Are you ready to stand out in your next interview? Understanding and preparing for Power Line Installation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Power Line Installation Interview

Q 1. Describe the different types of power lines and their applications.

Power lines are categorized based on voltage level and application. Think of it like roads – you have small residential streets, larger city roads, and then massive highways. Similarly, we have different types of power lines to handle varying power demands.

- Low-Voltage Lines (LV): These lines typically operate at voltages below 1000 volts and distribute electricity to individual homes and small businesses. They’re like the smaller residential streets in our analogy, handling lower traffic (power demand).

- Medium-Voltage Lines (MV): Operating between 1 kV and 35 kV, these lines connect substations to distribution transformers, feeding power to larger areas. Imagine these as the city roads, handling a significant amount of traffic.

- High-Voltage Lines (HV): These lines operate at voltages ranging from 35 kV to 230 kV and transmit electricity over long distances from power plants to substations. These are our highways, transporting massive amounts of power efficiently across vast distances.

- Extra-High-Voltage Lines (EHV) and Ultra-High-Voltage Lines (UHV): These are specialized lines used for transmitting very large amounts of power across extremely long distances, often exceeding 230 kV and sometimes reaching millions of volts. These are the specialized expressways, optimized for incredibly high capacity.

The choice of line type depends on the voltage requirements, distance of transmission, and power demand of the area it serves. For example, a new housing development would primarily use low-voltage lines, while a large industrial park might require medium-voltage lines, and a transmission line connecting a remote power plant to a major city would utilize high-voltage or even extra-high-voltage lines.

Q 2. Explain the safety procedures involved in working with high-voltage power lines.

Safety is paramount when working with high-voltage power lines. A single mistake can be fatal. We follow a strict hierarchy of safety protocols, often exceeding OSHA regulations. Imagine handling a coiled venomous snake – extreme caution and specific procedures are absolutely necessary.

- Lockout/Tagout (LOTO): Before any work begins, the power must be completely de-energized and locked out to prevent accidental re-energization. This involves physically locking out the circuit breaker to prevent anyone from turning the power back on unintentionally.

- Grounding: The lines must be thoroughly grounded using specialized grounding equipment to ensure that any residual charge is safely dissipated into the earth. This is crucial to prevent electric shock.

- Personal Protective Equipment (PPE): This includes insulated gloves, rubber boots, hard hats, safety glasses, and arc-flash protective clothing designed to protect against high-voltage arcs. Nothing is taken for granted here; every precaution is followed.

- Trained Personnel: Only highly trained and certified personnel are allowed to work on high-voltage lines. This training includes extensive safety procedures, proper use of equipment, and emergency response techniques. Regular safety training updates and drills are commonplace.

- Spotters and Communication: A team approach is mandatory. Spotters monitor the work area for potential hazards, and clear communication among crew members is essential to prevent accidents.

Compliance with these procedures is not merely a suggestion; it’s a life-saving necessity. We regularly audit our safety practices and undergo rigorous safety training to maintain the highest standards.

Q 3. What are the common tools and equipment used in power line installation?

Power line installation requires specialized tools and equipment. It’s like a surgeon’s toolkit – each instrument has a specific purpose, and precision is key.

- Aerial Lifts and Buckets: These allow workers to reach high-voltage lines safely and efficiently.

- Insulated Tools: These tools are specifically designed to prevent electrical shock, including insulated pliers, screwdrivers, and wrenches.

- Tensioning Equipment: Used to stretch and secure conductors to maintain proper tension and sag in the power lines.

- Stringing Equipment: This includes sheaves, rollers, and winches used to pull conductors along the power line route.

- Grounding Equipment: This includes grounding rods, clamps, and wires to safely discharge any electricity from the lines.

- Wire Splicing Tools: Used to join individual conductors together to create the continuous length of the power line.

- Testing Equipment: Various meters and testers are used to verify the integrity and proper operation of the power lines.

The specific equipment will vary based on the type of installation, the voltage level, and the terrain. We always ensure that all equipment is regularly inspected and maintained to prevent any malfunction during installation.

Q 4. How do you ensure the proper grounding of power lines?

Proper grounding is critical to ensure safety and prevent electrical surges. Imagine a lightning rod – it safely diverts the electrical charge into the earth. Grounding power lines achieves a similar effect.

Grounding involves connecting the power line system to the earth using low-resistance conductors. This provides a path for fault currents to flow to the earth, preventing dangerous voltage buildup and protecting equipment and personnel. Several techniques are employed:

- Ground Rods: These are driven deep into the earth and connected to the grounding system using heavy-gauge copper wire. They provide a reliable path for current to flow to the ground.

- Grounding Wires: Heavy-gauge copper or aluminum wires are used to connect the grounding system components together.

- Grounding Clamps: These clamps securely connect the grounding wires to the power lines or equipment.

- Grounding Grids: In some cases, a grid of interconnected ground rods is used to provide a more extensive and effective grounding system, particularly in areas with high soil resistivity.

Regular testing of the grounding system is essential to ensure its effectiveness. Resistance measurements are taken to verify that the grounding system maintains a low impedance path to earth. This is a continuous process to ensure maximum safety.

Q 5. Describe the process of installing a new power pole.

Installing a new power pole is a complex process requiring careful planning and execution. Imagine building a skyscraper – it’s a multi-stage project with specialized tasks.

