Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Pressure and Temperature Analysis interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Pressure and Temperature Analysis Interview

Q 1. Explain the principle of operation of a pressure transducer.

A pressure transducer converts pressure into an electrical signal. Imagine a tiny, incredibly sensitive diaphragm. When pressure changes, this diaphragm flexes. This flexing is then measured using various methods, depending on the type of transducer. For example, a strain gauge transducer uses tiny resistors bonded to the diaphragm; as the diaphragm bends, the resistance of these gauges changes, altering the electrical signal. Piezoresistive transducers work on a similar principle, but use the change in resistance of a semiconductor material. Capacitive transducers measure the change in capacitance between the diaphragm and a fixed plate. The resulting electrical signal is directly proportional to the applied pressure, allowing us to quantify pressure changes accurately.

For instance, in a car’s tire pressure monitoring system (TPMS), a pressure transducer in each tire constantly measures the air pressure. This data is then transmitted wirelessly to the car’s computer, alerting the driver if the pressure is too low. Another example is in industrial processes where precise pressure control is vital, such as in chemical reactors or pipelines.

Q 2. Describe different types of temperature sensors and their applications.

Several types of temperature sensors exist, each with specific applications. Thermocouples are based on the Seebeck effect, where a voltage is generated at the junction of two dissimilar metals when there’s a temperature difference. They offer wide temperature ranges but are less precise than other options. Think of them as the workhorses – reliable and versatile. Resistance Temperature Detectors (RTDs) measure temperature by detecting the change in electrical resistance of a metal, typically platinum, with temperature. They’re known for their high accuracy and stability, often used in precision applications. Imagine them as the meticulous scientists in the temperature measurement world. Thermistors are semiconductor devices whose resistance changes significantly with temperature. They are highly sensitive but often have a narrower operational range. Consider them the specialists, ideal for specific, sensitive temperature monitoring tasks. Finally, Infrared (IR) thermometers measure temperature remotely by detecting infrared radiation emitted by an object; no physical contact is needed. These are fantastic for measuring high temperatures or inaccessible locations, such as the temperature of a furnace or a moving part.

- Thermocouples: Furnaces, ovens, engines.

- RTDs: Calibration labs, scientific instruments, precise industrial processes.

- Thermistors: Temperature-sensitive circuits, medical devices.

- IR Thermometers: Industrial processes, safety inspections.

Q 3. What is the difference between absolute, gauge, and differential pressure?

The difference lies in their reference point: Absolute pressure measures the pressure relative to a perfect vacuum (zero pressure). It’s always positive. Think of it as the total pressure. Gauge pressure measures the pressure relative to atmospheric pressure. It can be positive (above atmospheric pressure) or negative (below atmospheric pressure, also known as vacuum). Imagine blowing into a balloon; you’re increasing the gauge pressure. Finally, differential pressure measures the difference in pressure between two points. This is crucial in many applications to understand pressure drops across components or between two vessels. Think of measuring the pressure drop across a filter or valve.

For example, a car tire might have an absolute pressure of 35 PSI, a gauge pressure of 25 PSI (35 PSI – 10 PSI atmospheric pressure), and a differential pressure of 5 PSI if compared to another tire with a pressure of 30 PSI.

Q 4. How do you calibrate a pressure transmitter?

Calibrating a pressure transmitter involves comparing its output to a known, accurate pressure standard. This usually involves using a deadweight tester, which applies precise pressures using calibrated weights. Here’s a step-by-step process:

- Zero Calibration: Apply zero pressure to the transmitter. Adjust the transmitter’s output so it reads zero.

- Span Calibration: Apply a known high pressure (span pressure) to the transmitter. Adjust the transmitter’s output to match the applied pressure.

- Verification: Apply multiple pressures throughout the transmitter’s range to verify accuracy and linearity.

- Documentation: Record the calibration data, including date, time, pressures applied, and corresponding outputs.

This ensures the transmitter provides accurate pressure readings within its specified tolerance. Regular calibration is essential to maintain accuracy and reliability, particularly in critical applications.

Q 5. Explain the concept of thermal expansion and its impact on process systems.

