Preparation is the key to success in any interview. In this post, we’ll explore crucial Proper Harnessing of Public Utility Line Equipment interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Proper Harnessing of Public Utility Line Equipment Interview

Q 1. Describe the different types of harnesses used in public utility line work.

Public utility line work employs several harness types, each designed for specific tasks and environments. The most common include:

- Full Body Harnesses: These are the most versatile and widely used, offering attachment points at the dorsal (back), chest, and legs. They provide maximum protection during falls, distributing forces across the body.

- Chest Harnesses: These harnesses offer a single attachment point at the chest and are typically used in conjunction with a positioning device, allowing for controlled movement during work. They are less common than full body harnesses due to increased fall risk if the positioning device fails.

- Positioning Harnesses: These are designed to keep workers safely positioned during tasks and don’t provide fall arrest. They allow for comfortable work but require other fall protection systems to be in place for added safety.

- Specialized Harnesses: Certain tasks may demand specialized harnesses, like those designed for confined spaces or rescue operations, often including extra features such as additional attachment points, padding, or quick-release buckles.

The choice of harness depends heavily on the job’s specifics, risk assessment, and regulatory requirements. Always select a harness appropriate for the anticipated hazards.

Q 2. Explain the proper procedure for donning and doffing a safety harness.

Donning and doffing a safety harness is a critical procedure that must be performed correctly every time. Here’s a step-by-step guide:

- Inspection: Before putting on the harness, thoroughly inspect it for any signs of wear, damage, or defects. This includes checking straps, buckles, stitching, and attachment points.

- Donning: Position the harness correctly on your body. Adjust the leg straps snugly but not so tight they restrict blood flow. Make sure the dorsal D-ring is positioned centrally between your shoulder blades. Adjust the chest and shoulder straps to maintain a comfortable and secure fit. A properly fitted harness should allow for free movement without being loose.

- Attachment: Attach the harness to a properly anchored lifeline or system. Double-check the connection to ensure it’s secure and reliable.

- Doffing: Disconnect from the lifeline first. Then carefully remove the harness, starting with the leg straps, followed by the chest and shoulder straps. Inspect the harness again before storing it.

Improper donning or doffing can significantly compromise the effectiveness of the harness, putting the worker at increased risk. Remember that proper training is crucial for safe harness use.

Q 3. What are the key components of a complete fall protection system?

A complete fall protection system includes several crucial components working together. Think of it as a chain; if one link is weak, the whole system fails. The key components include:

- Full Body Harness: Distributes the impact forces during a fall.

- Anchor Point: A secure structural element capable of supporting the weight of the worker and any additional equipment, with sufficient strength to withstand the forces of a fall.

- Connecting Device: This connects the harness to the anchor point. It can include lanyards, shock-absorbing lanyards, self-retracting lifelines (SRLs), or other approved devices.

- Fall Arrest System: This is the entire assembly of harness, anchor point, and connecting device designed to arrest a fall.

- Rescue Plan: A detailed, pre-planned procedure outlining steps for safe retrieval and emergency response in case of a fall.

Each component must be inspected regularly and maintained according to manufacturer’s recommendations. Skipping any component or using substandard equipment significantly reduces the system’s effectiveness and increases the risk of serious injury.

Q 4. How do you inspect a harness for wear and tear before each use?

Before each use, a thorough inspection is vital. Imagine it like a pre-flight check for an airplane – no shortcuts allowed! Check these areas:

- Straps: Look for cuts, abrasions, fraying, burns, or any signs of excessive wear. Feel the straps for stiffness or brittleness, indications of material degradation.

- Buckles: Ensure they function smoothly, latch securely, and show no signs of damage or corrosion. Check that the locking mechanism works perfectly.

- Stitching: Carefully examine all stitching for loose threads, broken seams, or areas of wear.

- D-rings and Attachment Points: Verify their integrity, looking for deformities, cracks, or damage. Make sure the metal is not corroded.

- Labels and Tags: Check for any tags indicating the harness is damaged or has exceeded its service life. Look for labels indicating the manufacturer, model, and any other relevant information.

If you find any damage, even minor, the harness should be immediately removed from service and replaced. A damaged harness could fail during a fall, leading to catastrophic injury.

Q 5. What are the limitations of a safety harness?

While essential for fall protection, safety harnesses have limitations. It’s crucial to understand these constraints to avoid unnecessary risk.

- Swing Falls: Harnesses only protect against vertical falls. A swing fall (a fall that causes the worker to swing into an obstacle) can result in serious injury even with a properly functioning harness.

- Impact Forces: Even with a fall arrest system, considerable forces are involved during a fall. These forces can cause injuries, especially to the spine, pelvis, and other body parts.

- Harness Failure: While rare, harness failure is possible due to wear, tear, or improper use. Regular inspections and proper maintenance are essential to mitigate this risk.

- Environmental Factors: Extreme temperatures, chemicals, or ultraviolet radiation can degrade harness materials over time, diminishing their effectiveness.

- User Error: Incorrect harness use, improper attachment, or failure to follow safety procedures are common causes of accidents. Training and adherence to safety protocols are critical.

These limitations highlight the need for thorough risk assessment, appropriate fall protection systems, and proper training for all personnel working at height. Never rely solely on the harness; consider additional safeguards.

Q 6. Explain the importance of proper body positioning while working at height.

Proper body positioning is paramount for maintaining balance and minimizing strain while working at height. Think of it like a gymnast maintaining their center of gravity. Poor posture can increase the risk of falls and injuries.

