The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Polymer Surface Modification interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Polymer Surface Modification Interview

Q 1. Explain the difference between physical and chemical surface modification of polymers.

The key difference between physical and chemical surface modification of polymers lies in the nature of the interaction between the modifying agent and the polymer substrate. Physical modification involves altering the surface properties without changing the chemical structure of the polymer. Think of it like applying a coat of paint – it changes the appearance and maybe some properties like wettability, but the underlying material remains the same. Examples include coating with a thin film of a different material, adsorption of molecules onto the surface, or simply polishing the surface. Chemical modification, on the other hand, involves creating chemical bonds between the modifying agent and the polymer chains. This is like permanently staining or dyeing fabric; the alteration is more profound and permanent, affecting the chemical structure and possibly leading to a change in bulk properties.

For example, applying a lubricant to a polymer surface is a physical modification, while introducing functional groups to enhance adhesion via plasma treatment is chemical modification.

Q 2. Describe various techniques used for plasma treatment of polymer surfaces.

Plasma treatment is a powerful technique for chemical surface modification of polymers. It uses a partially ionized gas (plasma) to introduce reactive species that modify the polymer’s surface. Several techniques exist:

- Glow Discharge Plasma: This is a common method where a low-pressure gas is energized by an electric field, creating plasma. The reactive species generated (e.g., oxygen radicals, nitrogen ions) bombard the polymer surface, causing etching, functionalization, or crosslinking.

- Microwave Plasma: This method uses microwaves to generate plasma, often offering better control over plasma parameters and higher processing speeds.

- Radio Frequency (RF) Plasma: RF energy is used to create plasma, allowing for more precise control over the plasma characteristics and potentially achieving a more uniform treatment.

- Atmospheric Pressure Plasma Jet (APPJ): This is a more recent advancement that generates plasma at atmospheric pressure, eliminating the need for vacuum chambers and simplifying the process for large-scale applications.

The choice of technique depends on the polymer type, desired surface properties, and processing requirements. For instance, oxygen plasma is often used to increase surface wettability, while nitrogen plasma can enhance surface adhesion.

Q 3. How does corona treatment alter the surface properties of polymers?

Corona treatment is a non-plasma surface modification method that uses a high-voltage electrical discharge in air to generate highly reactive species. These species interact with the polymer surface, primarily through oxidation and the introduction of polar functional groups (like carbonyl and hydroxyl groups). This alters the surface energy of the polymer, significantly increasing its wettability and improving its adhesion to other materials.

Think of it like roughening a surface: Corona treatment creates a more chemically active and polar surface, which allows for better bonding with inks, adhesives, or coatings. For example, corona treatment is frequently used to prepare plastic films for printing or improve the adhesion of coatings in packaging applications.

Q 4. Explain the principle of grafting polymer chains onto a substrate.

Grafting polymer chains onto a substrate involves chemically bonding new polymer chains to an existing polymer surface or other substrate. This is achieved by initiating polymerization from reactive sites on the substrate’s surface. The process typically involves:

- Surface Activation: This step creates reactive sites (radicals, ions) on the substrate surface. Techniques include plasma treatment, corona discharge, or chemical oxidation.

- Initiation: A suitable initiator is introduced to the activated surface, generating active centers for polymerization.

- Polymerization: Monomers are added to the activated surface, initiating polymerization and growing new polymer chains chemically bonded to the substrate.

This method offers a way to tailor the surface properties by introducing functional groups or specific polymer chains with desired characteristics. For instance, grafting hydrophilic polymers onto a hydrophobic surface enhances its wettability and biocompatibility.

Q 5. What are the advantages and disadvantages of using silane coupling agents for surface modification?

Silane coupling agents are organofunctional alkoxysilanes that are widely used for surface modification, particularly for improving adhesion between polymers and other materials (e.g., glass, metal). They contain two distinct reactive groups:

- Alkoxy groups (e.g., -OCH3): These react with hydroxyl groups on the substrate surface, forming strong covalent bonds.