Thermal expansion refers to the tendency of matter to change its volume in response to temperature changes. Most materials expand when heated and contract when cooled. Imagine heating a metal rod; it gets longer. This seemingly simple concept has significant implications in process systems. In pipelines, for instance, thermal expansion can cause substantial stress on the pipe joints if not accounted for. This could lead to leaks or even pipe failure. Similarly, in large structures like bridges or buildings, thermal expansion needs careful consideration to avoid damage. Expansion joints are commonly used to accommodate these changes.

An example is a long oil pipeline running across varying geographical regions with substantial temperature differences. If the thermal expansion is not correctly predicted and accommodated by expansion loops or similar design features, the pipeline could buckle, leading to costly repairs and potential environmental hazards.

Q 6. Describe different methods for temperature compensation in pressure measurements.

Temperature compensation in pressure measurements is crucial because temperature affects the physical properties of the pressure sensor, leading to inaccurate readings. Several methods exist:

- Temperature-Compensated Sensors: Many modern pressure sensors incorporate internal temperature sensors and circuitry that automatically compensates for temperature-related changes in the pressure sensor’s sensitivity.

- Two-Point Calibration: Calibrating the sensor at two different temperatures and using an interpolation equation to estimate the pressure at intermediate temperatures.

- Software Compensation: Using software algorithms to correct for temperature effects based on the measured temperature and known temperature characteristics of the sensor.

- Environmental Control: Maintaining a stable temperature around the sensor by using temperature-controlled enclosures or baths.

The choice of method depends on factors such as accuracy requirements, cost, and complexity.

Q 7. What are the common causes of pressure and temperature sensor drift?

Pressure and temperature sensor drift, the gradual change in output over time, can stem from various causes:

- Temperature Changes: Extreme or fluctuating temperatures can affect the sensor’s components, causing long-term changes in its output.

- Mechanical Stress: Vibration, shock, or other mechanical stresses can cause the sensor’s internal components to shift or deform, altering its response.

- Aging: Components degrade over time, leading to changes in the sensor’s properties. This is particularly relevant to the strain gauges.

- Environmental Exposure: Exposure to moisture, chemicals, or other harsh environments can damage the sensor’s materials and lead to drift.

Regular calibration and proper handling are essential to minimize drift and ensure accurate measurements. For instance, a poorly installed pressure sensor subjected to constant vibration could exhibit drift, rendering its measurements unreliable over time.

Q 8. How do you troubleshoot a faulty pressure or temperature sensor?

Troubleshooting a faulty pressure or temperature sensor involves a systematic approach. First, you need to understand the sensor’s specifications and operating range. Then, you’d check for obvious issues like loose wiring, damaged cables, or incorrect sensor installation. A visual inspection often reveals problems immediately. Next, compare the sensor’s readings to a known good sensor or a calibrated reference. Discrepancies indicate potential problems. If the problem persists, you would then employ calibration techniques using known pressure or temperature sources. If calibration fails to resolve the issue, the sensor itself may be faulty and needs replacement. You should always consult the sensor’s datasheet for specific troubleshooting guides and calibration procedures. For instance, if a pressure sensor consistently reads lower than expected in a pneumatic system, it might be due to a clogged line, a malfunctioning diaphragm, or even incorrect zeroing. Similarly, if a temperature sensor in a chemical reactor is showing erratic fluctuations, this could signify damage to the sensing element or electrical interference.

Q 9. Explain the importance of pressure and temperature control in process safety.

Pressure and temperature control are paramount in process safety because they directly influence the stability and integrity of many industrial processes. Uncontrolled pressure can lead to ruptures in vessels, pipes, and equipment, resulting in hazardous releases of materials or explosions. Similarly, improper temperature control can cause runaway reactions, equipment damage due to thermal stress, or the formation of unsafe byproducts. Maintaining these parameters within safe operating limits prevents catastrophic events. For example, in a refinery, precisely controlling the temperature and pressure during distillation prevents uncontrolled boiling and potential fires. In a nuclear power plant, extremely accurate temperature monitoring and control are critical for preventing meltdowns. Safety systems, including pressure relief valves and emergency shutdown procedures, are designed to mitigate risks when deviations from set points occur. These are critical design considerations during plant design and operation.

