Unlock your full potential by mastering the most common Proficiency in Generator and Excitation System Maintenance interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Proficiency in Generator and Excitation System Maintenance Interview

Q 1. Explain the principle of operation of a synchronous generator.

A synchronous generator, also known as an alternator, works on the principle of electromagnetic induction. When a rotating magnetic field interacts with stationary conductors, it induces a voltage in those conductors. This voltage, in turn, produces an alternating current (AC) output. Imagine a magnet spinning inside a coil of wire; the changing magnetic flux through the coil generates electricity. In a synchronous generator, the rotating magnetic field is created by DC current flowing through the rotor windings, creating a magnetic field that rotates at the same synchronous speed as the AC frequency generated.

More specifically, the prime mover (like a steam turbine or gas turbine) rotates the rotor. The rotor has field windings that carry DC excitation current, generating a rotating magnetic field. This rotating field cuts through the stator windings (stationary conductors), inducing an AC voltage. The frequency of the generated AC voltage is directly proportional to the rotor speed and the number of magnetic poles.

The strength of the generated voltage is directly related to the strength of the magnetic field produced by the DC excitation current. This allows for precise control of the generator’s output voltage.

Q 2. Describe different types of excitation systems used in power generation.

Several types of excitation systems are used to provide DC current to the rotor field windings of a synchronous generator. The choice depends on factors like generator size, voltage regulation requirements, and cost.

Static Excitation Systems: These systems use semiconductor devices (like thyristors or IGBTs) to rectify AC power from a separate source and provide the required DC excitation. They offer precise voltage control and quick response times, making them ideal for modern power plants. Think of them as highly efficient and controllable power supplies for the rotor.

Rotating Excitation Systems: In these systems, a smaller DC generator (exciter) mounted on the same shaft as the main generator provides the excitation current. They are simpler in design but have slower response times and less precise voltage control compared to static systems. This is like having a dedicated smaller generator solely for exciting the main generator’s magnetic field.

Brushless Excitation Systems: These systems are a variation of rotating excitation systems but use a rotating rectifier to supply DC excitation to the main generator’s rotor, eliminating the need for brushes and slip rings, leading to increased reliability and reduced maintenance.

Q 3. What are the common causes of generator overheating?

Generator overheating is a serious issue that can lead to damage and downtime. Common causes include:

Excessive Loading: Operating the generator beyond its rated capacity forces it to work harder, generating more heat.

Poor Ventilation: Inadequate airflow around the generator prevents efficient heat dissipation.

Worn or Damaged Bearings: Friction from worn bearings generates excessive heat.

Faulty Wiring or Connections: High resistance in the wiring can lead to resistive heating.

Internal Short Circuits: Short circuits within the generator windings or stator create significant heat.

Cooling System Malfunction: Problems with the generator’s cooling system (fans, radiators, coolant flow) prevent proper heat removal.

Regular inspections and maintenance, including checking winding temperatures and cooling system performance, are crucial to prevent overheating.

Q 4. How do you troubleshoot a generator’s voltage regulator?

Troubleshooting a generator’s voltage regulator involves a systematic approach. First, you need to understand the type of regulator used (static, rotating, etc.).

Check for obvious issues: Inspect the voltage regulator for loose connections, burned components, or physical damage. A visual inspection can often reveal the problem.

Verify input signals: Check the voltage and current levels at the input of the voltage regulator to ensure they are within specifications. Use a multimeter to measure these values.

Test the output: Measure the DC excitation current delivered to the generator’s field windings. A malfunctioning regulator might not provide the correct current.

Check the sensing circuits: Voltage regulators use sensors to monitor the output voltage and adjust accordingly. Check the sensing circuits for any faults or issues.

Use diagnostic tools: Many modern voltage regulators have built-in diagnostics or can be interfaced with specialized test equipment to pinpoint the problem.

Replace faulty components: Once the faulty component is identified (e.g., a failed thyristor, a short-circuited resistor), replace it with a new one.

Remember to always follow safety procedures and lock out/tag out the generator before working on it.

Q 5. Explain the importance of generator protection relays.

Generator protection relays are critical for ensuring the safe and reliable operation of a generator. They act as the generator’s ‘immune system’, detecting various fault conditions and initiating protective actions to prevent damage or injury.

These relays monitor various parameters like:

Overcurrent: Protects against excessive current draw, potentially caused by short circuits or overloads.

