Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Proper Mixing, Dispensing, and Curing Processes interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Proper Mixing, Dispensing, and Curing Processes Interview

Q 1. Explain the importance of proper mixing ratios in a specific application.

Maintaining the correct mixing ratios is paramount for achieving the desired properties in any material. Think of baking a cake – if you don’t follow the recipe precisely, the outcome won’t be what you expect. In professional settings, deviations can have significant consequences. For example, in epoxy resin applications, an incorrect resin-to-hardener ratio can lead to insufficient curing, resulting in a weak, brittle, or even sticky final product. Let’s consider a specific application: creating a high-strength composite material using carbon fiber and epoxy resin. A typical ratio might be 100 parts resin to 35 parts hardener by weight. If you add too much hardener, the mixture might cure too quickly, leading to trapped air bubbles and reduced strength. Too little hardener, and the curing process might be incomplete, resulting in a weak, unreacted product. Precise measurement using scales and careful mixing are vital to guarantee consistent performance and prevent costly rework.

Q 2. Describe different dispensing methods and their suitability for various materials.

Dispensing methods vary greatly depending on the material’s viscosity, required precision, and volume. For low-viscosity fluids like paints or some adhesives, simple gravity-fed systems or pressurized spray guns might suffice. For more viscous materials or applications requiring high precision, automated dispensing systems become necessary. These systems utilize pumps, valves, and controllers to deliver accurate and repeatable amounts. Here’s a breakdown:

- Gravity Feed: Simple, cost-effective, suitable for low-viscosity, non-hazardous materials. Think of a paint can with a small nozzle.

- Pressure Dispensing: Uses compressed air or a pump to dispense material, useful for higher-viscosity liquids or when faster dispensing rates are needed. Cartridges are often used here for precise volumes.

- Automated Dispensing Systems: Offer precise control over the amount and location of dispensing. Ideal for high-volume production, intricate applications, or hazardous materials. These are programmable and can use robots for consistent placement.

- Syringe Dispensing: Provides exceptional control and accuracy, ideal for micro-dispensing or when handling very small volumes of expensive or sensitive materials.

The choice depends on factors such as material properties, application complexity, production volume, and budget.

Q 3. What are the key factors affecting the curing process?

The curing process, the transformation of a liquid material into a solid state, is influenced by several key factors. Temperature plays a crucial role: higher temperatures generally accelerate curing, while lower temperatures slow it down. The chemical composition of the material itself is critical; some materials cure faster than others. Humidity can also significantly affect curing, especially for materials that are moisture-sensitive. The presence of catalysts or accelerators can dramatically shorten the curing time. Finally, the material’s mixing ratio, as discussed earlier, is a major factor; an improperly mixed material will not cure correctly. Imagine baking a cake again: oven temperature (heat), the ingredients (chemical composition), and the mixing of the batter all directly impact the final result.

Q 4. How do you ensure the quality of mixed materials before dispensing?

Ensuring the quality of mixed materials before dispensing is crucial to prevent defects in the final product. Visual inspection is the first step: look for lumps, air bubbles, or color inconsistencies that might indicate improper mixing. For more rigorous quality control, we can use techniques like viscosity measurements. A viscometer can quantitatively assess the material’s flow properties, helping to identify deviations from the expected values and indicating whether the mixing process was successful. We can also use specialized tests like density measurements or even small-scale cure tests to verify the material’s properties before dispensing large batches. A small sample can be cured under controlled conditions to check if the curing time and final properties align with expectations. Addressing any discrepancies early in the process prevents large-scale failures and minimizes waste.

Q 5. What are the potential consequences of improper mixing?

Improper mixing can lead to a cascade of negative consequences. The most obvious is a failure to achieve the desired material properties – resulting in a weaker, less durable, or less functional product. For instance, incomplete curing in an adhesive could lead to structural failure of a bonded assembly. Inaccurate mixing can also result in uneven curing, leading to internal stresses and cracks in the finished product. Furthermore, inconsistencies in the material can affect its appearance and color uniformity. In some cases, improper mixing might even produce hazardous byproducts, posing safety risks. Think of a situation where an improperly mixed two-part adhesive releases toxic fumes during curing. All of these consequences can lead to costly rework, material waste, and potentially safety hazards.

