The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Pulp Handling interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Pulp Handling Interview

Q 1. Describe your experience with different pulp handling equipment.

My experience with pulp handling equipment spans a wide range, encompassing both traditional and modern technologies. I’ve worked extensively with various types of pulp handling equipment, including:

- Hydrapulpers: These are crucial for defibrating and preparing pulp for processing. I’ve overseen their operation and maintenance, ensuring optimal performance and minimizing downtime.

- High-consistency Refiners: I have hands-on experience with these machines, responsible for refining the pulp fibers to achieve the desired properties. Understanding the impact of refining parameters on final product quality is vital, and I’ve honed that skill over years of experience.

- Pulp Stock Pumps and Valves: Efficient and reliable pumping and valving systems are critical for controlled pulp flow. I’ve managed systems, troubleshooting problems, and implementing preventative maintenance strategies to prevent disruptions.

- Thickening and Dewatering Equipment: I’m familiar with various methods like vacuum filters and presses, essential for managing pulp consistency and preparing it for storage or transportation. I understand the energy efficiency considerations and optimizing these processes for cost-effectiveness.

- Automated Systems: My expertise includes working with modern computerized control systems for pulp handling, enabling optimized and efficient operation.

In one particular project, I was instrumental in optimizing the hydrapulper’s operation, leading to a 15% increase in throughput and a significant reduction in energy consumption. This involved careful analysis of operational parameters, and implementing targeted adjustments to enhance performance.

Q 2. What are the common safety hazards associated with pulp handling?

Pulp handling presents several significant safety hazards, requiring stringent adherence to safety protocols. These hazards include:

- Mechanical Hazards: Rotating equipment like refiners and pumps pose risks of entanglement and crushing injuries. Regular inspections, lockout/tagout procedures, and appropriate personal protective equipment (PPE) are crucial.

- Chemical Hazards: Pulp and paper mills often use chemicals in the pulping process. Exposure to these chemicals can cause skin irritation, respiratory problems, or other health issues. Proper ventilation, protective clothing, and stringent handling procedures are mandatory.

- Electrical Hazards: Malfunctioning electrical equipment can lead to electric shocks or fires. Regular maintenance, ground fault circuit interrupters (GFCIs), and adherence to electrical safety regulations are paramount.

- Slips, Trips, and Falls: Wet and slippery surfaces are common in pulp mills, increasing the risk of slips, trips, and falls. Good housekeeping, proper lighting, and the use of non-slip footwear are essential for accident prevention.

- Dust Inhalation: Wood dust and other airborne particles can cause respiratory problems. Proper ventilation, respiratory protection (e.g., respirators), and dust suppression techniques are necessary to mitigate this risk.

Safety training, regular safety audits, and a strong safety culture are vital for minimizing these risks. I always emphasize proactive safety measures rather than reactive approaches.

Q 3. Explain the different types of pulp and their characteristics.

Pulp is broadly classified into different types based on the raw materials and pulping processes used. Key distinctions include:

- Kraft Pulp (Sulfate Pulp): This is a strong, versatile pulp made using a kraft process, known for its high strength and resistance to degradation. It’s widely used in packaging and corrugated board.

- Sulfite Pulp: Produced via the sulfite process, this pulp is brighter and softer than kraft, but it’s less resistant to degradation. It’s often used in paper for writing and printing.

- Mechanical Pulp (Groundwood Pulp): Made by grinding wood, this pulp is relatively inexpensive but has lower strength and durability compared to chemical pulps. It’s commonly used in newsprint and low-grade papers.

- Dissolving Pulp: This high-purity pulp is made to dissolve in solvents, used for making rayon, cellophane, and other cellulose products.

- Recycled Pulp: Made from recovered paper, this pulp is an environmentally friendly option. However, its quality and properties depend heavily on the source material and processing method.

Each pulp type exhibits unique characteristics in terms of fiber length, strength, brightness, and other properties, dictating its suitability for specific paper grades and applications. Understanding these characteristics is critical for effective pulp handling and processing.

Q 4. How do you ensure the quality of pulp during handling and storage?

Maintaining pulp quality during handling and storage requires a multi-faceted approach:

- Proper Storage Conditions: Pulp should be stored in a clean, dry environment to prevent contamination and degradation. Temperature and humidity control are crucial to avoid microbial growth or fiber degradation.