Q 10. Describe different types of pressure relief valves and their applications.

Pressure relief valves (PRVs) are safety devices designed to automatically release excess pressure from a system, preventing over-pressurization and potential catastrophic failure. Several types exist, each tailored to specific applications:

- Spring-loaded safety valves: These are the most common type, utilizing a spring to maintain the valve closed until the set pressure is exceeded. They are simple, reliable, and relatively inexpensive, suitable for various industries.

- Pilot-operated safety valves: These valves use a pilot mechanism to sense pressure and actuate the main valve. They offer more precise pressure control and are often used in applications requiring a quicker response time or a higher degree of accuracy.

- Rupture disks: These are disposable pressure relief devices that burst at a predetermined pressure, offering a fail-safe mechanism. They are often used in applications where the risk of failure is extremely high, or where the pressure relief event is a critical factor.

- Back pressure regulating valves: These valves maintain a constant downstream pressure, preventing the upstream pressure from exceeding safe limits. These are crucial in processes where the downstream pressure fluctuates.

The choice of PRV depends on factors like the process fluid, pressure level, required response time, and allowable leakage rate. For instance, a rupture disk might be preferred in a high-hazard application, like a chemical reactor containing highly reactive materials, while a spring-loaded valve might suffice for a lower-risk application, such as a steam boiler.

Q 11. How do you calculate the pressure drop across a pipe?

Calculating pressure drop across a pipe involves considering various factors, primarily friction and changes in elevation. The most common method uses the Darcy-Weisbach equation:

ΔP = f (L/D) (ρV²/2)

Where:

ΔPis the pressure drop (Pascals)fis the Darcy friction factor (dimensionless)Lis the pipe length (meters)Dis the pipe diameter (meters)ρis the fluid density (kg/m³)Vis the fluid velocity (m/s)

The Darcy friction factor (f) is dependent on the Reynolds number (Re) and the pipe’s roughness. Several correlations, such as the Colebrook-White equation or Moody chart, are used to determine f. For simpler calculations, approximations like the Blasius equation can be employed. In addition to frictional losses, pressure drop also occurs due to changes in elevation (hydrostatic head) and fittings (elbows, valves, etc.). These additional losses are often accounted for using equivalent length factors. Accurate pressure drop calculations are essential for pipe sizing, pump selection, and overall system design. In practice, software packages employing these equations are commonly used for accurate pressure drop estimation.

Q 12. Explain the concept of thermal equilibrium.

Thermal equilibrium refers to the state where two or more objects or systems in thermal contact have reached the same temperature. There is no net heat transfer between them. Think of it like this: if you place a hot cup of coffee on a table, heat will transfer from the coffee to the table and the surrounding air until both the coffee and its environment reach the same temperature. At this point, they are in thermal equilibrium. This concept is fundamental to thermodynamics and is crucial in understanding heat transfer processes. For example, in a heat exchanger, the goal is to achieve thermal equilibrium between the hot and cold fluids, maximizing heat transfer efficiency. Deviations from thermal equilibrium indicate ongoing heat transfer, which can either be beneficial or detrimental, depending on the application. Consider a refrigeration system. The refrigerant needs to absorb heat from a warmer environment and release it into a cooler environment, continuously moving away from thermal equilibrium.

Q 13. What is the relationship between pressure, volume, and temperature in an ideal gas?

For an ideal gas, the relationship between pressure (P), volume (V), and temperature (T) is described by the Ideal Gas Law:

PV = nRT

Where:

Pis the pressureVis the volumenis the number of moles of gasRis the ideal gas constantTis the absolute temperature (Kelvin)

This equation states that for a fixed amount of gas, the product of pressure and volume is directly proportional to the absolute temperature. If you increase the temperature, keeping the volume constant, the pressure will increase proportionally. Similarly, increasing the volume at constant temperature will cause a decrease in pressure. This law is a fundamental principle in many engineering applications, particularly in thermodynamics, fluid mechanics, and chemical processes. For example, understanding this relationship is vital for designing efficient internal combustion engines or predicting the behavior of gases in industrial processes.