Overvoltage/Undervoltage: Prevents damage from voltage excursions outside the acceptable range.

Loss of Excitation: Detects a loss of DC excitation to the generator’s field windings which can lead to instability and damage.

Reverse Power: Prevents power flow from the grid back into the generator, which can damage it.

Over/Under Frequency: Maintains grid stability by detecting frequency deviations.

Differential Protection: Compares the current entering and leaving the generator to detect internal faults.

If a fault is detected, the relay initiates appropriate protective actions, such as tripping the generator breaker to isolate it from the system and prevent cascading failures.

Q 6. What are the safety procedures for working on a live generator?

Working on a live generator is extremely dangerous and should only be done by qualified personnel with proper safety training and equipment. Key safety procedures include:

Lockout/Tagout (LOTO): The generator must be completely de-energized and locked out to prevent accidental energization.

Grounding: Ensure that the generator is properly grounded to prevent electrical shock.

Personal Protective Equipment (PPE): Always wear appropriate PPE, including insulated gloves, safety glasses, and arc flash protective clothing.

Use of insulated tools: Utilize insulated tools to prevent electrical shock.

Permit-to-work system: Follow a documented permit-to-work system that outlines the tasks, hazards, and safety procedures.

Emergency response plan: Have an emergency response plan in place in case of an accident.

Never compromise on safety. If you’re not sure about any procedure, consult with a qualified expert.

Q 7. Describe the process of performing a generator load test.

A generator load test verifies the generator’s ability to meet its rated output and performance characteristics under various load conditions. The process involves gradually increasing the load on the generator while monitoring various parameters.

Preparation: Ensure the generator is properly warmed up and ready for operation. Verify the generator’s cooling system is functioning correctly. Have appropriate monitoring equipment (multimeters, oscilloscopes, etc.) ready.

Incremental Loading: Gradually increase the load on the generator using resistive or inductive loads (like banks of resistors or motors) in increments of, for example, 25% of its rated capacity. Allow the generator to stabilize at each load step. Observe any signs of instability or overheating.

Monitoring: Continuously monitor key parameters, including voltage, current, frequency, power factor, and temperature (winding temperature, bearing temperature, exhaust temperature). Record these values at each load step.

Full Load: Reach the generator’s rated full load capacity and maintain it for a specified duration (typically 30 minutes to an hour). Monitor all parameters carefully during this phase.

Data Analysis: After the test, analyze the collected data to verify if the generator’s performance meets its specifications. Note any deviations from the expected values. Look for voltage regulation issues, efficiency dips, or temperature spikes.

Post-Test Inspection: Inspect the generator for any signs of damage or overheating.

Load testing provides valuable insights into the generator’s health and operational capabilities. The results help identify potential problems early on and inform maintenance decisions.

Q 8. How do you maintain generator brushes and slip rings?

Maintaining generator brushes and slip rings is crucial for efficient power generation and preventing costly damage. Think of the brushes as the vital link between the stationary part (slip rings) and the rotating part of the generator, allowing current to flow. Regular inspection and maintenance are key.

Inspection: Regularly inspect brushes for wear, damage (chipping, cracking), and proper seating. Check the slip rings for signs of wear (grooving, scoring), discoloration, and surface contamination. A visual inspection with a magnifying glass can be invaluable.

Cleaning: Clean the slip rings using a non-abrasive cleaner and a soft cloth. Never use steel wool or abrasive materials, as they can damage the slip ring surface. Compressed air can remove dust and debris. Ensure the brushes and slip ring surfaces are completely clean and dry before operation.

Brush Replacement: Replace worn brushes promptly. Worn brushes lead to poor electrical contact, increased arcing, and excessive heat generation, potentially damaging the slip rings and reducing the generator’s lifespan. Always use brushes that are specifically designed for your generator model.

Slip Ring Repair: In case of significant slip ring damage (deep grooves or scoring), professional repair or even replacement might be necessary. Improper repair can lead to instability and even generator failure.

Lubrication: While slip rings typically don’t require lubrication, some designs might have bearings that need periodic lubrication with a specialized grease. Always consult the manufacturer’s recommendations.

Example: In a recent project, I discovered a generator’s slip rings were severely grooved, leading to unstable voltage output and sparking. Replacing the rings resolved the issue and prevented a potential major failure.

Q 9. What are the common faults in excitation systems and their remedies?