- Organic functional groups (e.g., -CH3, -NH2): These interact with the polymer or another material, enhancing adhesion.

Advantages: Silanes are relatively easy to apply, offer excellent adhesion promotion, are available with various functional groups for tailored properties, and are cost-effective.

Disadvantages: The effectiveness of silane coupling agents is sensitive to surface cleanliness and humidity, requiring careful surface preparation. Hydrolysis and condensation reactions can be complex, requiring precise control over conditions. They may not be suitable for all polymer types or substrate materials.

Q 6. Describe the mechanism of surface modification using UV irradiation.

UV irradiation can induce various surface modifications in polymers, primarily through photochemical reactions. The UV light provides the energy to break chemical bonds in the polymer, leading to the formation of reactive sites (radicals). These radicals can:

- Initiate chain scission: Breaking the polymer backbone, leading to lower molecular weight and altered surface properties.

- Promote crosslinking: Forming new bonds between polymer chains, increasing the surface hardness and potentially reducing solubility.

- Initiate grafting: Similar to the grafting process discussed earlier, UV irradiation can activate the surface for the addition of new polymer chains.

- Photooxidation: Introducing oxygen-containing functional groups onto the surface, changing its wettability and reactivity.

Photoinitiators are often used to enhance the effectiveness of UV irradiation. The choice of method depends on the desired modification and the nature of the polymer.

Q 7. How do you characterize the surface properties of modified polymers (e.g., contact angle, XPS, AFM)?

Characterizing the surface properties of modified polymers is crucial for verifying the effectiveness of the modification process. Several techniques are used:

- Contact Angle Measurement: This simple technique measures the angle of a liquid droplet on the surface. It provides information about the surface energy and wettability. A lower contact angle indicates higher wettability.

- X-ray Photoelectron Spectroscopy (XPS): XPS provides detailed information about the elemental composition and chemical states of the surface atoms. This allows the identification of functional groups introduced during modification and the quantification of surface changes.

- Atomic Force Microscopy (AFM): AFM provides high-resolution images of the surface topography and roughness. It can reveal changes in surface morphology caused by the modification process, such as etching, deposition, or crosslinking.

- Other techniques: Other characterization methods include Fourier Transform Infrared Spectroscopy (FTIR) to identify functional groups, Secondary Ion Mass Spectrometry (SIMS) for depth profiling, and Water Contact Angle measurements for dynamic contact angles.

The choice of techniques depends on the specific information needed and the nature of the polymer modification.

Q 8. Explain the concept of surface energy and its importance in polymer adhesion.

Surface energy is a measure of the work required to increase the surface area of a material. Think of it like this: a droplet of water on a clean glass surface beads up less than on a waxy surface. This is because the glass has a higher surface energy, meaning its molecules strongly attract the water molecules, spreading them out. Conversely, the wax has low surface energy, causing the water to bead up.

In polymer adhesion, surface energy plays a crucial role. Good adhesion requires strong interfacial interactions between the polymer and the substrate (the material it’s sticking to). If the surface energies of the polymer and the substrate are similar, strong adhesive forces (like van der Waals forces or hydrogen bonds) can form across the interface, resulting in robust bonding. However, if there’s a large difference in surface energy, poor wetting and weak adhesion result.

For example, consider bonding a polymeric adhesive to a metal surface. If the polymer surface has low surface energy, it won’t wet the metal surface effectively. Surface treatment to increase the polymer’s surface energy can significantly enhance adhesion.

Q 9. What are some common challenges encountered during polymer surface modification?

Polymer surface modification, while offering significant advantages, presents several challenges. One common hurdle is achieving a uniform and consistent modification across the entire surface. Surface heterogeneity (variations in surface chemistry across the material) can lead to inconsistencies in the final properties.

Another challenge lies in controlling the thickness of the modified layer. Precise control is vital for many applications, especially those requiring specific functionalities. Over-modification can negate the desired properties, while insufficient modification may prove ineffective.