- Maintain a Balanced Stance: Keep your feet shoulder-width apart, maintain a stable base, and shift your weight gradually when changing position.

- Avoid Overreaching: Extending too far can easily throw you off balance. Use tools and equipment that minimize the need for overreaching.

- Keep Your Body Close to the Work Area: Work as close as possible to your anchor point to reduce the distance of a potential fall.

- Use Three Points of Contact: When climbing or moving on elevated surfaces, always maintain three points of contact. This means keeping two hands and one foot, or two feet and one hand, secured to a stable structure. This provides enhanced stability.

- Regular Breaks: Fatigue increases the risk of falls. Take regular breaks to rest, rehydrate, and reduce physical strain.

By focusing on correct body positioning, utility line workers can significantly reduce their risk of falls and injuries, ensuring safer work practices.

Q 7. Describe the different types of fall arrest systems used in utility line work.

Several fall arrest systems are used in utility line work, each with its advantages and disadvantages:

- Self-Retracting Lifelines (SRLs): These are a popular choice, automatically retracting the lifeline to prevent excessive fall distance. They are compact and easy to use but can be more expensive than other systems. They should have an appropriate fall arrest force to prevent injury.

- Shock-Absorbing Lanyards: These lanyards are designed to absorb some of the impact force during a fall, reducing the shock on the worker. The elongation of the lanyard during the arrest should be sufficient to prevent the worker from impacting the ground or obstacles.

- Fixed-Length Lanyards: These offer a shorter fall distance and are typically used for positioning or limited movement. They require very careful positioning to prevent impact with the ground during a fall, and their application is more restricted than other systems.

- Vertical Lifeline Systems: For situations requiring movement along a vertical axis, vertical lifeline systems provide continuous protection. These systems often include a traveling clamp for vertical movement. They often include energy absorption mechanisms to prevent excess force.

The selection of a fall arrest system depends on the specific work being performed, the height involved, the potential fall hazards, and the overall risk assessment. Each system must be used and inspected correctly to guarantee its effectiveness.

Q 8. What are the procedures for rescuing a fallen worker?

Rescuing a fallen worker from a height requires a coordinated and practiced approach prioritizing the safety of both the rescuer and the victim. First, ensure the scene is safe – de-energize power lines if possible and establish a secure perimeter. Never attempt a rescue alone; a minimum of two trained rescuers are needed.

- Assess the situation: Determine the victim’s condition and the stability of their position.

- Alert emergency services: Call emergency medical services immediately.

- Secure the victim: Use appropriate equipment like a rescue harness and specialized lifting devices to secure the victim and prevent further injury.

- Controlled lowering: Employ a controlled descent system, like a rope and pulley, to carefully lower the victim to the ground. Never attempt to simply pull the victim up.

- Post-rescue care: Provide immediate first aid and ensure the victim receives prompt medical attention.

Imagine a scenario where a lineman falls from a pole. A nearby crew member immediately calls for emergency services and uses a rescue harness and winch system to safely lower their colleague, stabilizing them throughout the descent. This prevents further injury and ensures a safe recovery.

Q 9. How do you perform a self-rescue from a fall?

Self-rescue from a fall, while possible in certain situations, is a last resort and should only be attempted if professional rescue is impossible and immediate danger exists. It relies heavily on having the correct equipment and training.

- Assess your situation: Evaluate your immediate surroundings and the stability of your position. Can you reach a stable point or safely lower yourself?

- Engage your self-rescue system: If you have a self-retracting lifeline (SRL) or a personal fall arrest system (PFAS), engage the mechanism and attempt to move yourself to a safe position.

- Controlled descent: If you must descend, do so slowly and methodically, ensuring your body remains clear of obstructions.

- Seek assistance: Once in a relatively safer position, immediately signal for help.

For example, if a worker is dangling from a platform and their SRL engages, they should try to reach a secure area, using their hands and feet cautiously. They might use their SRL’s descent control mechanism to reach a stable position and then signal for help instead of trying to climb up.

Q 10. What are the regulations and standards governing harness use in your region?

(Note: Regulations and standards vary by region. This answer provides a general overview and should not be considered legal advice. Consult your local OSHA or equivalent authority for specific requirements.)

In many jurisdictions, harness use is governed by occupational safety and health regulations such as OSHA (in the USA) or similar national bodies. These regulations typically mandate the use of approved fall protection systems, including harnesses, anchor points, and connecting devices, when working at heights exceeding a certain threshold (often 6 feet).

- Harness type: Regulations usually specify the required type of harness (full-body harness is typically preferred for maximum protection).

- Inspection: Regular harness inspection and maintenance are mandatory, with records required to be maintained.

- Training: Workers must receive appropriate training on harness use, fall protection systems, and rescue procedures.

- Anchor points: Regulations detail the requirements for secure anchor points to ensure adequate strength and stability.

For example, a utility company in the US must adhere to OSHA’s standards, requiring all workers to wear appropriately inspected and maintained harnesses, along with utilizing approved anchor points when working at heights.

Q 11. Explain the importance of using appropriate fall protection equipment for different tasks.

The choice of fall protection equipment depends heavily on the specific task and the environment. Using inappropriate equipment can severely compromise safety.

- Working on poles: Linemen working on utility poles will utilize a full-body harness with shock-absorbing lanyards and appropriate anchor points on the pole. The harness provides full body support, limiting the risk of swing falls.

