Unlock your full potential by mastering the most common Proficient in using heavy equipment attachments and accessories interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Proficient in using heavy equipment attachments and accessories Interview

Q 1. Describe your experience with various heavy equipment attachments, such as buckets, rippers, and augers.

My experience with heavy equipment attachments is extensive, encompassing a wide range of tools used for various tasks. I’ve worked extensively with buckets, from standard digging buckets to specialized ones like demolition buckets, rock buckets, and clean-up buckets. Each bucket type has unique design characteristics optimized for specific materials and excavation techniques. I’m also proficient with rippers, utilizing them for breaking up hard ground, compacted soil, and rocky surfaces. I understand the importance of selecting the right ripper shank type (e.g., single, double, or multi-shank) based on the soil conditions. Finally, I have considerable experience with augers, both earth augers used for creating holes for posts, foundations, or planting, and specialized augers for tasks such as drilling wells or creating drainage systems. I am familiar with various auger diameters and lengths to match specific job requirements.

For instance, on one project, we needed to dig through extremely dense clay. A standard bucket was insufficient, so we used a heavy-duty rock bucket, combined with a ripper to break up the toughest sections. Another project involved installing fence posts across varied terrain, requiring careful selection of auger diameter and length for optimal penetration and stability.

Q 2. Explain the safety procedures you follow when attaching and detaching equipment.

Safety is paramount when handling heavy equipment attachments. Before attaching or detaching any equipment, I always ensure the equipment is properly secured and the machine is completely shut down and the ignition key is removed. I use appropriate lifting techniques and employ safety blocks where necessary to prevent accidental drops. I always inspect the attachment points and quick-couplers for any damage or wear. I’m meticulous in following manufacturer’s instructions and adhering to all relevant safety regulations. Personal Protective Equipment (PPE), including gloves, safety glasses, and steel-toed boots, are always worn. If working near others, I maintain clear communication and establish safe zones to prevent accidents.

For example, when detaching a bucket, I always make sure the hydraulics are completely lowered and the bucket is fully supported before disconnecting the quick-coupler. I never work under a suspended load and always use the correct procedures outlined in the equipment’s operation manual.

Q 3. How do you inspect attachments for wear and tear before use?

Before each use, a thorough inspection of the attachment is crucial. I check for any obvious signs of damage, such as cracks, bends, or excessive wear on cutting edges or teeth. I carefully examine welds and hydraulic lines for leaks or damage. I also check the pins, bushings, and other connecting components for wear or looseness. The structural integrity of the attachment is my primary concern. Loose or damaged components could lead to catastrophic failure.

For example, I would carefully inspect the teeth on a bucket for wear and tear. If the teeth are significantly worn, they need to be replaced or sharpened to ensure effective digging. Likewise, checking the hydraulic hoses for leaks and abrasions is vital to prevent hydraulic fluid leaks and potential injury.

Q 4. What are the common causes of attachment failure and how do you troubleshoot them?

Attachment failure can stem from various sources. Common causes include overloading (exceeding the attachment’s weight and stress capacity), using the wrong attachment for the job, improper maintenance, and damage from impacts. Hydraulic failures, like leaks or damaged hoses, are also frequent culprits. Improper use, such as striking hard objects with the wrong attachment or forcing the equipment beyond its capabilities, can also lead to breakage.

Troubleshooting involves systematically investigating the possible causes. Start with a visual inspection, then check hydraulic pressure and fluid levels. If a hydraulic issue is suspected, it might require the expertise of a qualified technician. If it’s a structural failure, the attachment might need repair or replacement. Detailed records of usage, maintenance, and inspections are helpful in identifying the root cause of a failure.

Q 5. How do you select the appropriate attachment for a specific task?

Selecting the right attachment is critical for efficient and safe operation. The choice depends on several factors, including the type of material to be worked on (soil type, rock density, etc.), the desired outcome (digging, breaking, lifting, etc.), and the machine’s capacity. The attachment’s size and weight must be compatible with the machine. Using an oversized attachment can overload the machine, while an undersized one will be inefficient.

For example, when digging in rocky terrain, a heavy-duty rock bucket with sharp, durable teeth would be preferable to a standard digging bucket. Similarly, for breaking hard ground, a ripper would be more suitable than a bucket. Choosing the correct attachment ensures optimal performance, minimizing damage to both the equipment and the material being processed.

Q 6. Describe your experience with hydraulic systems in heavy equipment attachments.

My experience with hydraulic systems in heavy equipment attachments is extensive. I understand the principles of hydraulic pressure, flow, and control. I can diagnose common hydraulic problems, such as leaks, low pressure, and malfunctions in valves and cylinders. I am comfortable with troubleshooting and making minor repairs such as replacing hoses or seals. However, for major repairs or system overhauls, I always consult with certified technicians. Safety is paramount when working with hydraulic systems due to the potential hazards of high pressure and moving parts.

I’ve handled situations where a hydraulic leak developed in an auger during operation. I was able to identify the leak, isolate the section, and implement a temporary fix, allowing for the completion of the task. For more significant hydraulic repairs, such as internal valve issues, I ensured the machine was safely secured and worked only within the limits of my expertise before seeking expert assistance.

Q 7. How do you maintain and lubricate attachments to ensure optimal performance?

Regular maintenance and lubrication are crucial for optimal attachment performance and longevity. My maintenance routine includes checking for leaks, wear, and damage, as well as greasing all moving parts, such as pins and bushings, according to the manufacturer’s recommendations. I also inspect and clean hydraulic connections to prevent leaks. The frequency of lubrication depends on the usage intensity and environmental conditions. Proper lubrication reduces friction, prevents wear, and extends the life of the attachment.

For instance, I routinely grease the pins and bushings on the bucket’s linkage to ensure smooth operation and prevent premature wear. Failing to lubricate these points can lead to increased friction, difficulty in operation, and eventually, failure of the components.

Q 8. What are the different types of couplers used for heavy equipment attachments?