Finally, the stability of the modified layer over time is a key concern. Environmental factors like UV exposure, temperature fluctuations, and moisture can degrade the modification, reducing its effectiveness. Finding modifications that are durable and maintain their functionality over the long term is a critical area of research.

Q 10. How does surface roughness affect the effectiveness of surface modification?

Surface roughness significantly impacts the effectiveness of surface modification. A rough surface presents a much larger area for modification compared to a smooth surface. However, this increased surface area isn’t always beneficial.

While a higher surface area provides more sites for functionalization, it also introduces challenges. The modification may not reach all areas uniformly, especially in deep crevices. This can lead to inconsistencies and reduced overall effectiveness of the treatment. Furthermore, a rough surface can mechanically weaken the bond between the modified layer and the underlying polymer, potentially causing delamination (separation of layers).

Ideal surface modification often involves a balance. A slightly rough surface can improve adhesion by providing more mechanical interlocking, but excessive roughness can hinder the uniformity of the modification and decrease its long-term stability. Careful surface pretreatment, such as polishing or plasma treatment to smoothen the surface before modification, can often improve results.

Q 11. Discuss the role of surface modification in improving biocompatibility of polymers.

Improving the biocompatibility of polymers is crucial in biomedical applications, like implants and drug delivery systems. The body’s response to a foreign material is heavily influenced by the surface properties. Surface modification plays a key role in creating biocompatible surfaces.

For example, many polymers have inherently hydrophobic surfaces, which can lead to protein adsorption and cell adhesion issues. Surface modification techniques like plasma treatment or grafting hydrophilic polymers (such as polyethylene glycol or PEG) can dramatically improve biocompatibility. This modification creates a surface that is less likely to trigger an immune response and promotes better integration with the surrounding tissues. Hydrophilic surfaces also prevent blood clot formation, an important consideration for implants.

Another example includes the introduction of bioactive molecules onto polymer surfaces using techniques such as self-assembled monolayers (SAMs). This approach creates surfaces that promote cell adhesion and growth, or even stimulate specific cellular functions, leading to improved tissue integration and healing.

Q 12. Explain how surface modification can enhance the adhesion of polymers to other materials.

Surface modification enhances polymer adhesion to other materials by altering the surface chemistry and energy. Remember, similar surface energies promote strong adhesion.

Techniques like plasma treatment create reactive sites on the polymer surface, allowing for better bonding with another material. For example, plasma treatment can introduce polar functional groups onto a hydrophobic polymer surface, making it more compatible with polar substrates such as glass or metal. Another method is the deposition of an adhesion promoter layer between the polymer and the substrate. This intermediate layer acts as a bridge, improving the interfacial interaction.

Grafted polymers can also enhance adhesion. Grafting a polymer with strong adhesive properties onto the base polymer’s surface can significantly improve its ability to adhere to various substrates. A practical example would be the use of surface modification to improve the adhesion of a polymer coating to a metal part in an automotive application.

Q 13. Describe different methods for improving the hydrophilicity or hydrophobicity of polymer surfaces.

Several methods exist for tuning the hydrophilicity or hydrophobicity of polymer surfaces. To increase hydrophilicity (water-loving), one can introduce polar functional groups, such as hydroxyl (-OH) or carboxyl (-COOH) groups. This can be achieved through plasma treatment, chemical grafting, or the deposition of hydrophilic coatings.

Examples of techniques include:

- Plasma treatment: Exposure to plasma can introduce various functional groups onto the polymer surface, changing its wettability.

- Chemical grafting: Covalently attaching hydrophilic polymers (like PEG) alters the surface properties.

- Layer-by-layer deposition: Alternating layers of hydrophilic and hydrophobic polymers can create surfaces with precisely controlled wettability.

Conversely, increasing hydrophobicity (water-repelling) is accomplished by introducing non-polar groups like alkyl chains. Techniques like the deposition of fluorinated compounds or silanes are common methods for creating hydrophobic surfaces. This can improve water resistance in applications ranging from textiles to packaging.

Q 14. How can you control the thickness of a modified polymer layer?

