficiency and safety. This allows me to maneuver more effectively and reduces the need for manual adjustments.

Q 18. How do you ensure the proper functioning of the plow’s hydraulic systems?

Maintaining proper functioning of hydraulic systems is paramount. I regularly check fluid levels, ensuring they’re within the manufacturer’s specifications. I also look for leaks, unusual noises, and any signs of overheating. I’m familiar with troubleshooting common hydraulic problems, such as low pressure or pump failure. Preventative maintenance is key, including regular filter changes and fluid flushes. Understanding the hydraulic system schematics and knowing how to interpret pressure gauges are essential skills. I also know the importance of keeping the hydraulic components clean and free of debris. Ignoring these procedures can lead to costly repairs or even dangerous equipment failures.

Q 19. What is your understanding of weight distribution and its impact on plowing performance?

Weight distribution is critical for optimal plowing performance and safety. An improperly balanced plow truck can lead to reduced traction, difficulty steering, and increased wear and tear on tires and components. The weight needs to be distributed evenly across the axles, ensuring sufficient weight on the drive wheels for traction, especially when dealing with ice or packed snow. Factors like the type and amount of snow, the angle of the plow blade, and the truck’s payload all influence the ideal weight distribution. I always check the weight distribution before starting a job, adjusting the load as needed. In icy conditions, maintaining optimum weight distribution is even more critical for maintaining control and avoiding accidents. Improper weight distribution can easily cause loss of traction and lead to dangerous situations.

Q 20. Explain your experience with different types of plow trucks and their capabilities.

My experience encompasses various plow trucks, from smaller one-ton trucks suitable for residential areas to large, heavy-duty trucks equipped for extensive highway clearing. The capabilities differ significantly. Smaller trucks are agile and fuel-efficient, ideal for navigating narrow streets, while larger trucks offer greater plowing capacity and can handle heavier snowfalls and larger areas. I’m familiar with the operational characteristics of each type, understanding their strengths and limitations in various situations. Larger trucks might have features like advanced anti-lock braking systems (ABS) and traction control, essential for safety in challenging conditions. I’ve operated trucks with various transmission types (automatic, manual), and am comfortable with all of them, adapting my driving techniques accordingly. Knowing the specifics of each truck, including its weight capacity, blade size, and hydraulic system capabilities, is essential for efficient and safe operation.

Q 21. How do you address tire pressure and traction issues in various weather conditions?

Tire pressure and traction are intertwined. Maintaining proper tire pressure is crucial for optimal traction, especially in varied weather conditions. In snowy or icy conditions, slightly lower tire pressure can increase the contact patch, improving grip. However, excessively low pressure can lead to tire damage. I regularly check and adjust tire pressure based on the conditions. During warmer weather, higher pressure is typically necessary. Furthermore, I understand the importance of using appropriate tires; winter tires with deep treads are vital for enhanced grip on snow and ice. Chain usage is also part of my skillset, knowing when and how to install them properly. I’m adept at identifying and mitigating traction issues; I avoid sudden acceleration or braking and maintain smooth driving maneuvers to prevent skidding. A thorough pre-trip inspection always includes a careful check of tire pressure and condition.

Q 22. Describe your understanding of the relevant safety regulations and procedures.

Safety is paramount in plow machine operations. My understanding encompasses a wide range of regulations and procedures, starting with adhering to all OSHA (Occupational Safety and Health Administration) guidelines for heavy equipment operation. This includes daily pre-operation inspections, ensuring all safety devices like lights, reflectors, and blades are functional. I’m proficient in using Personal Protective Equipment (PPE), including high-visibility clothing, safety helmets, hearing protection, and gloves. Furthermore, I am trained in safe operating procedures in various weather conditions, including reduced visibility due to snow or fog. I understand and follow protocols for working near traffic, power lines, and other hazards. Regular training keeps me updated on best practices and emergency response protocols, including how to handle equipment malfunctions and accidents.

- Pre-trip inspections: I meticulously check fluid levels, tire pressure, blade condition, and lights before each operation.