Heavy equipment attachments utilize various couplers to ensure quick and safe changes. The most common types include:

- Pin-Grab Couplers: These are the simplest, using pins to secure the attachment. Think of them like a really strong, oversized key and lock system. They’re reliable but require manual pin removal and insertion, which is time-consuming.

- Hydraulic Quick Couplers: These are much faster and safer. A hydraulic mechanism locks and unlocks the attachment, significantly reducing downtime. They come in various configurations, including those with automatic locking systems to prevent accidental disconnects.

- Manual Quick Couplers: These offer a middle ground, providing quicker attachment changes than pin-grab systems but without the hydraulic assistance. They often employ a lever or handle mechanism to engage and disengage the coupler.

- Specialized Couplers: Some applications require specialized couplers, such as those designed for specific attachment types (e.g., high-flow hydraulic couplers for breakers) or those with safety features to prevent misconnections.

Choosing the right coupler depends on factors like the frequency of attachment changes, the weight of the attachment, and the overall safety requirements of the job site. For example, on a demolition project requiring frequent tool changes, a hydraulic quick coupler would be vastly superior to a pin-grab system.

Q 9. Explain your experience with quick-attach systems.

I have extensive experience with various quick-attach systems, from basic manual types to advanced hydraulic systems. My experience spans across different equipment types, including excavators, loaders, and backhoes. I’m proficient in both installing and maintaining these systems, including regular inspections to ensure proper function and safety. For example, on one project we were working with a particularly heavy breaker attachment. The hydraulic quick coupler was essential for efficiency and safety because it allowed for swift changes and minimized the risk of injury associated with the manual pin-grab system.

I understand the importance of pre-operational checks including inspecting the couplers for wear and tear, ensuring the hydraulic lines are free of leaks, and verifying that the locking mechanisms function correctly. Knowing how to troubleshoot and correct common problems, such as leaks or sticking mechanisms is crucial to preventing equipment damage and downtime. A broken coupler in the middle of a job is exceptionally disruptive. I am fully comfortable maintaining and repairing these systems.

Q 10. How do you ensure the stability and safety of an excavator when using a long reach attachment?

Using a long reach attachment on an excavator extends its operational envelope, increasing its reach but also its potential instability. To mitigate risks:

- Proper Counterweighting: Sufficient counterweight is critical to balance the extended reach and the weight of the attachment. This prevents tipping. I always verify the excavator’s counterweight is appropriate for the specific attachment’s weight and reach.

- Ground Conditions Assessment: The ground needs to be firm and level. Working on unstable ground with a long reach attachment is extremely dangerous and will likely result in a rollover. I always assess the ground thoroughly before commencing work.

- Slow and Controlled Movements: Operating slowly and deliberately is key. Rapid movements can easily lead to instability. Smooth, precise control is essential when using long reach attachments.

- Operator Skill and Training: Experienced operators with proper training are essential. They understand the limitations of the equipment and how to react safely to unexpected situations.

- Outriggers (if applicable): If the excavator has outriggers, extending them provides additional stability, particularly in soft ground conditions. I would always use them if available and appropriate for the task and ground conditions.

Ignoring these safety precautions can lead to serious accidents. I always prioritize safety and strictly adhere to these principles.

Q 11. Describe your experience working with different types of ground conditions and how you adapt attachment use accordingly.

Different ground conditions significantly impact attachment selection and operation. My experience includes working in a variety of terrains, from soft mud to solid rock.

- Soft Ground: Wide, low-ground-pressure attachments, such as wide buckets or specialized pads, are crucial to prevent sinking and damage. Reduced digging depth and careful movements are also necessary.

- Hard Ground: Heavy-duty attachments like rock breakers and specialized rippers are often used. Proper selection of tools and understanding the forces involved is very important here. You need to be sure that the attachment and equipment are sufficiently robust to handle the resistance.

- Rocky Ground: Rock breakers, rippers, and specialized buckets are used, with a focus on controlled blows to avoid damage to the equipment. Careful monitoring of the equipment for signs of stress is essential.

- Slopes: Working on slopes demands extra caution, with a focus on stability and controlled movements. The risk of equipment failure increases drastically in such situations. Understanding the potential for equipment slippage or tipping is extremely important.

Adaptability is key. I assess the ground conditions before selecting the attachment and adjust my operating techniques accordingly. Safety always comes first.

Q 12. How do you handle unexpected equipment malfunctions during operation?

Unexpected malfunctions require a calm, methodical response. My approach follows these steps:

- Immediate Shutdown: Safely shut down the equipment and attachment. Safety is the absolute priority.

- Assessment: Determine the nature of the malfunction. Is it a hydraulic leak, a broken component, or something else?

- Isolation: If possible, isolate the affected system to prevent further damage.

- Troubleshooting: Based on my experience and the available resources, I attempt to diagnose and resolve the problem. If I am unable to determine the cause of the malfunction I will seek assistance.

- Reporting and Repair: Document the malfunction, including the cause (if known), the steps taken to address it, and any additional necessary repairs. I then follow the appropriate reporting procedures and if the malfunction requires specialist repair I will call in an engineer or mechanic.

Proper maintenance and regular inspections are crucial in minimizing unexpected malfunctions. Prevention is always better than cure. I have also experienced situations where a quick repair could get the job completed, such as welding a minor crack on a bucket. I always carry basic tools and supplies to handle minor repairs in the field.

Q 13. What are the regulations and safety standards you follow when operating heavy equipment with attachments?

Safety is paramount. I adhere to all relevant regulations and standards, which vary depending on location and specific job requirements. Generally, these include:

- Pre-Operational Inspections: Thorough inspections of the equipment, attachments, and work area are mandatory before commencing operations.

- Personal Protective Equipment (PPE): Consistent use of appropriate PPE, such as hard hats, safety glasses, gloves, and high-visibility clothing, is non-negotiable.

- Safe Operating Procedures: Strict adherence to safe operating procedures, including proper lifting techniques, speed limits, and communication protocols, is always followed.