Excitation system faults can severely impact generator performance and stability. These systems are critical for regulating the generator’s voltage output. Here are some common faults and remedies:

Fault: Voltage Regulator Malfunction (AVR). This can lead to voltage instability or complete voltage collapse. Remedy: Inspect and potentially repair or replace the AVR. Check for loose connections, faulty components, and internal issues within the AVR unit. Calibration might also be needed.

Fault: Exciter Failure (e.g., faulty diodes in a rotating rectifier exciter). This leads to inadequate field current and loss of generator excitation. Remedy: Diagnose the exciter system components, testing diodes, brushes, and other electrical components. Replacement of faulty parts is often required.

Fault: Poor grounding or grounding issues. This can lead to spurious voltage fluctuations and system instability. Remedy: Check all grounding points, ensuring proper and secure connections. Address any corrosion or loose connections.

Fault: Open or short circuits in the excitation wiring. This can manifest as voltage spikes, loss of excitation, and system instability. Remedy: Carefully inspect all wiring for damage, breaks, or short circuits. Repair or replace faulty wiring. Proper insulation is crucial.

Fault: Over-excitation or under-excitation leading to voltage instability or damage to generator components. Remedy: Adjust the AVR settings to correct the excitation level, ensuring it’s within the acceptable range for the generator’s operation.

Example: I once encountered a situation where a generator experienced sudden voltage drops. Through systematic troubleshooting, we identified a faulty diode in the rotating rectifier exciter. Replacing the diode immediately restored normal operation.

Q 10. Explain the function of a power factor correction system.

A power factor correction (PFC) system improves the efficiency of electrical systems by reducing the reactive power component of the load. Imagine electricity as a river; the reactive power is like the current’s turbulence, hindering the flow of useful power (the actual water). PFC systems aim to smooth out this turbulence.

In essence, PFC systems use capacitors or other reactive elements to compensate for the inductive reactance of loads, like motors. This improves the power factor, which is the ratio of real power to apparent power. A higher power factor (closer to 1) means more efficient utilization of power and reduces energy waste.

Benefits:

- Reduced electricity bills.

- Improved system efficiency.

- Reduced line losses.

- Increased capacity of existing power systems.

Example: Installing PFC capacitors in a factory with many induction motors significantly reduces the reactive power demand, leading to a lower electricity bill and improved system stability.

Q 11. How do you interpret generator performance data?

Interpreting generator performance data is essential for proactive maintenance and preventing unexpected failures. This involves analyzing data points such as voltage, current, frequency, power factor, and temperature.

Key data points and their significance:

Voltage: Should remain stable within acceptable limits. Significant deviations indicate potential problems with excitation, wiring, or load.

Current: Provides an indication of the generator’s load. Sustained high currents suggest an overload condition.

Frequency: Should be maintained at the nominal frequency (e.g., 50Hz or 60Hz). Deviations indicate problems with speed control or the prime mover.

Power Factor: Should be close to unity (1.0). Low power factors suggest a reactive power problem that can be addressed with PFC.

Temperature: Monitoring winding and bearing temperatures is vital to prevent overheating. High temperatures could indicate insulation degradation or bearing wear.

Example: Regularly monitoring the generator’s temperature logs revealed a gradual increase in winding temperature over time. This prompted a thorough inspection, which identified a developing insulation fault, allowing for proactive repair before a major failure occurred.

Q 12. What is the significance of generator synchronizing?

Generator synchronizing is the process of matching the voltage, frequency, and phase of a generator to the existing electrical grid or another running generator before connecting it. Think of it like carefully merging two lanes of traffic – you need to match speed and position to avoid a collision.

Significance: Improper synchronization can lead to severe consequences:

- Damage to generators: Sudden large current surges can damage windings and other components.

- System instability: Frequency and voltage fluctuations can cause widespread power outages.

- Personnel safety: Arcing and electrical shocks pose significant risks.

Precise synchronization ensures smooth transition and prevents damage to equipment and harm to personnel.

Q 13. Describe the procedure for paralleling generators.

Paralleling generators, the process of connecting two or more generators to operate in parallel, increases power capacity and improves reliability. It requires careful attention to detail and adherence to established procedures.

Procedure (general steps):

Preparation: Ensure both generators are running at the same frequency and voltage. Verify the voltage and phase sequence match using synchroscope.

Synchronization: Closely monitor voltage, frequency and phase using synchroscope. Wait for the synchroscope to indicate proper alignment before closing the breaker.

Breaker Closure: Once synchronization is achieved, close the breaker to connect the generator to the busbar.