Q 6. How do you monitor and control the curing temperature and time?

Monitoring and controlling curing temperature and time are critical to ensure complete and consistent curing. This is often achieved using environmental chambers or ovens with precise temperature control. Sensors placed within the material or the curing chamber monitor the temperature continuously, and this data is recorded for later analysis. The curing time can be controlled by adjusting the temperature and by using timers, ensuring that the material is held at the optimal temperature for the required duration. For instance, we might use a programmable logic controller (PLC) to precisely manage the temperature profile of a curing oven over time. Data loggers record all temperature and time data for documentation and quality assurance. Deviation from the specified parameters could indicate a problem with the curing process, requiring investigation and corrective action.

Q 7. What safety precautions are essential during mixing and dispensing?

Safety is paramount during mixing and dispensing. Many materials used in these processes can be hazardous – some are irritants, others are flammable, and some might be toxic. Therefore, appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators are crucial. Proper ventilation is also essential to prevent the buildup of harmful fumes. When working with flammable materials, all ignition sources should be eliminated. The workplace should be clean and well-organized to minimize the risk of accidents. Material Safety Data Sheets (MSDS) must be readily available and understood by all personnel involved. Finally, regular training and adherence to strict safety protocols are critical to prevent injuries and ensure a safe working environment.

Q 8. Describe your experience with different types of mixing equipment.

My experience spans a wide range of mixing equipment, from simple hand-held mixers for small-batch applications to highly automated, computer-controlled systems for large-scale production. I’m proficient with various types, including:

- High-shear mixers: These are excellent for achieving homogenous mixtures, especially with high-viscosity materials or those containing dispersed phases. I’ve used them extensively in creating composite materials, where uniform distribution of fillers is crucial for performance.

- Static mixers: These offer a continuous mixing process without moving parts, making them ideal for inline mixing in production lines. Their low maintenance and energy efficiency are key advantages. I’ve utilized these in handling sensitive materials susceptible to shear degradation.

- Planetary mixers: These provide thorough mixing by rotating the mixing tools while simultaneously rotating the bowl, resulting in a very consistent mixture. I’ve found them particularly useful for mixing viscous pastes and dough-like materials in the food and cosmetic industries.

- Vacuum mixers: Essential for degassing materials, removing trapped air bubbles that can compromise the final product’s integrity and appearance. I’ve applied this in applications ranging from adhesives to polyurethane foams.

My selection of equipment always depends on factors like material properties (viscosity, reactivity), batch size, desired mixing intensity, and production throughput. I am always assessing the most efficient and effective method for each project.

Q 9. How do you troubleshoot issues related to incomplete curing?

Troubleshooting incomplete curing often involves a systematic approach. First, I analyze the affected material for visual signs like softness, tackiness, or discoloration. Next, I carefully examine the process parameters. Incomplete curing is usually a consequence of one or more of the following:

- Insufficient curing agent: The most common cause. I verify the correct ratio of resin to curing agent was used and that the dispensing system accurately measured and delivered the components.

- Improper mixing: Inadequate mixing leads to uneven distribution of the curing agent, resulting in areas that don’t cure completely. Thoroughness is critical, and this often requires testing to optimize the mixing process and time.

- Incorrect temperature/humidity conditions: Many curing reactions are highly temperature and humidity-sensitive. Checking and adjusting these parameters are crucial. Environmental controls within specific ranges are essential.

- Contamination: Impurities in the raw materials can inhibit the curing reaction. I might investigate the source materials and test for contaminants.

- Curing agent degradation: The curing agent might have degraded due to age or improper storage. Fresh material should always be used.

Once I’ve identified the problem area, I can adjust the process parameters or replace faulty components to address the issue. For instance, if insufficient mixing is the culprit, I might increase the mixing time or choose a more powerful mixer. If temperature is an issue, I might need to adjust the curing environment or employ a different curing method.

Q 10. Explain the concept of viscosity and its relevance to mixing and dispensing.

Viscosity is a measure of a fluid’s resistance to flow. Think of honey versus water; honey has a much higher viscosity. In mixing and dispensing, viscosity is paramount because it significantly impacts the mixing efficiency and the ability to dispense the material accurately and consistently.