Q 14. Describe different types of pressure control valves and their characteristics.

Pressure control valves regulate the flow of fluids to maintain a desired pressure within a system. Several types are available, each with specific characteristics:

- Globe valves: These are versatile valves offering good control but can exhibit higher pressure drop compared to other types. They are commonly used for throttling applications, offering precise pressure adjustments.

- Butterfly valves: These valves use a rotating disc to control flow. They are simple, compact, and suitable for large flow rates, but their control precision is generally lower compared to globe valves.

- Ball valves: These valves use a rotating ball to control the flow path. They are mainly used for on/off service and offer minimal pressure drop when fully open, but less precise control during throttling.

- Diaphragm valves: These valves use a flexible diaphragm to control the flow. They are suitable for applications involving corrosive or viscous fluids, offering good control and minimal leakage.

- Control valves (proportional valves): These valves are often used in automated control systems, offering continuous adjustment of flow to maintain a desired pressure using pneumatic or electric actuators. These usually incorporate feedback loops to maintain stable pressure.

The selection of a pressure control valve depends on factors like the fluid properties, required flow rate, pressure range, level of control precision, and cost. A high-precision control valve might be necessary for a critical process like a chemical reactor, while a simpler on/off valve may suffice for a less demanding application. The choice also depends on the need for automation; a manual valve is acceptable for less dynamic applications, but an automated control valve is necessary where pressure adjustments must be made rapidly and frequently.

Q 15. What is hysteresis and how does it affect pressure and temperature measurements?

Hysteresis is the phenomenon where the output of a system doesn’t immediately follow the input. Imagine stretching a rubber band: It doesn’t snap back to its original length instantly when you release it; there’s a slight lag. In pressure and temperature sensors, hysteresis means that the sensor’s reading might be slightly different depending on whether the pressure or temperature is increasing or decreasing.

For example, a pressure sensor might read 100 psi when the pressure increases to that value, but only 98 psi when the pressure decreases from 101 psi to 100 psi. This 2 psi difference is due to hysteresis. This lag can be caused by mechanical friction in the sensor’s components or other internal effects. It introduces inaccuracy into the measurement and needs to be accounted for in applications requiring high precision.

This effect significantly impacts measurements, leading to uncertainties in control systems and potentially causing process instability. Calibration procedures often include checks for hysteresis to quantify and compensate for it. For critical applications, sensors with minimal hysteresis are essential.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you select the appropriate pressure and temperature sensors for a given application?

Selecting the right pressure and temperature sensors involves carefully considering several factors:

- Accuracy and Precision: How much error can you tolerate? High-precision applications (e.g., aerospace) demand sensors with very low uncertainties.

- Measurement Range: What is the expected range of pressures and temperatures? The sensor must cover this range without saturation.

- Response Time: How quickly does the sensor need to react to changes? Fast response is crucial for dynamic processes.

- Operating Conditions: Consider the environment—temperature extremes, humidity, vibrations, and corrosive chemicals. The sensor must withstand these conditions.

- Output Type: Analog (e.g., 4-20 mA, 0-5V) or digital (e.g., I2C, SPI) signals. The choice depends on your data acquisition and control system.

- Cost: Balance performance requirements with budget constraints.

For instance, a simple industrial process might use a relatively inexpensive pressure sensor with moderate accuracy, while a medical device would require a highly accurate and biocompatible sensor.

Q 17. Explain the concept of process control loops and their importance in maintaining pressure and temperature.

A process control loop is a closed-loop system that uses feedback to maintain a desired value (setpoint) of a process variable, such as pressure or temperature. Think of a thermostat: it measures the room temperature (feedback), compares it to the desired temperature (setpoint), and adjusts the heating/cooling system (control element) to maintain the setpoint.

These loops consist of four basic elements:

- Sensor: Measures the process variable (pressure or temperature).

- Controller: Compares the measured value to the setpoint and calculates the necessary correction.