- Site Preparation: This involves surveying the location, excavating a hole of appropriate depth and diameter, and ensuring the ground is stable enough to support the pole.

- Pole Erection: The pole is carefully placed into the hole and possibly cemented or anchored to prevent it from moving. Specialized equipment like a crane might be used for heavier poles.

- Concrete Pouring (if applicable): If concrete is used, it’s poured around the base of the pole to secure it firmly in place. This needs to be done accurately to ensure the pole’s stability.

- Guy Wires (if needed): Guy wires are attached to the pole to provide additional stability, especially in areas with high winds or unstable soil conditions. These are tensioned to prevent pole movement.

- Conductor Installation: Once the pole is firmly in place, the power lines are strung from the pole to adjacent poles.

- Grounding: A grounding system is connected to the pole to ensure safety.

- Inspection and Testing: After installation, the entire system undergoes a thorough inspection and testing to ensure it meets all safety and performance standards.

The process is highly regulated and requires skilled labor to ensure proper installation and long-term reliability. Failure to follow proper procedures can result in safety hazards and system failures.

Q 6. Explain the different types of conductors used in power lines.

Power line conductors need to handle massive electrical currents and withstand environmental stresses. Think of them as the arteries of the power grid. We select conductors based on several factors.

- Aluminum Conductor Steel-Reinforced (ACSR): This is the most common type, combining the lightweight and good conductivity of aluminum with the strength of steel core wires. It balances weight, strength, and conductivity.

- All-Aluminum Conductor (AAC): Used in lower-voltage applications, AAC offers good conductivity but is less strong than ACSR. It’s suitable for lower stress environments.

- Aluminum Conductor Alloy Steel-Reinforced (ACAR): This type offers improved tensile strength and resistance to corrosion compared to ACSR.

- Copper Conductors: While offering superior conductivity to aluminum, copper is more expensive and heavier. It’s primarily used in situations demanding higher current-carrying capacity or lower resistance.

The selection depends on factors like voltage level, current capacity requirements, span length, environmental conditions (wind, ice, etc.), and cost considerations. For instance, long spans with high wind loads might require ACSR, while shorter spans with lower loads might use AAC. Careful conductor selection is crucial to ensure efficient power transmission and long-term reliability.

Q 7. How do you identify and resolve common power line faults?

Identifying and resolving power line faults is a critical aspect of maintaining a reliable power grid. Think of it as diagnosing a patient – we need to identify the symptoms and address the root cause.

Common faults include:

- Broken Conductors: These can be identified visually or through testing. Repairs involve splicing the broken conductor or replacing the section.

- Loose Connections: Poor connections can lead to overheating and potential fires. They are often detected through infrared thermography (heat detection) or by measuring voltage drops.

- Insulator Failures: Damaged insulators can cause short circuits. They’re often identified through visual inspection or by observing arcing or sparking.

- Tree Contact: Trees growing too close to power lines can cause short circuits or grounding faults. This requires tree trimming or removal.

- Lightning Strikes: These can damage insulators, conductors, or other equipment. Repairs often involve replacing damaged components.

Fault identification uses various methods including visual inspections, infrared thermography, electrical testing, and sophisticated monitoring systems. Troubleshooting often involves a combination of techniques to pinpoint the precise location and cause of the fault, followed by safe and efficient repair methods. Safety is always the top priority.

Q 8. What are the safety regulations and standards you must adhere to during installation?

Safety is paramount in power line installation. We adhere to a strict set of regulations and standards, primarily drawn from OSHA (Occupational Safety and Health Administration) guidelines and industry best practices. These regulations cover everything from personal protective equipment (PPE) to safe work practices around energized lines.

- PPE: This includes hard hats, safety glasses, insulated gloves, arc flash suits, and safety harnesses. The specific PPE required varies depending on the task and the voltage level.

- Lockout/Tagout Procedures: Before any work is performed on de-energized lines, a rigorous lockout/tagout procedure must be followed to prevent accidental energization. This involves physically locking out the power source and tagging it to indicate that work is being performed.

- Safe Distances: Maintaining safe distances from energized lines is crucial. These distances are determined by the voltage level and are strictly enforced. We use specialized tools and techniques to work near energized lines, minimizing the risk of electrical shock or arc flash.

- Grounding and Bonding: Grounding and bonding procedures are essential to prevent the accumulation of static electricity and ensure a safe working environment. We use grounding clamps and other equipment to create a safe path for electrical current.

- Competent Person Supervision: A designated competent person is always on-site to oversee the work and ensure that all safety regulations are being followed. This person is responsible for identifying and mitigating hazards.

For example, during a recent project involving high-voltage lines, we implemented a comprehensive safety plan that included daily toolbox talks, rigorous PPE checks, and frequent inspections of our equipment. This proactive approach ensured the safety of our entire crew.

Q 9. Explain the importance of proper tensioning of power lines.

Proper tensioning of power lines is critical for several reasons. Insufficient tension can lead to sagging lines, which can cause:

- Ground clearance issues: Sagging lines can come into contact with trees, buildings, or the ground, resulting in outages and potential safety hazards.

- Increased vibration and galloping: Under-tensioned lines are more susceptible to vibration and galloping (a type of severe oscillation), which can cause damage to the conductors and supporting structures.

- Reduced lifespan of conductors: Excessive stress due to improper tension shortens the lifespan of the conductors.