High-viscosity materials require more energy to mix properly and may necessitate specialized equipment like high-shear mixers to overcome their resistance. Inaccurate dispensing can occur because it’s difficult to reliably control the flow. Imagine trying to dispense thick paint from a container — it’s much harder than dispensing thinner liquids.

Low-viscosity materials, on the other hand, might be easier to mix but could be prone to air entrapment or splashing during mixing and dispensing. For example, many low-viscosity liquids need to be degassed and carefully poured or pumped to avoid issues.

Therefore, understanding the viscosity of a material is critical for selecting the appropriate mixing and dispensing equipment and optimizing the process parameters to achieve the desired outcome and prevent defects in the final product.

Q 11. What are the different types of curing agents and their applications?

Curing agents initiate and accelerate the hardening or polymerization process in many materials, transforming them from a liquid or semi-liquid state into a solid. They come in several forms:

- Peroxides: Commonly used with unsaturated polyester resins, vinyl esters, and some silicones. They initiate free-radical polymerization, resulting in a cross-linked network that forms a strong solid.

- Isocyanates: These react with polyols (polyhydroxy alcohols) to form polyurethane. They are used in many applications, including foams, coatings, and adhesives.

- Amines: Often employed with epoxy resins, acting as catalysts that accelerate the curing process. They initiate a reaction between the epoxy groups, leading to a rigid structure.

- UV initiators: Used for UV curing, these photo-initiators are activated by UV light and create a rapid cross-linking reaction, suitable for applications requiring fast curing.

The choice of curing agent depends on the base material, desired properties of the cured product (strength, flexibility, etc.), and the required curing time and conditions. For instance, when speed is crucial, UV curing is preferred, while applications requiring high heat resistance might utilize different chemistry.

Q 12. How do you ensure consistency in the mixing and dispensing process?

Consistency in mixing and dispensing is vital for achieving repeatable results and preventing product defects. To ensure this, I utilize several strategies:

- Precise metering: Employing accurate dispensing systems that ensure the correct ratio of components are measured and mixed. This usually involves calibrated pumps or automated dispensing equipment.

- Standardized procedures: Creating and adhering to strict written procedures outlining the mixing steps, mixing times, speeds, and dispensing methods. This reduces variability introduced by human error.

- Regular equipment calibration and maintenance: Periodic calibration of dispensing equipment and regular maintenance of mixers is essential. Equipment wear and tear, even slight, can affect the accuracy and consistency of the operation.

- In-process quality control: Implementing in-line quality control measures, such as viscosity checks, during the mixing and dispensing processes. This allows for immediate corrections if any deviations are detected.

- Environmental control: Maintaining a consistent temperature and humidity in the mixing and curing environments. These parameters can heavily affect the curing process, so stability is essential.

By implementing these measures, I can reduce process variability and ensure the consistent production of high-quality, defect-free products.

Q 13. Explain your understanding of different curing methods (e.g., UV, thermal).

Different curing methods utilize varying energy sources to initiate and complete the polymerization process:

- Thermal curing: This is the most common method, involving heat application to accelerate the curing reaction. This heat can be provided using ovens, hot plates, or even ambient temperature, depending on the specific material and its curing kinetics. The temperature and time of curing are critical parameters.

- UV curing: Utilizes ultraviolet (UV) light to activate photoinitiators within the material, causing a rapid polymerization reaction. This method is advantageous for its speed and energy efficiency, making it suitable for high-throughput applications. However, UV penetration depth can be limiting for thicker materials.

- Electron beam (EB) curing: A radiation-based curing method that generates high-energy electrons that initiate polymerization. This is typically used for thicker coatings and materials needing faster cure times and high cross-linking density.

The choice of curing method significantly impacts the production cycle, energy consumption, and final product properties. Each method has its own strengths and weaknesses, and the optimal choice depends on the material, application, and production requirements.

Q 14. How do you handle material waste during mixing and dispensing?

Material waste management is a crucial aspect of responsible manufacturing. My approach involves a multi-pronged strategy:

- Minimizing waste at the source: Accurate measurement and dispensing techniques are vital to minimizing material waste. Properly calibrated equipment and well-defined procedures help prevent excessive use or spillage.