- Preventative Maintenance: Regular maintenance of handling equipment, such as pumps and pipelines, ensures consistent flow and prevents contamination.

- Regular Quality Checks: Frequent testing for properties like brightness, viscosity, and freeness helps in identifying any quality deviations early on. I’ve used advanced analytical techniques, including optical brighteners and fiber length analysis, for precise quality assessment.

- First-In, First-Out (FIFO) System: This inventory management system helps ensure that older pulp is used first, preventing long-term storage issues.

- Protection from Contamination: Avoiding cross-contamination between different pulp types is critical. Strict segregation and cleaning procedures are crucial.

In a past role, I implemented a new quality control system that led to a significant reduction in pulp rejection rates, improving efficiency and reducing waste.

Q 5. Describe your experience with pulp consistency control.

Pulp consistency control is critical for efficient and effective pulp processing. It refers to the amount of water present in the pulp, usually expressed as a percentage of solids. Maintaining the desired consistency is crucial for many aspects of pulp and paper manufacturing. My experience involves:

- Instrumentation and Measurement: I’m proficient in using various instruments to measure pulp consistency, such as online consistency meters and laboratory methods. Accurate measurements are critical to effective control.

- Process Control Strategies: I have experience implementing and optimizing different control strategies, including feedback control loops, to maintain the desired consistency levels throughout the processing steps. This often involves working with programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems.

- Troubleshooting and Optimization: I’ve dealt with situations where consistency deviations occur, identifying and fixing the underlying causes, which can range from equipment malfunctions to changes in raw materials.

- Understanding Process Dynamics: A thorough understanding of the relationships between various process variables and consistency is essential for effective control. This knowledge helps in anticipating and preventing consistency fluctuations.

For example, in one instance, I successfully resolved a persistent consistency issue by identifying a leak in a dilution system and implementing a precise repair, restoring consistent pulp quality to the production line.

Q 6. What are the different methods used for pulp transportation?

Pulp transportation methods vary depending on factors such as distance, volume, and pulp consistency:

- Pipelines: High-consistency pulp is often transported via pipelines, particularly within a mill complex or between nearby facilities. This method is efficient for large volumes.

- Tank Trucks: For shorter distances, tank trucks are a common method, often transporting pulp in a high-consistency state.

- Railroad Tank Cars: Suitable for long distances and large quantities, rail transport offers cost-effective solutions for pulp transportation.

- Ships: Ocean-going vessels are used for international transport of pulp, typically in a more diluted state to manage viscosity and handling aspects.

The choice of transportation method involves considering factors like cost, time, and the risk of pulp degradation. Ensuring the integrity of the pulp during transportation, using appropriate containment and avoiding contamination, is critical.

Q 7. How do you manage pulp inventory effectively?

Effective pulp inventory management is essential for smooth production and cost optimization. My approach involves:

- Accurate Inventory Tracking: Implementing a robust inventory management system, often computerized, to monitor pulp levels in real-time is essential. This provides an up-to-date overview of stocks on hand and future requirements.

- Demand Forecasting: Predicting future pulp demand allows for proactive procurement and storage planning. Accurate forecasting minimizes the risk of shortages or excessive stockpiles.

- Storage Optimization: Efficient storage practices, including proper stacking and organization, maximize available space and minimize degradation risks. FIFO is crucial here.

- Quality Control During Storage: Regular checks during storage help detect potential quality issues early on and take necessary actions to mitigate losses.

- Waste Reduction: Effective inventory management minimizes waste from obsolescence or degradation, leading to significant cost savings.

In my previous role, I implemented a new inventory management system that improved forecasting accuracy by 15%, reducing storage costs and preventing stockouts. This involved close collaboration with the production and procurement teams.

Q 8. Explain the process of pulp bleaching.

Pulp bleaching is a crucial step in papermaking, aiming to brighten the pulp and remove residual lignin, a complex polymer that gives wood its brown color and reduces paper strength and brightness. The process typically involves several stages, each using different bleaching agents. Historically, chlorine-based bleaching was common, but environmental concerns have driven a shift towards more environmentally friendly methods.