Load Sharing: Adjust the governor and excitation systems of each generator to ensure proper load sharing. Monitor load and adjust as needed to maintain stable operation.

Example: In a power plant, multiple generators operate in parallel, enhancing reliability. If one generator fails, the others continue to supply power without interruption. Precise paralleling ensures seamless transition and prevents power loss.

Safety Note: Only qualified personnel trained in paralleling procedures should perform this operation. Proper safety precautions, including lockout/tagout procedures, must be followed to prevent accidents.

Q 14. Explain the function of a generator AVR (Automatic Voltage Regulator).

The Automatic Voltage Regulator (AVR) is the heart of the generator’s excitation system. It maintains the generator’s terminal voltage at a set value, despite variations in load or other disturbances. Think of it as the generator’s own internal thermostat, ensuring a stable output voltage.

Function:

Voltage Sensing: The AVR constantly monitors the generator’s terminal voltage using voltage sensors.

Error Signal Generation: It compares the measured voltage to the desired setpoint voltage. Any difference creates an error signal.

Excitation Control: The AVR uses the error signal to adjust the generator’s excitation system (e.g., the field current). Increasing excitation raises the voltage, while decreasing excitation lowers it.

Voltage Regulation: This feedback loop ensures the generator’s terminal voltage remains stable despite changes in load or other conditions.

Example: When a large motor starts, the generator’s voltage might dip temporarily. The AVR quickly increases the excitation, preventing a significant voltage drop and ensuring stable power to the load.

Q 15. How do you troubleshoot a loss of excitation in a generator?

Loss of excitation in a generator is a serious issue, leading to a rapid drop in voltage and potential damage. Troubleshooting involves a systematic approach, starting with the simplest checks and progressing to more complex investigations. First, we verify the excitation system’s power supply – are the control circuits receiving the necessary voltage? A simple visual inspection of fuses, circuit breakers, and wiring can often reveal the problem. Next, we check the exciter itself. Is it running? Are there any visible signs of damage or overheating? We’ll test the exciter’s output voltage using a voltmeter. If the exciter is functioning correctly, the problem might lie within the excitation control system. This could involve faulty sensors (like voltage regulators or current transformers), malfunctioning control logic, or issues with the communication between the generator and the control system. In complex systems, we’d consult the system’s schematic diagrams and utilize diagnostic software to pinpoint the fault. A loss of excitation could also stem from a problem within the generator itself, such as a short circuit or a damaged rotor winding, requiring a more in-depth inspection.

For instance, I once encountered a loss of excitation caused by a loose connection in the exciter’s power supply. A simple tightening resolved the issue, highlighting the importance of thorough visual inspection. In another case, a faulty voltage regulator needed replacement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of generator governors?

Generator governors are crucial for maintaining stable rotational speed. They’re classified into several types, each with its own strengths and weaknesses:

- Mechanical-hydraulic governors: These are robust and reliable, using hydraulic mechanisms to adjust fuel input based on speed deviation. They’re common in older or simpler systems. Think of a car’s carburetor – a similar principle is at play.

- Electronic governors: These utilize electronic sensors and control systems for precise speed regulation. They offer greater accuracy and responsiveness compared to mechanical governors, allowing for tighter speed control and smoother operation. They are often integrated with sophisticated control systems, enabling automatic synchronization and load sharing between multiple generators.

- Microprocessor-based governors: These represent the latest advancement, offering advanced features like automatic voltage regulation (AVR) integration, advanced control algorithms, and communication capabilities for remote monitoring and control. These provide the highest degree of precision and adaptability.

The choice of governor depends on factors such as generator size, application requirements, and budget considerations. Larger generators or those in critical applications often benefit from microprocessor-based governors for enhanced precision and reliability.

Q 17. Explain the concept of reactive power control in generators.

Reactive power control in generators is essential for maintaining voltage stability within the power system. Reactive power, unlike real power (which is consumed), flows back and forth in the system and is crucial for maintaining voltage levels. Generators can be controlled to either generate or consume reactive power, depending on the system’s needs. This is achieved primarily through adjusting the generator’s excitation system.

Increasing the excitation current increases the generator’s magnetic field strength, leading to an increase in reactive power generation (over-excited). Conversely, decreasing excitation current results in reactive power consumption (under-excited). Generators act as either reactive power sources or sinks to balance the reactive power demand in the network, preventing voltage fluctuations and ensuring efficient power transmission. This control is often automated using Automatic Voltage Regulators (AVRs) that respond to system voltage deviations, maintaining a stable voltage profile even under varying load conditions.