- Recycling and reuse: Whenever feasible, I explore the possibility of recycling or reusing leftover materials, especially in small-batch processes. This can depend on material compatibility, shelf life, and potential for degradation.

- Proper disposal: Unusable or contaminated materials are disposed of according to all relevant safety regulations and environmental guidelines. This may include specialized waste disposal services for hazardous materials.

- Inventory management: Efficient inventory management minimizes the risk of material spoilage or expiration. Tracking consumption and usage patterns help maintain optimal stock levels.

Environmental considerations are paramount. My goal is to minimize waste generation and ensure responsible disposal of materials throughout the mixing and dispensing process.

Q 15. Describe your experience with quality control testing in relation to cured materials.

Quality control testing of cured materials is crucial to ensure the final product meets the required specifications and performs as expected. My experience involves a multi-stage approach, starting with visual inspection for defects like air bubbles, cracks, or inconsistencies in color or texture. This is followed by more rigorous testing depending on the material and application. For instance, we might conduct tensile strength tests to measure the material’s resistance to stretching, flexural strength tests to assess its resistance to bending, and hardness tests to determine its resistance to indentation. We also employ non-destructive testing methods like ultrasonic testing to detect internal flaws without damaging the sample. Data is meticulously documented and compared against pre-defined acceptance criteria. In one project involving a high-performance epoxy adhesive, we discovered a batch with unexpectedly low tensile strength. Through thorough investigation, we traced the issue to a slight deviation in the curing temperature during the manufacturing process. This highlighted the importance of precise process control throughout the entire production cycle.

Beyond mechanical properties, we also assess chemical resistance, thermal stability, and dimensional stability. The specific tests chosen depend heavily on the intended use of the cured material. For example, a material destined for outdoor use might require additional weathering tests to evaluate its resistance to UV degradation. This comprehensive approach ensures that our cured materials consistently meet quality standards and customer expectations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of mixing errors and how do you prevent them?

Mixing errors are common pitfalls in material processing, often stemming from inaccuracies in measurement, improper mixing techniques, or inadequate equipment. Some common causes include:

- Inaccurate Measurement: Using incorrect scales or imprecise measuring tools can lead to inaccurate ratios of components, significantly impacting the final material properties. Imagine baking a cake – if you use too much baking soda, the cake will rise too much and be undesirable.

- Improper Mixing Technique: Insufficient mixing can result in uneven distribution of components, leading to inconsistencies in the cured material. Think of mixing paint; you need to thoroughly blend all the components to get a consistent color.

- Contamination: Introduction of foreign materials into the mix, such as dust or moisture, can negatively affect the reaction and final properties. This is like adding salt to a sweet dessert, completely changing the taste.

- Equipment Malfunction: Faulty mixers or dispensing equipment can lead to inconsistent mixing and dispensing volumes.

Preventing these errors involves a systematic approach: Employing calibrated instruments, adhering to strict mixing protocols (time, speed, and sequence), ensuring a clean and controlled environment, regularly maintaining and calibrating equipment, and thorough operator training. Implementing a robust quality control system, including regular checks of raw materials and in-process materials, is vital in minimizing the risks associated with mixing errors.

Q 17. How do you calculate the required quantities of materials for a specific application?

Calculating material quantities requires a thorough understanding of the application and the material’s properties. The process typically starts with determining the volume or area to be filled. For instance, if we’re filling a mold, we need to know its precise dimensions. Next, we consult the material’s technical data sheet, which provides information on its mix ratio (e.g., resin:hardener = 10:1 by weight or volume) and its density. This allows us to calculate the mass or volume of each component needed.

Let’s say we need to fill a mold with a volume of 1000 cm³ and the material has a mix ratio of 2:1 (Component A: Component B by volume) and a density of 1.2 g/cm³. First, we calculate the total volume of the mixture: 1000 cm³. Since the ratio is 2:1, we divide the total volume by 3 (2+1) to get the volume of Component B: 1000 cm³ / 3 ≈ 333.33 cm³. The volume of Component A is twice this: 666.67 cm³. We then convert volume to mass using density: Mass of A = 666.67 cm³ * 1.2 g/cm³ = 800 g, and Mass of B = 333.33 cm³ * 1.2 g/cm³ = 400 g. This detailed calculation ensures that we have the correct quantities of each component, leading to consistent and predictable results.