A common sequence involves using oxygen delignification, followed by stages using hydrogen peroxide, ozone, or chlorine dioxide. Oxygen delignification removes a significant portion of lignin under alkaline conditions. Subsequent stages, often referred to as ‘bleaching stages’, selectively remove the remaining lignin, enhancing brightness. The specific sequence and chemicals used depend on factors such as the type of pulp (e.g., kraft, sulfite), the desired brightness, and environmental regulations. For instance, Totally Chlorine-Free (TCF) bleaching uses no chlorine or chlorine-containing compounds, relying entirely on oxygen, hydrogen peroxide, and ozone.

Imagine it like cleaning a stained shirt. Oxygen delignification is like a pre-wash removing most of the dirt, while subsequent stages are like using specialized stain removers to achieve a pristine white.

Q 9. What are the environmental concerns related to pulp handling?

Pulp handling carries significant environmental implications. The production of pulp and paper is water-intensive, leading to potential water pollution from the discharge of process chemicals and wastewater. These discharges can contain dissolved organic matter, lignin, and residual bleaching chemicals, which can harm aquatic life. Air emissions from pulp mills also pose environmental concerns, including volatile organic compounds (VOCs) and greenhouse gases such as methane and carbon dioxide.

Furthermore, deforestation for pulpwood production contributes to habitat loss and biodiversity reduction. The use of chlorine-based bleaching agents historically contributed to the formation of dioxins and furans, highly toxic compounds. While TCF bleaching has greatly reduced this issue, the overall environmental impact needs continuous monitoring and improvement. Sustainable forest management practices and cleaner production technologies are essential to mitigate these concerns. Responsible pulp sourcing, supporting mills with robust environmental management systems, and actively reducing waste and emissions are crucial elements.

Q 10. Describe your experience with pulp refining and screening.

My experience with pulp refining and screening spans over ten years, encompassing various mill settings and technologies. Pulp refining is crucial for controlling the fiber properties, influencing the final paper’s strength, and improving the bonding between fibers. I’ve worked extensively with different refiner types, including conical refiners and disc refiners, optimizing their operation to achieve target freeness (a measure of the water content of the pulp). This involves adjusting the plate gap, refining consistency, and power consumption to achieve the desired fiber properties.

Screening is equally important, removing unwanted shives (unrefined wood fragments) and knots that would compromise the paper quality. I have hands-on experience with various screening systems, from primary screens to secondary screens and cleaners. Troubleshooting issues like screen plugging, poor screening efficiency, and maintaining optimal screen operation are part of my daily work. In one particular instance, we resolved a persistent screen plugging issue by optimizing the pulp consistency entering the screens and adjusting the screen plate vibrations, leading to a significant increase in production efficiency.

Q 11. How do you troubleshoot common problems in pulp handling?

Troubleshooting in pulp handling demands a systematic approach. I typically start by identifying the specific problem, whether it’s reduced production rate, pulp quality issues, or equipment malfunctions. I then gather data from various sources, such as process sensors, operator logs, and quality control reports. This data helps pinpoint the root cause of the problem.

For example, if the pulp consistency is too low, leading to reduced production, I might check the dilution water flow rate, the efficiency of the pulp pumps, or the consistency regulators. If the pulp strength is below specifications, I would investigate the refining conditions, the pulpwood quality, or potential issues in the chemical treatment processes. A structured approach, using control charts and process monitoring tools, is critical in identifying trends and preventing future problems. I always emphasize a collaborative approach, involving operators, maintenance personnel, and process engineers in the troubleshooting process.

Q 12. What are the key performance indicators (KPIs) for pulp handling operations?

Key Performance Indicators (KPIs) for pulp handling operations focus on efficiency, quality, and safety. These include:

- Production rate: Measured in tonnes per day or hour, this indicates the overall efficiency of the process.

- Pulp quality: This includes parameters like brightness, freeness, viscosity, and strength properties. These parameters are crucial for meeting customer requirements and ensuring consistent paper quality.

- Energy consumption: Monitoring energy usage per tonne of pulp produced helps in optimizing energy efficiency.

- Chemical consumption: Tracking chemical usage helps reduce costs and environmental impact. This includes bleaching chemicals, additives, and other process chemicals.