- Rooftop work: Workers on rooftops might use a full-body harness connected to a horizontal lifeline system, providing protection while moving across the roof.

- Working near edges: When working near unprotected edges, a guardrail system might be combined with a harness and lanyard to provide additional safety.

- Working in confined spaces: In confined spaces, special harnesses and fall protection systems are needed, potentially with added equipment for rescue.

For instance, a worker installing antennas on a tall building wouldn’t use the same equipment as a worker trimming trees. The building worker needs a harness connected to an appropriate anchorage point, possibly using a positioning lanyard. A tree worker may require a harness with more flexibility allowing for movement around the tree.

Q 12. How do you assess the risks associated with working at height in various weather conditions?

Weather conditions significantly impact the risks associated with working at heights. A comprehensive risk assessment must consider these factors.

- High winds: High winds increase the risk of being blown off balance. Work may need to be suspended or extra precautions taken, such as using additional anchors or wind protection.

- Rain and ice: Slippery surfaces increase the risk of slips and falls. Special non-slip footwear and potentially additional fall protection systems might be required.

- Extreme temperatures: Extreme heat or cold can affect worker performance and equipment. Heat exhaustion or hypothermia are serious risks.

- Lightning: Working during thunderstorms is extremely dangerous. Work should cease immediately during storms.

Consider a scenario where a worker needs to repair a power line during a light rain. The risk assessment should include the potential for the rain to make the surface slippery, and appropriate non-slip footwear should be used. If the rain intensifies or lightning is present, all work should cease immediately.

Q 13. Describe the emergency procedures to follow in case of a harness failure.

Harness failure is a critical situation requiring immediate and effective action. The procedures to follow depend on the nature of the failure, but general principles remain consistent.

- Assess the situation: Immediately determine the extent of the harness failure and any resulting injuries.

- Alert emergency services: Call for emergency medical services and inform them of the situation.

- Secure the remaining safety equipment: If other fall protection devices such as a lanyard or SRL are still functional, utilize them to help maintain a secure position.

- Safe descent or rescue: If possible, use any available equipment to effect a slow and controlled descent. Otherwise, prepare for a rescue by trained personnel.

- Post-incident investigation: After the rescue, a thorough investigation should be conducted to determine the cause of the harness failure.

Suppose a worker’s harness strap breaks. Immediate action would involve utilizing any functioning backup safety devices while calling for help. Once rescued, the damaged harness should be examined to understand the failure point and prevent similar incidents. The investigation might involve examining the harness material and stitching, the maintenance records and the usage history.

Q 14. Explain the importance of regular harness inspection and maintenance.

Regular inspection and maintenance of harnesses are crucial for ensuring their continued effectiveness and preventing accidents. A damaged harness is an unacceptable risk.

- Visual inspection: Before each use, conduct a thorough visual inspection, checking for fraying, cuts, tears, and any damage to stitching or buckles.

- Regular maintenance: Follow the manufacturer’s recommendations for routine maintenance, including cleaning and storage procedures.

- Periodic professional inspection: Harnesses should undergo periodic professional inspection by a qualified technician to ensure compliance with safety standards.

- Documentation: Maintain comprehensive records of inspections and maintenance, noting any repairs or replacements made.

- Retirement: Harnesses should be retired and replaced after a specified period or if they show signs of significant wear and tear.

Think of a car needing regular maintenance. Similarly, a harness needs routine checks. A frayed strap, a broken buckle, or unnoticed damage could mean the difference between safety and a serious accident. Following a regular inspection schedule ensures the harness remains safe and reliable.

Q 15. What are the signs of a damaged or compromised harness?

Identifying a damaged harness is crucial for safety. Look for several key indicators. Visible damage is the most obvious – this includes cuts, abrasions, fraying, or tears in the webbing. These weaken the harness’s structural integrity, potentially leading to failure during a fall. Check for signs of excessive wear, such as flattened or deformed straps. This suggests the harness has been subjected to significant stress over time. Hardware failure is another critical concern; look for broken or bent buckles, damaged stitching, or corroded metal parts. These components are vital for the harness’s function and a malfunction could be catastrophic. Lastly, chemical damage is often subtle but equally dangerous. Exposure to harsh chemicals or UV radiation can degrade the material, weakening it significantly. A good rule of thumb is to replace a harness if you’re unsure of its condition.

Example: Imagine a harness with a small cut near the leg strap. While it might seem insignificant, this cut reduces the harness’s strength and increases the risk of a catastrophic failure during a fall. Even if a component seems minor, it’s best to replace the entire harness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with your team while working at heights?

Effective communication at heights is paramount. Since shouting can be unreliable, visual cues are often necessary. We use a system of pre-arranged hand signals for basic commands like ‘raise’, ‘lower’, and ‘stop’. This helps to avoid verbal miscommunication in noisy environments or when workers are wearing hearing protection. For more complex instructions, pre-task briefings are essential. They clarify roles, procedures, and potential hazards, ensuring everyone understands the plan. Furthermore, using two-way radios with clear channels avoids interference and ensures immediate contact in emergencies. Finally, regular check-ins are crucial, especially during critical phases of the task, ensuring everyone is safe and working as planned.

Example: Before ascending a pole, we conduct a detailed briefing, ensuring every team member understands the specific risks associated with the job. We designate a spotter to watch for any signs of difficulty and provide safety support.

Q 17. Explain the proper use of a climbing belt and its role in fall protection.