Q 18. Explain your understanding of material safety data sheets (MSDS).

Material Safety Data Sheets (MSDS), now often referred to as Safety Data Sheets (SDS), are crucial documents providing comprehensive information on the hazards associated with a chemical product and how to handle it safely. They are essential for ensuring worker safety and environmental protection. An SDS typically contains information on the product’s physical and chemical properties, potential health hazards (acute and chronic), flammability, reactivity, and necessary precautions during handling, storage, and disposal. They also include emergency procedures and first-aid measures.

My understanding extends beyond simply reading an SDS. I use this information to develop and implement safe work practices. This includes selecting appropriate personal protective equipment (PPE) like gloves, eye protection, and respirators; establishing safe storage procedures to prevent spills or contamination; and ensuring proper ventilation in the work area. For instance, when working with isocyanates (found in some polyurethane systems), understanding the SDS is paramount to implement the necessary precautions to prevent respiratory problems. Ignoring SDS information can have severe health and safety consequences, which is why I consider it a foundational aspect of my work.

Q 19. How do you identify and address variations in material properties?

Variations in material properties can arise from various sources, including changes in raw material composition, environmental factors (temperature, humidity), and inconsistencies in the manufacturing process. Identifying these variations requires a combination of careful observation, testing, and data analysis. We use statistical process control (SPC) techniques to monitor material properties over time, looking for trends and outliers. For example, we might track the viscosity of a resin batch throughout the production process. Deviations from the expected range trigger an investigation.

Addressing variations involves identifying the root cause. This might involve checking the quality of raw materials, adjusting processing parameters, or recalibrating equipment. In one instance, we noticed variations in the cure time of an epoxy resin. By analyzing data and conducting further testing, we traced the problem to fluctuations in the ambient temperature during the curing process. Implementing a temperature-controlled curing chamber solved the issue. Documenting all findings and corrective actions is crucial to prevent recurrence and improve process consistency.

Q 20. Describe your experience with automated mixing and dispensing systems.

I have extensive experience with automated mixing and dispensing systems, having worked with various types of equipment, including piston pumps, gear pumps, and volumetric dispensers. These systems offer advantages in terms of precision, repeatability, and efficiency compared to manual mixing. Automated systems allow for precise control over the mixing parameters such as speed, time, and temperature. They can also handle hazardous materials more safely by reducing human exposure. The use of programmable logic controllers (PLCs) enables precise control of the entire process, ensuring consistency from batch to batch.

In a previous role, we implemented an automated mixing system for a high-volume production line of two-part adhesives. This resulted in a significant reduction in material waste, increased productivity, and improved consistency in the final product quality. The system also incorporated features like automatic cleaning cycles, reducing downtime and ensuring the absence of cross-contamination between batches.

Q 21. How do you maintain and calibrate mixing and dispensing equipment?

Maintaining and calibrating mixing and dispensing equipment is crucial for ensuring accuracy and reliability. A regular maintenance schedule includes visual inspections to detect wear and tear, cleaning procedures to remove residue and prevent contamination, and lubrication of moving parts. We use calibrated instruments to verify the accuracy of dispensing volumes and mixing speeds. Calibration procedures follow established protocols and traceable standards. Calibration logs and maintenance records are meticulously maintained to ensure compliance with regulations and internal quality control standards.

For instance, we regularly calibrate our piston pumps using precision volumetric glassware. Any deviations from the expected values trigger adjustments or repairs. Regular maintenance prevents costly downtime and ensures consistent product quality. Neglecting maintenance can lead to inaccurate dispensing, inconsistent mixing, and ultimately, inferior final product quality.

Q 22. What are the effects of temperature and humidity on the curing process?