- Waste generation: Monitoring the amount of waste generated helps identify areas for improvement and reduction of environmental impact.

- Safety incidents: Tracking safety incidents and near misses is vital for maintaining a safe working environment.

Regular monitoring and analysis of these KPIs allow for timely interventions and process improvements. For example, a sudden drop in production rate might indicate a blockage in the pipeline, while consistently low pulp brightness may point to problems with the bleaching process.

Q 13. Explain the process of pulp drying.

Pulp drying is a critical process aimed at removing water from the pulp, typically to a moisture content of around 10%, making it suitable for storage and further processing. The most common method is using large cylindrical dryers, often arranged in a multi-stage configuration. The pulp is typically spread thinly onto a continuously moving wire mesh or fabric, and hot air or steam is used to evaporate the water. The heat transfer is efficient due to the large surface area.

Other drying methods include flash drying and air drying, each with its advantages and disadvantages. Flash drying involves rapidly drying the pulp using hot air in a short residence time, while air drying is a slower process, often used for specific types of pulp or in smaller-scale operations. The choice of drying method depends on several factors, such as pulp type, desired drying rate, and energy costs. Efficient drying is crucial to reduce energy consumption and ensure consistent pulp quality. Improper drying can lead to fiber damage, poor sheet formation, and reduced paper quality.

Q 14. Describe your experience with pulp stock preparation.

Pulp stock preparation involves preparing the pulp for the paper machine. This includes several steps to ensure that the pulp is at the correct consistency, freeness, and has the desired fiber properties. My experience encompasses various aspects of stock preparation, from handling and mixing different pulp types to adjusting the additives and controlling the consistency and freeness of the pulp mixture. It’s like preparing a recipe for baking a cake – each ingredient (different pulp types, additives) has its role and must be precisely measured and mixed to achieve the desired final product (paper).

This process involves the use of equipment like mixers, refiners, and consistency regulators. Precise control of these parameters is crucial for maintaining paper quality and uniformity. For example, improper mixing of different pulp grades could lead to uneven sheet formation and poor paper strength. I’ve been involved in optimizing stock preparation processes to reduce energy consumption and improve the uniformity of the pulp supply to the paper machine, leading to significant quality improvements and cost savings. It requires a deep understanding of the interrelationship between different parameters and their impact on the final paper quality.

Q 15. How do you maintain the efficiency of pulp handling systems?

Maintaining the efficiency of pulp handling systems requires a multi-faceted approach focusing on preventative maintenance, optimized processes, and skilled personnel. Think of it like keeping a well-oiled machine running smoothly.

- Preventative Maintenance: Regular inspections and scheduled maintenance of equipment, such as conveyor belts, pumps, and digesters, are crucial. Identifying and addressing minor issues before they escalate prevents costly downtime. For instance, regularly checking conveyor belt tension prevents slippage and material jams.

- Process Optimization: Analyzing the entire pulp handling workflow, from wood chipping to storage, helps identify bottlenecks. Implementing improvements, like automating certain processes or upgrading equipment, can significantly enhance efficiency. For example, using advanced sensors to monitor pulp consistency can optimize the digesting process.

- Personnel Training: Well-trained operators are essential. Regular training on safe operating procedures, troubleshooting, and preventative maintenance ensures smooth operations and minimizes errors. A skilled operator can quickly identify and resolve minor problems before they become major issues.

- Data Analysis: Utilizing data analytics to track key performance indicators (KPIs) like throughput, downtime, and energy consumption provides insights for improvement. Identifying trends allows for proactive adjustments to maximize efficiency. For example, tracking energy consumption can identify areas where energy-efficient technologies could be implemented.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the regulations and standards related to pulp handling?

Pulp handling is subject to a variety of regulations and standards, primarily focused on safety, environmental protection, and worker well-being. These vary by location but generally include:

- Occupational Safety and Health Administration (OSHA) regulations (USA): These cover worker safety aspects, including personal protective equipment (PPE), machine guarding, and emergency response procedures.

- Environmental Protection Agency (EPA) regulations (USA): These address air and water pollution control, waste management, and proper disposal of pulp mill by-products. This includes stringent regulations on wastewater treatment and air emissions.