- Actuator: The device that adjusts the process (e.g., a valve controlling flow, a heater).

- Process: The system being controlled.

Maintaining pressure and temperature is crucial for safety, product quality, and process efficiency. Without control loops, variations could lead to equipment damage, product spoilage, or even hazardous situations.

Q 18. Describe different types of control algorithms used for pressure and temperature control.

Several control algorithms are used for pressure and temperature control. The choice depends on the specific application and process characteristics:

- Proportional (P): The control action is proportional to the error (difference between setpoint and measured value). Simple but may exhibit steady-state error.

- Proportional-Integral (PI): Adds an integral term that eliminates steady-state error. More robust than P control.

- Proportional-Integral-Derivative (PID): Includes a derivative term that anticipates future error based on the rate of change. Provides the best overall performance in many applications.

- Model Predictive Control (MPC): A more advanced technique that uses a process model to predict future behavior and optimize control actions over a prediction horizon.

For example, a simple temperature control system might use PI control, while a complex chemical reactor might use MPC for optimal performance and safety.

Q 19. How do you handle pressure surges in a process system?

Pressure surges are sudden, significant increases in pressure that can damage equipment and compromise safety. Handling them requires a multi-pronged approach:

- Pressure Relief Valves (PRVs): These valves automatically vent excess pressure, preventing catastrophic failure. They are essential safety devices.

- Surge Dampeners: Devices that absorb pressure fluctuations by storing and releasing energy. They can significantly reduce the impact of surges.

- Slow-Start Procedures: Gradual startup of equipment minimizes the risk of sudden pressure changes.

- System Design: Properly sized piping and equipment reduce the potential for pressure buildup. The use of flexible piping helps to dissipate pressure spikes.

- Process Monitoring and Alarms: Real-time pressure monitoring with alarms warns of potential surges, allowing for timely intervention.

In the event of a surge, immediate action is crucial. Shutting down the system or activating emergency procedures might be necessary depending on the severity of the situation.

Q 20. Explain the importance of regular maintenance and calibration of pressure and temperature sensors.

Regular maintenance and calibration are crucial for ensuring the accuracy and reliability of pressure and temperature sensors. Neglecting this can lead to inaccurate measurements, process instability, and potentially hazardous situations.

Maintenance typically includes inspecting the sensors for physical damage, cleaning them, and checking for proper connections. The frequency depends on the application and environmental conditions.

Calibration involves comparing the sensor’s readings to a known standard. This allows for the detection of drift and correction of any errors. The calibration frequency depends on factors like sensor type, application criticality, and regulatory requirements. A well-defined calibration schedule, including documentation of calibration results, is essential for traceability and compliance.

A simple analogy is a car’s speedometer. Regular checks ensure it accurately reflects the vehicle’s speed. Similarly, periodic calibration ensures that pressure and temperature sensors provide reliable data.

Q 21. Describe the safety considerations when working with high-pressure and high-temperature systems.

Working with high-pressure and high-temperature systems presents significant safety risks. Mitigation strategies include:

- Personal Protective Equipment (PPE): This includes heat-resistant clothing, gloves, eye protection, and hearing protection. Proper PPE selection is crucial for mitigating burns, hearing damage and other risks.

- Pressure Relief Systems: Properly designed and maintained pressure relief valves (PRVs) are essential to prevent over-pressurization.

- Emergency Shut-off Systems: Easily accessible shut-off valves allow for quick system isolation in emergencies.

- Lockout/Tagout Procedures: These procedures ensure that equipment is safely isolated before maintenance or repair.

- Regular Inspections and Testing: Equipment should be regularly inspected for leaks, corrosion, and other damage.

- Training and Procedures: Operators must be thoroughly trained on safe operating procedures and emergency response protocols.

- Appropriate Ventilation: This is crucial to avoid exposure to toxic gases or vapors.

Safety should always be the top priority when working with high-pressure and high-temperature systems. Following established safety procedures and using appropriate safety equipment are essential for preventing accidents.

Q 22. What are the common units used for measuring pressure and temperature?