- Safe operating speeds: I always maintain a safe speed appropriate for conditions, slowing down significantly in adverse weather or when approaching intersections.

- Communication protocols: I utilize two-way radios to communicate with dispatch and other team members, ensuring efficient and safe coordination.

Q 23. How do you manage workload and prioritize routes effectively during a snowstorm?

Managing workload and prioritizing routes during a snowstorm is a crucial aspect of efficient snow removal. My approach involves a combination of strategic planning and real-time adaptation. I begin by reviewing the pre-planned snow removal routes, considering factors such as traffic volume, road gradients, and areas most susceptible to accumulation. Then, I incorporate real-time information, such as weather updates and reports of hazardous conditions from dispatch, to dynamically adjust priorities. High-traffic areas, steep inclines, and intersections present the highest risk and are thus prioritized. I employ a systematic approach, focusing on clearing major arteries before tackling residential streets to ensure the safe movement of emergency vehicles and commuters. The use of GPS and route management software enhances efficiency and allows for real-time monitoring of progress.

For example, during a blizzard, I might initially prioritize major highways and intersections to keep traffic flowing, and then shift my focus to hospital access routes and bus routes. Following this, I would clear residential areas.

Q 24. Explain your experience with winter road maintenance best practices.

My experience in winter road maintenance aligns with best practices that emphasize proactive snow and ice control. This begins with pre-treatment, applying brine or de-icing chemicals to road surfaces before snowfall to prevent ice adhesion. During snow events, I focus on continuous plowing, aiming for a consistent snow depth across the road surface to prevent the formation of dangerous ice patches. I understand the importance of using appropriate plow blade angles and speeds based on snow type and depth, avoiding unnecessary wear and tear on equipment and maximizing efficiency. Post-storm procedures involve clearing intersections and ensuring visibility at all times. I also pay close attention to the placement of snow piles to avoid obstructing visibility or causing other hazards. Knowing when to utilize sand or salt effectively is equally crucial for maximizing traction and preventing black ice formation.

Q 25. What are your skills in using and interpreting weather forecasts for planning purposes?

Interpreting and utilizing weather forecasts is essential for effective planning. I regularly monitor weather reports from reliable sources, paying close attention to snowfall predictions, wind speed, and temperature. I translate these forecasts into operational plans, adjusting routes and prioritizing areas based on the expected severity and timing of the storm. For example, a forecast predicting heavy snowfall and high winds might prompt me to pre-treat vulnerable areas and allocate extra time to high-risk routes. I use weather apps and specialized meteorological websites to gain more granular information. My ability to anticipate changing conditions allows for proactive adjustments, improving efficiency and ensuring safety.

Q 26. How do you contribute to a team environment during snow removal operations?

Teamwork is vital in snow removal. I actively contribute to a positive team environment by maintaining clear communication, sharing information about road conditions, and assisting colleagues when needed. This includes providing updates on my progress, reporting any potential hazards or equipment malfunctions, and helping others when they encounter difficulties. I believe in mutual respect and collaboration, which fosters a safe and efficient working environment. Sharing expertise with less experienced team members through on-the-job training and mentoring is also an important part of my role. In essence, we work as a coordinated unit, not just as individuals.

Q 27. Describe your experience with record-keeping and reporting on plowing activities.

Accurate record-keeping and reporting are crucial for accountability and operational efficiency. I maintain detailed logs of my activities, including the start and end times of each shift, routes covered, amount of snow removed, and any encountered issues. This information includes the type of equipment used, material consumption (salt, sand), and any accidents or near misses. I’m proficient in using both manual and electronic reporting systems. These records are essential for billing purposes, performance evaluations, and identifying areas for improvement in future snow removal operations. I strive for complete and accurate documentation to ensure the best possible record-keeping.

Q 28. How do you stay up-to-date on new technologies and advancements in plow machine operation?