- International Standards Organization (ISO) standards: Numerous ISO standards relate to quality management, environmental management, and occupational health and safety in the pulp and paper industry. These provide frameworks for best practices.

- Local and regional regulations: Specific regulations may exist at the state or local level regarding land use, zoning, and transportation of pulp materials.

Compliance with these regulations requires meticulous record-keeping, regular inspections, and adherence to strict safety protocols. Failure to comply can result in significant fines and legal repercussions.

Q 17. How do you handle pulp spills and other emergencies?

Handling pulp spills and other emergencies requires a well-defined emergency response plan and trained personnel. Think of it as a fire drill, but for pulp.

- Emergency Response Plan: This plan should detail procedures for different types of emergencies, including spills, equipment failures, and fires. It must clearly define roles, responsibilities, and communication protocols.

- Containment and Cleanup: Spills should be contained immediately using absorbent materials, and then cleaned up following environmental regulations. The type of absorbent material used will depend on the type of pulp and the environment.

- Personal Protective Equipment (PPE): Appropriate PPE, such as respirators, gloves, and eye protection, must be worn during cleanup operations to protect personnel from exposure to pulp and chemicals.

- Notification: Relevant authorities, such as environmental agencies and emergency services, must be notified immediately of any significant spill or incident.

- Post-Incident Investigation: After the incident, a thorough investigation should be conducted to identify the root cause, implement corrective actions, and prevent similar incidents from happening again.

Regular drills and training exercises are crucial to ensure personnel are prepared and can react effectively in an emergency.

Q 18. Describe your experience with different types of pulpwood.

My experience encompasses a wide range of pulpwood types, each with unique properties affecting handling and processing. The choice of wood significantly impacts the final pulp quality.

- Softwoods (e.g., pine, spruce, fir): These are commonly used for producing kraft pulp, known for its strength and long fibers. Handling requires care to avoid fiber damage during chipping and transportation.

- Hardwoods (e.g., eucalyptus, birch, aspen): Hardwoods are used for various pulps, including dissolving pulp (used for rayon and other textiles). They often require more intense processing to separate fibers.

- Recycled Pulp: This presents unique challenges due to potential contaminants and varying fiber lengths. Careful sorting and cleaning are vital to produce high-quality recycled pulp.

Understanding the properties of each wood type allows for tailoring the handling process to optimize efficiency and minimize damage. For example, hardwoods might require more robust chipping equipment compared to softwoods.

Q 19. How do you optimize the pulp handling process to minimize waste?

Minimizing waste in pulp handling requires a holistic approach, encompassing all stages of the process. Think of it as a continuous improvement cycle.

- Optimized Chipping: Precisely sized chips reduce the amount of fines (small, unusable wood particles) generated during chipping. This also improves pulping efficiency.

- Efficient Digesting: Optimizing the digesting process (temperature, time, chemicals) maximizes pulp yield and minimizes chemical usage. Monitoring parameters carefully allows for fine-tuning.

- Reduced Transportation Losses: Proper handling and secure transportation minimize pulp loss during transit. Careful loading and unloading procedures are critical.

- Wastewater Treatment: Effective wastewater treatment recovers valuable chemicals and minimizes environmental impact. Modern treatment plants achieve high recovery rates.

- Recycling and Re-use: Utilizing pulp mill by-products (e.g., bark, sludge) for energy generation or other applications reduces waste and promotes sustainability.

Continuous monitoring, data analysis, and process adjustments are crucial to achieve ongoing improvements in waste minimization.

Q 20. What are the different types of pulp digesters and their applications?

Several types of pulp digesters are used, each with specific applications and advantages. The choice depends on the type of pulp desired and economic factors.

- Batch Digesters: These are traditional digesters where wood chips and cooking liquor are loaded, cooked, and then emptied in batches. They are relatively simple but less efficient than continuous digesters.

- Continuous Digesters: Wood chips and cooking liquor are continuously fed into and out of these digesters, offering higher productivity and better process control. They are more complex but economically advantageous for large-scale production.

- Kamyr Digesters: A type of continuous digester known for its high efficiency and gentle cooking process, resulting in high-quality pulp. They are particularly suited for kraft pulping.

- Impingement Digesters: These digesters use high-pressure steam to cook wood chips, achieving rapid and efficient pulping. They are suitable for various pulping processes.