Controlling the thickness of a modified polymer layer is crucial for achieving desired properties and functionality. Several techniques allow for precise control.

For example, in chemical grafting, the concentration of the grafting agent and the reaction time determine the density and thickness of the grafted layer. Techniques like Atomic Layer Deposition (ALD) allow for highly precise control, offering angstrom-level control over layer thickness. Other techniques, such as spin coating, allow control through the concentration and speed of the spin coater.

Characterizing the thickness of the modified layer often involves techniques like ellipsometry, atomic force microscopy (AFM), or X-ray photoelectron spectroscopy (XPS). These techniques provide valuable data for understanding and optimizing the modification process.

Q 15. What are the key factors influencing the durability of surface modification?

The durability of a polymer surface modification hinges on several crucial factors. Think of it like painting a house – a poorly prepared surface or subpar paint won’t last. Similarly, a weak bond between the modification and the polymer substrate will lead to rapid degradation.

- Strength of the bond: A strong chemical bond (covalent bonding is ideal) between the modifying agent and the polymer surface is paramount for long-term stability. Weak physical interactions like van der Waals forces will easily break down under stress.

- Thickness and uniformity of the modified layer: A thin, uneven coating is more susceptible to wear and tear than a thick, uniform one. Imagine a thin layer of sunscreen – it’s easily rubbed off, unlike a thicker application.

- Environmental stability: The modified surface needs to withstand the intended environment. For example, a modification designed for outdoor use needs to resist UV radiation, moisture, and temperature fluctuations. A coating that works flawlessly indoors might fail miserably outdoors.

- Type of modification: Some modification techniques inherently create more durable surfaces than others. Plasma treatment, for example, often results in robust modifications compared to simple dip-coating methods.

- Post-treatment processes: Certain post-treatment steps, such as annealing or curing, can significantly improve the durability of the modified layer by enhancing crosslinking and reducing stress within the modified surface.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of creating a superhydrophobic polymer surface.

Creating a superhydrophobic surface, meaning a surface that repels water extremely effectively (think lotus leaf), on a polymer involves a two-pronged approach: creating a rough surface texture and introducing low surface energy material.

Step 1: Roughening the surface: This can be achieved through various techniques, such as etching with plasma, creating micro- or nano-scale structures using lithography, or employing template-assisted methods. This creates a bumpy surface that traps air pockets.

Step 2: Low Surface Energy Coating: After roughening, the surface is coated with a low surface energy material, typically a fluorinated compound or silicone. These materials minimize the contact between water and the polymer surface.

Imagine trying to spread water on a bumpy surface covered in Teflon – it beads up immediately! The combination of roughness and low surface energy creates the superhydrophobicity. The specific method chosen (e.g., sol-gel, chemical vapor deposition, layer-by-layer assembly) will depend on factors such as the desired roughness scale, the chemical properties of the polymer, and the required durability.

Q 17. Explain the role of surface modification in enhancing the barrier properties of polymers.

Surface modification plays a critical role in enhancing the barrier properties of polymers. Barrier properties refer to the polymer’s ability to prevent the passage of gases, liquids, or other substances. Many polymers inherently have limitations in this area.

Surface modification can create a denser, more compact surface layer that limits diffusion through the polymer. For instance, coating a polymer with a thin layer of a highly impermeable material can greatly increase its resistance to water vapor or oxygen permeation. This is particularly important in applications like food packaging, where the goal is to maintain the freshness and quality of the food product. Imagine modifying polyethylene film with a silica coating – this would enhance its barrier against oxygen, significantly extending the shelf life of packaged foods.

Additionally, surface modification can reduce the polymer’s interaction with other substances, preventing absorption or penetration. For example, treating a plastic container with a specific coating prevents its interaction with the contents and prevents contamination or degradation.

Q 18. How can surface modification improve the printability of polymers?

Improving the printability of polymers is crucial in various applications, such as packaging and electronics. Many polymers inherently have poor surface energy, leading to poor ink adhesion and uneven printing results.