Over-tensioning, on the other hand, can also be detrimental, potentially leading to broken conductors and damage to hardware. Therefore, achieving the correct tension, as specified by the manufacturer and engineering designs, is crucial. We use specialized tensioning tools, such as tension meters and pullers, to ensure that lines are installed with the correct amount of tension.

Imagine a guitar string; if it’s too loose, it won’t produce a clear sound and might break easily. Similarly, if power lines are not properly tensioned, they can be prone to damage and disruptions.

Q 10. How do you handle emergency situations during power line installation?

Emergency situations during power line installation require immediate and decisive action. Our procedures emphasize quick response and prioritization of safety.

- First Aid and Emergency Response: We have trained personnel who are certified in first aid and CPR. In case of an accident, immediate first aid is administered, and emergency services are contacted immediately.

- Evacuation Procedures: A clear evacuation plan is in place for various scenarios, including inclement weather and equipment malfunctions. Our crew is trained to evacuate safely and efficiently.

- Communication: We use two-way radios and other communication tools to maintain contact with the crew and emergency services during an emergency.

- Hazard Mitigation: Our procedures emphasize immediate mitigation of hazards, such as securing fallen power lines or isolating equipment that is malfunctioning.

For example, during a storm, we had to quickly evacuate the work site due to high winds and lightning. Our pre-planned procedures ensured the safe and orderly evacuation of the crew and equipment. Post-incident, we reviewed the procedures and adapted the plan to include additional safety measures for future stormy weather conditions.

Q 11. Describe your experience with different types of climbing equipment.

My experience with climbing equipment is extensive. I am proficient in using various types of climbing equipment, including:

- Safety Harnesses: Full-body harnesses are essential for ensuring safe ascent and descent. I am experienced with different harness types and know how to properly adjust and inspect them.

- Climbing Ropes and Lanyards: I am familiar with various rope types and know how to inspect them for damage before each use. Proper use of lanyards for fall protection is vital.

- Ascenders and Descenders: I am proficient in using ascenders and descenders for controlled ascent and descent on poles and structures. These tools allow for safe and efficient movement.

- Climbing Spurs: I am experienced with using climbing spurs on wooden poles, understanding the techniques for safe and efficient climbing.

- Buckets and Platforms: I have experience using various types of buckets and platforms for work at height, ensuring their secure attachment and safe operation.

I understand the importance of regular inspection and maintenance of all climbing equipment, and I always prioritize safety when using these tools. For instance, I once discovered a small fray in a climbing rope during a routine inspection, preventing a potential fall hazard.

Q 12. How do you perform preventative maintenance on power lines?

Preventative maintenance is key to ensuring the long-term reliability and safety of power lines. Our maintenance program includes:

- Regular Inspections: We conduct regular visual inspections of power lines, looking for signs of damage such as corrosion, wear, and broken insulators. Infrared thermography is also used to detect overheating.

- Vegetation Management: Trees and other vegetation near power lines can cause significant damage. We employ various techniques to manage vegetation growth, including trimming and removal.

- Hardware Checks: We regularly inspect the condition of hardware components such as insulators, clamps, and connectors, replacing any damaged or worn-out parts.

- Conductor Testing: Electrical testing is conducted periodically to ensure the integrity of the conductors and detect any faults.

- Corrosion Prevention: We apply protective coatings and use other corrosion prevention techniques to extend the lifespan of metal components.

A proactive maintenance program not only ensures the safety and reliability of power lines, but it also reduces the likelihood of costly repairs and service disruptions. We often use predictive modeling based on historical data and environmental factors to prioritize maintenance tasks.

Q 13. Explain your understanding of the National Electrical Code (NEC).

The National Electrical Code (NEC) is a comprehensive set of standards for the safe installation and maintenance of electrical systems in the United States. My understanding of the NEC is crucial to my work, ensuring that all installations meet the required safety standards. The NEC covers many aspects relevant to power line installation, including:

- Wiring Methods: The NEC specifies acceptable wiring methods for different voltage levels and environments. We ensure proper grounding and bonding according to NEC guidelines.

- Conductor Sizing: The NEC provides guidelines for selecting appropriately sized conductors to handle the expected current loads. Incorrect sizing can lead to overheating and fire hazards.

- Protection Devices: The NEC mandates the use of appropriate protective devices such as fuses and circuit breakers to protect against overcurrents and short circuits. These ensure safety and reliability of the system.

- Grounding and Bonding: The NEC outlines strict requirements for grounding and bonding electrical systems to protect against electrical shock and prevent damage to equipment.

- Safety Regulations: The NEC integrates numerous safety regulations, mandating procedures and equipment use to ensure safety during the installation and maintenance processes.

We constantly update our knowledge of the NEC to stay compliant with the latest regulations. We keep up-to-date copies of the code on site and ensure that all our work aligns with these safety regulations.

Q 14. Describe your experience with aerial lift equipment.

I have extensive experience operating aerial lift equipment, including bucket trucks and boom lifts. Safety is always my top priority when using this equipment.

- Pre-Operation Inspections: Before operating any aerial lift, I always conduct a thorough pre-operation inspection to ensure that it’s in safe working condition. This includes checking hydraulic fluids, brakes, and safety mechanisms.

- Safe Operating Procedures: I am familiar with and strictly adhere to all safe operating procedures for aerial lifts. This includes understanding weight limitations, avoiding overloading, and maintaining stable footing.

- Emergency Procedures: I am trained in emergency procedures for aerial lifts, including how to respond to equipment malfunctions and how to safely evacuate in case of an emergency.