The selection of a digester type is a critical decision influenced by factors such as production capacity, pulp quality requirements, and capital investment costs.

Q 21. Describe your experience with pulp storage and warehousing.

Pulp storage and warehousing are crucial for maintaining pulp quality and ensuring smooth production. Proper storage prevents degradation and ensures consistent supply.

- Storage Facilities: These can range from simple open-air piles (for short-term storage) to sophisticated covered storage facilities or silos, designed to protect pulp from the elements and prevent contamination. The choice of storage depends on the type of pulp, storage duration, and climate.

- Material Handling: Efficient material handling systems (e.g., conveyor belts, cranes, stackers) are essential for moving pulp in and out of storage areas quickly and safely.

- Inventory Management: Precise inventory management is vital to ensure the availability of pulp while minimizing storage costs and preventing degradation. Modern inventory systems use sensors and tracking technologies for optimal management.

- Environmental Controls: Storage facilities may require environmental controls (e.g., temperature and humidity regulation) to maintain pulp quality, particularly for specialized pulps. This is important to prevent degradation and maintain consistency.

Proper pulp storage ensures that the quality is maintained and the supply chain runs smoothly, preventing production disruptions and minimizing losses.

Q 22. How do you ensure the traceability of pulp throughout the handling process?

Ensuring pulp traceability is crucial for quality control, efficient inventory management, and regulatory compliance. We achieve this through a multi-layered approach, starting with meticulous record-keeping at the source. Each batch of pulp receives a unique identification number, linked to its origin, processing parameters (e.g., wood species, pulping method, chemical treatments), and quality test results. This information is digitally recorded and tracked through every stage of handling.

As the pulp moves through the system – from storage to processing, and eventually to paper production – we use barcodes or RFID tags to monitor its location and status in real-time. This data is integrated into a centralized database, allowing for instant retrieval of the complete history of any pulp batch. For instance, if a quality issue arises in the final product, we can quickly trace it back to the specific pulp batch and identify the root cause. This systematic approach minimizes waste, prevents product recalls, and improves overall operational efficiency. Regular audits and cross-checks ensure data integrity and the effectiveness of our traceability system.

Q 23. Explain the importance of pulp consistency in papermaking.

Pulp consistency, expressed as the percentage of solid wood fibers in a water suspension, is paramount in papermaking. It directly impacts the quality, uniformity, and efficiency of the entire process. A consistent pulp consistency is vital for maintaining a stable flow through the paper machine, ensuring even fiber distribution on the paper sheet. Variations in consistency lead to uneven paper formation, causing defects like holes, streaks, or variations in weight and strength.

Imagine trying to build a brick wall with inconsistent mortar – some bricks would stick, others wouldn’t, resulting in a weak and uneven structure. Similarly, inconsistent pulp consistency results in an uneven and weak paper sheet. Therefore, maintaining optimal consistency throughout the papermaking process is crucial for producing high-quality paper with the desired properties. We employ sophisticated measuring instruments and control systems to monitor and adjust the consistency continuously, ensuring a smooth, reliable, and high-quality output.

Q 24. How do you manage the costs associated with pulp handling?

Managing pulp handling costs requires a multifaceted strategy. Optimizing transportation is key. This involves selecting efficient routes, utilizing appropriate transport modes (e.g., rail for large volumes, trucks for smaller, more localized deliveries), and negotiating favorable rates with carriers. Efficient storage is equally important, minimizing storage times and maximizing warehouse space utilization through techniques like proper stacking and efficient inventory management systems. We also actively monitor energy consumption, implementing energy-saving measures in our equipment and processes, such as using more energy-efficient pumps and conveyor systems.

Preventive maintenance is crucial to prevent costly breakdowns and downtime. Regularly scheduled maintenance of equipment extends its lifespan and reduces the need for costly repairs. Furthermore, we continuously evaluate and improve our processes, seeking opportunities for automation and streamlining to reduce labor costs and improve efficiency. Data analysis plays a crucial role; by tracking key metrics such as energy usage, transportation costs, and maintenance expenses, we can pinpoint areas for improvement and make data-driven decisions to optimize our cost structure.