- Emergency Procedures: Understanding and practicing emergency procedures, including what to do in case of equipment malfunction, fire, or injury, is essential.

- Local Regulations: Familiarity with and adherence to all local regulations, permits, and site-specific safety rules are critical.

I regularly review safety guidelines and participate in refresher training to stay up-to-date with best practices. My commitment to safety reflects my commitment to protecting myself and others on the job site.

Q 14. Describe a time you had to repair a damaged attachment in the field.

During a road construction project, the hydraulic cylinder on a grading bucket suffered a significant crack. The repair couldn’t wait as the grading work was critical to the project schedule. The crack wasn’t too extensive, and after assessing the damage, I determined that a field repair might be feasible. I carefully cleaned the cracked area, used a high-quality welding rod suited for the cylinder material, and carefully welded the crack. After welding, I allowed it to cool, then inspected the weld thoroughly for any imperfections. I then carefully pressure tested the cylinder.

While a proper workshop repair would’ve been ideal, the field repair enabled us to resume operation in a timely manner, minimizing project delays. It was a temporary fix, but it held up long enough to complete the critical grading operations. I later documented the repair and ensured the cylinder received a proper repair at a workshop as a preventative measure to prevent future issues.

Q 15. How do you identify and address potential hazards related to attachment use?

Identifying and addressing hazards related to heavy equipment attachments is paramount for safety. My approach is multifaceted, starting with a thorough pre-operation inspection. This includes checking for:

- Structural Integrity: Inspecting for cracks, bends, or excessive wear on the attachment itself, the mounting points, and hydraulic lines.

- Hydraulic System: Checking for leaks, proper fluid levels, and smooth operation of cylinders and hoses. I’ll listen for unusual noises or vibrations.

- Pin and Connector Security: Ensuring all pins are properly secured with cotter pins or retaining clips, and that quick-connects are properly engaged and free from damage.

- Sharp Edges and Protrusions: Identifying and mitigating any sharp edges or points that could pose a risk to personnel or damage the surrounding environment.

- Environmental Factors: Considering ground conditions (soft ground, uneven terrain), visibility (weather conditions, lighting), and proximity to power lines or other obstacles.

Addressing identified hazards involves immediate corrective action. This might range from tightening a loose bolt to replacing a damaged component. If the hazard cannot be safely addressed on-site, the equipment is taken out of service until repairs are completed. I firmly believe in the principle of ‘if in doubt, check it out’ – preventing accidents is always the priority.

For example, during a recent job involving a demolition attachment, I noticed a small crack in the cutting edge. Instead of continuing, I immediately reported it, and the attachment was replaced to prevent a catastrophic failure during operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of materials handling attachments?

My experience with materials handling attachments is extensive and covers a wide range of equipment, including:

- Grapples: I’m proficient in using various grapple types, from demolition grapples for scrap metal to logging grapples for timber handling. I understand the importance of proper grapple jaw adjustments for efficient and safe material handling.

- Buckets: I have experience with a variety of buckets – standard digging buckets, ditch cleaning buckets, and specialized buckets for specific materials like asphalt or demolition debris. I know how to select the appropriate bucket size and type for the task.

- Forks: I’m familiar with pallet forks and various other fork attachments for loaders. This includes understanding safe load limits and ensuring proper fork placement to prevent damage and accidents.

- Clamps: I’ve utilized various clamps for lifting and carrying a variety of materials, including concrete pipes, large blocks, and other bulky items. I carefully assess the load center and stability before lifting.

- Magnetic Lifters: I have experience with magnetic lifters, understanding their limitations and the importance of safe detachment procedures. I always conduct a thorough check for ferrous materials prior to use.

The ability to select the right attachment for the job and use it safely and efficiently is a crucial skill I’ve developed over my career.

Q 17. Explain your understanding of the limitations of various attachments.

Understanding the limitations of various attachments is critical. Each attachment has a specific application and operational limits. Exceeding these limits can result in damage to the equipment, injury to personnel, or even catastrophic failure. Here are some key examples:

- Load Capacity: Each attachment has a maximum load capacity, often specified by weight or volume. Exceeding this limit puts significant stress on the attachment and the carrier equipment.

- Reach and Stability: Attachments extend the reach of the equipment, which can compromise stability, particularly when operating on uneven terrain or when handling heavy loads. Careful consideration of reach and balance is essential.

- Material Compatibility: Some attachments are designed for specific materials. Using the wrong attachment for a given material can lead to damage or inefficient operation. For example, using a standard bucket to handle sharp rocks will damage the bucket.

- Operating Conditions: Environmental factors such as temperature, ground conditions, and visibility also affect attachment performance and safety. Extreme temperatures or muddy terrain may compromise stability or operation.

Understanding these limitations helps prevent accidents and ensures efficient work practices. I always double-check the attachment’s specifications and operating manual before starting any task.

Q 18. How do you ensure the proper weight distribution when using attachments?

Proper weight distribution is fundamental to safe and efficient operation. I ensure proper weight distribution by following these steps:

- Center of Gravity: I carefully consider the center of gravity of the load and the attachment, adjusting its position as needed to maintain stability. This often involves careful placement of materials within the attachment.

- Load Capacity: I never exceed the load capacity of the attachment or the carrier equipment. This information is always readily available in the equipment’s manuals.

- Terrain Assessment: I consider the terrain before lifting or moving any load. Soft ground or slopes require extra caution and may necessitate adjusting the load to prevent tipping.

- Visual Inspection: I regularly inspect the equipment and load during operation, adjusting as necessary to maintain balance. If I see any signs of instability, I immediately stop and rectify the issue.

- Swing Radius: I’m acutely aware of the swing radius, especially when operating close to obstacles. I maintain a safe distance from other structures and people to prevent any damage or injuries.

For example, when lifting heavy materials with a crane-like attachment, I will often use multiple lifts of smaller loads rather than attempting to lift the entire load at once to prevent instability.

Q 19. What is your experience with preventative maintenance schedules for attachments?