- Proper Training and Certification: I have completed the necessary training and have the appropriate certifications to operate aerial lift equipment.

For example, during a recent project, we had to use a boom lift to replace a damaged insulator on a high-voltage line. I followed all safety procedures, ensuring that the lift was properly positioned and stabilized. The job was completed efficiently and safely thanks to my expertise.

Q 15. What are the different types of insulators used in power line construction?

Power line insulators are crucial for preventing current leakage and ensuring the safety of the power transmission system. They come in various types, each suited for different voltage levels and environmental conditions.

- Pin insulators: These are the simplest type, consisting of a porcelain or glass body with a pin at the top and a groove at the bottom. They are commonly used for lower voltage lines.

- Suspension insulators: Used for high-voltage transmission lines, these consist of several porcelain discs strung together. This arrangement improves the overall strength and increases the creepage distance, which is vital in preventing flashover (an electrical discharge across the insulator). Imagine them like a chain – if one disc breaks, the others still support the line.

- Strain insulators: These are specially designed to withstand high tensile stresses at the points where the direction of the power line changes. They are usually stronger and more robust than standard suspension insulators.

- Post insulators: These are used for high-voltage applications, often in substations. They offer a compact design, consisting of a single, large, strong insulator unit.

- Long-rod insulators: These are used in applications that require longer creepage distances, such as areas with heavy pollution or in high-humidity environments.

The choice of insulator depends on factors like voltage level, environmental conditions (pollution, humidity, temperature), and the mechanical strength required.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage weather-related challenges during power line installation?

Weather significantly impacts power line installation. Safety and efficiency demand careful planning and execution.

- Wind: High winds can make working at heights extremely dangerous. We use specialized equipment like elevated platforms and cranes to minimize exposure, and we always adhere strictly to wind speed limits before commencing work. If winds exceed safe levels, work is halted until conditions improve.

- Rain and Snow: Wet conditions can make the lines slippery and increase the risk of electrical shock. Work often needs to be postponed during heavy precipitation to ensure the safety of the team. We use proper safety equipment like insulated gloves and boots, even in light rain, to mitigate risks.

- Ice and Freezing Temperatures: Ice accumulation can weigh down lines and lead to breakage. We employ de-icing techniques and monitor weather forecasts closely, often adjusting work schedules to avoid the worst conditions.

- Lightning: Lightning strikes pose a significant risk. We have strict safety protocols, including grounding procedures and weather monitoring to pause work during storms. Early warning systems and lightning detection equipment are invaluable.

Effective weather management includes thorough weather forecasting, flexible scheduling, and unwavering adherence to safety protocols. Prioritizing safety is paramount – no job is worth jeopardizing lives.

Q 17. Explain your experience working with different types of transformers.

My experience encompasses a wide range of transformers, from small distribution transformers used in residential areas to large power transformers found in substations.

- Distribution Transformers: These are typically pole-mounted or pad-mounted and step down voltage from the transmission lines to a usable level for homes and businesses. I’ve worked extensively with their installation, maintenance, and testing, ensuring proper grounding and connection to the distribution network.

- Power Transformers: These massive transformers are located in substations and handle significantly higher voltages and power levels. My experience with these includes working with specialized lifting equipment, precise alignment during installation, and understanding the critical safety measures required given their high voltage capabilities. I’ve also been involved in the commissioning and testing of these units.

- Autotransformers: I’ve worked with these in situations where a small voltage adjustment is needed. Understanding their unique characteristics and safety implications is critical.

Transformer work always emphasizes meticulous safety procedures, proper grounding, and thorough testing to guarantee reliable operation and prevent accidents. Each type requires specialized knowledge and handling procedures. For example, the high-voltage aspects of power transformers demand extensive safety training and specialized equipment.

Q 18. How do you ensure the quality and reliability of your work?

Quality and reliability are non-negotiable in power line installation. We adhere to a rigorous process to ensure consistent high standards.

- Strict Adherence to Codes and Standards: We strictly follow all relevant national and international electrical codes and safety standards, such as those published by IEEE and ANSI. This ensures the safety and longevity of our installations.

- Thorough Inspections and Testing: Every step of the installation process involves detailed inspections and testing, including visual checks, insulation resistance testing, and continuity checks. This helps to identify and rectify any defects early on.

- Proper Documentation: Meticulous record-keeping, including detailed drawings, testing results, and material specifications, is essential for maintaining a clear audit trail and facilitating future maintenance. This is vital for traceability and problem-solving.

- Quality Control Procedures: We implement regular quality control audits and training programs to continuously improve our processes and maintain a high level of workmanship.

- Use of Quality Materials: We only use materials from reputable suppliers that meet the required specifications and standards. This helps prevent material failures and ensures long-term reliability.

Our commitment to quality and reliability isn’t just about meeting standards; it’s about ensuring the safety and dependability of the power supply for our communities.

Q 19. Describe your experience with underground cable installation.

Underground cable installation presents a unique set of challenges compared to overhead lines. I have extensive experience in various aspects of this work.

- Trenching and Excavation: This involves careful planning and execution to avoid damaging existing underground utilities. We use sophisticated equipment like trenchers and excavators, coupled with locating services to pinpoint the exact locations of buried pipes and cables.

- Cable Laying and Pulling: This requires specialized equipment, including cable pulling equipment and winches, to carefully lay and pull the cables into the trench. Proper cable handling is crucial to prevent damage to the cable insulation.