Staying current with new technologies and advancements is crucial for optimizing efficiency and safety. I regularly attend industry conferences and workshops to learn about new plow technologies, such as GPS-guided systems, automated blade control, and advanced weather forecasting tools. I actively seek out online resources, industry publications, and manufacturer updates to keep abreast of the latest developments. Furthermore, I actively participate in training sessions on new equipment and software to enhance my operational skills. Embracing technological advancements ensures I’m equipped with the best tools and techniques for effective and safe snow removal.

Key Topics to Learn for Plow Machine Operations Interview

- Machine Mechanics: Understanding the inner workings of plow machines, including engine systems, hydraulics, and transmission components. This includes preventative maintenance and troubleshooting common mechanical issues.

- Operational Techniques: Mastering safe and efficient plowing techniques for various soil types and terrains. This involves adjusting plow depth, speed, and angle to optimize performance and minimize soil compaction.

- Safety Procedures: Thorough knowledge of all relevant safety regulations and protocols for operating plow machines, including pre-operational checks, personal protective equipment (PPE) usage, and emergency procedures.

- GPS and Precision Farming: Familiarity with GPS-guided plowing systems and their applications in optimizing field efficiency and reducing overlap. This also includes understanding data analysis related to field operations.

- Maintenance and Repair: Practical experience in performing routine maintenance tasks, identifying potential malfunctions, and carrying out minor repairs on plow machines. This includes understanding diagnostic tools and procedures.

- Problem-Solving and Troubleshooting: Developing the ability to quickly diagnose and resolve operational issues that may arise during plowing, ensuring minimal downtime and maximizing productivity.