Pressure and temperature are fundamental parameters in various engineering disciplines. Several units are commonly used, depending on the context and the system of units employed.

- Pressure: The most common units include Pascals (Pa), which is the SI unit, kilopascals (kPa), megapascals (MPa), bars (bar), atmospheres (atm), pounds per square inch (psi), and millimeters of mercury (mmHg). For instance, tire pressure is often measured in psi, while atmospheric pressure is typically given in atm or hPa (hectopascals).

- Temperature: The most frequently used units are degrees Celsius (°C), degrees Fahrenheit (°F), and Kelvin (K). Kelvin is the absolute temperature scale, where 0 K represents absolute zero. Celsius is widely used in scientific contexts and everyday life, while Fahrenheit is prevalent in some countries, particularly the United States. In many industrial processes, Kelvin is preferred for its absolute nature, eliminating the need for conversions.

Understanding the appropriate unit for a specific application is crucial for accurate measurements and calculations. Incorrect unit usage can lead to significant errors, especially in safety-critical systems.

Q 23. Explain the concept of deadband in pressure and temperature control systems.

Deadband refers to the range of input values over which the output of a control system remains unchanged. Think of it as a small ‘dead zone’ where the controller ignores minor fluctuations. In pressure and temperature control, a deadband is intentionally introduced to prevent the system from constantly adjusting due to minor, insignificant variations in the measured parameter. This prevents unnecessary wear and tear on actuators and reduces energy consumption.

For example, imagine a thermostat controlling room temperature. If the deadband is set to 1°C, the heater will not turn on or off until the temperature deviates by more than 1°C from the setpoint. This prevents the heater from cycling on and off constantly, leading to more stable temperature and energy efficiency. Similarly, in a pressure control system, a deadband can minimize the frequency of valve actuation, extending the lifespan of the components.

Q 24. Describe the differences between analog and digital pressure and temperature sensors.

Analog and digital pressure and temperature sensors differ fundamentally in how they represent the measured quantity.

- Analog Sensors: These sensors produce a continuous signal that is proportional to the measured pressure or temperature. The signal is typically a voltage or current that varies smoothly as the measured parameter changes. For instance, a thermocouple generates a voltage proportional to the temperature difference between its junctions. Analog sensors often require signal conditioning circuits to convert the raw signal into a usable form.

- Digital Sensors: Digital sensors directly convert the measured quantity into a digital signal, usually a binary code. This eliminates the need for signal conditioning. Digital sensors often include an internal microprocessor to perform calculations and provide outputs such as temperature and pressure readings in readily interpretable units. They typically use interfaces like I2C or SPI for communication.

Digital sensors generally offer better accuracy, repeatability, and easier integration into digital control systems. However, they can be more expensive than their analog counterparts. The choice between analog and digital sensors depends on the specific application requirements, such as accuracy needs, budget, and system architecture.

Q 25. How do you interpret pressure and temperature data from a process control system?

Interpreting pressure and temperature data from a process control system involves a combination of understanding the system’s behavior, recognizing trends, and identifying anomalies.

First, I would check for data validity. Are the readings within expected ranges? Are there any obvious errors or inconsistencies? Then, I would analyze the data for trends over time. Are there gradual increases or decreases in pressure or temperature? Are there any cyclical patterns? This involves examining plots of the data over different time scales.

Next, I’d compare the measured data with setpoints or target values. Are the pressures and temperatures consistently meeting their specified targets? If not, what are the deviations and what might be causing them? Finally, I would investigate any unusual or sudden changes in pressure or temperature. These could indicate potential problems or process upsets that require immediate attention.

This analysis often involves using software tools to visualize the data and perform calculations. Statistical methods can also be applied to identify trends and outliers.

Q 26. Explain the concept of PID control and its application in pressure and temperature control.

PID (Proportional-Integral-Derivative) control is a widely used feedback control algorithm. It’s effective in regulating processes like pressure and temperature by continuously adjusting a control element (like a valve) based on the difference between the desired setpoint and the measured value.

- Proportional (P) control: The control action is proportional to the error (difference between setpoint and measured value). A larger error leads to a larger control action.