- Cable Splicing and Termination: Underground cables often require splicing and terminations for connections and repairs. These must be done precisely and carefully to ensure a waterproof and electrically sound connection. Specialized splicing kits and equipment are employed.

- Backfilling and Restoration: Once the cables are laid, the trenches are backfilled, and the ground is restored to its original condition, ensuring the cables are properly protected from damage.

Underground cable installation is often more complex and requires detailed planning and execution, but it provides a safer and more aesthetically pleasing power distribution system compared to overhead lines. It also offers better protection against harsh weather conditions.

Q 20. What are the different methods used for splicing power lines?

Splicing power lines involves creating a continuous, electrically sound connection between two cable ends. Several methods are employed depending on the voltage level, cable type, and the environment.

- Compression Splicing: This method uses specialized compression connectors that mechanically connect the conductors. It’s quick, relatively simple, and commonly used for lower voltage applications.

- Mechanical Splicing: This involves using various mechanical connectors that clamp the conductors together. These often require specialized tools and are suitable for a wider range of cable types and voltage levels.

- Exothermic Welding: This creates a permanent bond between conductors by using an exothermic reaction. It’s highly reliable, strong, and often used in high-voltage applications. The reaction generates intense heat, melting the cable ends and creating a solid weld.

- Fusion Splicing: Specifically for fiber optic cables, this method uses heat to melt the cable ends, fusing them together to create a seamless connection. Precision and cleanliness are crucial for fiber optic splicing.

Each splicing method demands specialized training and the use of appropriate tools and materials to ensure a reliable and safe connection. The choice of method depends heavily on the specifics of the project.

Q 21. How do you use a line locator?

A line locator, also known as a cable locator, is an essential tool for locating underground utilities, including power lines, before excavation. It helps prevent accidental damage to underground cables and pipes, which can be dangerous and costly.

The process typically involves:

- Selecting the appropriate mode: Line locators offer various modes depending on the type of utility being located (e.g., active or passive). For power lines, the active mode, which uses the cable’s electromagnetic field, is usually employed.

- Grounding the locator: This step is critical to establish a reference point for the locator’s readings. The grounding stake must be placed at a safe distance from the area being surveyed.

- Scanning the area: The locator is then swept across the area where the cable is suspected to be located. The locator emits signals and detects the electromagnetic fields of the buried utilities.

- Interpreting the signals: The locator will provide visual and/or auditory signals indicating the location and depth of the underground cable. A strong signal indicates a close proximity to the cable.

- Marking the location: Once the location is identified, it’s marked using paint or flags to guide the excavation crew.

Careful interpretation of the signals is crucial, as interference from other utilities can sometimes create inaccurate readings. Experience and training in the use of line locators are critical to ensuring accurate and safe detection of underground power lines.

Q 22. How familiar are you with OSHA regulations regarding power line work?

OSHA regulations are paramount in power line work, governing safety procedures to minimize risks. My familiarity extends to all relevant standards, including Subpart V – Electrical, covering everything from lockout/tagout procedures to fall protection and arc flash hazard mitigation. I’m well-versed in the regulations concerning personal protective equipment (PPE), such as insulated tools, arc flash suits, and safety harnesses. I understand the importance of regular safety training and inspections to ensure compliance. For example, I know that before commencing any work near energized lines, a thorough risk assessment must be conducted, and appropriate safety measures, like de-energizing the lines if possible, must be implemented. My experience includes maintaining detailed records of safety compliance and actively participating in safety meetings to reinforce best practices.

Q 23. Explain the importance of proper communication and teamwork during installation.

Effective communication and teamwork are the cornerstones of safe and efficient power line installation. Imagine a complex puzzle where each team member is a piece; without clear communication and coordination, the puzzle remains incomplete and unstable. During installation, we use a variety of methods including pre-job briefings, hand signals, and radio communication to coordinate actions. For instance, one team might be responsible for stringing the wire, another for installing insulators, and yet another for grounding. Clear communication ensures everyone understands their role, potential hazards, and the actions of others. This prevents accidents and ensures a smooth workflow. Teamwork ensures problems are identified and solved collaboratively, leading to efficient and safe completion of the project. A lack of communication could easily lead to miscommunication that may cause injury or damage.

Q 24. Describe your problem-solving skills related to power line installation issues.

Problem-solving in power line installation often involves quick thinking and adaptability. For example, I once encountered a situation where a section of land proved unexpectedly unstable for trenching. Instead of proceeding blindly, I collaborated with the engineering team to assess the situation. We devised an alternative route, minimizing disruption and ensuring the project stayed on schedule. My approach involves analyzing the problem, identifying potential solutions, evaluating risks, and selecting the safest and most efficient approach. This often includes seeking input from experienced colleagues and utilizing available resources, such as technical manuals and engineering drawings. Documentation of the problem, solution, and lessons learned is crucial for continuous improvement.

Q 25. How do you handle working at heights?

Working at heights is an inherent part of power line installation and requires rigorous adherence to safety protocols. I am fully trained and certified in fall protection techniques, and always utilize appropriate safety equipment, including harnesses, lanyards, and safety nets. Before starting work at any height, I conduct a thorough inspection of the equipment, ensuring everything is in perfect working order. I understand the importance of maintaining three points of contact whenever possible and regularly check the integrity of my equipment and anchors. My experience includes rescue training and emergency response procedures should an accident occur. Safety is not just a procedure, it’s a mindset; it’s about respecting the potential consequences of complacency and maintaining constant vigilance.