Surface modification techniques can increase the surface energy of the polymer, thereby enhancing ink wettability and adhesion. Methods like plasma treatment, corona discharge treatment, or chemical etching create a more reactive surface that readily interacts with inks, leading to sharper, more defined prints. For instance, plasma treatment of polyethylene terephthalate (PET) increases its surface energy, leading to enhanced ink adhesion for printing logos on plastic bottles.

It’s like preparing a canvas before painting – roughening the surface creates a better grip for the paint. Similarly, modifying the polymer surface improves ink adherence, making for higher-quality prints.

Q 19. Discuss the application of surface modification in the medical device industry.

Surface modification is vital in the medical device industry, impacting biocompatibility, functionality, and longevity. It allows for the tailoring of a material’s surface properties to suit specific needs. For example:

- Improved biocompatibility: Modifying the surface to reduce protein adsorption or cell adhesion can prevent the body from rejecting the implant. A common approach is to coat the surface with hydrophilic polymers or create a biocompatible coating to reduce inflammation.

- Enhanced drug delivery: Surface modification can create a surface that enables controlled release of therapeutic agents. The modification can include creating pores that contain and release drugs upon stimulation.

- Improved tissue integration: Modifying the surface to promote cell adhesion and growth can improve the integration of implants with surrounding tissues. Creating surface structures with specific geometries or adding bioactive molecules that mimic the extracellular matrix can enhance cell adhesion and growth.

- Antimicrobial properties: Introducing antimicrobial agents onto the surface of medical devices prevents infections. This is crucial for catheters, implants, and other devices that come into direct contact with the body.

In essence, surface modification allows us to create medical devices that are not only functional but also safe and compatible with the human body.

Q 20. Describe the use of surface modification in the packaging industry.

The packaging industry utilizes surface modification to enhance various properties of packaging materials. Key applications include:

- Improved barrier properties: As discussed earlier, surface modification can greatly improve the barrier properties of packaging materials, preventing the passage of gases, liquids, or other substances, thereby extending the shelf life of food and other products.

- Enhanced printability: Surface modification ensures that packaging materials can be easily printed on, allowing for clear and durable labels and branding.

- Increased adhesion: Modifying the surface improves the adhesion of coatings or labels to the packaging material, ensuring that they don’t peel off easily.

- Modified wettability: Adjusting the surface wettability can make the packaging material more resistant to water or other liquids, preventing damage or degradation during storage and transportation.

- Antimicrobial properties: Modifying surfaces with antimicrobial agents can prevent bacterial growth and protect packaged products from spoilage. This is particularly important for food packaging and medical packaging.

Essentially, surface modification allows the creation of packaging materials that are not only functional and protective but also attractive and aesthetically pleasing.

Q 21. What is the importance of surface cleaning prior to polymer modification?

Thorough surface cleaning is absolutely paramount before any polymer modification. Think of it as preparing the ground before planting a seed – if the soil isn’t clean, the seed won’t grow properly. Similarly, contaminants on the polymer surface can significantly hinder the effectiveness of the modification process.

Contaminants, such as oils, greases, dust, or other residues, can interfere with the bonding process, resulting in a weak and non-uniform modified layer. This can lead to poor durability and failure of the modification. The cleaning process needs to remove these contaminants while avoiding damage to the underlying polymer surface. Appropriate cleaning methods such as ultrasonic cleaning, plasma cleaning, or solvent cleaning are selected based on the nature of the polymer and the type of contaminants.

A clean surface ensures that the modifying agent can properly interact with the polymer substrate, forming a strong and stable bond for a successful and durable modification. Failing to clean properly can lead to wasted effort and resources. It is always better to over-clean than under-clean.

Q 22. How do you assess the effectiveness of a surface modification treatment?

Assessing the effectiveness of a polymer surface modification treatment hinges on understanding the desired outcome. We need to carefully select appropriate characterization techniques to quantify the changes made to the surface. This isn’t a one-size-fits-all approach; the best method depends heavily on the specific modification and its intended purpose.