Temperature and humidity significantly impact the curing process, primarily affecting the reaction rate and the final properties of the cured material. Think of it like baking a cake – too low a temperature and it won’t cook properly; too high and it burns. Similarly, with curing:

Temperature: Higher temperatures generally accelerate the curing reaction, leading to faster cure times. However, excessively high temperatures can lead to uneven curing, internal stresses, and reduced mechanical properties. Lower temperatures slow down the reaction, potentially resulting in incomplete curing or longer cure times. The optimal temperature is usually specified by the resin manufacturer and depends on the specific resin system.

Humidity: Humidity can affect curing, especially for moisture-sensitive resins. High humidity can introduce water into the system, hindering the curing reaction or leading to undesirable byproducts. This can result in weakened material, poor adhesion, and even complete failure. In some cases, controlled humidity environments are needed to ensure consistent and reliable curing.

For instance, epoxy resins are particularly sensitive to humidity. Working in a controlled environment with low humidity is crucial to ensure proper cure and avoid issues like bubbling or poor adhesion.

Q 23. Describe a time you encountered a problem during mixing or curing and how you solved it.

During a large-scale project involving a UV-curable resin, we experienced inconsistent curing depths. Some areas were fully cured, while others remained tacky. We initially suspected a problem with the UV lamp intensity. However, after careful investigation, we discovered the issue stemmed from variations in the resin’s viscosity due to improper mixing. The resin had two components that needed to be mixed in a precise ratio with thorough agitation. We had relied on visual inspection to judge proper mixing, which proved insufficient.

To solve the problem, we implemented a two-pronged approach:

Improved Mixing Protocol: We introduced a standardized mixing procedure using a calibrated mixing machine with a timed cycle. This ensured consistent mixing of both components. We also implemented a visual inspection checklist to help us detect any inconsistencies in the mixture’s appearance.

Quality Control Testing: We added viscosity testing of the mixed resin before dispensing it using a rotational viscometer. This ensured consistent viscosity across batches and caught any mixing errors before they reached the curing stage.

By implementing these changes, we resolved the inconsistent curing depth issue, resulting in consistently cured parts meeting project specifications.

Q 24. How do you ensure the accuracy of measurements during mixing and dispensing?

Accuracy in measurements is paramount in mixing and dispensing. Even small variations in ratios can significantly affect the final product’s properties. We use several techniques to ensure precise measurements:

Calibrated Equipment: We exclusively use calibrated scales, graduated cylinders, and other volumetric measuring devices. These are regularly checked and recalibrated to ensure accuracy. We maintain detailed calibration logs to document these checks.

Automated Dispensing Systems: For larger projects or when consistency is critical, we utilize automated dispensing systems that precisely meter the required amounts of each component. These systems reduce human error and enhance repeatability.

Multiple Measurements and Verification: We frequently perform multiple measurements and cross-check them to minimize errors. A second person often verifies measurements, especially for critical applications.

Proper Cleaning and Maintenance: Thorough cleaning of all equipment after each use is crucial. Residual materials can affect subsequent measurements, leading to inaccuracies.

For instance, when mixing epoxy resin, a small deviation in the hardener-to-resin ratio can drastically alter the final cured material’s strength and curing time.

Q 25. What are your strategies for optimizing the curing process for faster turnaround times?

Optimizing the curing process for faster turnaround times requires a multi-faceted approach:

Elevated Temperature Curing: Increasing the temperature can significantly reduce curing times. However, this requires careful consideration to avoid overheating and potential damage. This is often coupled with precise temperature control using ovens or heated chambers.

Pressure Assisted Curing: Applying pressure during the curing process can accelerate the reaction rate, leading to faster cure times. This is common in specific applications such as resin transfer molding.

Catalytic Additives: Certain additives can act as catalysts, accelerating the curing reaction without significantly altering the final properties of the cured material. The selection of these additives is crucial and needs to be tailored to the specific resin system.

Improved Mixing and Degassing: Efficient mixing and removal of air bubbles can allow for more consistent resin penetration and faster curing. This can be achieved through vacuum degassing or using optimized mixing techniques.

Process Optimization Software: Software can simulate and optimize the curing process, helping determine the ideal conditions for faster curing without sacrificing quality.

For example, in a production environment, even a small reduction in curing time can significantly increase throughput and reduce overall production costs.

Q 26. Explain your experience with different types of resins or polymers and their associated mixing and curing processes.