Q 26. What is your experience with using various hand tools and power equipment?

I am proficient in using a wide range of hand tools, from basic wrenches and pliers to specialized equipment for wire splicing and termination. I also have extensive experience operating power equipment including digger derricks, bucket trucks, and trenchers. My experience encompasses the safe and efficient use of these tools, including preventative maintenance and understanding their limitations. I understand the importance of using the right tool for the job and regularly inspect equipment for wear and tear before use to prevent accidents. For example, I can confidently explain the differences between various types of wire splices and choose the most appropriate technique for a given situation, and this choice may vary based on the voltage and material of the wire.

Q 27. How do you interpret blueprints and schematics for power line installation?

Interpreting blueprints and schematics is a fundamental skill. I can easily decipher complex drawings, understanding symbols, dimensions, and specifications. This includes understanding the location of poles, conductors, transformers, and other infrastructure components. I use these drawings not only to understand the planned layout but to anticipate potential challenges during installation. For example, I can identify potential conflicts with existing underground utilities, and plan my approach accordingly. My experience includes using both traditional paper drawings and digital CAD software to visualize and understand project requirements. Accurate interpretation prevents errors and improves efficiency.

Q 28. Describe your experience with trenching and backfilling for underground lines.

My experience with trenching and backfilling for underground lines includes all aspects from planning and surveying to the actual excavation and restoration. I’m proficient in operating trenching equipment, adhering to all safety regulations, and ensuring the trench is properly braced to prevent collapse. I understand the importance of identifying and protecting underground utilities before excavation, using methods like calling ‘One-Call’ services to locate and mark existing lines. After cable installation, backfilling involves compacting the soil properly to prevent settling and damage to the line. This also includes restoring the land surface to its original condition, minimizing environmental impact. My approach always prioritizes safety and environmentally responsible practices.

Key Topics to Learn for Power Line Installation Interview

- Safety Regulations and Procedures: Understanding and applying OSHA regulations, lockout/tagout procedures, and safe work practices in various environments (e.g., aerial lifts, underground work).

- Pole Top Rescue and First Aid: Practical knowledge of rescue techniques and first aid procedures relevant to working at heights and in potentially hazardous situations.

- Conductor Installation and Termination: Understanding different conductor types (copper, aluminum), splicing techniques, and proper termination methods for ensuring reliable connections.

- Transformer Installation and Maintenance: Knowledge of different transformer types, installation procedures, and basic maintenance tasks to ensure optimal performance.

- Underground Cable Installation: Understanding trenching techniques, cable laying procedures, and the importance of proper grounding and shielding.

- Power Line Equipment and Tools: Familiarity with various tools and equipment used in power line installation, including their safe and efficient operation.

- Blueprint Reading and Design Interpretation: Ability to interpret schematics, drawings, and specifications to understand project requirements.

- Troubleshooting and Problem-Solving: Demonstrating the ability to identify, analyze, and solve common problems encountered during installation and maintenance.

- Electrical Theory Fundamentals: A solid grasp of basic electrical principles, including voltage, current, resistance, and power calculations.

- Teamwork and Communication: Highlighting experience in collaborating effectively within a team environment and communicating clearly with supervisors and colleagues.