Wettability: Contact angle measurements using a goniometer are crucial for evaluating changes in hydrophilicity or hydrophobicity. A decrease in contact angle indicates increased wettability.

Surface Energy: Techniques like inverse gas chromatography (IGC) provide a more comprehensive understanding of surface energy components, revealing interactions with different probe molecules.

Surface Chemistry: X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) directly analyze the elemental and molecular composition of the surface, confirming the presence of the desired functional groups.

Surface Morphology: Atomic force microscopy (AFM) and scanning electron microscopy (SEM) visualize surface roughness and topography changes, impacting properties like adhesion and friction.

Mechanical Properties: Nanoindentation can assess changes in surface hardness, modulus, and adhesion strength after modification.

Biological Response (for biomedical applications): Cell adhesion assays and protein adsorption studies evaluate the impact of modification on cell behavior and biocompatibility.

For example, if we’re modifying a polymer to improve its biocompatibility for a medical implant, we’d focus on techniques like XPS to confirm the presence of specific functional groups promoting cell adhesion, and cell assays to observe cell growth and proliferation on the modified surface.

Q 23. Discuss the environmental impact of some polymer surface modification techniques.

The environmental impact of polymer surface modification techniques varies greatly depending on the method employed. Some techniques are inherently greener than others. Let’s look at a few examples:

Plasma treatment: While generally considered relatively low-impact, the gases used (e.g., oxygen, nitrogen) should be handled carefully to prevent release into the atmosphere. The energy consumption of the plasma equipment should also be considered.

Solvent-based techniques: These often involve volatile organic compounds (VOCs), contributing to air pollution and posing health risks. Solvent selection and proper waste disposal are critical to minimize environmental harm. The use of supercritical CO2 as a solvent is a more environmentally friendly alternative.

Chemical grafting: The reagents used can be toxic or generate hazardous byproducts. Careful selection of reagents and proper waste management protocols are crucial. Bio-based monomers and catalysts are gaining traction as more sustainable options.

Electrochemical methods: These are often less environmentally damaging compared to solvent-based approaches, but still require careful consideration of the electrolyte solutions used and the energy consumption during the process.

Life cycle assessment (LCA) studies are becoming increasingly important in evaluating the overall environmental footprint of these techniques, taking into account energy consumption, material usage, waste generation, and greenhouse gas emissions.

Q 24. Explain the concept of surface functionalization.

Surface functionalization is the process of modifying the chemical composition of a polymer surface to introduce specific functional groups. These functional groups alter the surface properties, enabling the material to interact differently with its surroundings. Think of it like adding different ‘hooks’ or ‘tags’ to the surface to make it ‘sticky’ for certain molecules or change its behaviour.

For instance, we might add hydroxyl (-OH) groups to make the surface hydrophilic (water-loving), improving its biocompatibility or allowing better adhesion to other materials. Conversely, adding alkyl chains can increase hydrophobicity, making it repel water. The functional groups can be introduced through various techniques such as plasma treatment, chemical grafting, or layer-by-layer deposition.

A practical example is functionalizing a polymer surface with carboxyl (-COOH) groups to enhance its ability to bind proteins or drugs in biomedical applications. The choice of functional group is determined by the desired modification of the surface properties.

Q 25. What are the safety precautions to be taken when performing polymer surface modification?

Safety is paramount when working with polymer surface modification. The specific precautions depend on the chosen technique and reagents, but general principles include:

Proper ventilation and personal protective equipment (PPE): Many techniques involve volatile chemicals or gases that can be harmful if inhaled. A well-ventilated workspace and the use of fume hoods, gloves, lab coats, and safety glasses are essential.

Handling of hazardous materials: Many reagents used in surface modification are toxic, corrosive, or flammable. Follow safety data sheets (SDS) carefully, and use appropriate storage and handling procedures.

Electrical safety: Techniques involving plasma treatment or electrochemical methods require adherence to strict electrical safety protocols to prevent shocks and fires.

Waste disposal: Proper disposal of chemical waste is crucial. Follow all relevant regulations and guidelines for safe handling and disposal.