My experience spans various resin and polymer systems, each with unique mixing and curing characteristics:

Epoxy Resins: These are two-part systems requiring precise mixing ratios. Curing is typically thermally activated, with variations in temperature significantly affecting the cure time and final properties. I’ve worked with various epoxy formulations, from low viscosity resins suitable for infiltration to high-strength structural adhesives.

Polyurethane Resins: Polyurethanes are also commonly two-part systems, but the chemistry differs from epoxies. They exhibit different reactivity and cure profiles. I’ve used them in applications ranging from flexible coatings to rigid foams, where precise control over reaction parameters is essential.

UV-Curable Resins: These resins cure rapidly upon exposure to ultraviolet light, making them ideal for high-speed applications. However, maintaining consistent UV intensity is crucial for even curing. I’ve used these resins in various applications such as 3D printing and coating.

Acrylic Resins: Acrylics are versatile and offer different curing mechanisms, such as thermal curing or UV curing. Their properties can be tailored for various applications, requiring adjustments to the mixing and curing processes to achieve optimal results.

Understanding the specific chemistry of each resin system is crucial for determining the appropriate mixing, dispensing, and curing methods to ensure optimal performance.

Q 27. How do you document and track your work related to mixing, dispensing, and curing?

Detailed documentation and tracking are vital for ensuring quality and repeatability. My approach involves:

Batch Records: Each batch of mixed resin is meticulously documented, including the date, time, materials used, quantities, mixing method, and any observations during the mixing process. This information is crucial for tracing any issues back to their source.

Process Parameters Log: We record all parameters relevant to the curing process, such as temperature, pressure, humidity, UV intensity (if applicable), and cure time. This allows for thorough analysis and optimization of the process.

Quality Control Testing Data: We perform regular quality control tests (e.g., viscosity, hardness, tensile strength) on the cured material and document the results. This provides evidence of compliance with specifications and helps identify potential problems.

Digital Database: We utilize a digital database system to store all this information securely and efficiently, making it readily accessible for analysis and reporting.

This comprehensive documentation is not only essential for quality control but also for regulatory compliance in various industries.

Q 28. What are the environmental considerations related to mixing, dispensing, and curing processes?

Environmental considerations are crucial throughout the mixing, dispensing, and curing processes:

Volatile Organic Compounds (VOCs): Many resins and their curing agents release VOCs, which can have harmful effects on human health and the environment. We utilize low-VOC or VOC-free materials wherever possible, and employ adequate ventilation to minimize exposure.

Waste Management: Proper disposal of waste materials, including uncured resin and used solvents, is crucial. We adhere to all relevant environmental regulations and employ safe disposal practices.

Energy Consumption: The curing process, particularly those involving elevated temperatures or UV lamps, consumes energy. We seek energy-efficient equipment and processes to minimize our environmental footprint.

Hazardous Material Handling: Many resins and their components are hazardous materials. We strictly adhere to safety protocols for handling and storage, utilizing proper personal protective equipment (PPE).

Sustainability is a key aspect of our operations. We continually strive to improve our processes to minimize environmental impact while maintaining high-quality results.

Key Topics to Learn for Proper Mixing, Dispensing, and Curing Processes Interview

- Material Properties and Selection: Understanding the characteristics of different materials used in mixing and their impact on the final product. This includes considerations of viscosity, reactivity, and compatibility.

- Mixing Techniques and Equipment: Familiarize yourself with various mixing methods (e.g., high-shear, low-shear, vacuum mixing) and the types of equipment used in each process. Be prepared to discuss the advantages and disadvantages of each.

- Dispensing Methods and Precision: Mastering accurate and efficient dispensing techniques is crucial. Understand different dispensing methods and their application based on material properties and desired outcome. This includes considerations for minimizing waste and maintaining consistency.

- Curing Principles and Optimization: Learn about the chemical and physical changes that occur during the curing process. Understand how factors like temperature, humidity, and time affect curing and the resulting product properties. Be prepared to discuss methods for optimizing the curing process.

- Quality Control and Testing: Explore various quality control measures used to ensure proper mixing, dispensing, and curing. Familiarize yourself with relevant testing methods to verify the quality and consistency of the final product.