- Integral (I) control: Addresses persistent errors. It integrates the error over time, ensuring the system eventually reaches the setpoint even with a constant offset.

- Derivative (D) control: Anticipates future errors by considering the rate of change of the error. This helps to dampen oscillations and improve response time.

In pressure control, a PID controller might adjust a control valve to maintain a specific pressure in a vessel. If the pressure drops, the controller opens the valve proportionally, integrating the error to eliminate any persistent pressure drop and using derivative action to prevent overshooting. Similarly, in temperature control, a PID controller could regulate a heating element or cooling system to maintain the desired temperature.

Tuning the PID parameters (proportional gain, integral gain, and derivative gain) is crucial for optimal performance. Improper tuning can result in poor response, oscillations, or instability. Various tuning methods, such as Ziegler-Nichols, are available to find suitable parameters.

Q 27. Describe your experience working with different types of pressure and temperature control systems.

Throughout my career, I’ve worked extensively with various pressure and temperature control systems, ranging from simple pneumatic controllers to complex distributed control systems (DCS).

I have experience with pneumatic systems, using pressure regulators and valves for basic process control. I’ve also worked with electronic controllers using analog and digital sensors, and I’m familiar with different types of sensors including thermocouples, RTDs (Resistance Temperature Detectors), and pressure transducers based on strain gauges or capacitive principles. My experience also includes implementing and tuning PID control algorithms in programmable logic controllers (PLCs) and DCS systems for various industrial processes, such as chemical reactors, heat exchangers, and distillation columns. I’m proficient in using software for data acquisition, analysis, and visualization, including developing custom scripts for data processing.

Furthermore, I have practical experience in troubleshooting and maintaining these systems. This includes diagnosing issues related to sensor malfunctions, valve leakage, and control algorithm performance and implementing corrective actions.

Q 28. Explain how pressure and temperature analysis can improve process efficiency and reduce costs.

Precise pressure and temperature analysis significantly improves process efficiency and reduces costs in numerous ways.

- Optimized Process Control: Accurate measurement and control of pressure and temperature minimize product variability and improve yield. This reduces waste and enhances product quality.

- Energy Savings: Efficient control minimizes energy consumption by avoiding unnecessary heating or cooling. For instance, precise temperature control in a heat exchanger can significantly reduce the energy needed for heating or cooling a process stream.

- Reduced Maintenance: Preventing equipment damage through monitoring helps reduce maintenance costs. Early detection of pressure or temperature anomalies can prevent catastrophic failures.

- Improved Safety: Monitoring pressure and temperature helps ensure safe operation and prevents potential hazards. For example, in a pressure vessel, high-pressure alarms provide early warnings of impending failures.

- Better Process Understanding: Analyzing pressure and temperature data provides valuable insights into the process itself. Identifying bottlenecks or inefficiencies allows for targeted improvements and process optimization.

In summary, by implementing a robust pressure and temperature monitoring and control strategy, companies can achieve substantial savings, improved product quality, and enhanced safety.

Key Topics to Learn for Pressure and Temperature Analysis Interview

- Thermodynamics Fundamentals: Understanding fundamental thermodynamic principles like ideal gas laws, enthalpy, entropy, and specific heat capacity. This forms the bedrock of pressure and temperature analysis.

- Pressure Measurement Techniques: Familiarize yourself with various pressure measurement devices (e.g., Bourdon tubes, pressure transducers, manometers) and their principles of operation, accuracy, and limitations.

- Temperature Measurement Techniques: Gain expertise in various temperature measurement techniques (e.g., thermocouples, RTDs, thermistors) and understand their calibration, accuracy, and appropriate applications.

- Process Control and Instrumentation: Learn about the integration of pressure and temperature sensors into process control systems, including feedback loops, PID controllers, and safety interlocks.

- Fluid Mechanics: Grasp the principles of fluid flow, particularly as they relate to pressure drops and temperature changes in pipelines and other systems. Understanding concepts like Bernoulli’s equation and Reynolds number is crucial.

- Heat Transfer: Explore different modes of heat transfer (conduction, convection, radiation) and their impact on pressure and temperature within a system. This includes understanding heat exchangers and insulation principles.