Next Steps

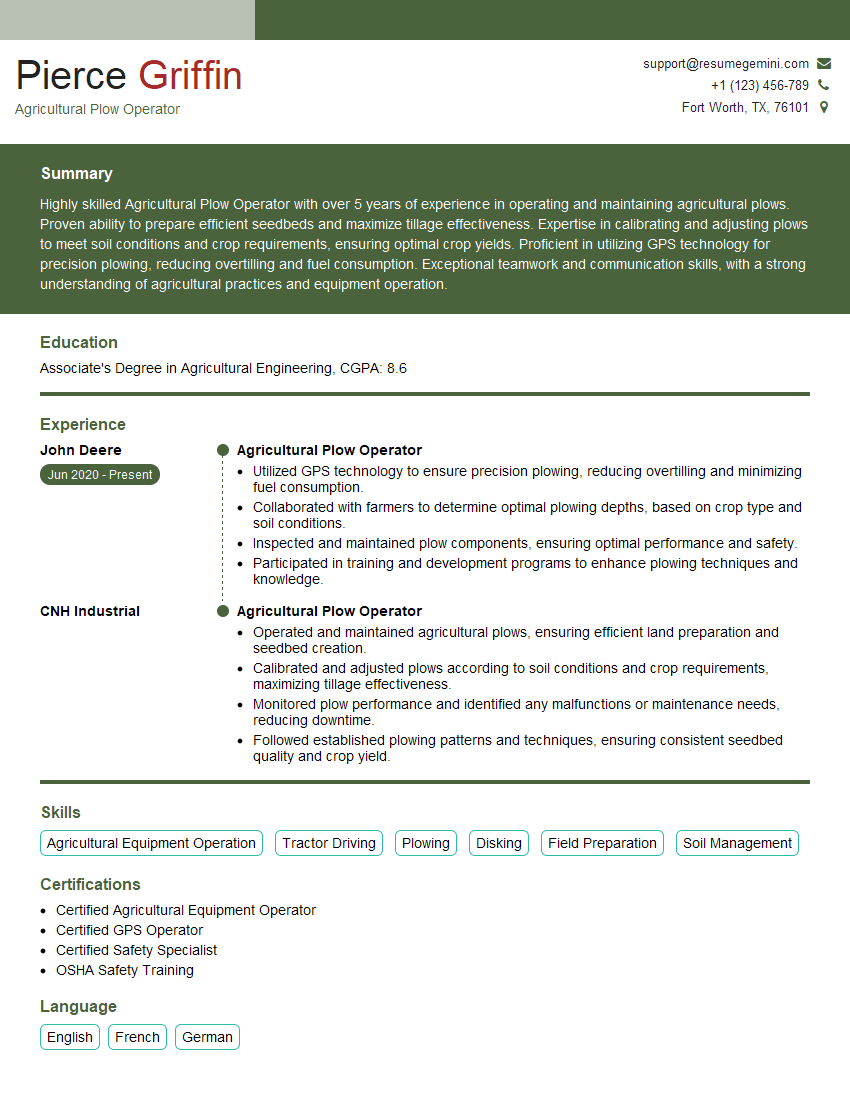

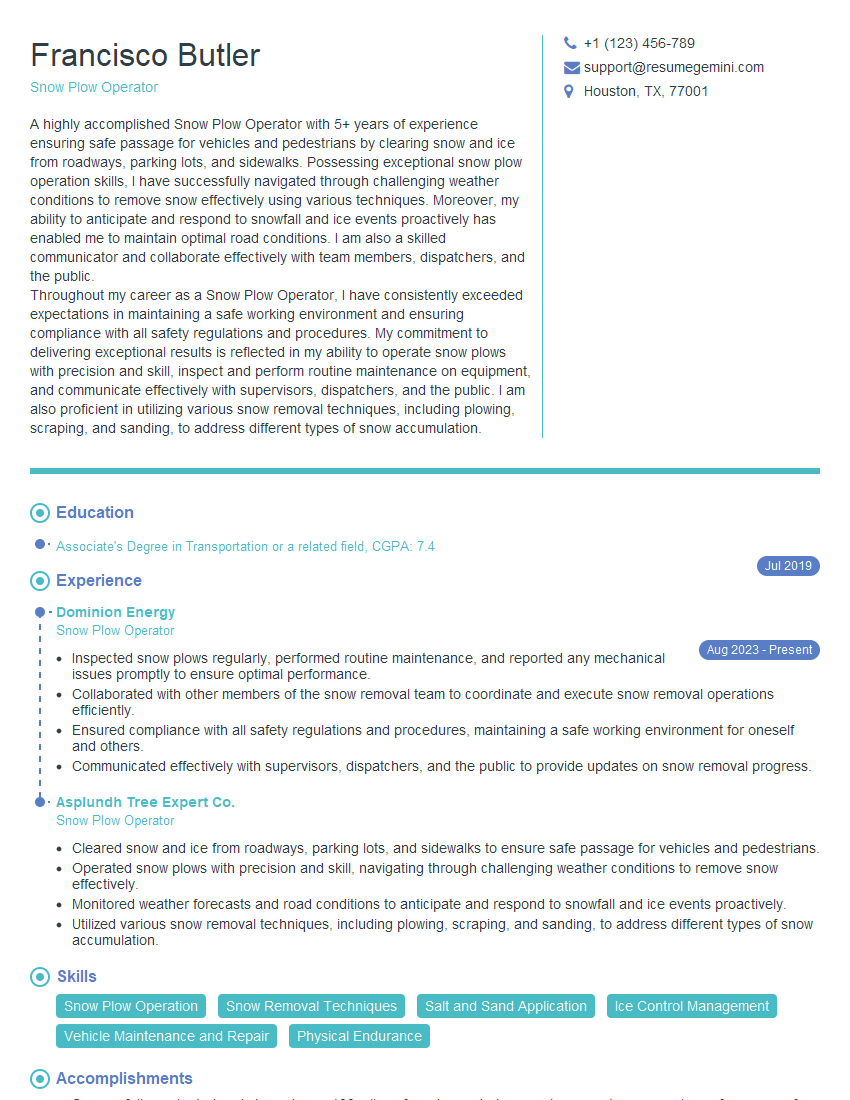

Mastering Plow Machine Operations opens doors to rewarding careers with excellent growth potential in agriculture and construction. Proficiency in this area demonstrates valuable skills in both technical operation and problem-solving, making you a highly sought-after candidate. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the eye of recruiters. Examples of resumes tailored to Plow Machine Operations are available to help guide you. Take this opportunity to showcase your expertise and secure your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.