Preventative maintenance is crucial to ensure the longevity and safety of attachments. I’m familiar with various maintenance schedules, often dictated by the manufacturer’s recommendations. These schedules typically involve:

- Daily Inspections: Checking for damage, leaks, loose bolts, and proper operation before each shift. This is non-negotiable.

- Regular Lubrication: Lubricating moving parts according to the schedule helps to prevent wear and tear and extend the life of the attachment.

- Hydraulic System Checks: Regularly checking fluid levels, hoses, and connections for leaks is important to prevent costly repairs and potential hazards.

- Wear Part Replacement: Replacing worn parts, such as cutting edges, teeth, or bushings, before they cause significant damage is a key component of preventative maintenance. This also prevents unexpected downtime.

- Thorough Inspections: More thorough inspections are conducted at set intervals or after periods of intensive use. This may involve dismantling parts for a closer examination.

Maintaining a logbook of all maintenance activities helps track issues and ensure that everything is up to code. A well-maintained attachment is a safer and more efficient attachment.

Q 20. Describe your proficiency with operating various types of excavators and their corresponding attachments.

I’m proficient in operating various types of excavators, including mini-excavators, long-reach excavators, and heavy-duty excavators. My experience encompasses a wide array of attachments:

- Digging Buckets: I’m comfortable using different sizes and types of digging buckets for various applications, adapting my technique for different soil conditions.

- Hydraulic Breakers: I’m experienced in operating hydraulic breakers safely and effectively for demolition and rock breaking. This includes understanding the importance of using the correct breaker size for the job and maintaining safe operating distances.

- Rippers: I’m proficient in using rippers to loosen hard ground or break up compacted material. I understand the different types of rippers and their application.

- Grapples: I’ve worked extensively with various grapples attached to excavators for material handling and sorting, particularly demolition debris.

- Augers: I’m experienced in using various sizes of augers for tasks such as post-hole digging, which requires skill and precision.

My experience spans various applications, from trenching and foundation work to demolition and site preparation. Safety is always my top priority when operating heavy equipment, including proper use of stabilizers and understanding the machine’s limitations.

Q 21. Explain your familiarity with different types of loaders and their attachments.

My experience with loaders encompasses various types, including wheel loaders and skid steer loaders. I’m familiar with the attachments commonly used with these machines:

- Buckets: I’ve used a range of buckets, from general purpose buckets to those specifically designed for handling materials like sand, gravel, or snow. I’m adept at selecting the correct bucket for the job, based on material type and volume.

- Pallet Forks: I’m proficient in using pallet forks for handling pallets, understanding the importance of proper load placement and securing the load to prevent damage or accidents.

- Backhoes: I’ve operated loaders equipped with backhoe attachments, effectively performing digging and trenching tasks. I am aware of the necessary safety procedures when using these attachments.

- Augers: Similar to excavators, I’ve used augers with loaders for a variety of tasks like post-hole digging or drilling.

- Specialised attachments: I have also experience with less common attachments such as bale handlers, brush grapples, and snow blowers. I am adept at learning new attachments as required.

I understand the differences in operation between wheel loaders and skid steer loaders and can adapt my technique accordingly, always prioritizing safety and efficiency.

Q 22. How do you handle situations where an attachment is not functioning correctly?

Troubleshooting a malfunctioning attachment begins with a systematic approach. First, I’d perform a visual inspection, checking for obvious issues like loose connections, hydraulic leaks, or damaged components. Think of it like a doctor’s examination – you need to observe before diagnosing. For example, if a grapple isn’t closing properly, I’d check the hydraulic hoses for leaks or kinks, and ensure the grapple’s jaws aren’t obstructed. If the problem is hydraulic, I’d check oil levels and pressure. If it’s electrical, I would investigate the wiring and any control panels.

If a visual inspection doesn’t reveal the problem, I’ll consult the attachment’s operating manual. These manuals are incredibly detailed and often have troubleshooting guides. If the issue persists, I’ll contact the equipment’s manufacturer or a qualified technician for further assistance. Safety is paramount; if I’m unsure about the cause of the malfunction, I’ll shut down the equipment and avoid further attempts to operate it until a professional can assess it.

For instance, on one job, a breaker on a thumb bucket kept tripping. Initial checks revealed no obvious damage. Following the manual’s troubleshooting section, I checked the amperage draw—it was significantly higher than normal, indicating a potential short circuit in a motor. The issue was eventually traced to a pinched wire inside the bucket’s hydraulic arm; after replacing the section of wire, the problem was solved.

Q 23. What safety measures do you take when working near power lines with attachments?

Safety near power lines is non-negotiable. Before commencing any work near overhead lines, I always establish a safe working distance, consulting the site’s safety plan and ensuring I understand the voltage of the lines. I treat all power lines as energized and deadly, even if they appear to be deactivated.

Specific measures include: using spotters to maintain awareness of the equipment’s position relative to power lines; employing non-conductive tools and equipment; ensuring the heavy equipment’s boom and attachments are kept well away from the wires, even during movement; and ensuring all team members are briefed about the power line hazards and the need to maintain strict adherence to established safety distances. I would never operate under power lines unless authorized by a qualified linesman or safety professional and only after all necessary safety measures have been implemented. Any doubt about safety leads to an immediate halt to the operation.

Q 24. How do you manage your time efficiently when performing tasks requiring multiple attachments?

Efficient time management with multiple attachments hinges on careful planning and execution. Before starting a project, I create a detailed plan that sequences the tasks, taking into account the optimal use of each attachment. This plan would include the order of attachment changes, the time allocated for each task, and potential delays.

To minimize downtime, I ensure that any necessary attachment changes can be completed quickly and safely. I practice quick-change attachment techniques so it does not take excessive time. This often involves using a system that allows a faster change of attachments on the machine. It is a combination of preparation and skill. For example, if a task calls for both a ripper and a bucket, I’ll arrange the work sequence to minimize the number of times I need to switch attachments. The preparation stage also includes ensuring all the necessary attachments are readily available and functional before starting work, greatly minimizing the delay of fixing attachments on the machine.