Imagine a water pump: Real power is the water being pumped, while reactive power is the pressure within the pipes. If the pressure is too low, the pump needs to generate more pressure (reactive power) to ensure proper water flow (real power). Similarly, the generator adjusts its reactive power output to maintain the optimal voltage level within the electrical network.

Q 18. Describe the maintenance schedule for a generator.

A generator’s maintenance schedule is critical to ensure reliability and longevity. It’s typically a combination of preventative and corrective maintenance, tailored to the specific generator type, size, and operating conditions. A typical schedule includes:

- Daily Checks: Visual inspection for leaks, unusual noises, vibration, temperature readings, and fuel levels.

- Weekly Checks: More in-depth checks of lubricating oil levels and condition, coolant levels, and battery voltage.

- Monthly Checks: Includes testing of the automatic voltage regulator (AVR) response, checking air filter cleanliness, and inspecting the exhaust system.

- Quarterly Checks: More extensive inspections, potentially including lubricating oil analysis and testing of safety systems.

- Annual Maintenance: This is a major overhaul, encompassing thorough cleaning, component inspections (bearings, brushes, windings), testing, and any necessary repairs or replacements. This often involves specialized personnel and might require the generator to be taken out of service.

The exact schedule is best defined by the manufacturer’s recommendations and the specific operating environment, with factors such as the number of operating hours greatly influencing the frequency of inspections and maintenance tasks. Keeping detailed records of maintenance activities is vital for tracking performance and predicting potential issues.

Q 19. How do you prevent generator insulation failure?

Preventing generator insulation failure is paramount for safe and reliable operation. Insulation breakdown can lead to short circuits, fires, and equipment damage. The primary preventative measures include:

- Maintaining proper operating temperatures: Overheating is a major cause of insulation degradation. Regular checks of cooling systems and proper ventilation are vital. Think of it like protecting your skin from sunburn – excessive heat can cause damage.

- Preventing moisture ingress: Moisture is an excellent conductor and can cause insulation breakdown. Regular cleaning, sealing, and proper storage are essential, particularly in humid environments.

- Regular insulation resistance testing: Periodic testing of insulation resistance using a megohmmeter can reveal developing insulation weaknesses before they lead to failure. This is a crucial diagnostic tool that allows for proactive intervention.

- Avoiding voltage surges and overloads: Transient voltage surges can severely stress insulation. Surge protection devices (SPDs) can mitigate this risk, providing protection from unexpected voltage spikes.

- Proper grounding and bonding: Correct grounding and bonding procedures are crucial for minimizing the risk of voltage spikes and preventing stray currents that could damage insulation.

Proactive maintenance and regular testing are far more cost-effective than dealing with the consequences of a major insulation failure.

Q 20. What are the common causes of generator bearing failure?

Generator bearing failure can stem from several factors, significantly impacting the generator’s operation and lifespan. Common causes include:

- Lubrication issues: Insufficient lubrication, use of improper lubricant, or contamination of the lubricant (water, dirt) leads to increased friction and premature wear. Regular oil changes using the correct grade and cleanliness checks are vital.

- Overloading and vibration: Excessive loads and vibrations can cause stress on bearings, leading to premature wear and failure. Regular inspections and load management are crucial.

- Misalignment: Incorrect shaft alignment can cause increased stress and vibration on bearings, leading to premature failure. Proper alignment procedures are critical during installation and maintenance.

- Improper installation: Incorrect installation techniques can damage bearings or lead to misalignment, compromising their functionality and lifespan. Following the manufacturer’s instructions is imperative.

- Bearing wear and tear: Bearings naturally wear out over time due to friction. Regular inspection and scheduled replacement, following manufacturer recommendations, are essential to prevent catastrophic failure.

Bearing failure often presents itself through increased noise, vibration, and eventually, complete seizure. Addressing the root cause is key to prevent recurring issues.

Q 21. What are the effects of harmonics on a generator?

Harmonics are unwanted frequencies in the power system, multiples of the fundamental frequency (typically 50Hz or 60Hz). They significantly impact generators, causing several adverse effects:

- Increased heating: Harmonics create additional losses within the generator’s windings and other components, leading to increased temperatures and potentially insulation damage. Excessive heat can reduce the lifespan of the equipment.