Q 25. Describe your experience with using pulp handling software and systems.

My experience with pulp handling software and systems spans several years. I’ve worked extensively with systems that manage inventory, track pulp movement, monitor quality parameters, and generate reports. These systems typically incorporate real-time data acquisition, enabling close monitoring of the entire process. I’m proficient in using software to analyze data, identify trends, and predict potential issues. For instance, I used a system that integrated data from sensors on conveyors and storage tanks to forecast potential bottlenecks and optimize the flow of pulp, preventing production delays.

Furthermore, I have experience implementing and integrating new software systems, from initial requirements gathering to testing and deployment. I’m familiar with both cloud-based and on-premise solutions and understand the complexities of data integration across various systems within a paper mill. My expertise extends to troubleshooting software issues, ensuring that the system provides accurate and timely information to support operational decision-making.

Q 26. What is your experience with different pulp measurement techniques?

I have hands-on experience with a range of pulp measurement techniques, from traditional methods to advanced technologies. Traditional methods include techniques like the Canadian Standard Freeness tester, which measures the drainage rate of pulp, providing insights into fiber length and refining intensity. We also utilize consistency meters, which measure the percentage of solids in the pulp suspension, ensuring proper consistency for downstream processes.

More advanced techniques include optical sensing technologies, which employ sensors to measure pulp properties in real-time, providing continuous monitoring of critical parameters. These advanced technologies offer improved precision, reduce the need for manual sampling, and provide crucial data for process optimization. My expertise extends to selecting and calibrating these instruments and interpreting the data to ensure accuracy and reliability of measurements. Understanding the strengths and limitations of each technique is vital in selecting the appropriate method for specific applications.

Q 27. How do you ensure compliance with health and safety regulations during pulp handling?

Health and safety are paramount in pulp handling. We strictly adhere to all relevant regulations and industry best practices. This includes providing comprehensive training to all personnel on safe handling procedures, use of personal protective equipment (PPE), and emergency response protocols. Regular safety inspections are conducted to identify potential hazards and ensure compliance with safety standards. We maintain detailed records of all safety training, inspections, and incidents.

Specific measures implemented include the use of appropriate personal protective equipment such as respirators, gloves, and safety glasses to minimize exposure to dust and chemicals. We use enclosed conveyor systems to minimize the release of airborne fibers and employ effective dust collection systems to control dust levels in the workplace. Emergency shutdown procedures are in place, and regular drills are conducted to ensure that personnel are well-prepared to respond effectively in case of an accident. Furthermore, we promote a strong safety culture through regular communication, feedback mechanisms, and proactive hazard identification.

Q 28. Explain your experience with different types of pulp conveyors

My experience encompasses various types of pulp conveyors, each suited to specific needs and applications. Belt conveyors are widely used for long-distance transport of pulp, particularly in large-scale operations. Their robust construction and high capacity make them ideal for handling high volumes of pulp. Screw conveyors are commonly used for shorter distances and for applications requiring precise control of pulp flow. Their gentle handling action minimizes fiber damage. Hydraulic conveyors offer a flexible solution, particularly suited for transporting pulp to different levels or locations within a mill.

Pneumatic conveyors use air pressure to transport pulp, often in a more dilute state. They are efficient for moving pulp over long distances and around obstacles. The choice of conveyor type depends on factors such as the distance of transport, the volume of pulp, the desired flow rate, and the sensitivity of the pulp to mechanical damage. My expertise extends to selecting, installing, maintaining, and troubleshooting different types of pulp conveyors to ensure smooth, efficient, and safe pulp transport throughout the mill.

Key Topics to Learn for Pulp Handling Interview

- Pulp Properties and Characteristics: Understanding fiber types, freeness, consistency, and their impact on processing.

- Pulp Handling Equipment: Familiarize yourself with various equipment like digesters, refiners, pumps, screens, and their operational principles. Be prepared to discuss maintenance and troubleshooting.

- Pulp Stock Preparation: Mastering the concepts of dilution, consistency control, and the impact on downstream processes like papermaking.

- Process Control and Automation: Understanding the role of instrumentation, sensors, and control systems in optimizing pulp handling efficiency and quality.