Q 25. Describe your problem-solving skills when dealing with complex attachment issues.

My problem-solving approach is systematic and methodical. When dealing with a complex attachment issue, I start with a thorough visual inspection. Then, I consult the relevant manuals and diagrams to understand the attachment’s mechanics. This often helps pinpoint the source of the malfunction and identify potential solutions. If the solution isn’t apparent, I employ a process of elimination, systematically testing different components to isolate the problem. I keep meticulous notes throughout the process, documenting my findings and actions.

For example, if a hydraulic breaker repeatedly jams, I might first check the hydraulic fluid levels and pressure, then examine the breaker’s internal components for blockages or damage. I might then look at the hoses and fittings for damage, and if necessary the valves and controls. I’ll always prioritize safety, ensuring the equipment is securely shut down before performing any maintenance or repairs.

If the issue is too complex for my skillset, I will promptly engage a specialist or the equipment manufacturer. It’s better to seek professional help than to risk causing further damage or injury.

Q 26. How do you communicate effectively with other team members about attachment use and maintenance?

Effective communication is critical for efficient teamwork and safety. I prioritize clear and concise communication with my team, using both verbal and written methods. Before starting any tasks involving attachments, I conduct a thorough briefing, explaining the intended use of each attachment, the appropriate safety precautions, and the planned work sequence.

During the operation, I maintain open communication with the spotter or other team members, constantly updating them on my progress and any potential issues. I make sure to use unambiguous language and avoid jargon, keeping communications consistent. After completing a task, I provide a concise report, documenting any problems encountered and recommendations for future improvements or maintenance. I also advocate for regular maintenance schedules and ensure that all team members understand the importance of proper equipment maintenance.

Q 27. What are your strategies for optimizing the efficiency of attachment use on a job site?

Optimizing attachment efficiency involves several key strategies. Firstly, selecting the right attachment for the specific task is crucial. Using an unsuitable attachment will reduce the speed and efficiency of the project. Secondly, ensuring the attachments are in good working order is paramount; regular maintenance prevents unexpected downtime and ensures maximum performance. Thirdly, efficient operating techniques are important; I always strive to develop the skill of using the attachments to complete the project in the fastest and safest way possible.

Another crucial aspect is careful planning; optimizing the sequence of tasks to minimize the need for attachment changes. Furthermore, I always consider the work site conditions to improve efficiency. Understanding the soil type, terrain, and other environmental factors helps in selecting the appropriate attachments and optimizing their use. Finally, incorporating feedback from past projects to refine my approach is a continual process to improve efficiency.

Q 28. How do you stay current with the latest technologies and advancements in heavy equipment attachments?

Staying current with advancements in heavy equipment attachments requires a multifaceted approach. I regularly attend industry conferences and trade shows, which provide valuable insights into new technologies and developments. I also actively subscribe to industry publications and online forums to keep myself informed about the latest trends and best practices.

Manufacturer websites are an invaluable resource, offering detailed specifications, operating manuals, and often even training materials for new attachments. Additionally, I participate in online training courses and workshops offered by equipment manufacturers or industry organizations to enhance my knowledge and skills. Networking with other professionals in the field allows for knowledge sharing and discussion of innovative attachment uses and maintenance techniques. Staying updated is continuous learning, as new technology and improvements constantly emerge in this field.

Key Topics to Learn for Proficient in using heavy equipment attachments and accessories Interview

- Understanding Attachment Types: Familiarize yourself with various attachment types (e.g., buckets, grapples, augers, hammers, blades) and their specific applications. Consider the differences in operation and maintenance for each.

- Safe Attachment Coupling and Decoupling: Master the procedures for safely attaching and detaching equipment. Understand the importance of using proper safety measures and checklists to prevent accidents.

- Operational Proficiency: Practice operating heavy equipment with different attachments. Focus on efficient and safe techniques for various tasks, including maneuvering, loading, and unloading.

- Maintenance and Troubleshooting: Learn about preventative maintenance procedures for attachments. Develop problem-solving skills to identify and address common issues and malfunctions in the field.

- Hydraulic Systems Knowledge: Gain a fundamental understanding of hydraulic systems used in heavy equipment and their connection to attachments. Know how to identify and address basic hydraulic problems.

- Regulations and Safety Procedures: Be aware of relevant safety regulations and industry best practices related to the operation and maintenance of heavy equipment and attachments.

- Impact of Attachments on Equipment Performance: Understand how different attachments affect the overall performance and efficiency of the heavy equipment. Learn to optimize usage for different tasks.

- Selecting the Right Attachment for the Job: Develop skills in assessing job requirements and choosing the appropriate attachment for optimal efficiency and safety.