- Increased vibration and noise: Harmonics can induce vibrations in the generator’s structure, leading to increased noise levels and potentially structural damage over time.

- Malfunctioning of sensitive equipment: Sensitive electronic devices connected to the power system can be negatively affected by harmonics, leading to malfunctions or premature failures.

- Reduced efficiency: Harmonics cause increased losses, reducing the overall efficiency of the generator.

- Overloading of components: Higher harmonic currents can overload components such as capacitors, transformers, and even the generator itself, leading to premature failure.

Mitigation strategies include using harmonic filters, selecting equipment with better harmonic tolerance, and employing power electronic devices designed to minimize harmonic generation. Understanding and addressing harmonic issues is critical for reliable and efficient generator operation.

Q 22. Explain the process of generator commissioning.

Generator commissioning is a crucial process that ensures the generator is installed correctly and operates safely and efficiently. It involves a series of meticulous checks and tests, starting from the initial inspection of the equipment to its final acceptance testing. Think of it like a thorough pre-flight check for an airplane, ensuring every system is ready for optimal performance.

- Pre-commissioning: This phase involves verifying the installation adheres to the manufacturer’s specifications, inspecting the generator and its components for any damage, and checking the auxiliary systems such as the cooling and lubrication systems are correctly installed and functional.

- Initial Startup and Testing: This stage involves a gradual and monitored startup of the generator, ensuring it reaches its rated speed and voltage without issues. Performance tests are carried out to verify parameters like voltage regulation, power factor, and harmonic distortion are within acceptable limits.

- Protection System Testing: The generator’s protection system, including overcurrent, overvoltage, and overspeed relays, are thoroughly tested to ensure they function correctly and protect the equipment in case of faults. This is like the safety net for the generator.

- Acceptance Testing: This final stage involves comprehensive testing under various load conditions to verify the generator meets its performance specifications. This provides conclusive evidence the generator is ready for operation.

- Documentation: Throughout the process, detailed records are maintained, including test results, observations, and any corrective actions taken. This documentation is essential for future maintenance and troubleshooting.

For example, during acceptance testing, we might run the generator at different load levels, measuring the voltage, current, and power output at each level. Any deviation from the expected values necessitates investigation and corrective actions.

Q 23. How do you perform a generator stator winding test?

Testing a generator’s stator winding is critical for ensuring its integrity and preventing catastrophic failures. We use several non-destructive tests to assess the insulation resistance, winding resistance, and for detecting any shorts or ground faults. Imagine it as a thorough medical check-up for the generator’s heart.

- Insulation Resistance Test (Megger Test): This test uses a megohmmeter to measure the insulation resistance between the winding and the ground, and between different phases. Low insulation resistance indicates insulation degradation and potential problems. We generally look for resistance values exceeding a certain minimum, as specified by the manufacturer.

- Winding Resistance Test: This test measures the DC resistance of each phase winding. This helps in detecting any broken conductors or loose connections. Significant variations in resistance between phases might indicate winding damage.

- High-Potential Test: This test involves applying a high voltage to the windings to stress the insulation and identify weak points. It’s a more rigorous test that helps in early detection of potential insulation failures.

- Turn-to-Turn Test: This sophisticated test uses specialized equipment to detect faults between individual turns within the winding. This is extremely helpful in pinpointing subtle insulation problems that other tests might miss.

For instance, if the insulation resistance test reveals a value significantly lower than the manufacturer’s specification, it indicates insulation degradation, possibly due to age, moisture, or overheating. This would require further investigation and potentially rewinding the affected portion of the stator winding.

Q 24. Describe the different types of generator cooling systems.

Generator cooling systems are essential for maintaining optimal operating temperature and preventing damage to the generator’s components. The type of cooling system depends on the size and application of the generator. Think of it as the generator’s circulatory system.

- Air Cooling: This is the simplest and most common method, using fans to circulate air around the stator and rotor windings to dissipate heat. It’s suitable for smaller generators.

- Hydrogen Cooling: Hydrogen is used as a coolant because of its high thermal conductivity and low density. It’s used in large generators to efficiently remove heat from the windings. This improves efficiency and allows for higher power outputs.

- Water Cooling: Water is circulated through jackets or tubes in contact with the stator windings to remove heat. This method is highly effective for large generators, especially in high-temperature environments.

- Air-Water Cooling: This hybrid system combines air and water cooling to provide a balance between efficiency and complexity. For example, air might be used for cooling the stator while water cools the rotor.