A climbing belt, or body harness, is the cornerstone of fall protection. It’s designed to distribute the impact force of a fall across the body, preventing serious injuries. The belt itself features multiple attachment points (d-rings) where safety equipment, like a rope or lanyard, can be connected. The proper use involves ensuring the harness fits snugly but comfortably. All straps should be adjusted correctly, and buckles must be securely fastened. The harness should also be inspected before each use to check for any damage or wear. During work at heights, the lanyard is connected to a secure anchor point, and the user is protected if a fall occurs. The harness spreads the force evenly across the hips and legs, minimizing the chances of internal injury. A climbing belt alone isn’t fall protection; it requires a complete system with a lanyard and anchor points.

Example: Imagine a lineman working on a power pole. A fall could be devastating. The climbing belt, attached to a properly installed lanyard and anchor point, distributes the force of the fall across his body, minimizing the chance of serious injury.

Q 18. Describe different types of anchor points and their limitations.

Anchor points are crucial for fall protection systems. Several types exist, each with limitations. Structural anchor points are built into structures like buildings or towers and are usually the strongest and most reliable. However, their availability may be limited depending on the work site. Overhead anchor points like beams or structural members require careful inspection for adequate load-bearing capacity. It’s important to verify the strength rating exceeds the combined weight of the worker and equipment. Independent anchor points are separate units, often installed temporarily, and need thorough inspection for stability and proper installation. Ground-based anchor points may be used in specific situations, but are less often suited for work on tall structures. Limitations include load capacity (weight limits), material degradation due to weather, and improper installation. Always check the strength rating and ensure it exceeds the necessary weight requirements.

Example: A steel beam might be a suitable structural anchor point, but a weakened or corroded beam would be unsafe and unacceptable.

Q 19. How do you select the correct harness for a specific task?

Harness selection depends on the specific task. Consider the work environment (height, potential hazards), the duration of the work, and the worker’s size and build. For instance, a full-body harness is generally preferred for work at significant heights, providing more overall protection. For shorter tasks or situations with limited space, a simpler harness may suffice. Always refer to manufacturer specifications for weight limits and application suitability. Harnesses designed for rescue operations will differ from those intended for routine maintenance. It’s crucial the harness fits correctly and comfortably, allowing for unrestricted movement while providing secure protection. Improper sizing can compromise safety.

Example: For work on a tall transmission tower, a full-body harness with multiple attachment points is necessary for secure connection to a fall arrest system. A lightweight harness would be insufficient.

Q 20. Explain the importance of regular training and certification in harness use.

Regular training and certification are non-negotiable for safe harness use. Training covers proper inspection, donning and adjusting, anchor point selection, and emergency procedures. Certification demonstrates competency and ensures adherence to safety standards. This also keeps workers up-to-date on the latest safety regulations, equipment advancements, and rescue techniques. It reinforces safe work practices and reduces the risk of accidents. Outdated knowledge can be dangerous and lead to critical errors in judgement. Regular refresher courses are essential to maintain proficiency.

Example: Annual refresher courses ensure workers stay current on new safety regulations and best practices, keeping skills sharp and increasing awareness of potential hazards.

Q 21. Describe the procedures for working near energized lines.

Working near energized lines demands extreme caution. The first priority is to ensure the lines are de-energized whenever possible. This may involve contacting the power company to schedule a power outage in the affected area. If de-energization isn’t possible (sometimes due to the urgency or type of work), strict safety protocols must be followed. This includes using insulated tools and equipment, maintaining a safe working distance based on voltage levels, and employing qualified spotters to monitor for potential hazards. Personal protective equipment (PPE) like insulated gloves, arc flash suits, and face shields is crucial. Furthermore, thorough pre-job planning is necessary, outlining all potential risks and mitigation strategies. Any doubt or uncertainty about safety should immediately halt the work until the issue is addressed. Always follow industry best practices and company safety manuals.

Example: Before working near a high-voltage power line, we would consult the power company to arrange a planned outage. If this isn’t feasible, we would work with qualified spotters, using appropriate insulated tools and PPE, and maintain the designated safe distance from the energized lines.

Q 22. How do you ensure compliance with all safety regulations during harness use?

Ensuring compliance with safety regulations during harness use is paramount. It’s a multi-faceted process starting long before the harness is even donned. We begin with thorough training, ensuring everyone understands relevant OSHA and industry-specific standards. This training covers proper harness fitting, inspection, connection points, fall protection systems, and emergency procedures.

Secondly, pre-job planning is critical. We conduct thorough risk assessments identifying potential hazards like overhead obstructions, electrical lines, and ground conditions. These assessments inform our choice of harness type, anchoring systems, and rescue plans. Regular inspections of all equipment – harnesses, lanyards, anchors, and fall arrestors – are mandatory before each job, documenting any wear and tear. Any damaged equipment is immediately removed from service.

Finally, we adhere strictly to the ‘permit-to-work’ system in high-risk environments. This system requires authorization from a competent person verifying that all safety measures are in place before commencing work. Think of it like a checklist for safety – nothing starts without a ‘green light’. This structured approach ensures everyone works within defined safety parameters, minimizing risks and maximizing compliance.

Q 23. What are the common causes of falls in utility line work?

Falls in utility line work are devastating and often stem from several preventable factors. A common culprit is improper harness use – incorrect fitting, damaged equipment, or inadequate training resulting in misuse. Another significant cause is failure to properly anchor the harness to a secure point. Using inadequate anchors or points that can’t withstand the required load leads to catastrophic failures.