- Safety Procedures and Regulations: Demonstrate knowledge of safety protocols, hazard identification, and regulatory compliance within a pulp and paper mill environment. This includes understanding Personal Protective Equipment (PPE) and emergency procedures.

- Troubleshooting and Problem-Solving: Practice identifying and addressing common issues related to pulp quality, equipment malfunctions, and process inefficiencies. Be ready to discuss your approach to problem-solving in a systematic way.

- Pulp Quality Control and Testing: Understanding various testing methods used to assess pulp quality, such as freeness, viscosity, and brightness measurements.

- Environmental Considerations: Be prepared to discuss environmental aspects of pulp handling, including water usage, waste management, and sustainability initiatives.

Next Steps

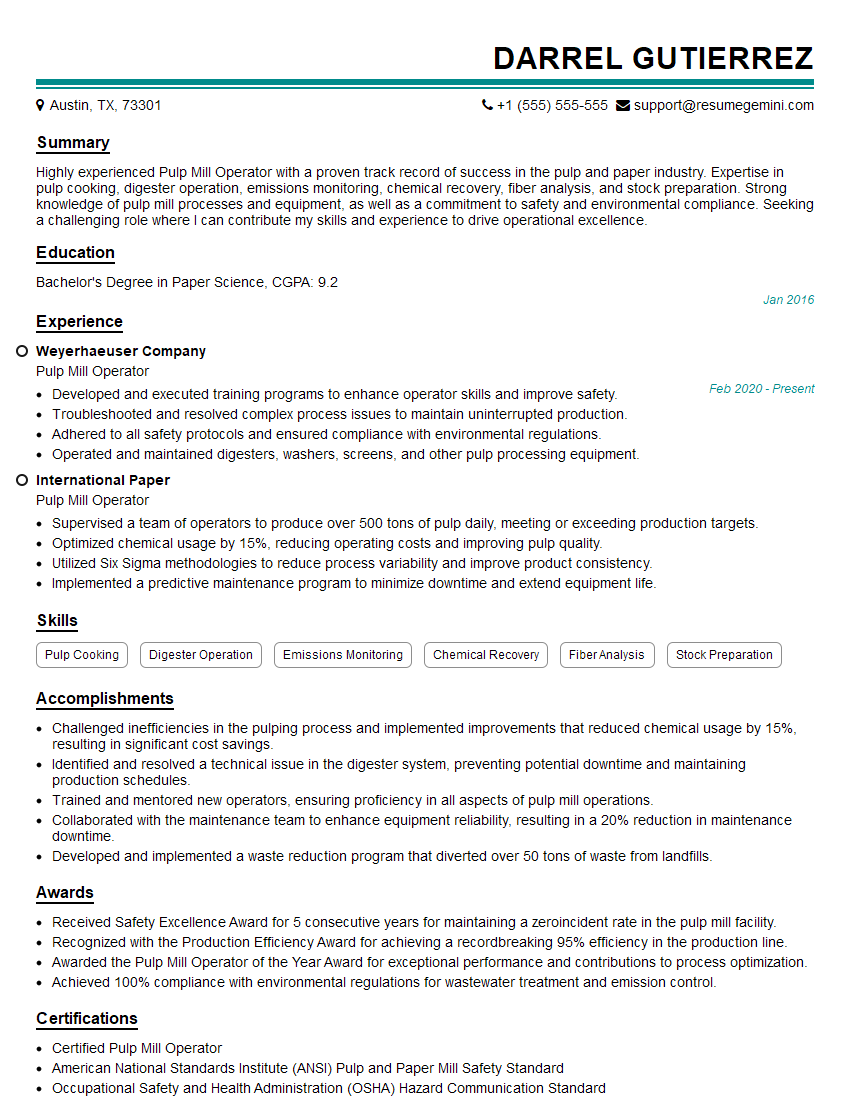

Mastering pulp handling opens doors to exciting career opportunities within the paper and pulp industry, offering diverse roles and continuous growth potential. A strong resume is crucial for showcasing your skills and experience effectively to potential employers. Building an ATS-friendly resume significantly increases your chances of getting your application noticed. ResumeGemini is a trusted resource to help you create a professional and impactful resume tailored to the specific requirements of pulp handling roles. Examples of resumes specifically designed for Pulp Handling positions are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.