For example, a large power plant generator will often use hydrogen cooling due to its superior heat transfer capabilities. Smaller generators in industrial settings often utilize air cooling for its simplicity and cost-effectiveness.

Q 25. What is the importance of proper grounding in a generator system?

Proper grounding in a generator system is critical for safety and reliable operation. It provides a low-resistance path for fault currents to flow, preventing dangerous voltage buildup and protecting personnel and equipment. Think of it as the generator’s safety valve.

- Personnel Safety: Grounding prevents electric shock by diverting fault currents to the ground, protecting personnel from potentially lethal voltages.

- Equipment Protection: Grounding minimizes the risk of equipment damage by providing a path for fault currents to flow to the ground, preventing voltage surges that could damage sensitive components.

- Lightning Protection: Grounding protects the generator from lightning strikes by providing a safe path for the surge current to flow to the earth.

- System Stability: Proper grounding improves the stability of the power system by reducing the impedance of fault currents, allowing faster fault clearing.

For example, if a lightning strike hits a generator’s enclosure, a well-designed grounding system will safely conduct the massive surge current to ground, preventing damage to the generator and avoiding a potentially disastrous power outage.

Q 26. How do you handle emergency situations related to generator failure?

Handling generator failures requires a swift and systematic approach to minimize downtime and prevent further damage. Our response depends on the nature of the failure but prioritizes safety above all.

- Immediate Actions: First, we secure the generator by isolating it from the grid to prevent further damage or injury. We ensure all personnel are safe and clear of any danger.

- Diagnosis: Once the generator is safe, we systematically diagnose the problem. This may involve checking fault indicators, reviewing logs, and performing initial visual inspections.

- Corrective Actions: Depending on the diagnosis, corrective actions can range from minor repairs to major component replacements. We utilize specialized tools and follow established procedures.

- Restoration: Once the fault is rectified, we conduct thorough testing and commissioning before returning the generator to service. All repairs are documented.

- Root Cause Analysis: After the generator is restored, we perform a root cause analysis to identify the underlying cause of the failure and implement preventive measures to minimize the likelihood of recurrence.

For example, if we suspect a faulty voltage regulator, we will replace the regulator, perform rigorous testing and document everything for future reference. If the failure is severe, we might need to contact the manufacturer for support or parts.

Q 27. Explain the concept of power system stability.

Power system stability refers to the ability of a power system to maintain its equilibrium under normal operating conditions and recover from disturbances. It’s the system’s resilience against shocks. Think of it as a balancing act.

- Angle Stability: This refers to the ability of the synchronous generators to remain synchronized after a disturbance. Loss of synchronism can lead to cascading outages.

- Frequency Stability: This deals with the system’s ability to maintain its frequency within acceptable limits following a disturbance. Significant frequency deviations can damage equipment or lead to instability.

- Voltage Stability: This relates to the system’s ability to maintain voltage levels within acceptable ranges. Voltage collapse can lead to widespread blackouts.

For example, a sudden loss of a large generator can cause a significant drop in frequency and voltage, potentially leading to instability. Power system stability studies use sophisticated simulations and models to assess the system’s resilience against various disturbances and ensure it remains stable.

Q 28. Describe the role of a generator in a microgrid system.

In a microgrid system, a generator plays a crucial role in providing power during grid outages or when operating in islanded mode. It’s the heart of the local power system.

- Backup Power: The generator serves as a reliable backup power source during grid outages, ensuring continuous power supply to critical loads.

- Islanded Operation: When the microgrid is isolated from the main grid, the generator becomes the primary power source, supplying power to the local loads.

- Peak Shaving: Generators can help reduce the peak demand on the main grid by supplying power during periods of high demand.

- Renewable Energy Integration: Generators can provide stability and reliability when integrating intermittent renewable energy sources like solar and wind power.

For instance, a hospital microgrid might use a generator to ensure continuous power supply during grid outages, protecting essential medical equipment and patient care. This backup power system is crucial for microgrids to maintain their integrity.

Key Topics to Learn for Proficiency in Generator and Excitation System Maintenance Interview

- Generator Principles: Understanding synchronous generators, their operation, and key performance indicators (KPIs) like power factor and efficiency. Be prepared to discuss different generator types and their applications.

- Excitation System Fundamentals: Mastering the principles of excitation systems, including AVR (Automatic Voltage Regulator) functions, excitation control strategies, and their impact on generator stability and voltage regulation. Discuss different excitation system types (static, rotating).