Emergency preparedness: Having readily accessible eyewash stations, safety showers, and a fire extinguisher is essential in any laboratory setting. A detailed emergency plan is important.

Thorough training and adherence to standard operating procedures are critical to ensure the safety of the personnel and the environment.

Q 26. Describe different types of polymer surface coatings and their applications.

Various polymer surface coatings are available, each offering unique properties and applications.

Self-Assembled Monolayers (SAMs): These are highly ordered molecular layers formed by the spontaneous adsorption of molecules onto a surface. They are often used to modify wettability, adhesion, and biocompatibility. For example, alkanethiol SAMs on gold are common.

Polymer Thin Films: These can be deposited using various techniques, including spin coating, dip coating, or spray coating. They offer good protection, modify mechanical properties, and can incorporate specific functionalities. Examples include coatings for scratch resistance, anti-fouling, or drug delivery.

Sol-Gel Coatings: These coatings are derived from the hydrolysis and condensation of metal alkoxides to form a network structure. They offer excellent hardness and corrosion resistance and are used in various applications, including protective coatings and sensors.

Electrodeposited Coatings: These involve depositing a conductive polymer or metal onto a surface using an electrochemical process. They are often used to create conductive tracks, sensors, or actuators.

Plasma Polymer Coatings: These involve creating thin films using plasma-enhanced chemical vapor deposition (PECVD). They offer a wide range of functionalities and can be tailored to specific applications. Examples include coatings for biocompatibility, anti-reflection, and corrosion resistance.

The choice of coating depends on the specific application requirements and the desired surface properties.

Q 27. How do you troubleshoot issues encountered during polymer surface modification processes?

Troubleshooting polymer surface modification processes often requires a systematic approach. The first step is to carefully identify the issue.

Inconsistent surface properties: This could be due to variations in the treatment parameters, non-uniformity of the polymer surface, or contamination. Careful monitoring of parameters and pre-treatment cleaning are crucial.

Low grafting efficiency: This might result from improper activation of the polymer surface, low concentration or reactivity of the grafting reagents, or incomplete reactions. Optimizing parameters such as reaction time, temperature, and reagent concentrations is essential.

Unwanted side reactions: This could be due to the presence of impurities or unwanted interactions between the reagents and the polymer. High purity reagents and careful control of reaction conditions are needed.

Lack of desired surface functionality: This could indicate an incorrect choice of modification technique or reagents. Confirmation of successful functionalization through characterization techniques is vital.

A structured approach involving careful observation, detailed records of the process parameters, and the use of appropriate characterization techniques will assist in pinpointing and resolving issues encountered during surface modification.

For example, if a plasma treatment leads to uneven modification, we might investigate the plasma power, gas flow rate, treatment time, and distance between the sample and the plasma source and adjust them accordingly.

Key Topics to Learn for Polymer Surface Modification Interview

- Polymer Chemistry Fundamentals: Understanding polymer structure, properties (e.g., hydrophobicity, crystallinity), and the relationship between structure and surface properties is crucial. Brush up on concepts like molecular weight, chain conformation, and glass transition temperature.

- Surface Characterization Techniques: Familiarize yourself with techniques used to analyze modified polymer surfaces. This includes, but is not limited to, contact angle goniometry, X-ray photoelectron spectroscopy (XPS), atomic force microscopy (AFM), and secondary ion mass spectrometry (SIMS).

- Surface Modification Techniques: Master the principles and applications of various surface modification methods. This includes plasma treatment, chemical grafting, layer-by-layer assembly, and surface coating. Understand the advantages and limitations of each technique.

- Practical Applications: Explore real-world applications of polymer surface modification. Consider examples in biomedical devices (e.g., implants, drug delivery systems), coatings (e.g., anti-fouling, anti-corrosion), and textiles (e.g., stain resistance, water repellency). Be prepared to discuss specific examples and their underlying principles.