Environmental factors also play a significant role. Slippery surfaces, inclement weather (wind, ice), and unstable working platforms can all increase the risk of falls. Distractions and lack of communication within the team can also be contributory factors, leading to unexpected movements or miscalculations. Finally, equipment malfunctions – failure of lanyards, deterioration of ropes, or problems with aerial lifts – can unexpectedly lead to a fall.

Q 24. Describe your experience with different types of aerial lifts and their safety features.

My experience encompasses a wide range of aerial lifts, from bucket trucks to articulating booms and scissor lifts. Each type has unique safety features that demand careful understanding and usage. Bucket trucks, for example, are popular but require strict attention to load limits and proper positioning to prevent overturning. They usually have features like outriggers for added stability and safety interlocks to prevent operation under unsafe conditions.

Articulating booms offer greater reach and maneuverability, but their complex movements demand heightened awareness. These often include emergency stop buttons, load indicators, and stability sensors to prevent tipping. Scissor lifts, while generally safer, still require attention to weight capacity and ground conditions. All aerial lifts undergo pre-operational inspections, including hydraulic fluid levels, electrical checks, and emergency controls, before any use. Training is crucial to ensure safe operation of each type of lift, emphasizing safe working heights, load capacity, and emergency procedures.

Q 25. How do you mitigate risks associated with working in confined spaces while using a harness?

Mitigating risks in confined spaces while harnessed involves a layered approach. First, a thorough risk assessment is conducted to identify potential hazards within the space – oxygen deficiency, toxic gases, or the potential for entrapment. This assessment informs the selection of appropriate personal protective equipment (PPE), which extends beyond the harness to include respirators and specialized clothing.

Secondly, we employ confined-space entry procedures. This involves checking the atmosphere before entry, ensuring adequate ventilation, and having a standby rescue team present. Within the confined space, movement should be restricted to prevent entanglement with the harness or any equipment. The harness itself should be designed to minimize the risk of entanglement and connected to a lifeline for retrieval in case of an emergency. Communication is paramount – clear communication channels must be established between the worker inside the confined space and the team outside.

Q 26. Explain the use of rescue systems in high-risk situations.

Rescue systems are vital in high-risk situations and involve careful planning and specialized equipment. These systems often include self-retracting lifelines (SRLs) or other fall arrest systems, capable of arresting a fall and preventing injury. More importantly, the entire team needs thorough training in rescue techniques. This training includes how to safely access the fallen worker, how to use rescue equipment (pulleys, ropes, winches), and how to provide first aid while awaiting emergency services.

The design and implementation of a rescue plan are critical; it’s not just about the equipment but also about clear communication, coordination, and the readiness of the rescue team. Regular drills and practice scenarios are essential to ensure everyone is prepared and can respond efficiently and effectively during a real emergency. Rescue plans must consider the specific hazards and challenges of the work environment.

Q 27. Describe your understanding of lockout/tagout procedures related to harness usage.

Lockout/tagout (LOTO) procedures are crucial when working near energized equipment, even when using a harness. Before any work begins near a potential energy source, the power must be completely isolated and locked out. This prevents accidental energization during maintenance or repairs. A tag is affixed to the lockout device, clearly indicating the work being performed, the person responsible, and the time of lockout.

When a harness is involved, the LOTO procedure extends to ensure that the harness itself isn’t inadvertently connected to live wires or other hazardous energy sources. The procedure ensures that all energy sources are controlled, preventing any potential for electrical shock or other hazards. Strict adherence to the LOTO procedure is mandatory, and only authorized personnel are permitted to remove the lockout device.

Q 28. Explain the importance of pre-job planning and risk assessments when using a harness.

Pre-job planning and risk assessments are fundamental before using a harness, forming the bedrock of safe work practices. Planning begins with identifying the tasks, the location, and the potential hazards. This includes assessing the working height, the type of fall protection needed, the condition of the anchor points, and the potential for environmental hazards like weather conditions or ground instability.

The risk assessment translates the identified hazards into practical risk-mitigation strategies. This might involve selecting the appropriate harness, using additional fall protection equipment, implementing rescue plans, and establishing clear communication protocols. The more thorough and detailed the assessment, the more robust and effective the safety measures will be. This proactive approach eliminates or significantly reduces the risk of accidents, contributing to a safer working environment. It’s not just a ‘box-ticking’ exercise; it’s about prioritizing safety and understanding the potential consequences of inaction.

Key Topics to Learn for Proper Harnessing of Public Utility Line Equipment Interview

- Safety Regulations and Standards: Understanding OSHA regulations, industry best practices, and company-specific safety protocols related to harnessing and working at heights.

- Harness Components and Functionality: Detailed knowledge of harness parts (body harness, lanyard, shock absorber, etc.), their individual functions, and how they interact as a system. This includes proper inspection techniques.

- Proper Donning and Doffing Procedures: Mastering the safe and efficient methods for putting on and taking off a harness, ensuring compliance with all safety guidelines.

- Anchor Point Selection and Assessment: Critical evaluation of potential anchor points, understanding load limits, and identifying appropriate and safe anchor systems for various situations.

- Fall Protection Systems: Knowledge of different fall protection systems (e.g., self-retracting lifelines, fall arrest systems), their applications, and limitations.

- Working at Heights Techniques: Understanding safe work practices, including positioning, movement, and communication while working aloft.

- Emergency Procedures and Rescue Techniques: Familiarity with emergency protocols, rescue procedures, and the use of appropriate equipment in case of a fall or other emergency.