Next Steps

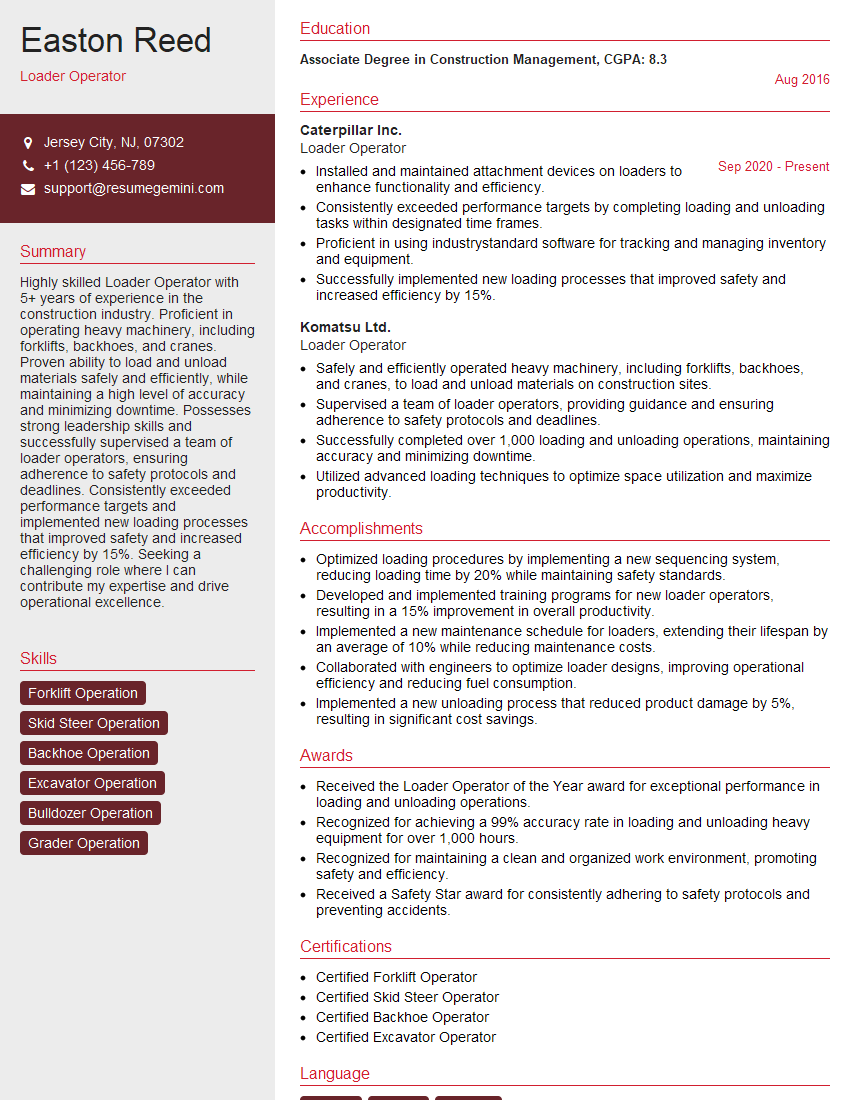

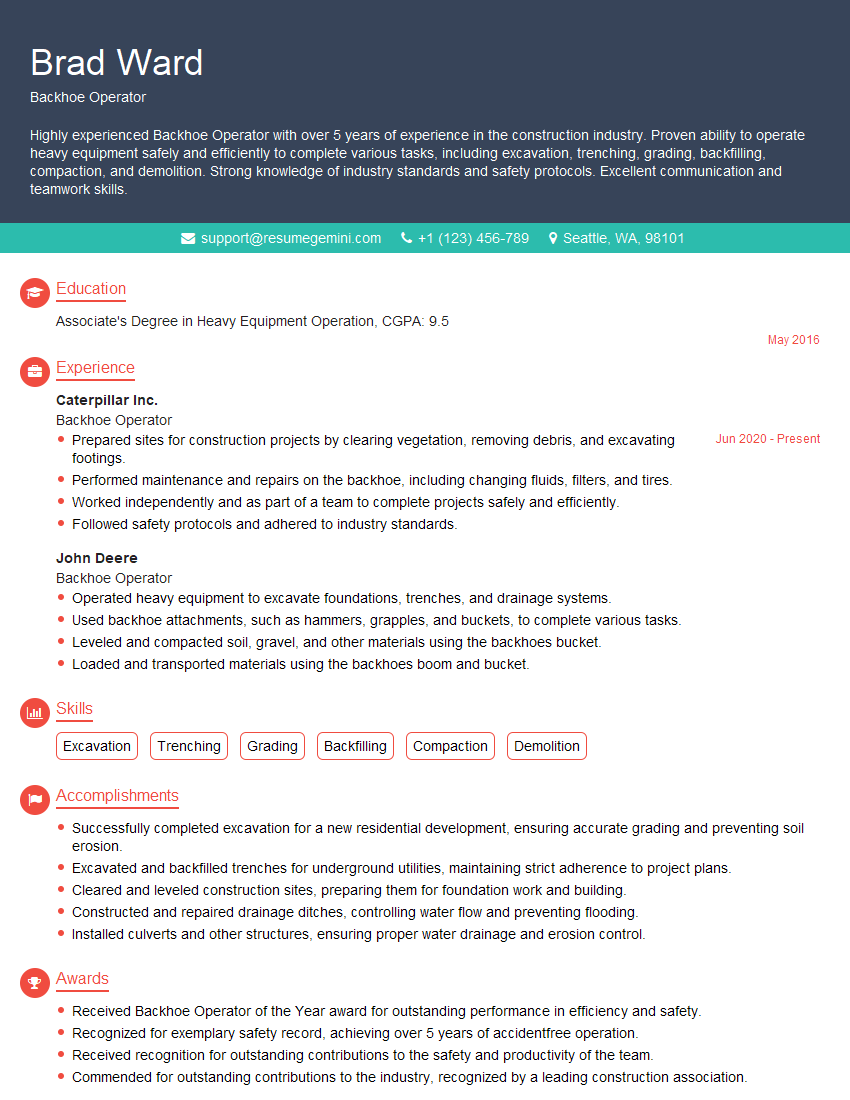

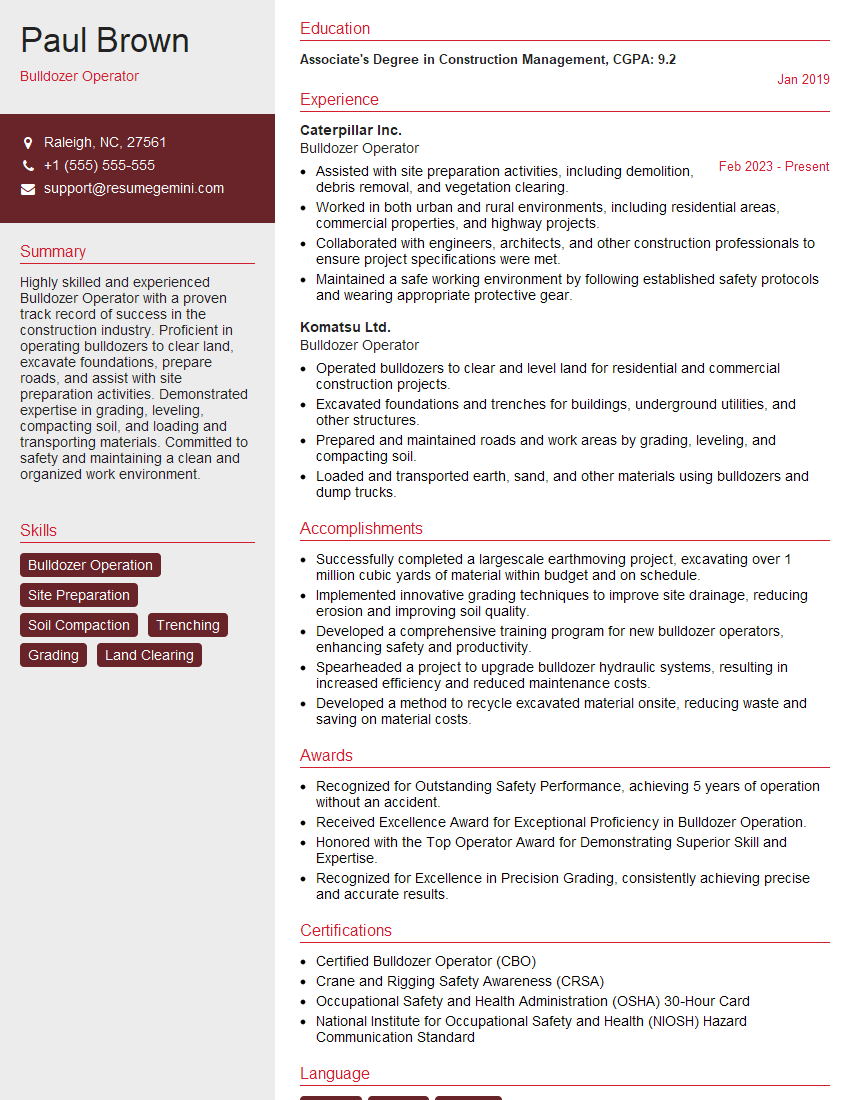

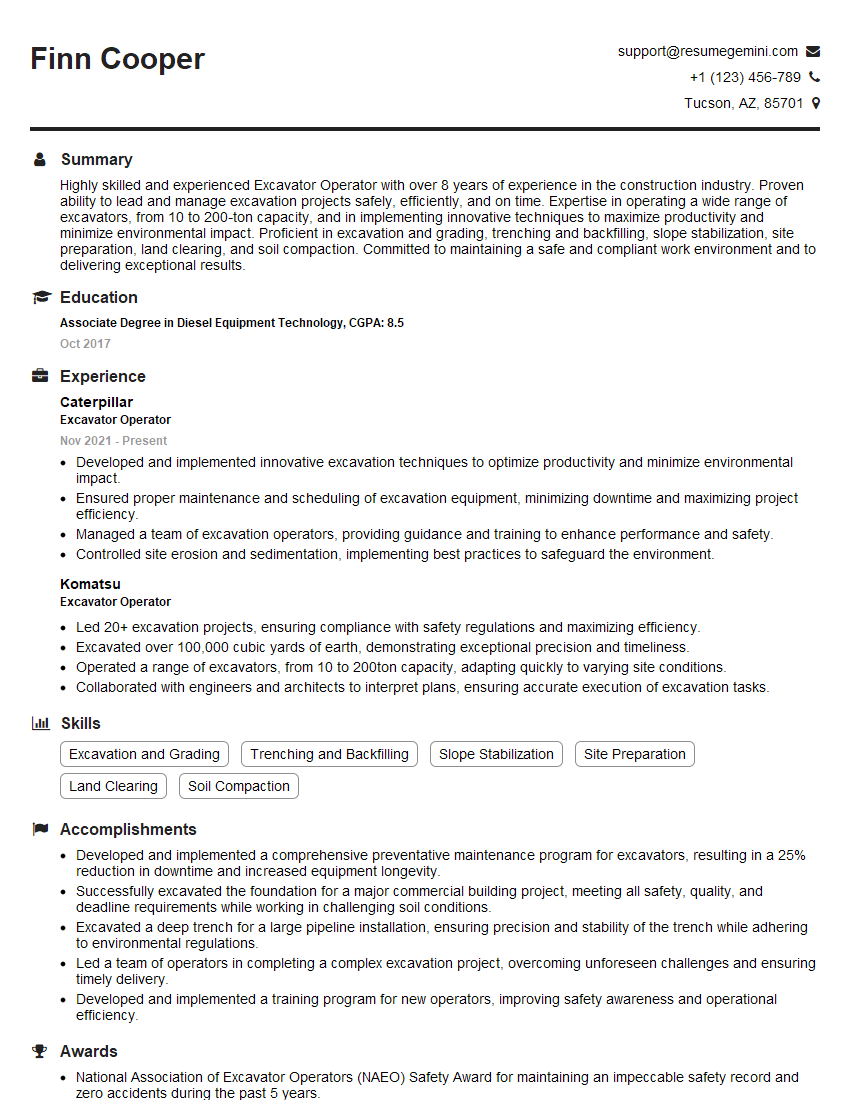

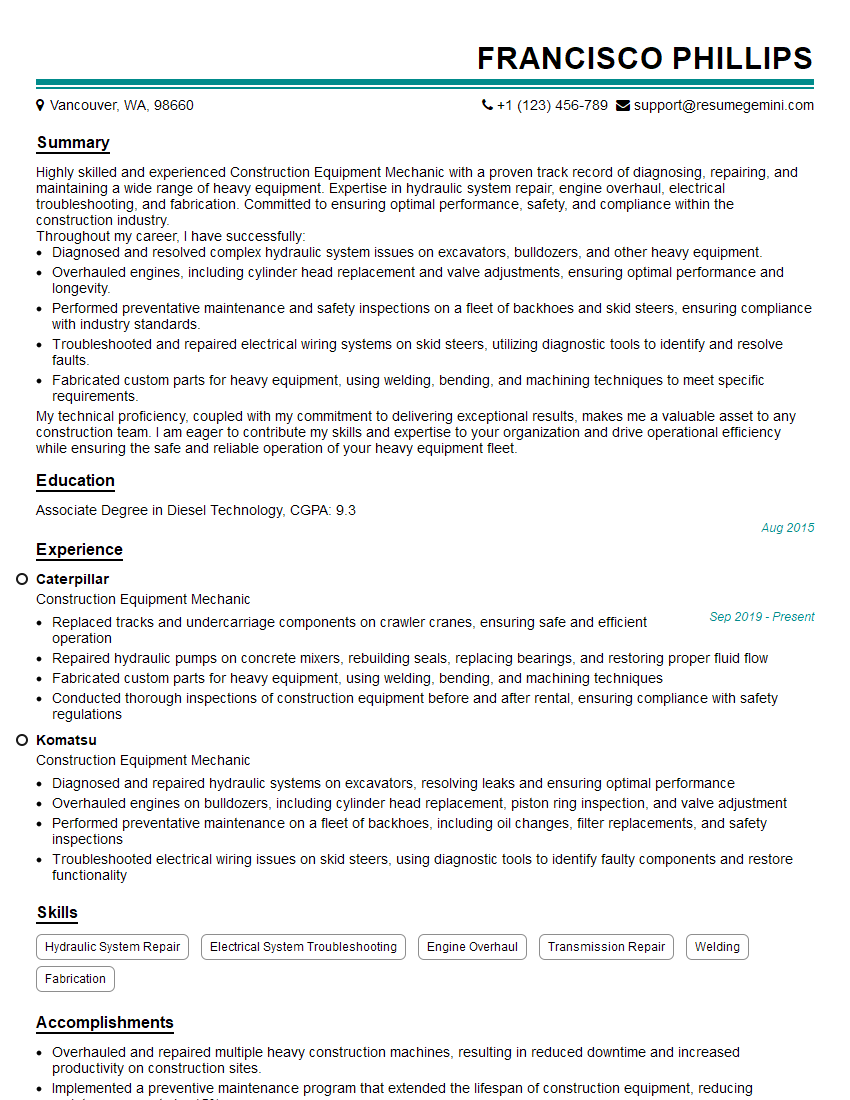

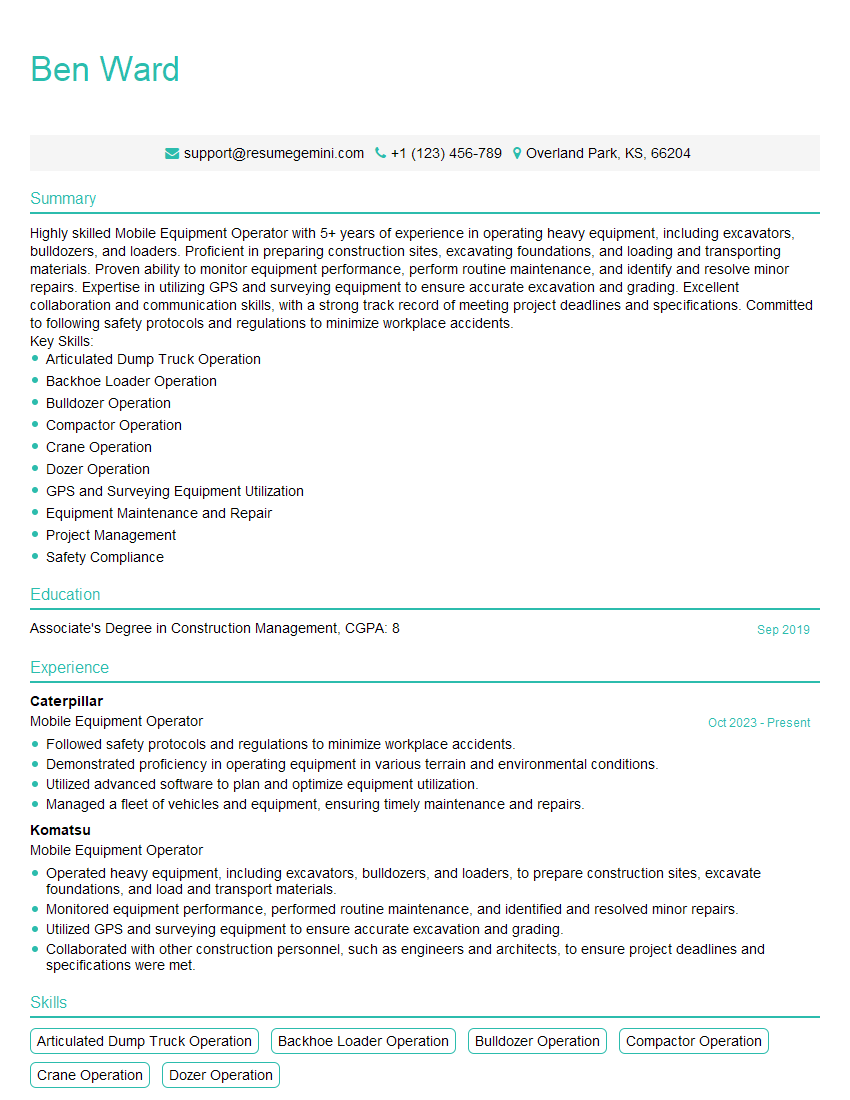

Mastering the proficient use of heavy equipment attachments and accessories is crucial for career advancement in the construction, demolition, and materials handling industries. It demonstrates your versatility and problem-solving abilities, leading to increased job opportunities and higher earning potential. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. We strongly recommend using ResumeGemini to build a professional and impactful resume that catches the attention of recruiters. ResumeGemini offers valuable tools and resources, and examples of resumes tailored to “Proficient in using heavy equipment attachments and accessories” are available to help you create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.