- Problem-Solving and Troubleshooting: Develop your ability to analyze surface modification challenges. Practice identifying potential issues during the modification process and proposing solutions. Consider scenarios involving unexpected results or process optimization.

- Adhesion and Wettability: Deepen your understanding of the factors influencing adhesion and wettability of polymer surfaces. This is critical for many applications, and you should be able to explain the role of surface energy and interfacial interactions.

Next Steps

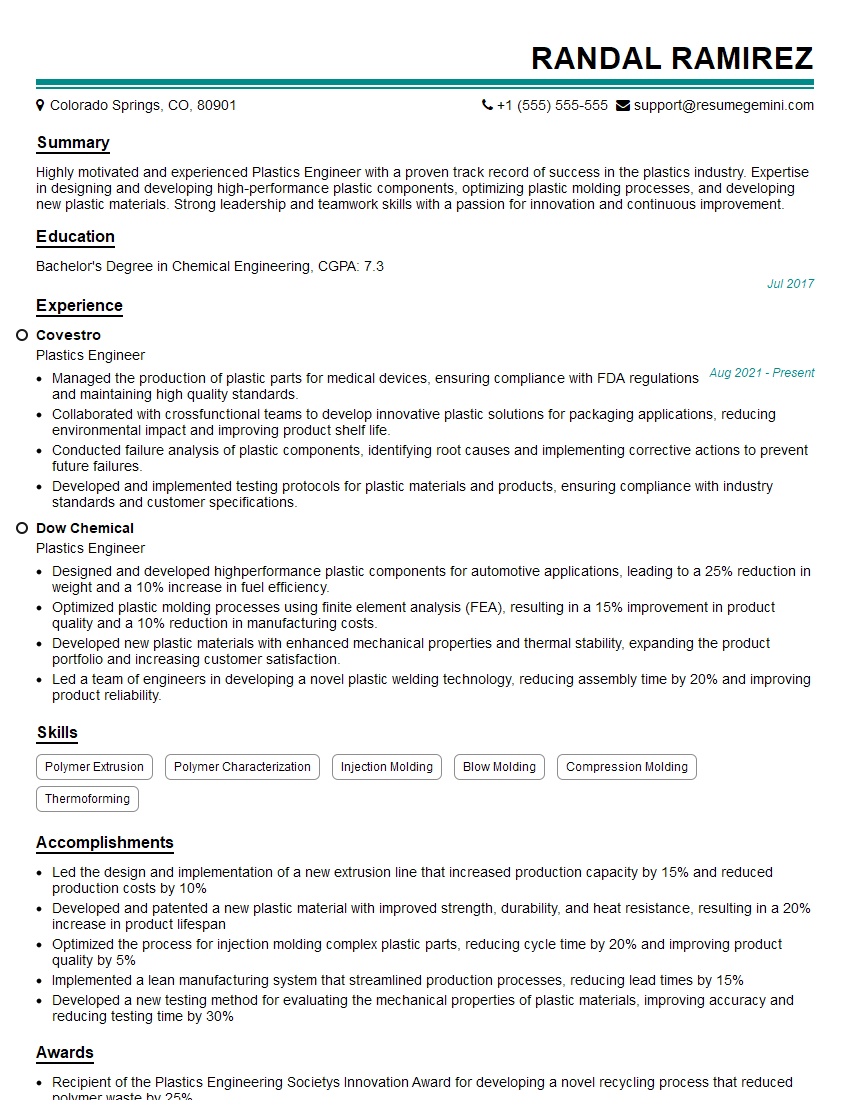

Mastering Polymer Surface Modification opens doors to exciting career opportunities in diverse fields, offering excellent prospects for growth and innovation. To significantly boost your job prospects, it’s vital to create a resume that effectively showcases your skills and experience to Applicant Tracking Systems (ATS). ResumeGemini can help you craft a professional and ATS-friendly resume that highlights your expertise in Polymer Surface Modification. ResumeGemini provides examples of resumes tailored to this specific field, enabling you to create a compelling application that stands out from the competition. Invest in your future by leveraging the resources available to build a strong and effective resume.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.