- Types of Utility Line Equipment and Harnessing Considerations: Understanding the specific harnessing requirements for different types of utility line equipment and the associated risks.

- Troubleshooting and Problem Solving: Developing the ability to identify and resolve common harnessing issues, ensuring safety and efficiency.

- Documentation and Record Keeping: Understanding the importance of accurate record-keeping regarding inspections, training, and incidents.

Next Steps

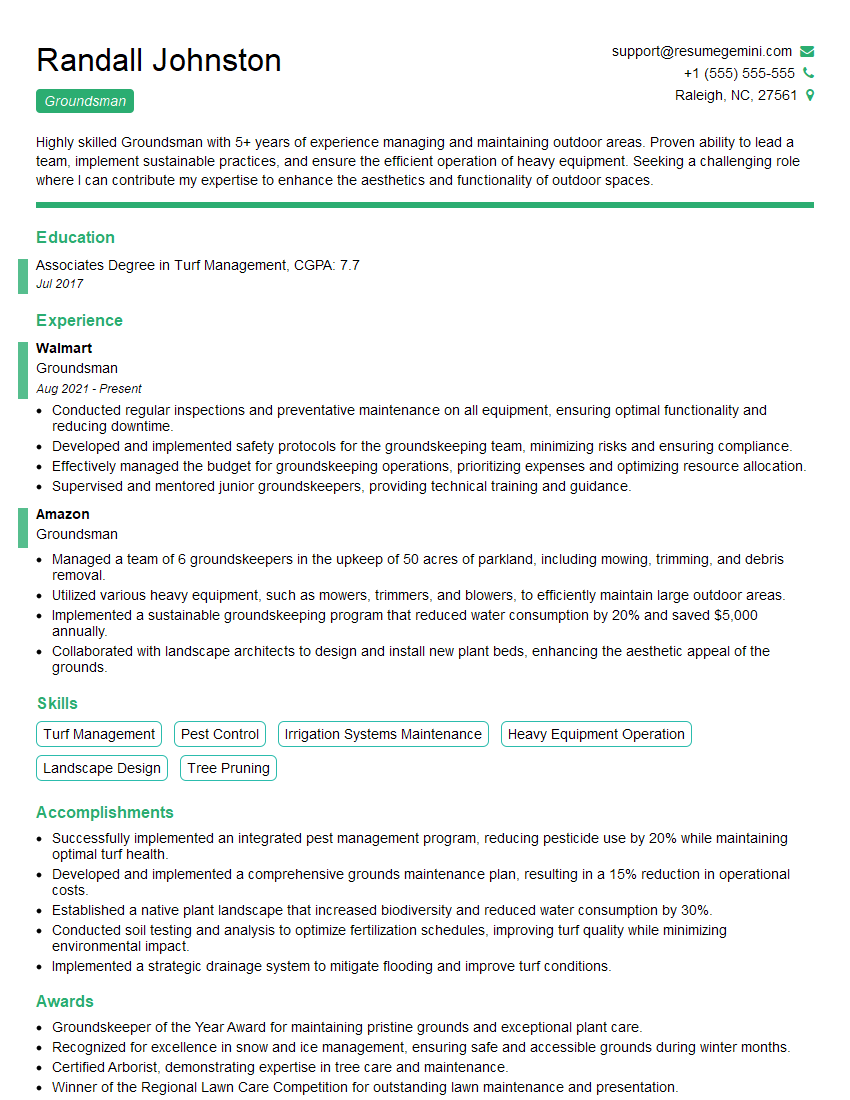

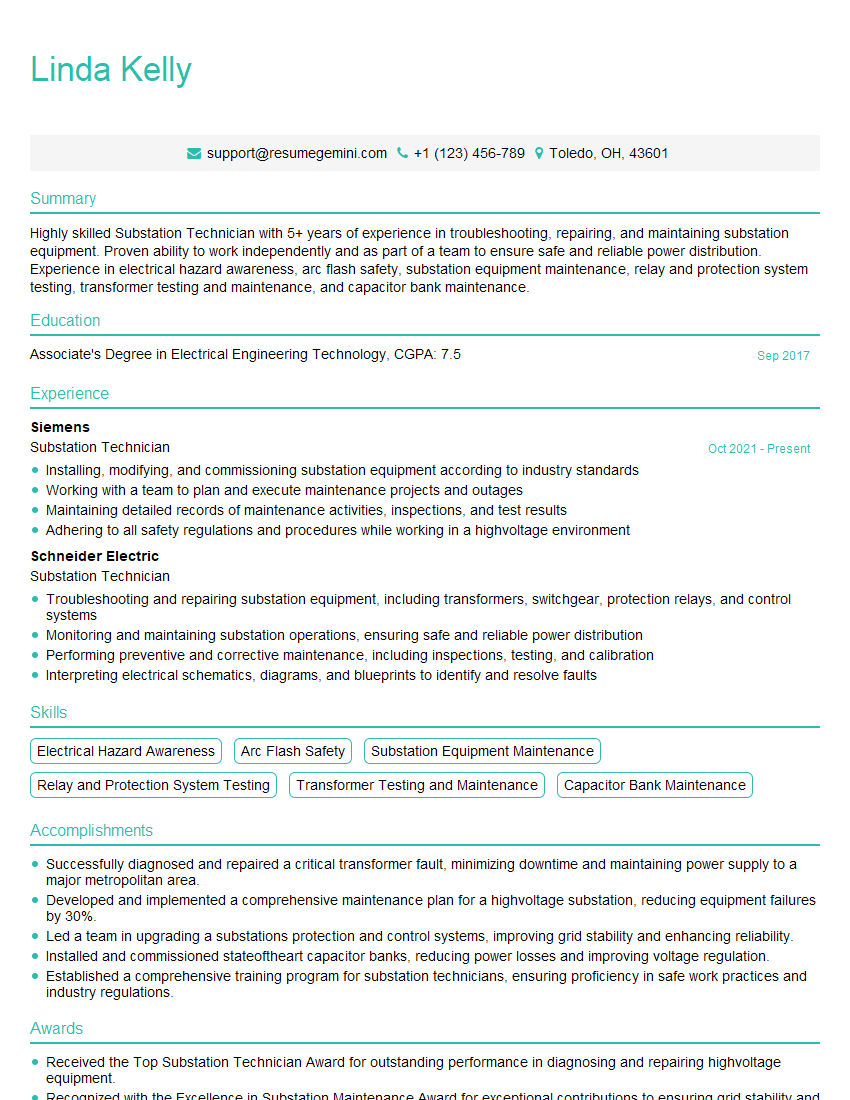

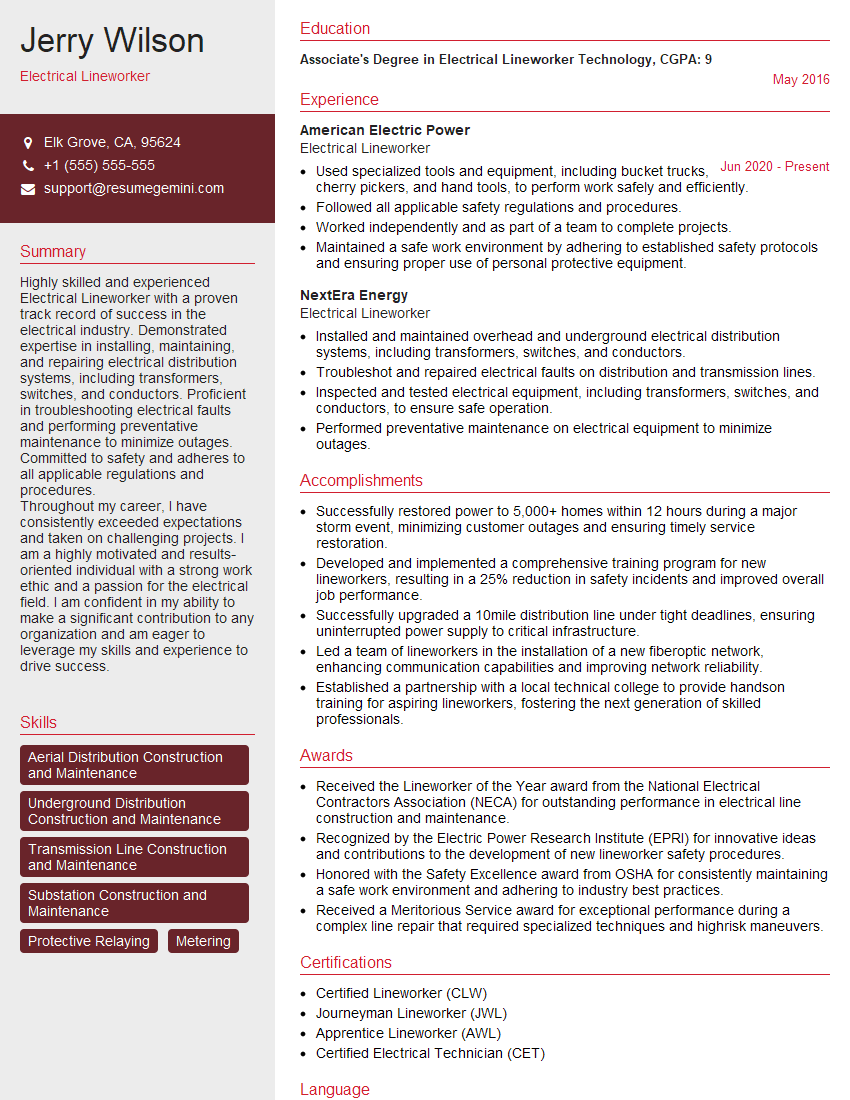

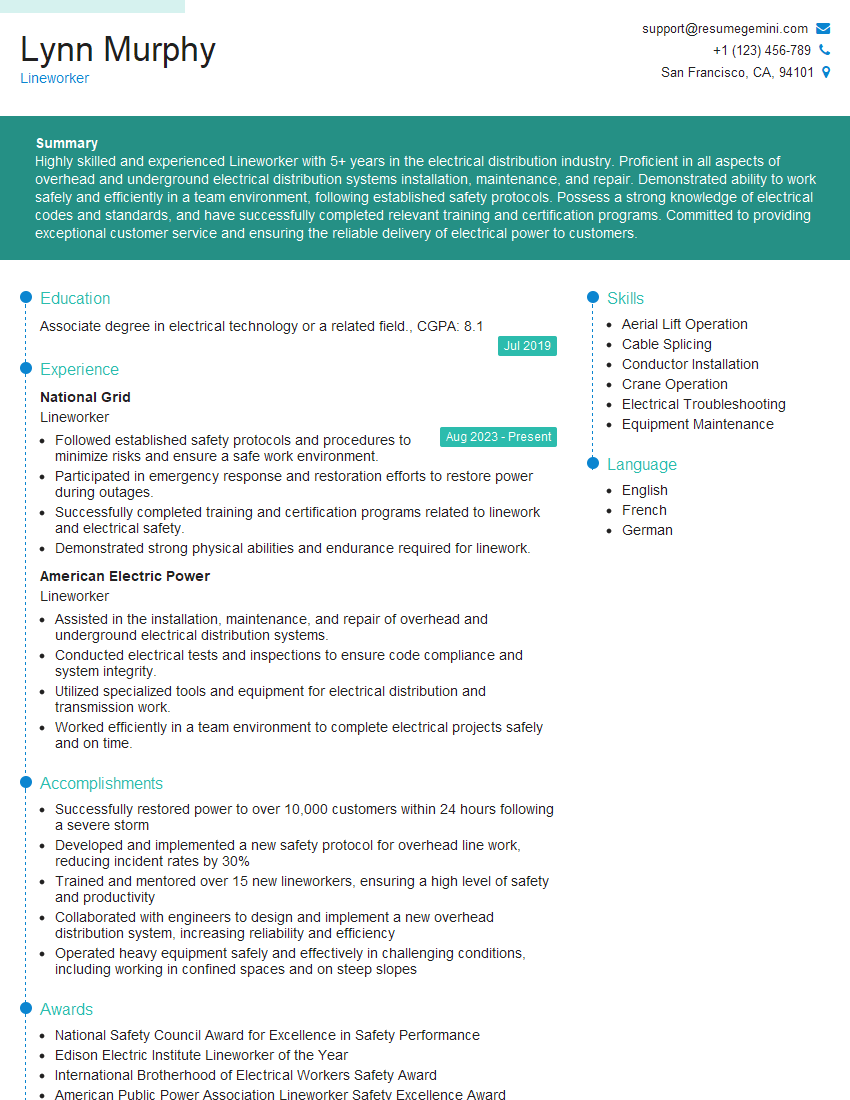

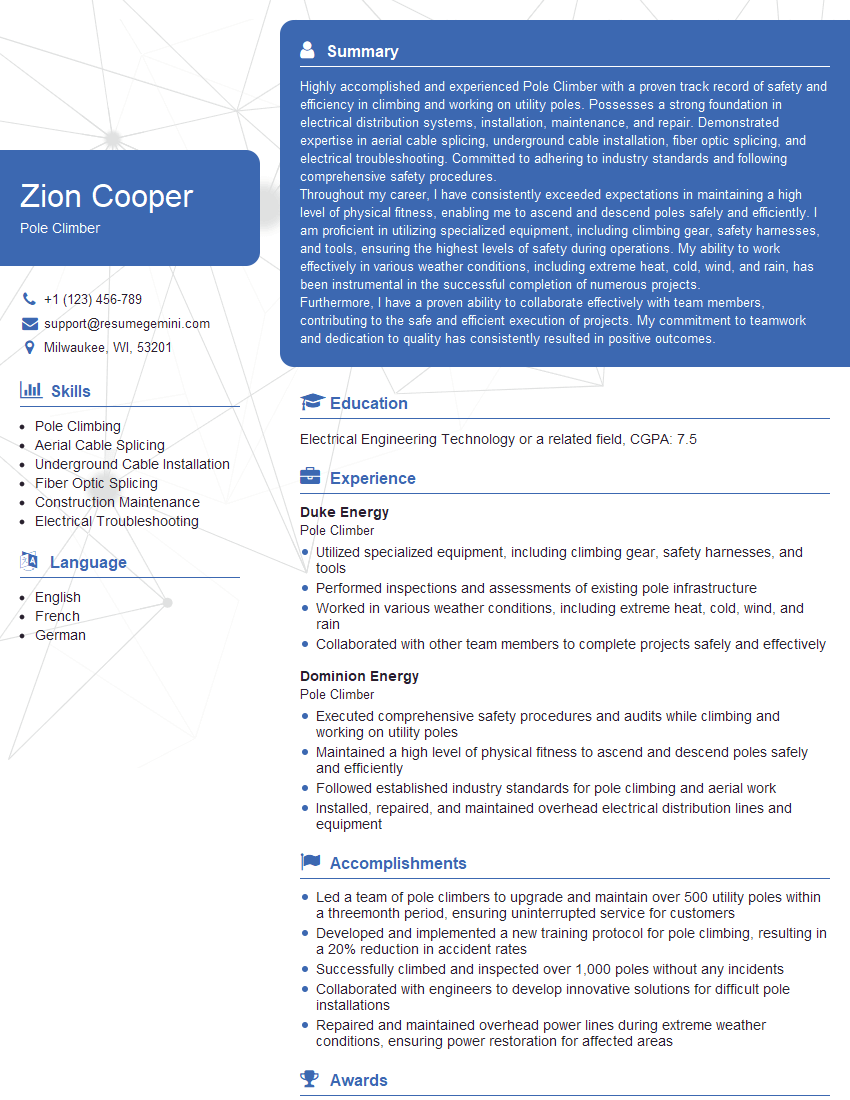

Mastering proper harnessing of public utility line equipment is crucial for career advancement in this field, demonstrating your commitment to safety and operational efficiency. A strong resume is essential to highlight your skills and experience to potential employers. To increase your chances of getting noticed by Applicant Tracking Systems (ATS), create an ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They even offer examples of resumes tailored to the Proper Harnessing of Public Utility Line Equipment field, providing you with a valuable template to model your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.