- Protection and Safety Systems: Thorough knowledge of protective relays, circuit breakers, and safety protocols related to generator and excitation system operation. Be ready to discuss fault detection and isolation procedures.

- Maintenance Procedures: Demonstrate familiarity with routine maintenance tasks, troubleshooting techniques, and predictive maintenance strategies for generators and excitation systems. Include preventative maintenance scheduling and its importance.

- Troubleshooting and Diagnostics: Be prepared to discuss common generator and excitation system malfunctions, their causes, and effective troubleshooting methodologies. Practice diagnosing problems based on symptoms and data analysis.

- Electrical Power Systems Integration: Understanding how generators and excitation systems interact within larger power systems. Discuss concepts like power flow, synchronization, and system stability.

- Data Acquisition and Analysis: Familiarity with data acquisition systems used to monitor generator and excitation system performance. Be able to interpret data and identify potential issues.

Next Steps

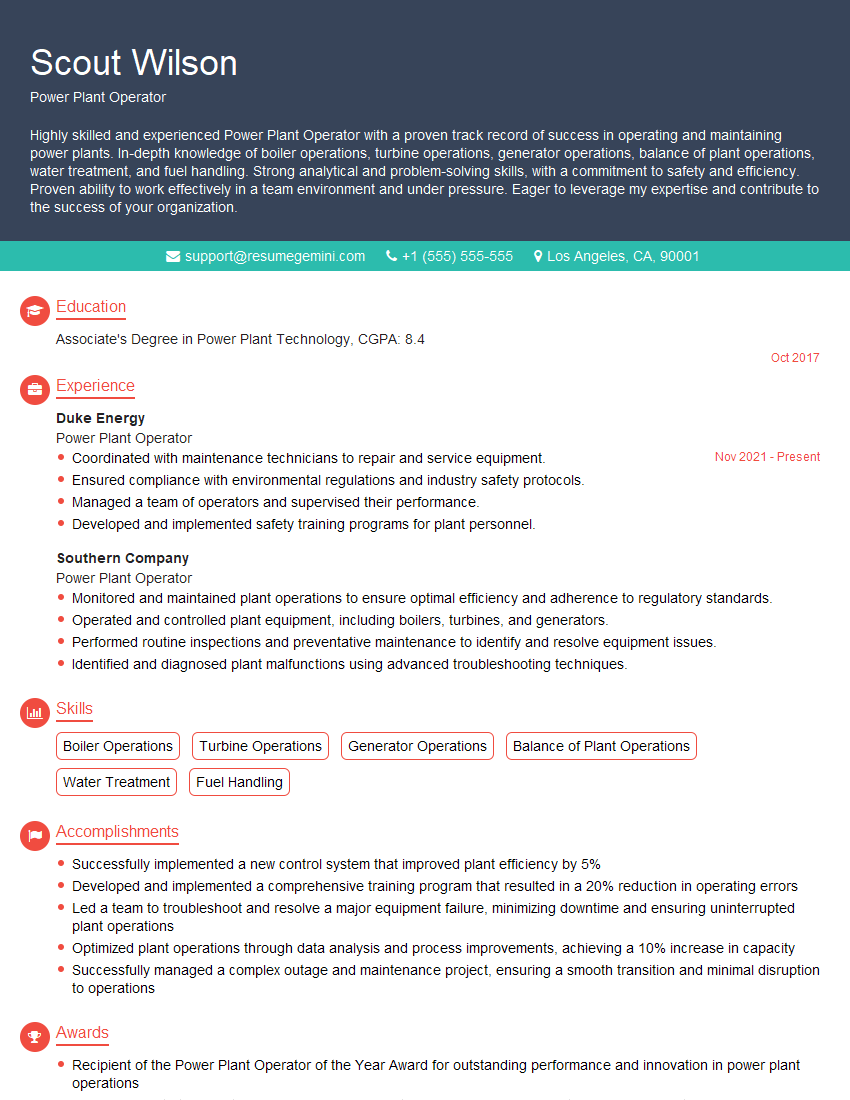

Mastering Proficiency in Generator and Excitation System Maintenance opens doors to exciting career advancements and higher earning potential within the power generation industry. A strong understanding of these systems is highly valued by employers. To showcase your expertise effectively, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Proficiency in Generator and Excitation System Maintenance to guide you in crafting your application. Invest time in creating a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.