- Troubleshooting and Problem-Solving: Develop your ability to identify and resolve common problems that can arise during mixing, dispensing, and curing. Consider scenarios like incomplete mixing, improper curing, or inconsistencies in the final product.

- Safety Procedures and Regulations: Understand and be prepared to discuss relevant safety protocols and industry regulations related to handling and processing the materials involved.

- Documentation and Record Keeping: Understand the importance of accurate and detailed record-keeping throughout the entire process. This includes batch numbers, material specifications, and process parameters.

Next Steps

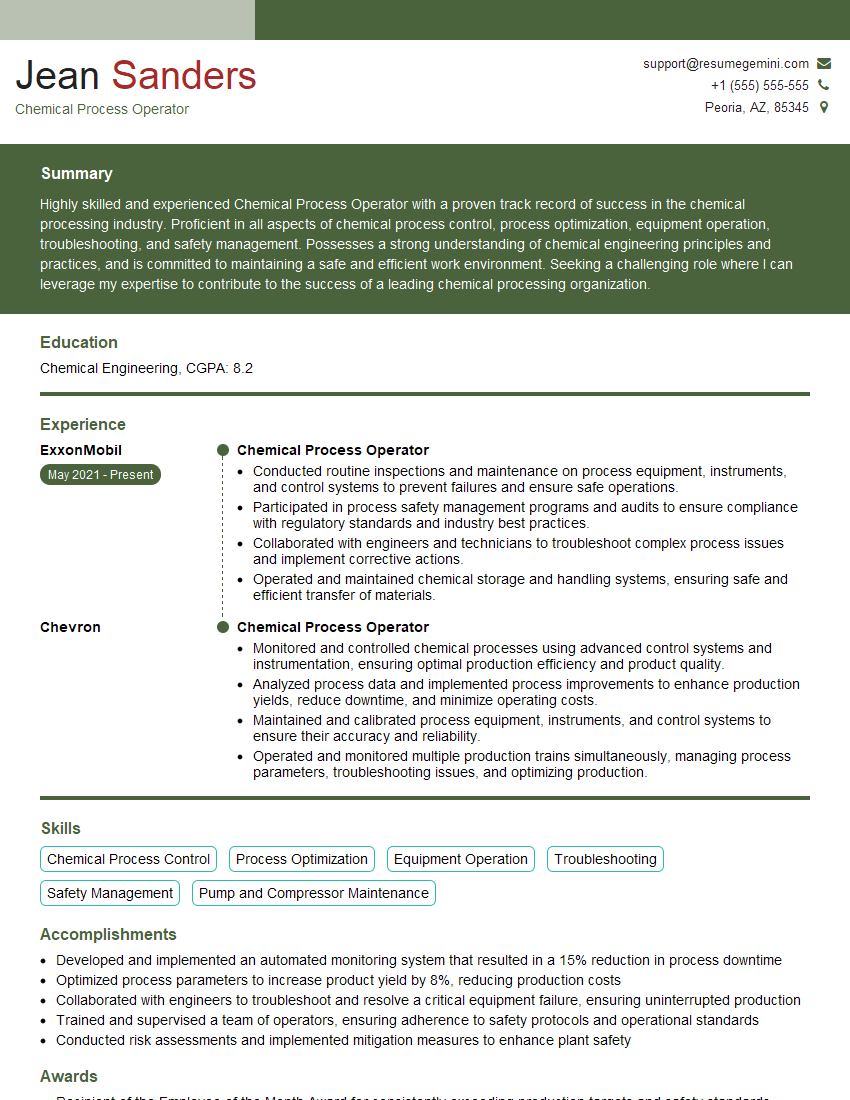

Mastering proper mixing, dispensing, and curing processes is essential for career advancement in many fields. A strong understanding of these processes demonstrates your technical expertise and problem-solving skills, making you a highly valuable asset to any team. To showcase your skills effectively, invest time in creating a professional and ATS-friendly resume. ResumeGemini is a trusted resource that can help you build a compelling resume that highlights your qualifications. ResumeGemini offers examples of resumes tailored to the Proper Mixing, Dispensing, and Curing Processes industry, providing you with a strong foundation for building your own successful application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.