- Data Analysis and Interpretation: Develop strong skills in analyzing pressure and temperature data, identifying trends, and interpreting results. This may involve using statistical methods and data visualization techniques.

- Troubleshooting and Problem Solving: Practice identifying and resolving common issues related to pressure and temperature measurement and control systems. Develop a structured approach to diagnosing problems.

- Safety Considerations: Understand the safety implications of high-pressure and high-temperature systems and relevant safety regulations and procedures.

- Practical Applications: Consider applications across diverse industries like chemical processing, power generation, HVAC, and oil and gas. Understanding real-world examples will enhance your interview performance.

Next Steps

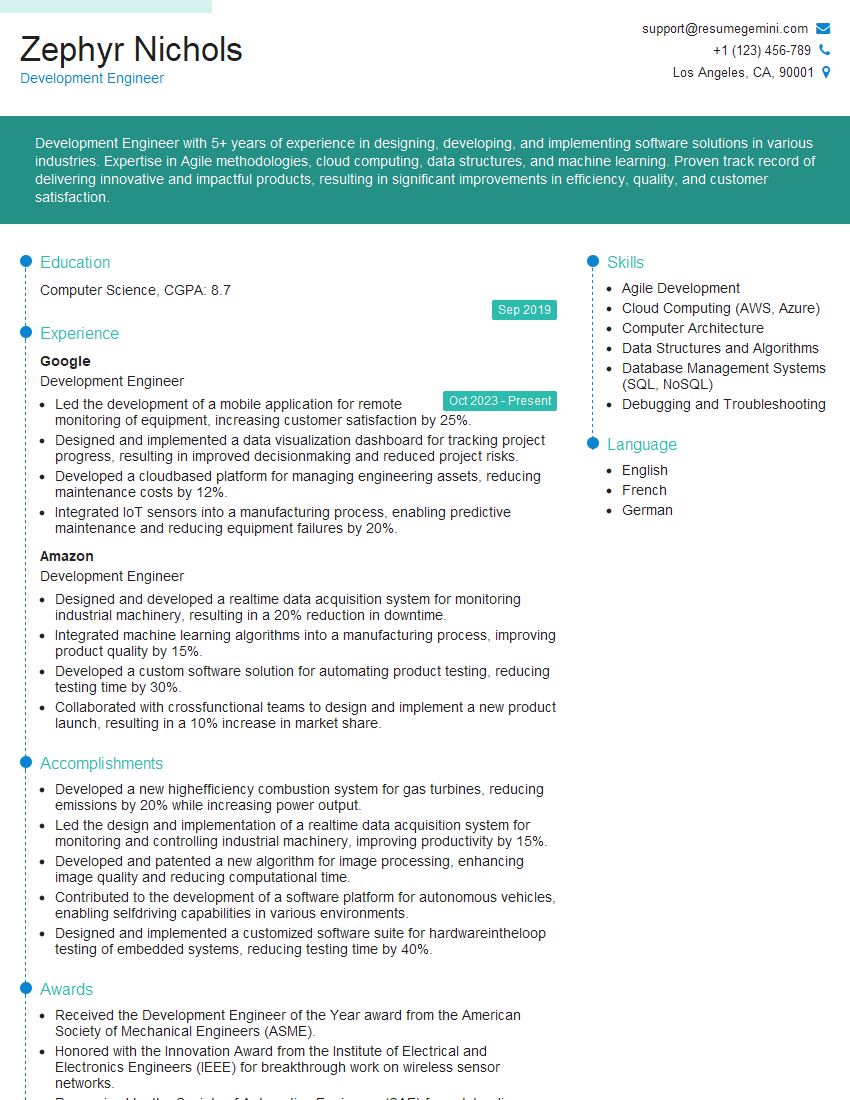

Mastering Pressure and Temperature Analysis opens doors to exciting and rewarding careers in various engineering and scientific fields. A strong understanding of these principles is highly valued by employers. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to Pressure and Temperature Analysis are available to help you get started. Invest time in crafting a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.