Next Steps

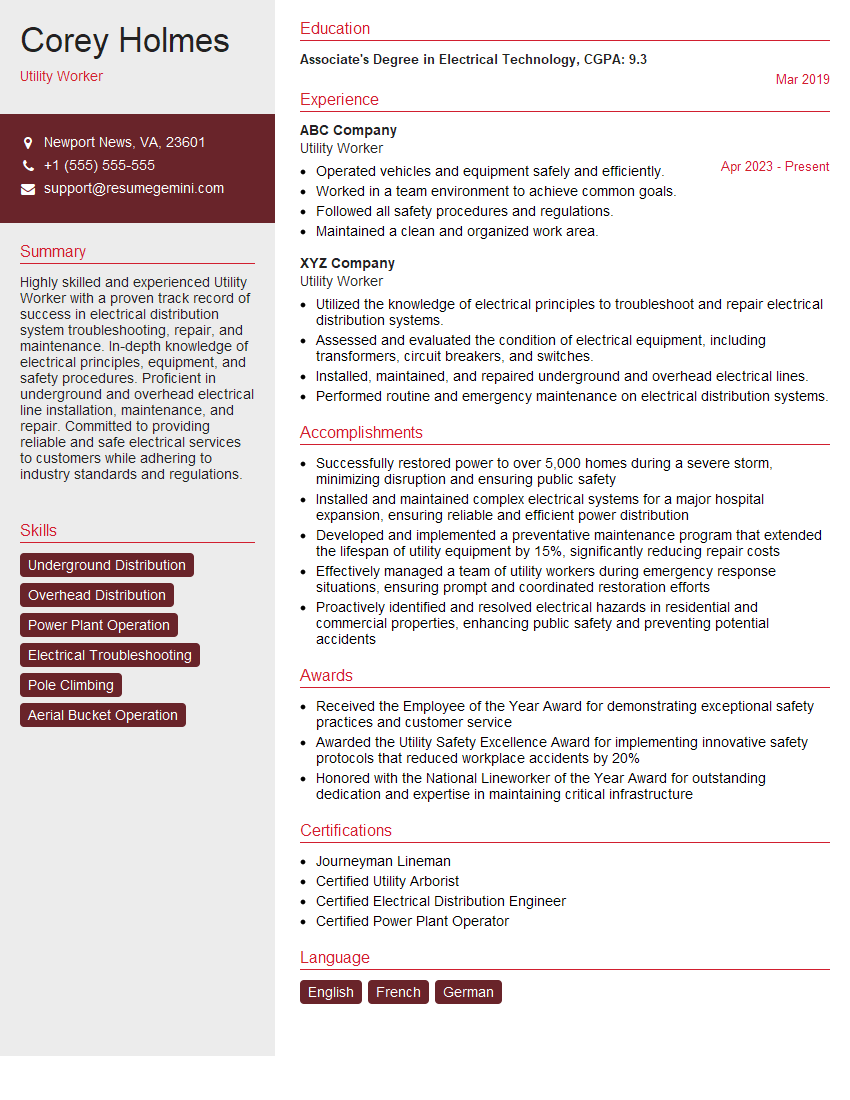

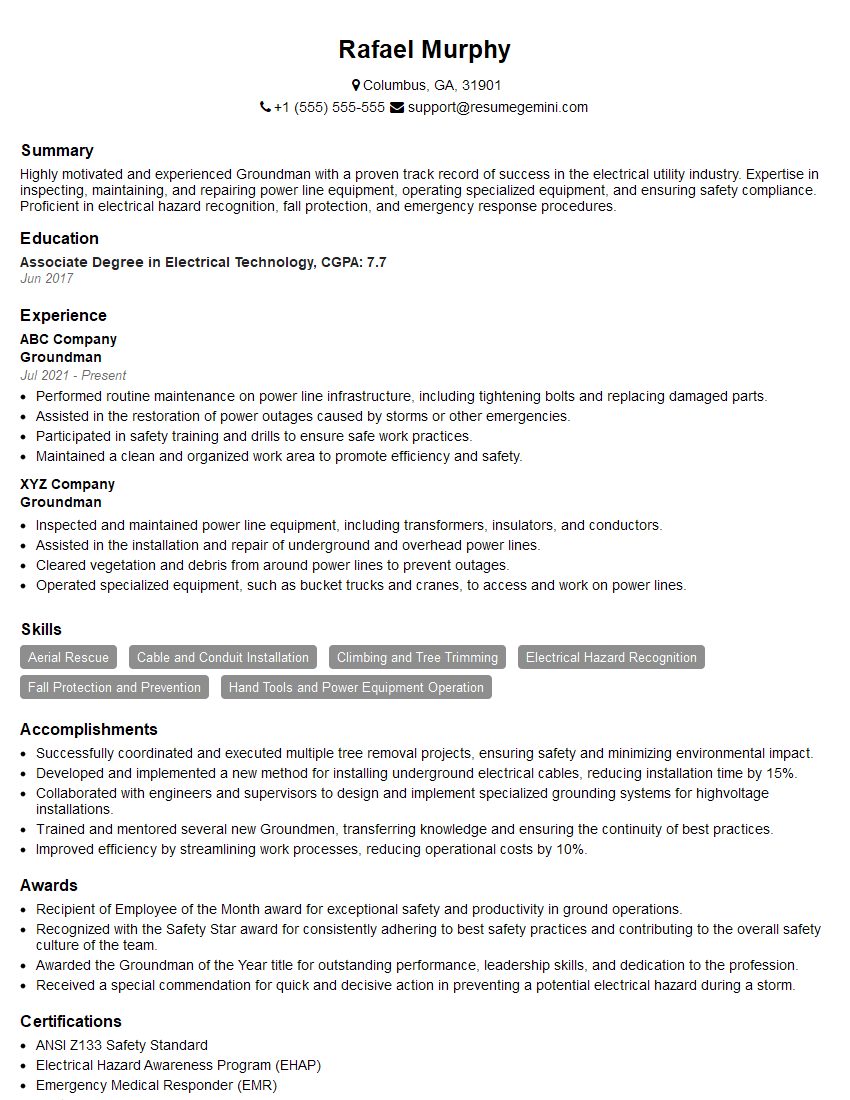

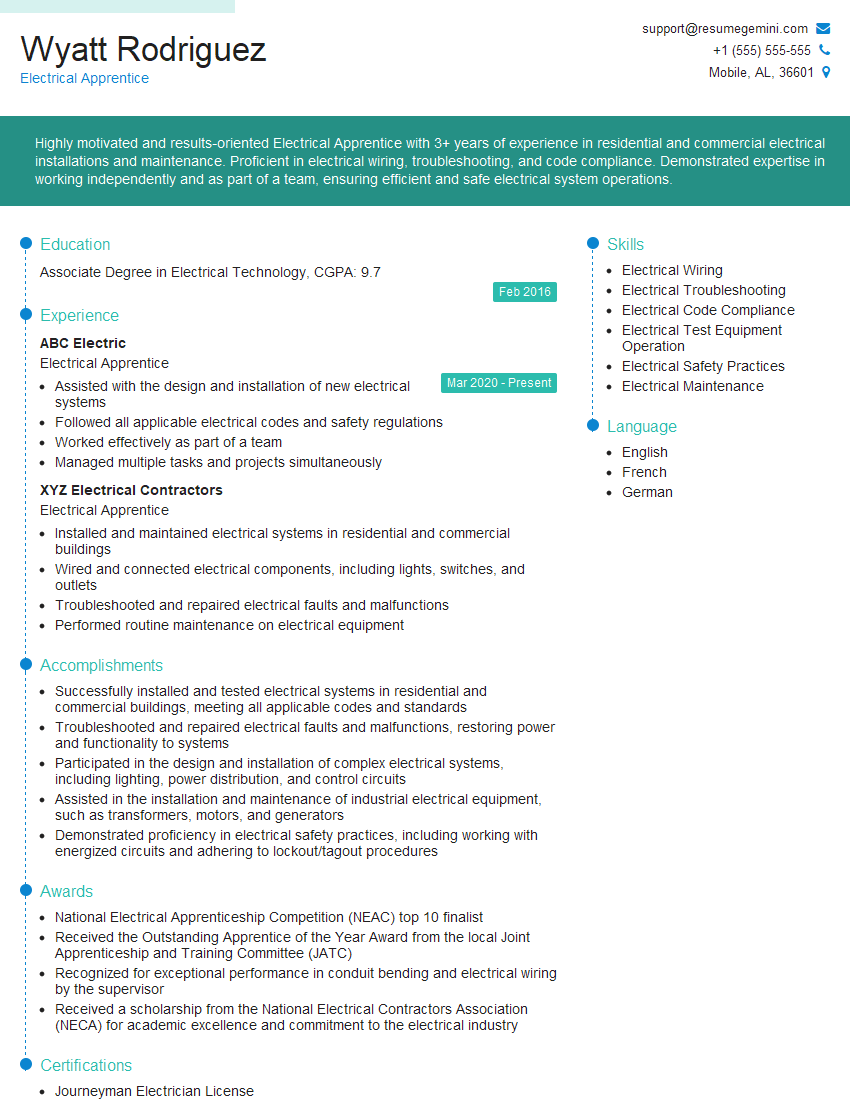

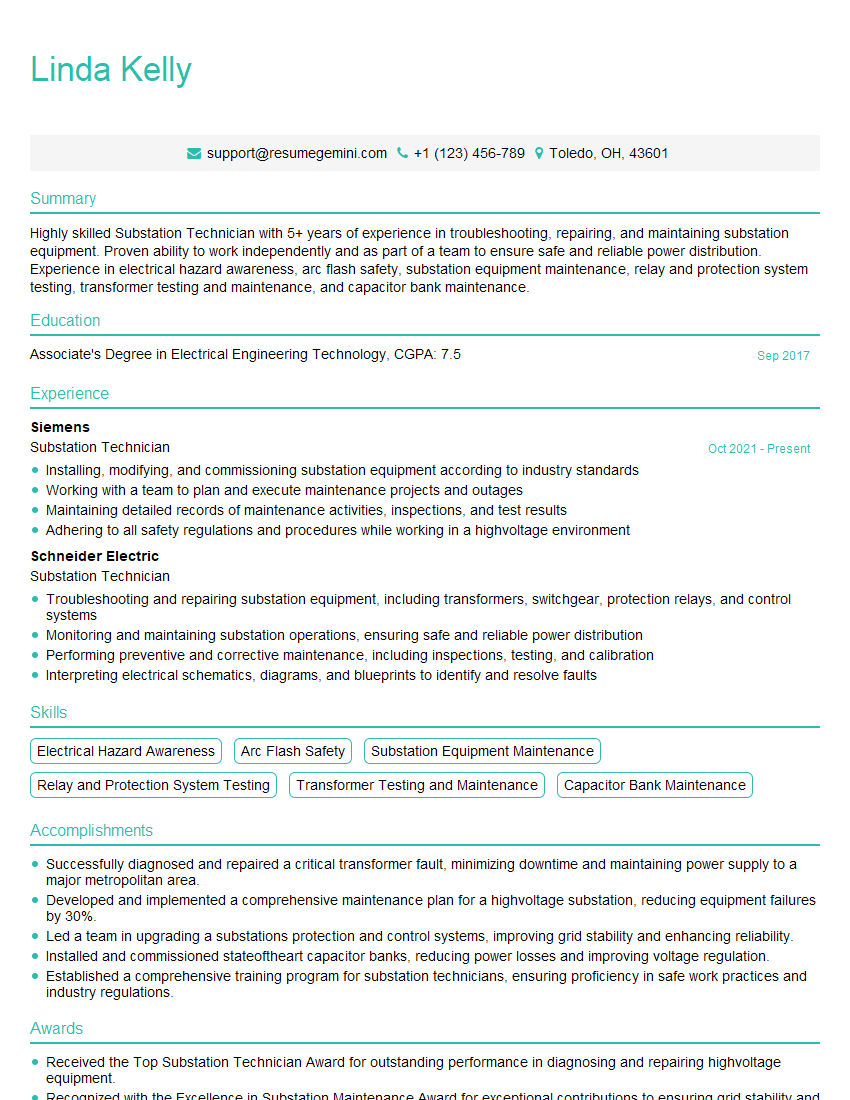

Mastering power line installation opens doors to a rewarding career with excellent growth potential. This specialized skillset is in high demand, leading to competitive salaries and opportunities for advancement. To maximize your job prospects, it’s crucial to create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out to potential employers. They offer examples of resumes tailored to Power Line Installation, providing a valuable template to guide your resume creation process. Invest time in crafting a strong resume – it’s your first impression and a key step towards securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.